If you’re someone who designs parts for a living, you might be thinking: Who cares? As long as I get the parts on time and at a reasonable price, it doesn’t matter to me how they’re made, right? Well, not necessarily. Just as you need a basic understanding of how a motor vehicle safely reaches its destination, a reasonable grasp of machine tool technology is necessary for any parts designer.

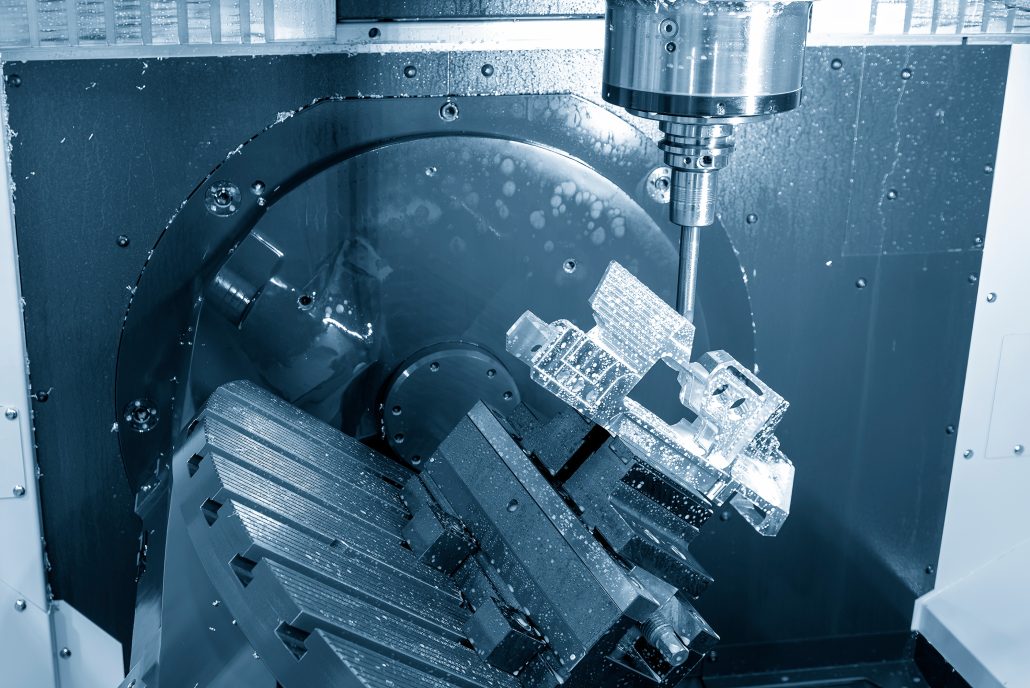

If you’re in the business of manufacturing, you know that CNC machining is an essential tool for producing precision parts in a short amount of time. Whether you’re producing parts for prototyping or small-scale production, CNC machining can greatly benefit your business.

At our CNC machining facility, we specialize in the production of prototype and small-batch production parts. We use the latest in CNC machining technology to produce parts that meet or exceed your exact specifications.

Why Choose CNC Machining for Your Prototype and Small Batch Production Parts

CNC (Computer Numerical Control) machining is a manufacturing process that uses computers to control machining tools such as lathes, mills, routers, and grinders. CNC machining offers many benefits when compared to traditional manufacturing methods such as manual machining, casting, and forging.

Precision: CNC machining is incredibly precise, allowing for high-quality parts that meet tight tolerances. This precision ensures that every part produced is of the same quality as the last, regardless of quantity.

Speed: CNC machines can produce parts at a much faster rate than traditional machining methods. This means that you can produce more parts in less time, allowing you to meet tight deadlines and customer demands.

Flexibility: CNC machining allows for a high degree of flexibility in terms of the types of materials and shapes that can be produced. This is especially important for prototyping and small-batch production where you need to test and refine your designs.

Cost-effectiveness: While CNC machining may have a higher initial investment compared to traditional manufacturing methods, it becomes more cost-effective over time when you factor in the high precision, speed, and flexibility it offers.

Types of Parts That Can be Machined

CNC machining can produce all kinds of parts, from small, highly detailed components to large, complex assemblies. Common types of parts that can be machined include:

- Prototypes for testing and validation

- Small scale production runs

- Custom designs for unique applications

- Replacement parts for existing machinery or equipment

- Complex geometries that cannot be produced through other manufacturing processes

Steps Involved in the CNC Machining Process

The CNC machining process involves several steps, each of which is critical in ensuring the final product meets the specifications and requirements of the customer. These steps include:

- Design: The design of the part is created using computer-aided design (CAD) software. Once the design is complete, it is converted into a format that can be read by the CNC machine.

- Programming: The CNC machine is programmed to create the part, following the specifications and requirements of the customer.

