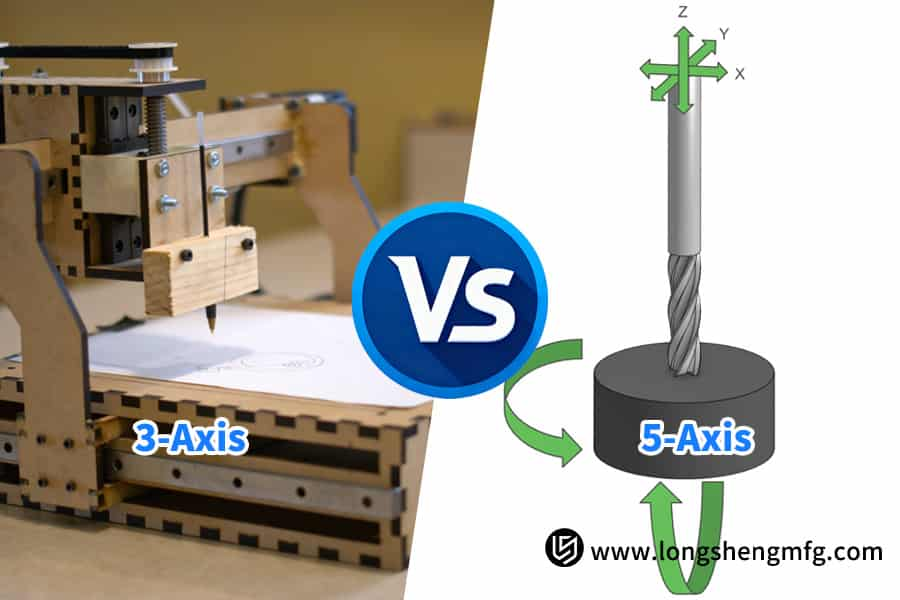

5-Axis CNC Machining has become the established solution for manufacturing complex precision parts. When components contain deep cavities, inclined surfaces, or complex contours, traditional 3-axis machines—limited by their degrees of freedom—require multiple setups. This leads to accumulated tolerances, reduced efficiency, and increased costs, as 3-axis technology cannot complete multi-angle machining in a single clamping.

This article provides a clear 3-axis vs 5-axis machining, empowering you to select the optimal technology for your application. Leveraging advanced 5-axis systems and extensive experience, LS Manufacturing transforms design challenges into manufacturable solutions without compromising quality or productivity. Below, we outline the key differences to help you identify the most economical and efficient approach for your projects.

3-Axis vs 5-Axis CNC Machining Quick Reference Table

| Comparison Dimensions | 3-Axis Machining | 5-Axis Machining |

| Key Point | Machining can be performed by the tool moving in 3 linear directions, that is in the X, Y, and Z directions. | It is also possible to do machining on 3 linear axes and two rotary axes simultaneously. |

| Applicable Cases | Applies to the parts with a simple structure and features in the same direction. | It is designed for irregularly shaped parts, including complex curved surfaces, deep cavities, and inclined surfaces. |

| Machining Efficiency | Lower efficiency results due to several clamping operations and long preparation times. | Whereas reduced clamping with special fixtures provides a significant improvement in production efficiency. |

| Machining Costs | Low per-unit cost, but labor and time costs may be higher overall. | Higher equipment investment, but at an overall advantageous cost per unit for complex parts. |

| Design Freedom | Severely limits the geometry because design has to yield to machining. | Greatly unleashes design potential that can realize easily complex and innovative structures. |

It’s mainly a trade-off between the equipment cost and the overall manufacturing cost in choosing between 3-axis and 5-axis machining. 3-axis machining is suitable for simple, batch-produced standard parts, while 5-axis machining, by improving accuracy and efficiency, has become a key technology to solve complex manufacturing challenges and unleash design innovation.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

Within the last decade alone, over 50,000 pieces of 5-axis parts with complicated structures have been delivered successfully. This is not about merely accumulating quantity but about overcoming core technical difficulties in a systematic way. All suggestions in this guide will be put to severe application testing, which is guaranteed by this practical experience.

We understand in-depth how to select a suitable cutting strategy in view of different material properties, control chatter during thin-walled machining, and optimize process paths under conditions of small-batch rapid iteration. This valuable knowledge base is integrated into the decision logic of this guide.

