When it comes to CNC machining plastics, a common misconception is to assume they are inferior to metallic machined parts. In fact, computer numerical control (CNC) machining services with plastics like Kevlar or Ultra-high molecular weight polyethylene (UHMWPE) offer a similar strength-to-weight ratio.

Therefore, using plastic parts on CNC machines depends on the intended design application and tolerance. How many supported plastic CNC machining materials do you know? This article highlights different engineering plastics for your next custom CNC machining project.

What are CNC machining plastics?

CNC machining plastics are those plastic materials suitable for automated manufacturing on computer numerical control machines. CNC machining is a subtractive manufacturing process, and this article focuses on suitable plastic materials.

40 common plastics for CNC machining

Your choice of machinable plastics can affect the machining cost. Therefore, we have carefully listed the following CNC plastics with their advantages and disadvantages for plastic CNC machining applications.

1.Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile Butadiene Styrene (ABS) is a very common CNC machining plastic with impressive strength and impact resistance. It is the easiest plastic to CNC machine and is available in various grades on the thermoplastic market.

Advantages

- Strong mechanical properties

- Excellent machinability/customization

- Budget-friendly

Disadvantages

- Low heat resistance

- Not suitable for food contact

- Not UV stable

2.Nylon (polyamide)

Nylon or polyamide (PA) is a synthetic thermoplastic polymer with excellent thermal and mechanical properties. The nylon 66 grade is the commonly used polyamide for plastic CNC machining services.

Advantages

- Good chemical resistance

- Excellent wear resistance

- Lightweight polymer

- Great shock absorption

Disadvantages

- Prone to absorb moisture

- Poor dimensional stability

- Limited heat resistance

- Sensitive to UV radiation

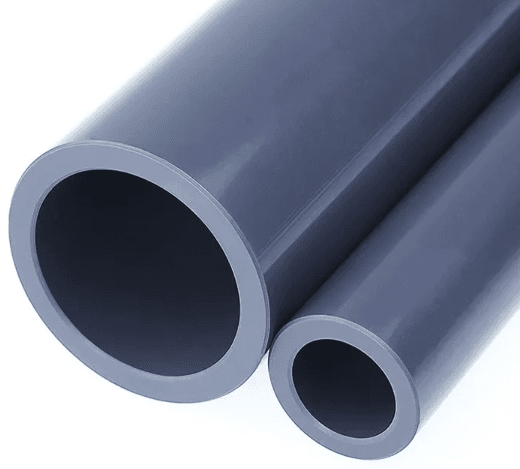

3.Polyvinyl chloride (PVC)

PVC is another easy-to-machine thermoplastic polymer suitable for plastic CNC machining. It is lightweight, and machined parts can withstand harsh environmental factors like sunlight.

Advantages

- Flame and chemical resistance

- Very durable

- Budget-friendly

- Electrical insulator

Disadvantages

- Produces harmful chlorine gas during recycling

- Limited heat resistance

4.Chlorinated polyvinyl chloride (CPVC)

Using CPVC plastics for CNC machining services is similar to conventional polyvinyl chloride (PVC) applications. However, CPVC makes up for the low thermal properties of PVC.

Advantages

- Same as PVCs

- Higher temperature resistance

Disadvantages

- More expensive than ordinary PVCs

- Slight environmental chlorine concerns

5.Polysulfone (PSU)

Polysulfone (PSU) is a semi-transparent, high-performance thermoplastic polymer with high mechanical strength in machined parts design. In addition, PSU plastics on CNC machines can withstand high temperatures and are suitable for biomedical applications.

Advantages

- Good chemical and heat resistance

- Dimensional stability

- Electrical insulators

Disadvantages

- PSU plastics can be expensive

- Sensitive to UV radiation

- Poorer machinability than close alternatives

6.Polyphenylene Sulfide (PPS)

The PPS plastic is an alternative engineering thermoplastic with thermally stable properties up to about 425°F. It is a perfect fit for precision CNC machining plastics projects that require dimensional stability.

