This article explains the factors that affect the cost of CNC machining and provides a method for calculating the cost per part. CNC machining is a widely used manufacturing process that involves pre-programmed software to control the movement of tools and machinery. The cost of CNC machining depends on several factors, including the complexity of the part, the material used, the quantity produced, and the time required for machining.

By understanding these factors and using the CNC machining cost calculation method, manufacturers can accurately calculate the cost per part and plan their production accordingly.

What are the Costs Involved in CNC Machining Metal Parts?

CNC machining is a manufacturing process that involves the use of computers to control machine tools. It is a popular method for producing metal parts, as it allows for high precision and consistency. However, the costs of CNC machining parts can vary depending on a number of factors.

Factors Affecting Costs

- Material: The cost of the raw material used to make the part is a major factor in the overall cost. Metals such as aluminum and steel are generally less expensive than exotic alloys like titanium or Inconel.

- Complexity: The complexity of the part is another factor that affects cost. Parts with intricate designs or tight tolerances require more time and effort to produce, which can drive up the cost.

- Quantity: The number of parts being produced can also affect the cost. CNC machining is generally more cost-effective for larger production runs, as the initial setup costs can be spread out over a larger number of parts.

- Finishing: The finishing process, such as deburring or polishing, can add to the overall cost.

Cost Breakdown

The cost of CNC machining metal parts is typically broken down into the following components:

- Material cost: This includes the cost of the raw material used to make the part.

- Labor cost: This includes the cost of the operator’s time and any additional labor needed for setup or finishing.

- Tooling cost: This includes the cost of any tooling needed to produce the part, such as cutting tools or jigs.

- Overhead cost: This includes any additional costs associated with running the machine, such as electricity or maintenance.

CNC Machining Cost Calculation Method

The cost of CNC machining can be calculated using the following formula:

Cost per part = Material cost + Machining cost

Material cost = (Material density x Part volume x Material cost per unit volume)

Machining cost = (Machining time x Machine rate) + Setup cost

Machine rate = (Machine tool hourly rate x Length of tool path) / Material removal rate

Setup cost = (Machine tool hourly rate x Setup time) / Number of parts produced

By using the above formula, the cost per part can be calculated based on the material cost and machining cost. The material cost is calculated based on the density of the material, part volume, and material cost per unit volume. The machining cost is calculated based on the machining time, machine rate, and setup cost.

Conclusion

CNC machining metal parts can be a cost-effective method for producing high-quality parts. However, the cost can vary depending on a number of factors, such as material, complexity, quantity, and finishing. By understanding these factors and their associated costs, manufacturers can make informed decisions about the most cost-effective way to produce their parts.

What Determines CNC Machining Cost?

CNC (Computer Numerical Control) machining is a manufacturing process that uses computer software to control the movement of machinery and tools in order to create precise and complex parts. The cost of CNC machining can vary depending on several factors including:

1. Material

The cost of the material used for CNC machining can have a significant impact on the cost of the final product. Materials such as titanium, stainless steel, and high-performance plastics are more expensive than aluminum or mild steel, which can affect the cost of the finished part.

2. Complexity

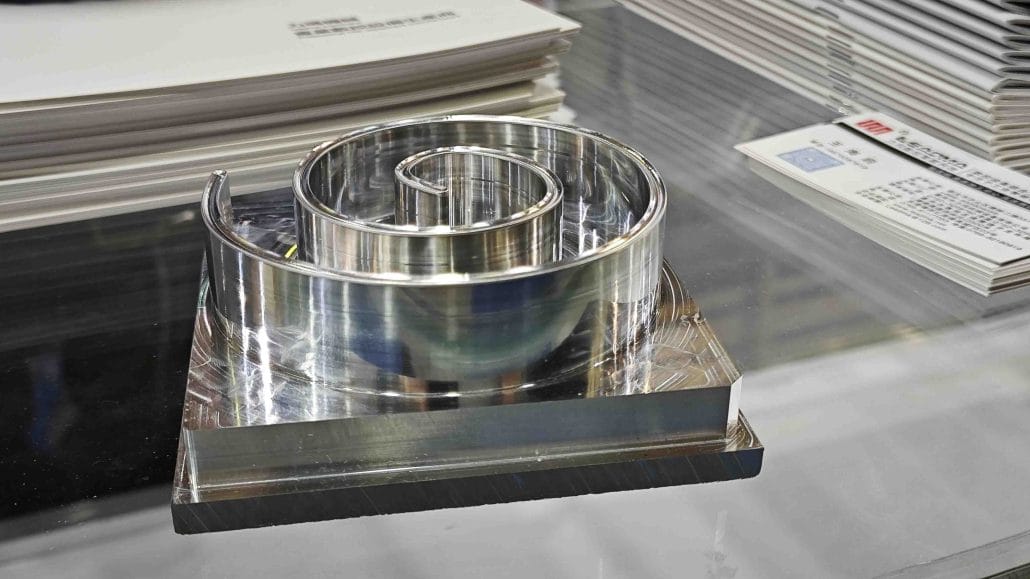

The complexity of the part being manufactured is another factor that can determine the cost of CNC machining. Parts with complex geometries or intricate designs require more time and resources to manufacture, which can increase the cost.