Our strictly followed ISO 9001 quality management system ensures controllability throughout the process, from programming down to the finished product, by referring to relevant standards provided by the NIST. It is this adherence to professional standards that constitutes the basic guarantee of reliability and authority regarding this guide.

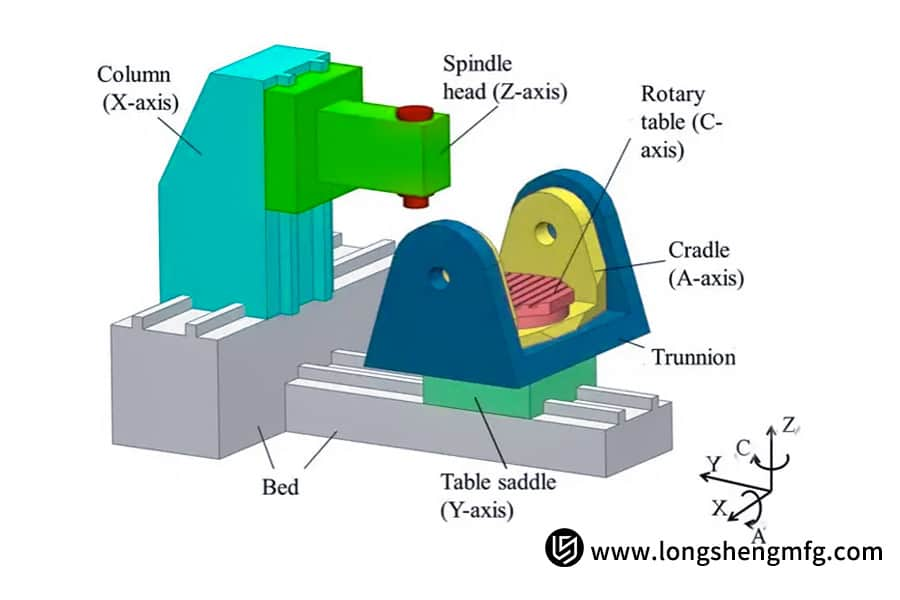

What is the fundamental difference in motion principles between 3-axis and 5-axis CNC machining?

The key to understanding the difference between 3-axis and 5-axis CNC machining lies in recognizing the additional degrees of freedom of motion brought about by the two additional rotary axes in the latter. This addition is not just a matter of quantity but more one of quality: it is a leap from “fixed posture” to “flexible response.” Following is a visual table comparing the core differences between the two:

| Comparison Dimensions | 3-axis machining | 5-axis machining |

| Core Analogy | Just as a stamp with an engraving angle of a fixed size can move up and down vertically. | Like universal-jointed robotic arm which can freely change the angle. |

| Motion Method | The tool can only move on 3 linear axes, that is, on X, Y, and Z. | On top of the 3 linear axes, 5-axis machining adds two rotary axes, A and B. |

| Tool Posture | The direction of the tool axis is fixed, usually only vertically downwards. | 5-axis machining can be deflected and tilted to approach the workpiece surface at any spatial angle. |

| Machining Efficiency | The idea of machining sides and inclined surfaces would be ineffective and interference-prone. | 5-axis machining can maintain the best cutting angle at any time, which perfectly handles complex curved surface work. |

The meaning of 3-axis machining is “workpiece moves, direction is fixed,” while that of 5-axis machining is “workpiece and tool linked, angle is flexible.” It is these additional rotary axes that provide unparalleled flexibility in 5-axis machining, which lets precision machining be done on complex geometries in one setup.

How does 5-axis machining fundamentally change the manufacturing process through “one-time clamping”?

The core advantage of five-axis CNC machining lies in completing all machining of complex workpieces in a single setup, which is the essence of multi-axis CNC machining. This is far from just an increase in efficiency-it constitutes a fundamental reshaping of the logic of the whole production. Its value will be reflected in the following four key aspects:

To achieve a “precision leap” and root out cumulative errors

in the case of traditional 3-axis machining, every re-clamping brings about micron-level positioning errors caused by datum plane conversion. The 5-axis technology finishes 5 or even all complex feature machining with only one clamping, ensuring extremely high original accuracy in the geometric positions between all features, and fundamentally eliminating the precision loss and quality instability caused by multiple clamping.

