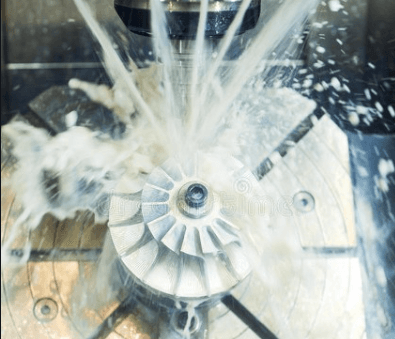

CNC milling machining is a versatile manufacturing process that involves cutting, drilling, and shaping a workpiece using computer-controlled machines. To achieve the desired results, different types of cutting tools are used for various applications.we will explore the different types of cutting tools used in CNC milling machining and their benefits.

End Mills

End mills are one of the most commonly used cutting tools in CNC milling parts machining. They are cylindrical in shape and have cutting edges on the end and sides. End mills can be used for a wide range of applications, including cutting slots, profiling, and drilling.

Ball End Mills

Ball end mills are similar to end mills, but they have a rounded end instead of a flat end. This design allows them to create rounded profiles and contours in the workpiece. Ball end mills are commonly used for 3D contouring and surface finishing.

Face Mills

Face mills are designed to remove material from the face of a workpiece. They have multiple cutting edges and can remove material quickly and efficiently. Face mills are commonly used for roughing and finishing operations.

Fly Cutters

Fly cutters are single-point cutting tools that are used for facing and surfacing operations. They have a single cutting edge that removes material in a circular motion. Fly cutters can be used for both roughing and finishing operations.

Drill Bits

Drill bits are used for creating holes in a workpiece. They come in a variety of sizes and shapes, including twist drills, center drills, and spot drills. Drill bits can be used for both through holes and blind holes.

Reamers

Reamers are used for finishing and sizing holes that have already been drilled. They have multiple cutting edges and can remove small amounts of material to achieve a precise diameter.

Taps

Taps are used for cutting threads into a hole that has already been drilled. They come in a variety of sizes and can be used for both through and blind holes.

Conclusion

CNC milling machining requires a variety of cutting tools to achieve the desired results. End mills, ball end mills, face mills, fly cutters, drill bits, reamers, and taps are just a few of the cutting tools used in CNC milling machining. By understanding the different types of cutting tools and their benefits, manufacturers can choose the best tool for their specific needs and requirements.

If you’re interested in learning more about the different types of cutting tools used in CNC milling machining or how to implement CNC milling machining in your manufacturing process, be sure to consult with experts in the field to determine the best solutions for your specific needs and requirements.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items