Metal casting shrinkage is a natural physical phenomenon during the casting process. However, uncontrollable metal casting shrinkage leads directly to product scrap, dimension error, and exorbitant costs. Therefore, accurate prediction and control of metal casting shrinkage become crucial to ensuring the casting quality and effective production.

Not only does this piece compare the rates of shrinkage of three common metals—iron, steel, and aluminum—logically to reveal their trends and differences, but also displays how LS Precision applies cutting-edge prediction and compensation technology to pre-control the risk of shrinkage from the process design phase and later, precisely compensating for shrinkage.

This immensely increases the first-pass molding success ratio and offers accurate casting dimensions and production economics right from the start. To save you time, here’s a quick overview of the core conclusions.

Metal Casting Shrinkage Quick Reference Table

| Metal Type | Range of Linear Shrinkage (%) | Influencing Factors of Importance | Common Defects and Precautions |

| Cast Iron | 0.9% – 1.3% | Carbon Equivalent: A high carbon equivalent causes excess graphitization expansion and low shrinkage. Casting Structure: Differences in wall thickness control the rate of cooling, so that there is non-homogeneous shrinkage. | Low shrinkage caused by the expansion effect of graphite precipitation. Consider if the molding sand can withstand this expansion and hence needs to be given enough strength. |

| Cast Steel | 1.8% – 2.2% | Alloy Composition: The content of elements such as carbon and chromium plays a dominant role. Pouring Temperature: The higher the temperature, the greater the shrinkage. Processing (Annealing/Normalizing): Heat treatment removes stresses, affecting final size. | Shrinkage is fastest, and shrinkage cavities and porosity are most likely to be found at hot spots. Correct risers are needed for shrinkage feeding.

|

| Cast Aluminum | 1.2% – 1.6% | Alloy Type: Large volume fraction silicon hypoeutectic alloys are relatively low-shrinkage alloys. Cooling Rate and Mold Temperature: Both are most critical and need to be controlled very accurately. | Large solidification range alloys are prone to shrinkage porosity. A sophisticated riser and cooling control system are required to ensure density. |

Metal casting shrinkage is a complex and advanced phenomenon, not simply a numerical comparison:

- Cast steel shrinks most and is most difficult to feed;

- Cast iron shrinks least due to expansion caused by graphitization;

- Aluminum alloy is extremely sensitive to process conditions.

The key to achieving successful one-shot molding is with the use of precise prediction and compensation technologies, such as those invented by LS Precision.

This technology can preventively combat shrinkage in advance at mold design, minimizing risk beforehand prior to casting, ensuring proper dimensions and cost savings.

Why Trust This Guide? Practical Experience From LS Experts

The underlying principles and methods of this guideline directly result from LS Precision’s over two decades of experience in precision casting. We have developed a proprietary database for eight of the major categories of metals, from steel and iron all the way to aluminum, and have supplied industries with very close dimensional tolerances, such as aerospace and high-end hydraulics, for many years. This requires our technology system to be based on precise prediction and closed-loop verification, rather than on common industry guesstimates.

In a practical example, LS Precison helped a client to correct the problem of high deformation of a huge ductile iron guide rail. On analysis, we recognized that the cause was not that simple shrinkage, but rather the buildup of shrinkage stresses owing to non-uniform wall thickness. Through simulation, we also optimized the riser system and chiller layout and gating, and we dynamically set the shrinkage compensation rate in strategic areas higher than the standard 1.0% to as much as 1.25%.

We then achieved a smooth first-pass trial run, thus saving the client hundreds of thousands of yuan in rework of mold and trial production costs. This real-world information and problem-solving logic from the factory front lines is the unshakeable foundation for the value of this handbook.

Cast Iron, Cast Steel, and Aluminum Alloys– The Differences in Their Shrinkage Characteristics?

To regulate the size of casting correctly, one must know the fundamental differences of shrinkage characteristics among different materials first. It has direct influence on the selection of the following processes. For ease of understanding, the following table gives a comparison of shrinkage data for major cast metals.

| Category | Linear Shrinkage Range (%) |

| Gray Iron Cast | 0.9% – 1.3% |

| Ductile Iron Cast | 0.8% – 1.2% |

| Carbon Steel Cast | 1.8% – 2.2% |

| Stainless Steel Cast | 1.9% – 2.3% |

| Aluminum Alloy Cast | 1.2% – 1.6% |

1. Cast Iron Shrinkage:

The variations here are based on material science. The considerably smaller shrinkage of cast iron is primarily due to graphitization and solidification expansion. The precipitated graphite in gray and ductile iron, for example, possesses a very large specific volume, and its volume expansion actually partially compensates for some of the solidification of molten metal shrinkage. This is a natural “self-compensating” ability gifted by cast iron.