Simplify “tooling dependence” and greatly reduce the cost

“One-time clamping” refers to not having to design, manufacture, and debug a lot of dedicated fixtures for each process. It saves directly not only expensive fixture costs but also greatly reduces the time for pre-production preparation, thus providing companies with much quicker responses to market changes, especially suitable for flexible production models featuring small batches and multiple varieties.

Compress the “Production Chain” and Accelerate the Delivery of Products

The time consumed by workflow transitions, waits, and debugging among processes is the “hidden killer” in the production cycle. 5-axis machining highly integrates machining tasks that were originally scattered across multiple machines and workstations, transforming serial production into parallel processing. This has dramatically shortened the “non-machining time” of the workpieces in the workshop, realizing the fastest path from drawing to finished product.

Unlocking “Design Barriers” and Empowering Product Innovation

Because it can deflect flexibly, the 5-axis machine tool can easily machine deep cavities or concave structures that could not have been reached by 3-axis equipment. This breaks the constraints of traditional machining on designers and allows engineers to boldly adopt more efficient fluid channels and lighter topologies, truly unleashing innovative potential.

It directly transforms manufacturing advantages into superior performance of a product, stronger market competitiveness, and higher commercial return by improving the accuracy, reducing cost, shortening the cycle, and releasing design freedom. “One-time setup” is the core competitiveness of modern precision manufacturing.

Under what circumstances in particular would the decision for 5-axis machining give you the best return?

When to Use 5-Axis vs 3-Axis? When your project involves this type of complex geometry, that’s the best time to use 5-axis instead of 3-axis. Following are some high-value application scenarios that best illustrate the technical benefit of 5-axis machining:

Aerospace structure thin-wall frame part:

Traditional 3-axis machining needs several clamping processes, which easily causes accumulative error and deformation. 5-axis machining can finish multi-angle machining in one clamping, ensure even wall thickness, thus enable lightweight forming of the whole structure at one time, therefore greatly improve the component’s overall integrity and fatigue strength.

Impeller/turbine parts:

Even in continuously twisted blade parts, 3-axis machine tools cannot guarantee the tool is always perpendicular to the surface normal. Residual tool marks remain on the surface. In this respect, 5-axis simultaneous machining optimizes the angle of the tool continuously along the surface normal, therefore completing flow channel finishing in one pass and improving airflow efficiency by over 15%.

Medical Devices: Bone Scaffolds

In triaxial indexing, which performs machining on implant surfaces, the biomimetic micropore continuity is destroyed. Based on dynamic tool axis control, 5-axis technology can perform precise machining of 0.2 mm micropores on any complicated curved surface; porosity can be controlled at 90 ± 5%, thereby significantly improving the ingrowth of bone cells.

Automotive Engine Blocks

Special angular tooling is required for the 3-axis machining of the irregularly-shaped inclined oil passages and cooling chambers in cylinder blocks, with alignment errors easily occurring. Tool axis tilting is achieved by the 5-axis solution, which enables the one-time forming of 75° deep holes, thereby raising the quality of oil passage sealing threefold and considerably increasing the reliability of engines.

Precision Mold Cavities

The deep cavity parts, such as the mold of a mobile phone casing, cannot be machined directly for corner clearing due to interference on 3-axis machine tools and must depend on electrode discharge. 5-axis machining adopts the extended tool holder side milling technology to directly complete 1.5mm deep cavity mirror surface machining, reducing mold delivery cycle from 3 weeks to 6 days.

In addition to the advantages in improving the surface quality and increasing the production efficiency, 5-axis machining reduces clamping times, optimizes tool posture for parts with multi-direction features, complex curved surfaces, or strict geometric tolerances, and solves the technical bottlenecks of 3-axis machining.

Why is 5-axis machining more cost-effective in some situations?

Considering the total project cost, the advantages of 5-axis CNC machining often make it a more economical choice. The conclusion negates the stereotype “5-axis machining is necessarily expensive.” Its cost-effectiveness is not reflected in lower equipment unit prices but rather in optimization of the whole manufacturing process:

- Tooling and labor savings can be substantial: Traditional 3-axis machining relies heavily on specialized fixture designs and manufacturing, relying on operators to perform repetitive skilled clamping and positioning during the processing of complicated parts. The 5-axis machining realizes single clamping, which can directly eliminate expensive fixture costs and a lot of manual operation time, reduces the dependence on skilled labor and corresponding labor costs.