Advantages

- Excellent chemical resistance

- Good heat resistance

- Low moisture absorption

Disadvantages

- Not UV stable

- Polyphenylene Sulfide (PPS) is not cheap

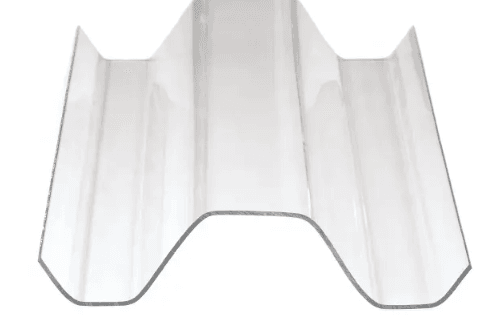

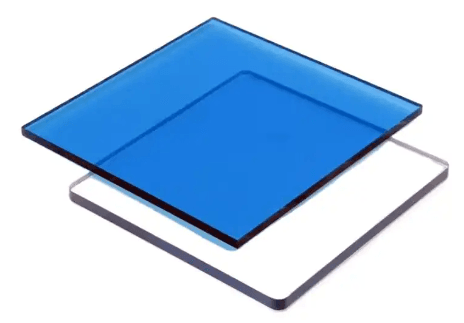

7.Polycarbonate (PC)

Customers interested in custom machined parts design that is transparent and durable should consider polycarbonate (PC) plastic parts in their next computer numerical controlled machining projects.

Advantages

- Easy-to-machine plastics

- Great for transparent applications like windows

- Excellent strength-to-weight ratio

Disadvantages

- Highly susceptible to scratches

- Low chemical resistance

8.Polysiloxane (Silicone)

The silicone CNC machining plastics are colorless and rubber-like polymer materials of the −R2Si−O−SiR2 organic group.

Advantages

- Non-toxic and biocompatible

- High flexibility and elasticity

- Can withstand temperatures between 150°F and 550°F

- UV stable

Disadvantages

- Silicone is not cheap

- Some silicone grades have low tensile strength

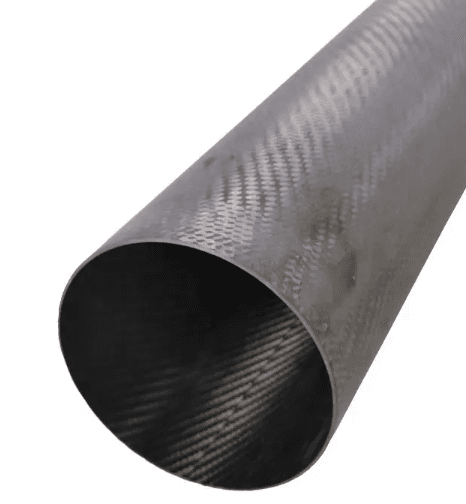

9.Carbon Fiber

Carbon fiber is a composite lightweight polymer with a base plastic and thin but tightly woven carbon strands. Carbon fiber-reinforced materials can withstand up to 3632°F during plastic CNC machining.

Advantages

- High strength-to-weight ratio

- Aesthetic appeal

- Corrosion resistance

Disadvantages

- Carbon fiber is not cheap

- Not UV stable

10.Polyethylene terephthalate (PET)

PET is a semi-crystalline lightweight polymer suitable for CNC plastic machining under moderate temperature conditions.

Advantages

- Transparent material

- Highly recyclable

- PET plastic is not expensive

- Good chemical resistance

Disadvantages

- Limited heat resistance

- Not ideal for extreme weather

11.Polyetherimide (PEI)

Polyetherimide (PEI) is a non-crystalline material that works for plastic CNC machining. Custom PEI machined parts have similar engineering thermoplastic characteristics to PEEK but are slightly less expensive.

Advantages

- Good tensile strength

- Dimensional stability

- Can withstand high temperatures

Disadvantages

- PEI is not cheap

- Not the best machinability

- Not UV stable

12.Polyetheretherketone (PEEK)

Aside from its expensive cost, PEEK is exceptional for custom CNC machining plastics projects. It is colorless and has good electrical insulating properties.

Advantages

- Can withstand up to 649.4°F

- Chemical resistance

- Good mechanical strength

- Biocompatibility

Disadvantages

- Very expensive

- Often requires special tooling

- Not UV stable

13.Polyphenylene oxide (PPO)

Polyphenylene oxides (PPO) are excellent machining plastic alternatives for computer numerical control engineering projects that require high abrasive resistance and UV stability.

Advantages

- Chemical and heat resistance

- Dimensional stability

- Electrical insulator

- Biocompatibility

Disadvantages

- Poor machinability

- It can be expensive

14.Styrofoam (XPS)

Styrofoam or extruded polystyrene foam (XPS) is a lightweight material supported for plastic CNC machining. However, wear dust masks and safety glasses during machined plastic production.