2. Cast Steel Shrinkage:

The very reverse, cast steel tends to have maximum shrinkage. Solidifying molten steel is not graphitized and, in addition, possesses a larger cooling range from pour temperature to room temperature, leading to maximum total shrinkage. This is the basic difference between cast iron and cast steel shrinkage.

3. Aluminum alloy shrinkage:

Aluminum alloy shrinkage is significantly dependent upon the crystallization temperature range of the alloy. Matured dendrites occlude feeding channels in hypoeutectic aluminum-silicon alloys like A356, which freeze in one temperature range. While the overall shrinkage is moderate, it is more susceptible to the formation of dispersed micro-shrinkage cavities and therefore extremely sensitive to conditions of processing.

The only fundamental difference lies in their solidification processes:

- Cast iron, due to its graphitization expansion, possesses “self-feeding” behavior and has minimum shrinkage.

- Cast steel is immune to this effect, possesses maximum shrinkage and is prone to localized shrinkage cavities.

- Aluminum alloys, due to their broad crystallization temperature interval, are prone to dispersed shrinkage cavities and are extremely sensitive to conditions of processing.

Besides The Material, What Other Key Factors Influence The Final Shrinkage?

For actual casting production, the material shrinkage is merely a baseline. Final casting shrinkage is influenced by a system of variables that are quite complex. Strict control depends on a complete understanding and coordination of such factors influencing metal shrinkage.

1. Casting Structure Design:

Inhomogeneous wall thickness is a serious issue. “Hot spots” formed in heavy areas cool down slowly, resulting in higher shrinkage and shrinkage control difficulty, which has a strong inclination towards developing shrinkage cavities and warpage. Although the use of low cast iron shrinkage material is practiced, unfavorable structure design can also lead to scrap through inhomogeneous shrinkage.

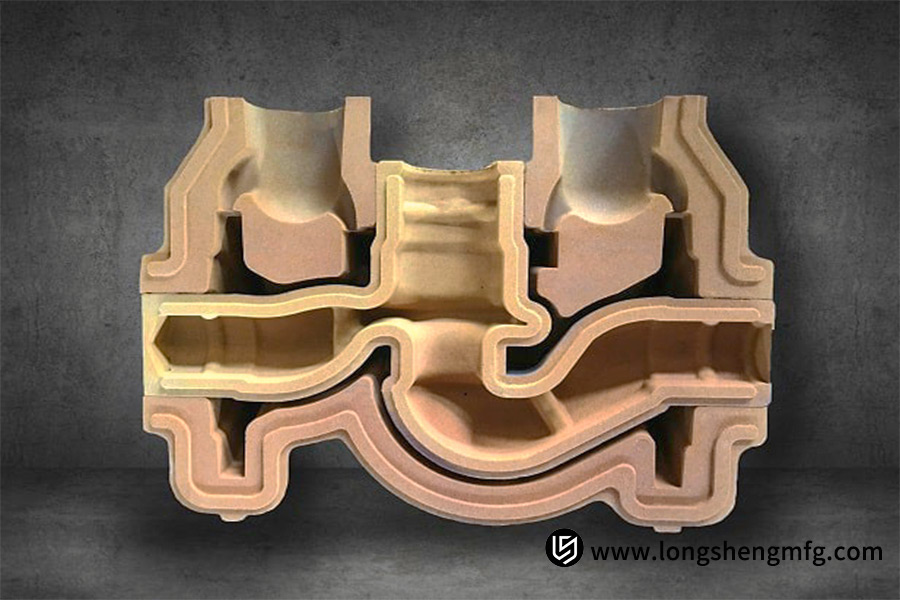

2. Molding Materials and Processes:

Casting mold yield (such as sand molds and metal molds) is significant. Sand molds yield partially to allow free shrinkage in part of the casting. Metal molds are extremely rigid and impose significant constraint on shrinkage, which can raise internal stresses and even cause thermal cracking and distort observed shrinkage significantly.

3. Casting Process Parameters:

Pouring temperature is an important variable. High temperatures increase the liquid shrinkage of the metal extensively, thereby leading to more overall shrinkage and exacerbating risks such as gas entrapment and coarse grains.

4. Riser System Design:

This is the principle that directional solidification and effective shrinkage control rely on. A proper design ensures the presence of sufficient liquid metal to feed shrinkage from the riser to feed into the metal under formation and thus feed macro-shrinkage defects into the riser itself. This is, however, not the case for an ineffective design, which is unable to fight against shrinkage problems even for the shrinkage of aluminum alloys.