- Effectively reduced secondary machining and outsourcing costs: The processing of many complex features-such as oblique holes, irregular curved surfaces, and other geometries-cannot be directly completed on 3-axis machine tools; they have to be transferred to the EDM or beveling machine for further processing, or outsourced to manufacturers. All these can be directly milled by a 5-axis machine, which saves extra equipment occupancy fees, transportation costs, outsourcing processing fees associated with process transfer, and simplifies management processes.

- Significantly reduced scrap rate and quality risk: Multiple clamping operations are the source of these errors in accuracy and operational mistakes, which easily lead to the scrapping of parts. The single-clamping strategy of 5-axis machining prevents repetitive positioning errors from the very beginning, greatly improving the consistency in accuracy and product yield, saving material and labor losses brought about by scrap, and reducing quality costs significantly.

- Extremely compressed production cycles accelerate the time to market: The biggest hidden cost is time. In 5-axis machining, multistage processes are concentrated in one machine for continuous completion and greatly reduced time spent moving parts between different workstations, waiting, and debugging. A drastic reduction in a production cycle means products hit the market faster and seize more opportunities, thus bringing huge commercial returns.

Integration in the production cycle and by improving accuracy and efficiency, 5-axis machining reduces the overall cost of a part. For structurally complicated parts, it often saves much more in the costs of fixtures, secondary processes, scraps, and time than the difference in their own processing rates, hence showing better economics from an overall standpoint.

How did we achieve integrated manufacturing of a lightweight fuselage for a drone manufacturer?

This case study exemplifies how multi-axis CNC machining can solve the challenges of complex integrated components. It demonstrates how advanced manufacturing technologies can directly enhance a product’s core competitiveness. A drone manufacturing company once confronted great difficulties in designing a lightweight magnesium alloy fuselage for its new model.

Customer’s Dilemma:

The fuselage has complicated inner flowing channels and outer curved surfaces, which at least require 5 clampings with traditional 3-axis machining. This has caused many joints with heavy wall thickness due to different machining datums, weakened strength, repeated positioning errors, and overall weight overloading. The consistent low yield rate, which is around 65%, has seriously restricted product performance and cost control.

LS Manufacturing Solution:

We provided added value with a state-of-the-art 5-axis machining center. After clamping the blank in a single operation, its rotary axes allow the cutting tool to approach the workpiece at an optimal angle, while all features can be machined in one continuous cycle, including external curved surfaces and internal flow channels. This guaranteed uniform fuselage wall thickness and structural integrity.

Results and Value:

Ultimately, this customer achieved a 15% weight reduction in the integrated fuselage, avoided weak spots due to multiple clamping operations, and increased structural strength in key components by 20%. Manufacturing cycles were reduced by 60%, while yield rate saw a leap from 65% to 98%. In addition, this brought down the unit cost sharply and gave the product a decisive advantage in the marketplace on endurance and reliability.

The 5-axis machining method solved not only the bottleneck of the traditional process but also became a key technological support to promote innovation and upgrading of high-end equipment, enhance the core competitiveness of products, and help an enterprise gain the decisive advantage in the fierce market competition.

Is 3-Axis Machining Still a More Reliable and Practical Choice?

Choosing the most suitable machining solution is always our core suggestion. For most two-dimensional and simple 3-dimensional parts, the comparison between 3-axis and 5-axis CNC machining concludes that 3-axis machining is more cost-effective.

| Consideration Dimensions | Applicable Scenarios for 3-Axis Machining | Core Advantages |

| Part Geometry | Plate-type, box-type parts, or parts only requiring machining of a single-direction 2D contour or simple 3D features. | For such simple geometries, planning a 3-axis machining path is straightforward, hence the machining efficiency is very high. |

| Project Budget | Projects with a low or restricted initial investment budget; projects producing products of low added value and ultra-sensitive to unit cost. | Lower investment in equipment depreciation and machine time; lower technical barriers and investment in programming and operating personnel. |

| Production Lot | In the mass production of some simple and high-volume parts, efficiency can be optimized by using a dedicated fixture without complex linkages. | In mass production, 3-axis processes are stable, cycle time control is mature, and output can be reliably guaranteed. |

| Process Maturity | Product design is frozen, and there is a proven stable and reliable 3-axis machining process solution demonstrated over substantial time. | The use of a mature process will avoid the risks and time costs of trial and error; hence, it will ensure continuity in production. |