Advantages

- Easy to machine plastic

- Shock absorption

- Good thermal insulator

- Chemical resistance

Disadvantages

- Low melting point

- Environmental concerns

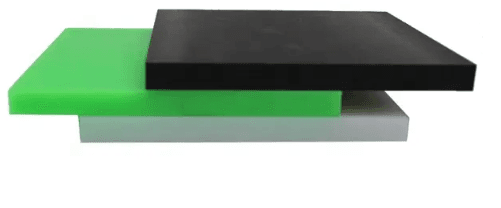

15.Polyethylene (PE)

Polyethylene (PE) is a common plastic CNC machining material known for its versatility. PE could exist as low-density polyethylene (LDPE) or high-density polyethylene (HDPE).

Advantages

- Easily available and affordable

- Safe for industrial food packaging

- High flexibility

Disadvantages

- Not UV stable

- Difficult to bond

16.Low-density polyethylene (LDPE)

The LDPE are polyethylene plastic parts with lower density but common applications like prosthetics and orthotics. They are not suitable for plastic CNC machines set up at high temperatures.

17.High-density polyethylene (HDPE)

HDPE plastics for CNC machining have more robust mechanical properties and are not transparent like low-density polyethylene (LDPE).

18.Polypropylene (PP)

Polypropylene (PP) is another thermoplastic polymer for CNC plastic machining. It offers good chemical resistance, but machined plastics pose challenges with painting surface finishing methods.

Advantages

- It is not expensive

- Excellent moisture resistance

- Durable and lightweight

Disadvantages

- Low heat resistance

- Not UV stable

19.Polyphenylsulfone (PPSF)

Polyphenylsulfone (PPSF) materials are transparent CNC machining plastics made of aromatic rings. They are suitable for food packaging and sterilization applications.

Advantages

- Good chemical resistance

- Long-lasting

- Can withstand high temperatures

Disadvantages

- High fouling tendency

- Low water permeability

20.Polytetrafluoroethylene (PTFE)

PTFE is a synthetic polymer derivative of tetrafluoroethylene. Its trademark name is Teflon®, and it is best for non-stick CNC applications in medical equipment or artificial body parts.

Advantages

- Dimensional stability

- Excellent thermal stability (620.6°F)

- Good chemical resistance

- Electrical insulator

Disadvantages

- Difficult to bond

- It is expensive

21.Acetal or Polyoxymethylene (POM)

Acetals are sometimes referred to as Delrin plastics or polyoxymethylene (POM). You can use them for plastic CNC machining applications that require fine machinability properties and low surface friction.

Advantages

- Can withstand harsh environmental conditions

- Impact resistance

- Good aesthetics

Disadvantages

- Low compatibility with adhesives

- Flammable

- Poor acid resistance

22.Kapton

Kapton is a high-performance polyimide film supported for plastic CNC machining projects. Its temperature range is usually between -452°F to 536°F.

Advantages

- Good thermal stability

- Chemical resistance

- Easy to machine plastic

Disadvantages

- It is not cheap

- Limited UV resistance

23.Acetal copolymer

Acetal copolymers, known as Celcon, are CNC machining plastics with excellent mechanical strength, dimensional stability and low-friction surface.

Advantages

- Impact resistance

- Dimensional stability

- Easy to machine plastic

Disadvantages

- Limited heat resistance

- It is slightly expensive

24.Acrylics

Acrylic plastics for CNC machining are also called Poly (methyl methacrylate) (PMMA). They are transparent thermoplastics with common engineering trade names like Perspex, Crylux and Plexiglas.

Advantages

- Biocompatibility

- Shatter resistant

- Easy to machine plastic

- Lightweight

Disadvantages

- Prone to scratch

- Lower heat resistance

25.Polyethersulfone (PES)

Polyethersulfone (PES) plastics are transparent yellowish/reddish brown high-performance polymers. Their outstanding feature as CNC machining plastics is the ability to withstand high temperatures for prolonged plastic machining time.

Advantages

- High-temperature resistance

- Good tensile strength

- Dimensional stability

Disadvantages

- Polyethersulfone is not cheap

- Hydrophobic under certain conditions

26.Thermoplastic polyurethane (TPU)

TPU is a thermoplastic elastomer that has excellent machinability on CNC machines. The machined plastic parts are long-lasting and abrasive-resistant. You can also recycle TPU plastics for CNC machining.

