This article explores the differences between additive manufacturing and CNC machining, two different manufacturing processes used to create objects. While both processes have their strengths and weaknesses, choosing the right manufacturing process depends on the specific needs of the project.

Additive manufacturing and CNC machining are different. Although they all have their own advantages and disadvantages, choosing the correct manufacturing process depends on the specific needs of the project. Understanding the differences between these two processes can help manufacturers make informed decisions about which process to use to produce their products.

What is CNC Machining?

CNC machining, also known as computer numerical control machining, is a manufacturing process that involves the use of computer controlled machine tools. These machine tools can include lathes, milling machines, routers, grinders, and so on.

CNC machining is a highly precise and accurate manufacturing method that allows the creation of complex and complex parts with strict tolerances. It is widely used in various industries, including aerospace, automotive, medical, etc. This process involves using software programs to generate a set of instructions that the machine tool needs to follow, guiding it through the manufacturing process. This makes the finished product highly consistent and accurate.

What is Additive Manufacturing?

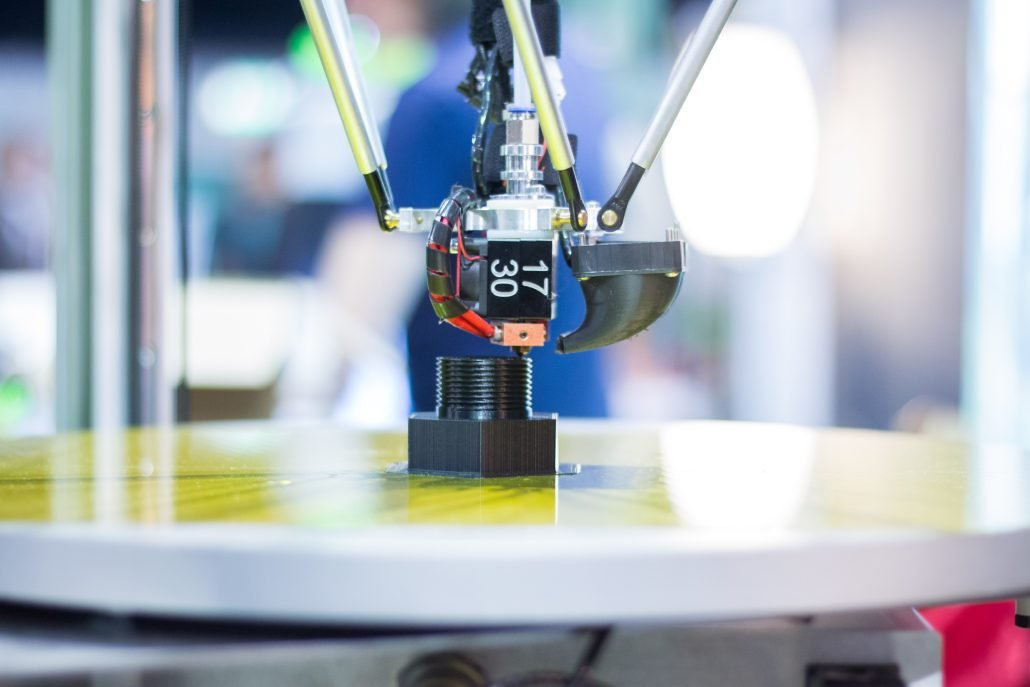

Additive Manufacturing, also known as 3D Printing, is a process of creating three-dimensional objects by adding successive layers of material on top of each other. This technology allows for the creation of complex geometries and shapes that are difficult or impossible to achieve with traditional manufacturing methods. Additive Manufacturing has a wide range of applications, from creating prototypes and tooling, to producing end-use parts for various industries such as aerospace, healthcare, and automotive.

The process involves designing a digital model of the object using computer-aided design (CAD) software, which is then sliced into layers and sent to the 3D printer for production. The printer then builds the object layer by layer using materials such as plastics, metals, ceramics, and even food. Additive Manufacturing has the potential to revolutionize the manufacturing industry by reducing lead times, minimizing waste, and enabling mass customization.

CNC Machining vs Additive Manufacturing:Overview

CNC machining and additive manufacturing are two distinct manufacturing techniques that are widely used in the production of parts and components.

CNC machining involves the use of computer-controlled machines to remove material from raw materials, such as metal or plastic, to create a final product. This process involves a subtractive method, where material is removed until the desired shape is achieved.

CNC machining is best suited for producing parts with complex geometries, tight tolerances, and high surface finish requirements.

On the other hand, additive manufacturing, also known as 3D printing, involves the layer-by-layer addition of material to create a final product. This process is additive, where material is added until the desired shape is achieved.

Additive manufacturing is best suited for producing parts with complex geometries, low to medium tolerances, and a range of surface finishes.

While both CNC machining and additive manufacturing have their own advantages and disadvantages, the choice between the two largely depends on the specific requirements of the project. Factors such as cost, lead time, material selection, and design complexity should all be considered when deciding which manufacturing method to use.

In conclusion, CNC machining and additive manufacturing are both valuable manufacturing techniques that have their own unique strengths and weaknesses. Understanding the differences between the two can help manufacturers make informed decisions when it comes to selecting the best manufacturing method for their specific needs.

Is Additive Manufacturing the Same as CNC Machining?

Additive manufacturing and CNC machining are both methods used to create parts from digital designs, but they are not the same.

Additive manufacturing, also known as 3D printing, involves building up layers of material to create a part. This process is additive because material is added layer by layer until the part is complete.