Put briefly, what we promise to you is the most economical solution, not just technologies put together. 5-Axis vs 3-Axis CNC, when your part features are relatively simple and your core requirements are cost control and consistent delivery, 3-axis machining is beyond doubt the most reliable and pragmatic choice, as proven by the market over a long period.

How to correctly determine whether your project needs upgrading to 5-axis machining?

This CNC machining guide is designed to help you make informed decisions about when to use 5-axis machining instead of 3-axis machining. You can easily evaluate whether your project needs an upgrade by doing a self-assessment based on the checklist of key questions below.

1. Does the part have multiple surfaces or complex angles to be machined?

If your part has features distributed in several directions, 3-axis machining requires multiple re-clamping operations. This is far from efficient and, due to the cumulative errors caused by datum conversion, it’s impossible to assure the accurate positional relationship among the feature surfaces.

2. Does the design contain deep cavities, concave areas, or steep slopes?

Such machining is impossible without very specialized fixtures since the rigid spindle of a 3-axis machine tool can hit the workpiece due to deep cavities or steep side walls in parts. Interference is effectively avoided by 5-axis machining in tool yaw, which achieves efficient milling.

3. Is the form and position tolerances and surface quality requirements of the product extremely stringent?

This is one of the central capabilities of 5-axis machining: “one-time setup” is essential if the demands for roundness, parallelism, or coplanarity in your project are very high. This is because it avoids multiple positioning steps, thus eradicating errors and bringing ultra-high dimensional consistency with surface quality right from the source.

4. Is the production volume targeted for high-volume, high-efficiency production or for fast iteration with high mixing?

Even for relatively simple parts, the efficient, integrated molding of 5-axis machining can offer significant time and cost savings for high-volume production. On small-batch and rapidly iterating R&D projects, the flexibility provided by 5-axis machining enables rapid responses to design changes and saves a large amount of tooling preparation time.

If the answer to either of these questions is “yes” , your project likely has the potential to benefit from 5-axis technology. The most pragmatic approach from here is detailed consultation with our 5-axis machining experts. Based on your specific drawings and needs, we will provide a precise technical and economic analysis that will help you make the most forward-looking decisions.

Why can LS Manufacturing’s 5-axis machining services be your strategic advantage?

Choosing LS Manufacturing 5-axis machine tool services means you’ll transform complex manufacturing challenges into reliable technological advantages. We strive to be your trusted technology partner-not just an OEM. This strategic advantage is rooted in the deep expertise of four core areas:

- Current Equipment Strength: We have invested in high-precision imported 5-axis machining centers. These machines not only possess excellent dynamic accuracy and thermal stability but also maintain machining consistency over the long term, providing a reliable physical platform for the efficient and high-quality forming of complex parts.

- Software and Programming Skills: While having advanced 5-axis CAM software is just a starting point, the core advantage really comes from our engineering team, which is able to efficiently plan and optimize the toolpaths for given geometries by intelligently avoiding interference between the tools and fixtures to maximize machining efficiency without compromising surface quality.

- Extensive Process Experience: We have conducted trial production and mass production of complex parts in many industries, including but not limited to, titanium alloy, high-temperature alloy, composite material, and lightweight structural material represented by aluminum alloy and magnesium alloy, thus accumulating a mature cutting parameter library for difficult-to-machine materials. That means whatever material your product is made from, you will get the best machining strategy.

- Full Quality Assurance: We have established a complete quality control system covering all aspects from programming to machining and finally to inspection. By using machine measurement and CMM inspection, we realize real-time monitoring and feedback of the machining process, ensuring that every delivered part accurately meets the drawing requirements and achieves a reliable quality closed loop.

This is not simply a matter of machining capability; it’s about comprehensive solutions to help you optimize product design, speed up product launch, and assure product reliability. In-depth collaboration will, therefore, transform your manufacturing challenges into the core competitiveness of your product in the marketplace.