Simple measurement of material shrinkage alone is insufficient. LS Precision’s sophisticated, integrated strategy accounts for all the above considerations affecting metal shrinkage through simulation, enabling precise prediction and control of end shrinkage to guarantee a first-pass mold success and avoid expensive mold rework.

How To Accurately Calculate And Compensate For Shrinkage In Practice?

In practice, casting shrinkage calculation is more than a table lookup; it is an integrated material, structure, and process system. LS Precision enforces a rigorous process in transforming theoretical shrinkage to an actual mold magnification factor for the final casting size tolerance.

1. System Analysis and Initial Value Selection:

The process begins by performing a detailed analysis of the part drawing. Engineers would then take an initial proposed range of shrinkage either from the material (such as cast steel usually works with a default 2.0% shrinkage rate) or general structural intricacy of the casting, based on an internal database of comprehensive field-measured data.

2. Refined Correction and Simulation Verification:

This is the critical step. The initial value is dynamically adjusted under some conditions. Various compensation coefficients are employed in various positions in complex shapes with non-uniform wall thicknesses or thermal joints. Furthermore, the selected process (e.g., the yield of sand mold and restraint of metal mold) is also taken into account in calculation. Then computer solidification simulation is conducted using computer simulation software to graphically display the shrinkage behavior and potential defects of each casting section such that the scale can be adjusted suitably.

3. Mold Implementation and Closed-Loop Verification:

The resulting, corrected shrinkage rate (i.e., “scale”) is then applied directly to the 3D model of the mold such that the measurements of the mold are scaled up suitably in the first place. Through trial manufacture and precise measurement of the first item, the outputs are returned to the database to form a closed-loop, continuous optimisation system.

The key to correct calculation of casting shrinkage is to break away from fixed empirical values and, through the use of a systematic “data + simulation” approach, dynamically calculate and accurately compensate for shrinkage behaviour, and thereby ensuring success at the mould design stage.

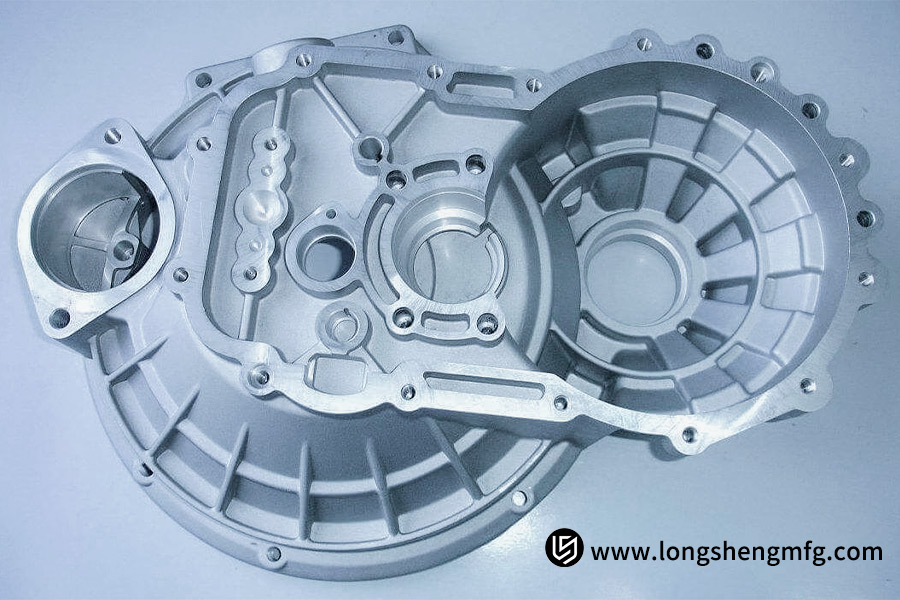

LS Saves a Large Cast Steel Gearbox Project with Shrinkage Control Technology

Dimensional stability of gigantic steel castings during high-tech machinery production has a direct impact on the success of the project. The following case of LS Casting is just the example showing how our thorough knowledge and precise control of shrinkage in cast steel deliver value to our customers’ projects.

1. Customer Pain Point:

One of the clients faced a grave issue in a large cast steel gearbox project. Three sequential batches of their blanks got rejected by a second vendor. The problem always started with the critical “bearing stop”: Post-machining allowance in this area was inadequate due to dimensional instability in this area, falling short of assembly specifications. Conventional default cast steel shrinkage rate was utilized but was not working, and the project was delayed and causing tremendous pressure on cost and schedules.