- Material Preparation: The raw materials, such as metal or plastic, are prepared for machining, ensuring that they are the correct size and shape.

- CNC Machining: The actual machining process begins, whereby the CNC machine creates the part by removing material from the raw material block or sheet, following the programmed instructions.

- Quality Control: The final part is inspected and measured using precision tools and equipment to ensure that it meets the required specifications and requirements.

- Finishing: Once the part is deemed acceptable, it is cleaned, polished, or coated as required.

Optimization of parts machining design considerations

In addition to actually programming and operating the machine tool for several years, the best advice is to work closely with your machined parts supplier. Ask questions, especially “How can the parts be made easier to process?” With this in mind, here are some key considerations when exploring ways to optimize part machining design:

Keep things simple

One of the most common mistakes that even experienced design engineers and product developers make is making their part designs too complicated. Consider breaking down single-piece, multifaceted “superparts” into simpler parts that can be bolted, glued, or screwed together. Sweeping surfaces should be avoided unless functionally required, as these often require long, more expensive machining with ball-end milling cutters. A part designed with features that can be cut as far as possible from one side. This avoids multiple operations and possible special clamps, as well as having to use more expensive five-axis machining centers, or machining centers with tilt rotation (3+2) capabilities.

Avoid processing words

Machine-processed text looks cool. This is great for permanent marking parts with numbers, instructions and company logos. The problem is, it’s pretty expensive to produce. Each character had to be tracked with a tiny cutter, which consumed precious machine time. Don’t even think about raised text, because that means grinding out everything that doesn’t look like a letter or number. There are better options, including laser marking and even rubber-ink watermarking.

Be careful with thin-walled parts

Similarly, thin-walled parts can be deflected, but since most workpiece materials are not nearly as hard as the cutting tools used to work them, the rules are stricter. Again, this depends on part characteristics and materials, but a good rule of thumb is to design walls that are no deeper than twice as thick, and understand that any wall that is less than 1/32 inch or so thick can cause problems. As always, please consult our process engineer for advice.

Deep drilling can be tricky

Hole machining is the most common of all machining operations. This is usually done with drill bits that are slightly different from those you can find in any hardware store. As the hole gets deeper (say, five or six times the diameter of the bit), it becomes more difficult to displace the metal “shards” that form during any machining operation. If your product design requires deep holes, know that the deeper they are in relation to the diameter, the more expensive the part will be.

A sharp corner

Corners can also be tricky in machining. Let’s say you’re designing an electronic casing for a product. On one side of the part, you will need a pocket in which a 2 inch square circuit board will be placed. Someone unfamiliar with machining practices might design a square pocket, a pocket slightly larger than the board itself, in order to provide clearance. That’s not a good idea. These squares will cost you dearly because the only way to generate them is to burn them off using EDM, which is a common process in the injection molding, tool and die industry. Where space allows, consider oversized pockets so that end milling cutters can be used, in this example a 1 “/” tool may be appropriate, which means adding half of its diameter (1/4 “) to all sides of the board plus any additional gaps to fit the board. Another option is to cut relief or “dog ears” on all four corners. This may give the pocket a stereoscopic or T-shaped appearance, but will make machining easier.

Design precision thread

Adding thread features to machined parts is also a challenge. The internal thread can be machined with a tap, a cutting tool very similar to a bolt or fastener, or a special tool called a thread cutter. Either way, deep threads are difficult for the same reasons that deep holes are difficult, namely chip removal, in the case of thread milling, radial cutting pressure. In most cases, twice the diameter of the thread depth provides sufficient strength and is less costly to produce. If this is not enough, consider using inserts such as spiral coils or key inserts to reinforce thread integrity, especially in plastic parts. Finally, thread tolerances are specified in “H” limits, most commonly H2 or H3. However, the latter has tighter tolerances and is therefore more expensive to produce, and the best option is to call H2 for all but critical applications.

Why Choose Our CNC Machining Facility

At our CNC machining facility, we take pride in our commitment to quality and precision. We use only the latest in CNC machining technology and our team of skilled technicians has years of experience in producing high-quality parts.

We can handle everything from prototyping to small-batch production and we work closely with our clients to ensure that each part meets their exact specifications. We understand the importance of deadlines and we work tirelessly to ensure that all orders are delivered on time and on budget.

We specialize in producing parts for a wide range of industries including aerospace, automotive, medical, and more. Our goal is to help our clients achieve their manufacturing goals while maintaining the highest standards of quality and precision.

Conclusion

CNC machining is an ideal manufacturing process for producing high-quality prototypes and small batch production parts. At our CNC machining company, we have the expertise, experience, and technology required to ensure that every part we produce meets the highest standards of quality and precision. Contact us today to learn more about our CNC machining services and how we can help you bring your ideas to life.