On the other hand, CNC machining involves removing material from a block to create a part. This process is subtractive because material is removed until the final shape is achieved.

While both methods can produce high-quality parts, they have different strengths and weaknesses. Additive manufacturing is great for creating complex geometries that would be difficult or impossible to make with CNC machining. CNC precision parts machining, on the other hand, is better suited for creating parts with tight tolerances and smooth surfaces.

In conclusion, while additive manufacturing and CNC machining are both used to create parts from digital designs, they are different processes with different applications

What are the Advantages and Disadvantages of Additive Manufacturing over CNC Machining?

Additive manufacturing, also known as 3D printing, and Computer Numerical Control (CNC) machining are two popular methods for creating parts and prototypes. While both methods have their own strengths and weaknesses, this document will explore the advantages and disadvantages of additive manufacturing over CNC machining.

Advantages of Additive Manufacturing

- Design Flexibility: Additive manufacturing allows for more complex geometries and designs that are difficult or impossible to produce with CNC machining. It offers greater freedom in design, enabling the production of optimized and customized parts.

- Cost-Effective: Additive manufacturing can be more cost-effective for small production runs and prototypes, as it does not require expensive tooling and can produce parts with less material waste.

- Shorter Lead Times: With additive manufacturing, parts can be produced more quickly since there is no need for tooling or set-up time.

- Reduced Assembly: Additive manufacturing can produce parts with complex geometries in a single build, eliminating the need for assembly and reducing the risk of errors.

Disadvantages of Additive Manufacturing

- Limited Materials: Additive manufacturing is limited in the range of materials that can be used, compared to CNC machining. Most 3D printing technologies use polymers or metals, while CNC machining can work with a wide variety of materials.

- Quality Issues: Additive manufacturing can produce parts with lower strength, accuracy, and surface finish than CNC machining. This can be addressed with post-processing, but it adds time and cost to the production process.

- Part Size Limitations: Additive manufacturing has size limitations due to the build volume of 3D printers. Large parts may need to be printed in sections and assembled later, which can compromise the strength and accuracy of the final product.

Additive manufacturing and CNC machining are both valuable tools for creating parts and prototypes. While additive manufacturing offers greater design flexibility, cost-effectiveness, and shorter lead times, it also has limitations in terms of materials, quality, and part size. Choosing between the two methods depends on the specific requirements of the project and the available resources.

What are the Advantages and Disadvantages of CNC Machining over Additive Manufacturing?

CNC (Computer Numerical Control) machining and Additive Manufacturing (AM) are two popular manufacturing techniques used in various industries. CNC machining is a subtractive manufacturing process that involves removing material from a solid block to create the final product. On the other hand, AM is an additive manufacturing process that builds the product layer by layer using materials such as plastics, metals, and composites. we will discuss the advantages and disadvantages of CNC Machining over Additive Manufacturing.

Advantages of CNC Machining

CNC machining is known for its high precision and accuracy. The computer-controlled machines can achieve tolerances as low as 0.005mm, making it ideal for manufacturing complex parts with tight tolerances. online CNC machining produces high-quality parts with smooth surface finishes. The parts produced are free from burrs, rough edges, and other surface imperfections.

CNC machining can work with a wide range of materials such as metals, plastics, and composites. This makes it ideal for manufacturing a diverse range of products. CNC machines can produce parts at a faster rate compared to AM. The production speed of CNC machines is not affected by the complexity of the part. CNC machining is ideal for manufacturing parts with high precision and quality.

Disadvantages of CNC Machining

CNC machining can be expensive, especially when manufacturing small quantities of products. The cost of tooling, programming, and setup can make CNC machining uneconomical for small-scale production.

CNC machining produces a lot of waste material. The process involves removing material from a solid block, which results in significant material wastage. CNC machining has design limitations. The process is not ideal for manufacturing complex geometries and intricate designs.

In conclusion, both CNC machining and Additive Manufacturing have their advantages and disadvantages. The choice between the two depends on the specific requirements of the product and the production volume.

CNC machining is an ideal choice for manufacturing high-precision and high-quality parts, while additive manufacturing is suitable for manufacturing complex geometric shapes and small batch production. Ultimately, the decision on which manufacturing process to use will depend on the specific needs of the product and the resources available to the manufacturer.

FAQ

Additive manufacturing is generally better suited for low-volume production runs because there is little setup time required. With additive manufacturing, there is no need for expensive tooling or molds, making it a cost-effective option for small batch production. CNC machining, on the other hand, requires significant setup time and is better suited for larger production runs.

CNC machining is generally faster than additive manufacturing. With CNC machining, parts can be produced quickly and efficiently, making it ideal for high-volume production. Additive manufacturing, on the other hand, is generally slower due to the layer-by-layer printing process, but it offers unique advantages such as the ability to produce complex geometries and internal structures.

Additive manufacturing is generally better suited for creating parts with intricate geometries and internal structures. With additive manufacturing, complex shapes can be created layer by layer, allowing for the production of parts with internal structures and complex geometries that would be difficult or impossible to produce with traditional manufacturing techniques. CNC machining, on the other hand, is limited to producing parts with more basic geometries.

CNC machining is generally better suited for parts that require high precision and tight tolerances. With CNC machining, parts can be produced with high accuracy and tight tolerances, making it ideal for applications that require precise dimensions and high-quality finishes. Additive manufacturing, on the other hand, may produce parts with slight variations due to the layer-by-layer printing process, although this can be minimized with advanced printing techniques and post-processing.