Advantages

- Transparency

- Good resistance to oils, abrasion and chemicals

- UV stable

Disadvantages

- Thermoplastic polyurethane is not cheap

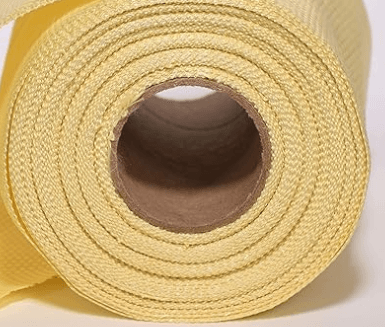

27.Poly Paraphenylene Terephthalamide (Kevlar)

Poly paraphenylene terephthalamide (Kevlar®) is a synthetic crystalline polymer that surpasses some metals like steel on an equal strength-to-weight basis.

Advantages

- Lightweight

- Good tensile strength

- Abrasion resistance

- Dimensional stability

Disadvantages

- It is expensive

- Difficult machinability

- Absorbs moisture

28.Thermoplastic elastomers (TPE)

Thermoplastic elastomers (TPE) are polymers that combine rubber-like characteristics with the processing style of plastics.

Advantages

- Good flexibility and elasticity

- Lightweight

- Recyclable

- Multiple grades of hardness

- Electrical insulators

Disadvantages

- Limited heat resistance

- Deformation under elevated temperatures

29.Polyvinylidene fluoride (PVDF)

Polyvinylidene fluoride (PVDF) is a plastic CNC machining material recommended for engineering thermoplastic processes requiring non-reactive polymers.

Advantages

- Good chemical resistance

- Thermally stable

- UV resistant

- Electrical insulator

Disadvantages

- High dissipation factor

- Difficult to bond

30.Ethyl vinyl acetate (EVA)

EVA CNC machining plastics consist of ethylene and vinyl acetate polymers. The percentage composition of vinyl acetate in EVA thermoplastics determines its flexibility or rubber-like properties.

Advantages

- Lightweight

- Shock absorption

- Chemical resistance

- Non-toxic and recyclable

Disadvantages

- Limited heat resistance

- EVA is not cheap

31.Ultra-high molecular weight polyethylene (UHMWPE)

Otherwise referred to as high-modulus polyethylene (HMPE), the UHMWPE is another supported plastic material for custom CNC machine design. UHMWPE materials are odorless and non-toxic, with high impact strength.

Advantages

- Best for withstanding impact

- Excellent abrasion resistance

- Good chemical resistance

Disadvantages

- Not UV stable

- Poor heat resistance

32.Polyamide-Imide (PAI)

As the name implies, the PAI plastics for CNC machining combine polyamide (nylons) and polyimide. Hence, polyamide-imide (PAI) plastic parts have exceptional mechanical and thermal properties.

Advantages

- High-temperature resistance

- Chemical resistance

- Biocompatibility

- Dimensional stability

Disadvantages

- Polyamide-imide is quite expensive

- Brittle at low temperatures

33.Polycarbonate/acrylonitrile butadiene styrene (PC-ABS)

PC-ABS for plastic CNC machining is excellent because of the blend of polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) properties.

Advantages

- High impact resistance

- Good chemical resistance

- Flame resistance

- Dimensional stability

Disadvantages

- PC-ABS plastics are not cheap

- Limited heat resistance

34.Polylactic acid (PLA)

Polylactic acid (PLA) is another engineering thermoplastic polymer with versatile applications like CNC machining plastics. Besides, PLA is gradually replacing conventional petroleum-based plastic parts because of its eco-friendly properties.

Advantages

- Transparent

- Excellent machinability

- Safe for food packaging

Disadvantages

- Low impact strength

- Thermally unstable

- Mildly hydrophobic

35.Polyethylene Terephthalate Glycol (PETG)

PETG is another transparent thermoplastic with good machinability on CNC machines. Its plastic parts include glycol that offers additional benefits like enhanced shock resistance compared to polyethylene terephthalate (PET).

Advantages

- Good chemical resistance

- Recyclable

- Good thermal stability

- Impact resistance

- Safe for food packaging

Disadvantages

- Prone to scratches

- Not UV stable

- Very hygroscopic

36.Polycarbonate/Polybutylene terephthalate (PC-PBT)

Using PC-PBT plastics for CNC machining services offers a blend of polycarbonate and polybutylene terephthalate properties. Therefore, the plastic machined parts are transparent and mechanically strong like polycarbonates (PC) and dimensional stable with excellent polybutylene terephthalate (PBT) chemical resistance.

Advantages

- Good heat resistance

- Excellent machinability

- Dimensional stability

- Good mechanical strength

Disadvantages

- PC-PBT is expensive

- Hygroscopic

- Limited UV resistance

37.High-impact polystyrene (HIPS)

The high-impact polystyrene (HIPS) plastic is similar to the regular polystyrene (PS) but with modified rubber. The presence of rubber in HIPS as CNC machining plastics enhances their durability and shock resistance.