3. Quantity

The quantity of parts being produced can also affect the cost of CNC machining. Small production runs may be more expensive per unit than larger runs due to the setup and programming costs associated with CNC machining.

4. Tolerances

The tolerances required for the finished part can also impact the cost of CNC machining. Parts with tight tolerances require more precise machining, which can increase the cost of production.

5. Finishing

The finishing process, such as coating or polishing, can also affect the cost of online CNC machining. Additional finishing steps can add time and labor costs to the manufacturing process.

In conclusion, the cost of CNC machining depends on a variety of factors including the material, complexity, quantity, tolerances, and finishing requirements of the part being manufactured. By understanding these factors, manufacturers can make informed decisions about the most cost-effective way to produce their parts.

Longsheng CNC Machining Solution

Longsheng is a leading provider of CNC machining solutions for a wide range of industries. With years of experience in the field, we have earned a reputation for delivering high-quality products and exceptional customer service.

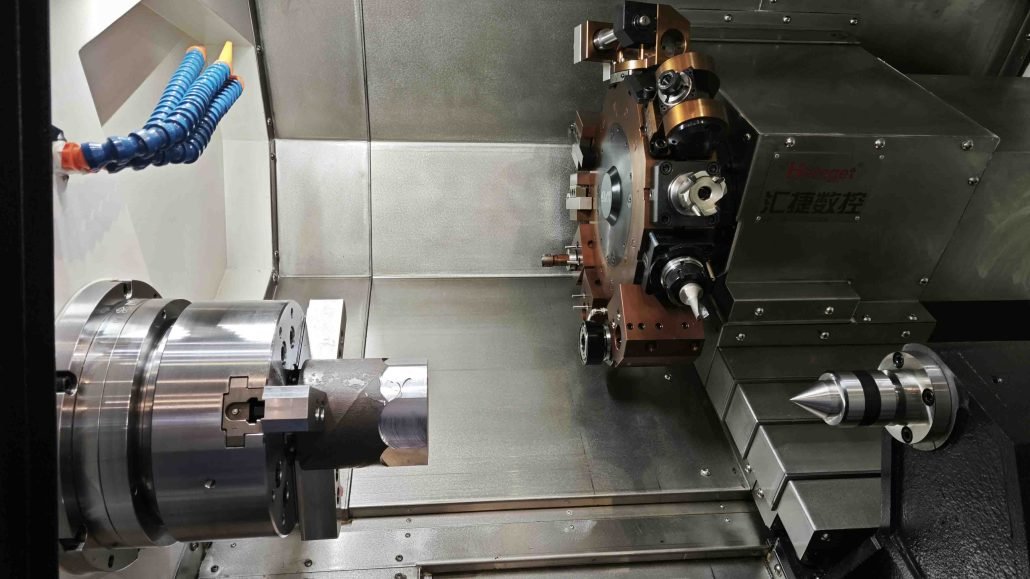

Our team of skilled engineers and technicians use the latest technology and equipment to provide precision machining services that meet the needs of our clients. We offer a wide range of services, including CNC milling, turning, drilling, and grinding.

At Longsheng, we pride ourselves on our ability to work with a variety of materials, including aluminum, brass, steel, and plastics. We use only the highest-quality materials and employ strict quality control measures to ensure that our products meet the highest standards of quality and durability.

In addition to our machining services, we also offer a range of value-added services, including design assistance, prototyping, and assembly. Our team of experts can work with you to develop custom solutions that meet your specific needs and requirements.

Whether you need a single component or a complex assembly, Longsheng is your trusted partner for CNC machining solutions. Contact us today to learn more about our services and how we can help you meet your machining needs.

FAQ

The cost of CNC machining can be calculated using the following formula: Cost per part = Material cost + Machining cost.

By understanding the factors affecting CNC machining cost and using the CNC machining cost calculation method, manufacturers can calculate the cost per part accurately and plan their production accordingly.

The machine rate is calculated using the machine tool hourly rate, length of tool path, and material removal rate.

The cost of CNC machining depends on several factors, including the complexity of the part, the material used, the quantity produced, and the time required for machining.