Can I get an analysis of my part for a machining solution by consulting LS Manufacturing now?

We firmly believe that clear and professional preliminary analysis is the first step toward successful cooperation. Submit your drawings now and experience the professional analysis and solutions provided by the LS Manufacturing 5-axis machine tool team. The whole process is easy and efficient:

- Get a free professional process analysis report: Simply provide a 3D model or detailed drawings of your part, and our engineering team will conduct a comprehensive evaluation and prepare a detailed process analysis report for you free of charge. This goes beyond a simple quote to include an in-depth explanation of the technical feasibility of manufacturing.

- Get unbiased recommendations on machining strategies: According to the geometry of your part, precision requirements, and volume of production, we will provide you with the most practical machining strategy recommendations. Based on a transparent analysis of the pros and cons of a 3-axis, 5-axis, or combined process, our recommendations are completely matched to your technical and business goals in order to help you make the best choice.

- Get a transparent preliminary cost and time estimate: The analysis report will include preliminary machining cycle and cost estimates. The report will help you accurately budget and schedule your project, thereby making the decision more transparent and confident.

Whether you decide to use us for your part or not, this report in itself has great value. We look forward to the opportunity to bring our expertise and experience to clearly define the technical path for your future projects and further your success.

FAQs

1. Is 5-axis machining always much more expensive than 3-axis?

Not by a long shot. While 5-axis machining equipment is more expensive on a per unit basis, the capability of doing complex multi-faceted machining in one setup greatly reduces specialized fixture costs, multiple setup costs, and the secondary outsourcing that comes with it. In many ways, 5-axis machining is more often cost-effective from an overall project cost perspective.

2. My part isn’t that complicated; should I not consider 5-axis machining at all?

Correct. For simple features such as plates and 2D contours, mature 3-axis machining is the most effective and economic option. We insist on objective evaluation and will never recommend 5-axis machining for simple parts, which ensures that every penny of your investment is worthwhile.

3. Can 5-axis machining guarantee a better surface finish?

5-axis machining can always enable the tool side edge to contact complex curved surfaces at the best angle and avoid low-speed cutting at the ball end mill tip, so as to obtain better and more uniform surface quality. This is particularly important for mold surfaces and high-end appearance parts.

4. How do you ensure tool-workpiece collision safety during 5-axis machining?

We rely on advanced CAM systems for full-process virtual simulation. This will give an accurate prediction of the motion trajectory of machine tools, cutting tools, tool holders, and workpieces. All the programs undergo 100% collision detection prior to machining; thus, the root of interference risks is eliminated altogether.

5. Is the transition from 3-axis to 5-axis very difficult and expensive?

That won’t be a problem with us. We have a professional 5-axis programming team with a mature process library validated by numerous projects. You will enjoy the advantages of 5-axis machining without investment in high learning costs and software fees.

6. Are the machining accuracy of 5-axis machine tools lower than that of 3-axis?

The principle of “one-time clamping” in 5-axis machining eliminates the accumulation of errors that can be involved with multiple positioning. It better assures geometric tolerances between complex features and attains higher and more stable accuracy compared to multi-process 3-axis machining.

7. Can 5-axis machining also be applied for small batches of prototype parts?

Very suitable. In particular, the high flexibility of 5-axis machining is best for prototyping; it can turn those complicated designs from drawings without any special tooling into real things in the shortest time with high accuracy, thus largely hastening product development, test, and iteration cycles.

8. How do I get started using LS Manufacturing to start my 5-axis machining project?

Simply upload your 3D drawings and technical requirements through our website or email. Our process experts will provide a preliminary solution in 4 hours, including machining strategies, timelines, and a transparent quote to help you make a quick decision.

Conclusion

The choice between 3-axis and 5-axis machining is a matter of strategic rather than purely technical trade-offs along three central elements: product performance, production efficiency, and overall cost. With comprehensive machining capabilities, in-depth process knowledge, and customer-centric service, LS Manufacturing is capable and committed to becoming your most reliable manufacturing consultant and partner.

Contact us and let professional analysis guide you to the most efficient manufacturing path! Simply upload your 3D model now for a free machining solution analysis and quote, or schedule a one-on-one in-depth consultation with our technical experts directly.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.