Advantages

- Impact resistant

- Excellent machinability

- Cost-effective

- Lightweight

Disadvantages

- Limited heat resistance

- Not UV stable

38.Polymethylpentene (PMP)

Polymethylpentene (PMP) is suitable for plastic CNC machining projects with transparency and lightweight specifications. PMP thermoplastics are sometimes called TPX®.

Advantages

- Dimensional stability

- Chemical resistance

- High-temperature resistance

- Lightweight

Disadvantages

- It is not cheap

- Brittleness

39.Cellulose Acetate (CA)

Consider cellulose acetate (CA) as an alternative for CNC plastic machining because of its excellent machinability traits and transparent materials. CA thermoplastics are processed from a combination of acetic acids and cellulose fibers.

Advantages

- Lightweight

- Chemical resistance

- Biodegradable

- Highly transparent

Disadvantages

- Hygroscopic

- Limited heat resistance

- It is not cheap

40.Acrylonitrile Styrene Acrylate (ASA)

Processing of acrylonitrile Styrene Acrylate (ASA) is similar to the acrylonitrile butadiene styrene (ABS) plastics. However, ASA for plastic CNC machining offers enhanced resistance to chemicals, heat and UV radiation.

Advantages

- Good mechanical strength

- Easy-to-machine plastics

- Dimensional stability

- Chemical resistance

- UV stable

Disadvantages

- It is quite expensive

- Hygroscopic

How to choose the best CNC machining plastics

With numerous alternatives, your best CNC machining plastics should be the ones that tick more boxes for the factors explained below.

Mechanical properties

Depending on the selected plastic CNC machining applications, check for mechanical characteristics like tensile strength, impact resistance, hardness and flexibility.

Chemical resistance

Chemical resistance of CNC plastics is their ability to withstand exposure to chemicals without degrading. The chemical substances include acids, bases, fuels, oils and solvents.

Moisture, heat and UV resistance

The best plastic for CNC applications in the aerospace or automotive industry should effectively withstand sunlight rays and different thermal conditions. Absorption of moisture must also be minimal.

Appearance

The aesthetics of custom CNC machining plastics are essential in applications like toys, home windows, or containing vessels. You should also consider features like transparency and resistance to scratches.

Corrosion resistance

Industrial applications like aerospace require plastic materials with the best corrosive resistance. Examples are polypropylene (PP), polyethylene (PE), polyvinylidene Fluoride (PVDF), polytetrafluoroethylene (PTFE), and polyvinyl Chloride (PVC).

Budget

Yes, budget greatly determines your choice of CNC machining plastics. Check out the material costs for some common plastics below.

| Plastic Type | Material Cost (0.25in x 12in x 12in) |

| Polyethylene (PE) | $13 |

| Polyvinyl chloride (PVC) | $15 |

| Acrylonitrile Butadiene Styrene (ABS) | $17 |

| Acrylics (Plexiglass) | $25 |

| Polyethylene terephthalate (PET) | $29 |

| Polyetheretherketone (PEEK) | $175 |

Applications of CNC machining plastics

The versatility of CNC machining plastics keeps increasing because of their general properties like lightweight, flexibility and corrosion resistance. Here are the common applications of plastic CNC machining:

1.Medical industry

CNC plastics are commonly employed in manufacturing healthcare equipment such as sterilization or vitals monitoring devices. Their biocompatibility with the strict safety regulations of the medical field makes them essential. An example is low-density polyethylene (LDPE) for making artificial body parts and orthotic equipment.

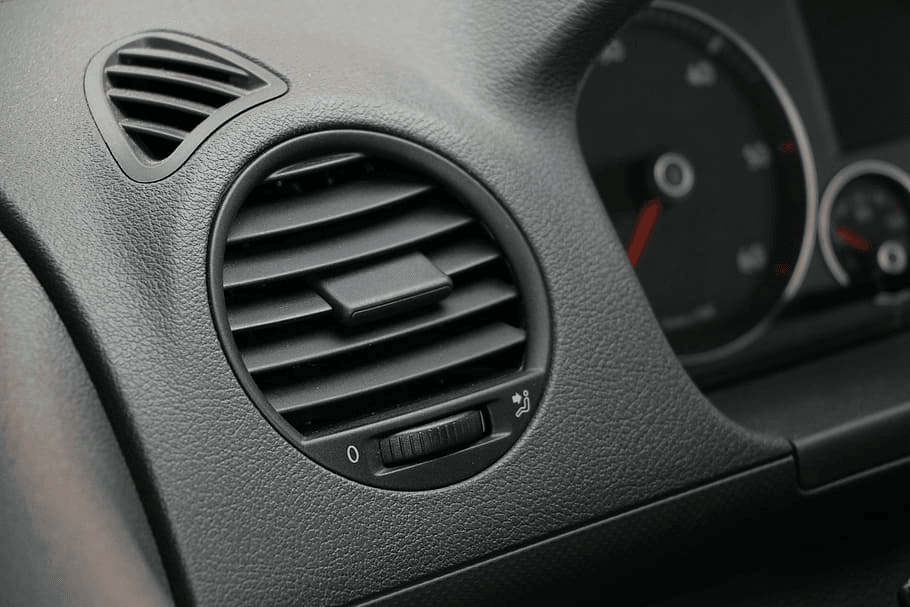

2.Automotive parts

Machinists now use computer numerical control (CNC) processes to produce plastic machined parts of automobiles. That includes custom automotive parts like the dashboard, bumpers, door handles, and engine covers. The lightweight and corrosive resistance of plastics enhances their appeal in such instances.

3.Electronics

CNC machinable plastics like Polyvinyl chloride (PVC), Polysulfone (PSU), and Polytetrafluoroethylene (PTFE) have more applications other than electrical insulators. Electronics companies also use plastic CNC-manufactured parts for LCD screens, keypads, and casing of devices.

4.Food processing

While plastics can serve as food packaging material, some plastics like ABS are unsafe for food contact. However, many plastic materials like nylon, polyethylene (PE), and polyphenylsulfone (PPSF) are non-toxic, safe and preferable to metallic materials that might corrode.

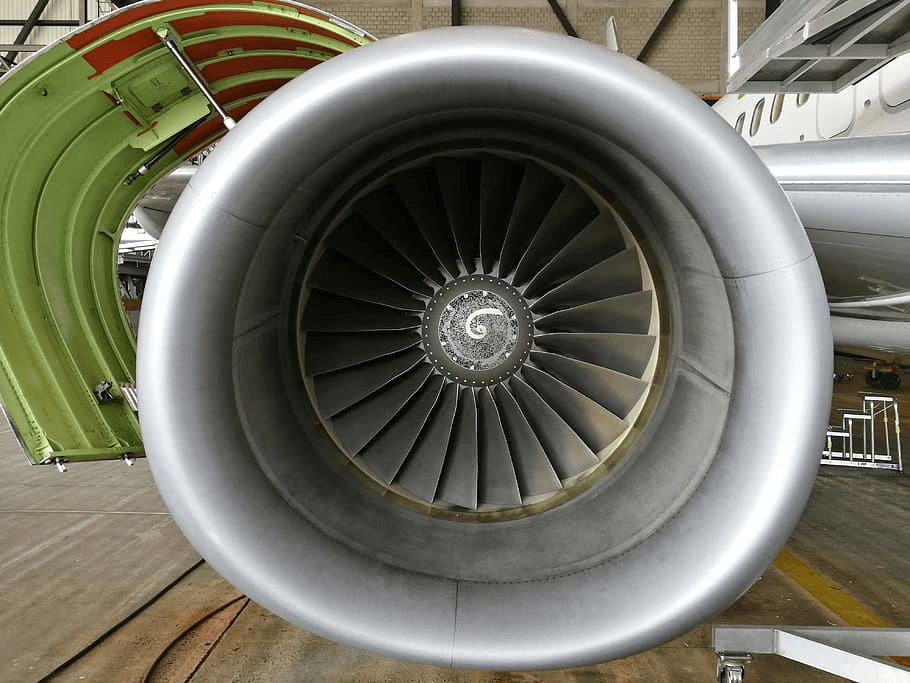

5.Aerospace industry

Aerospace applications involve CNC machining plastics with very high corrosion resistance, impact strength, and compatibility with extreme outdoor pressure conditions. Suitable plastic materials include Acetals (Delrin) for bushings and gears and ABS for interior parts like the dashboard. The engineering CNC plastics should also be lightweight and flexible.

Conclusion

Plastic CNC machining is beneficial for its faster machining time and high-precision manufacturing. This article explained how to choose the best plastic materials based on specific design considerations.

You could also outsource to a professional CNC service provider like Longsheng to help with the material pick and machining process. Contact our machining experts today and get an instant quote for your next custom CNC machining project.