2. LS Precision’s Solution:

We did not use traditional shrinkage rates automatically when we started this tough case; instead, we initiated a comprehensive structural examination of the gearbox and discovered significant wall thickness differences. Due to the fact that the bearing stop had such a complex configuration, solidification shrinkage was thoroughly constrained by the encircling ribs.

By modeling the solidification process using simulation software, we were able to accurately forecast the distribution of hot spots and actual shrinkage resistance in every region. This was used as a reference to customize shrinkage compensation rates for different regions of the gearbox and implement proper compensation in the mold design. We also optimized riser and chiller locations in order to ensure sequential solidification and proper shrinkage compensation towards the risers.

3. Achievements and Value:

With the LS solution tailored, the first batch of trial parts were cast in one operation. The test results ensured that all critical bearing stop sizes were in tolerance, with equal and optimal machining allowances, fully meeting operating requirements. This project not only saved the client’s project from failure and avoided huge financial losses, but also earned their trust and established a long-term strategic partnership.

This LS Precision casting case further confirms that precise control of cast steel shrinkage is essential to the successful one-shot molding of intricate large castings.

Is There A Useful Quick Reference Table For Shrinkage Rates?

An accurate casting shrinkage table is definitely a useful reference tool for the initial process design or cost estimation. To make life easier for you, we have compiled the following quick reference on typical materials based on LS’s extensive practical experience.

| Typical Grade Example | Linear Shrinkage Reference Range (%) |

| Cast Iron Gray Iron (HT250) | 0.9% – 1.2% |

| Ductile Iron (QT450-10) | 0.8% – 1.1% |

| Cast Steel Carbon Steel (ZG270-500) | 1.8% – 2.2% |

| Stainless Steel (ZG0Cr18Ni9) | 2.0% – 2.3% |

| Cast Aluminum Alloy A356 / ZL101 | 1.2% – 1.5% |

This shrinkage chart of castings provides an empirical range based on standard sand casting operations. It is a starting point for design and analysis, not the only solution. In actual production, there are many variables such as the structure of the casting, mold, and gating/riser system that can significantly affect the resulting shrinkage behavior.

We therefore highly recommend that for any complicated or important castings, please refer to this chart and discuss with LS Precision’s technical experts.

LS Precision Manufacturing employs sophisticated simulation technology and a huge historical database to provide you project-specific, precisely calculated shrinkage solutions to ensure first-time casting success from the start.

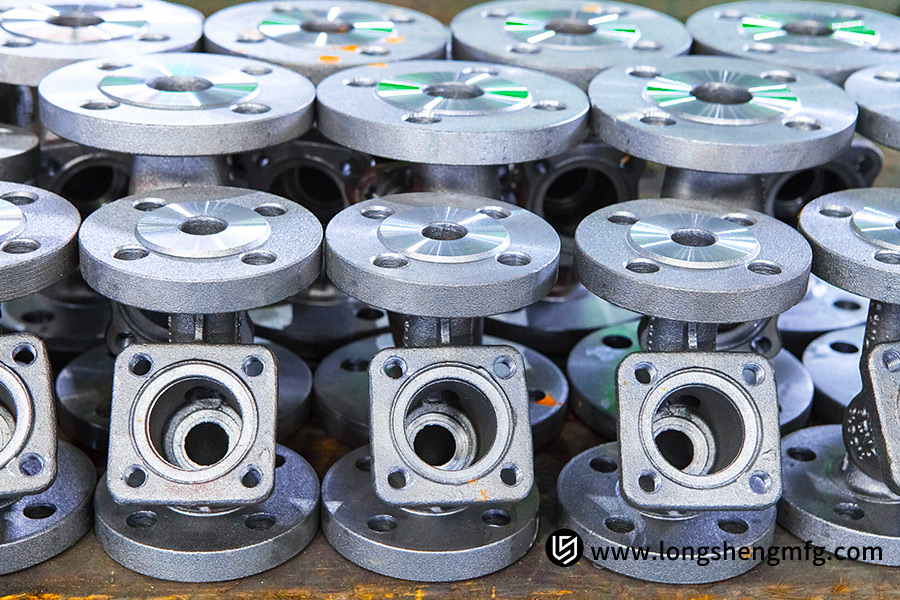

What Guarantees Do You Get When Choosing LS For Metal Casting?

When you partner with LS Precision as your metal casting business ally, you gain not only a quality product, but a system based on state-of-the-art technology and immense expertise as well. We are committed to creating direct value for you, specifically in the areas of precision casting and dimensional control:

- Lower overall cost and risk: With precise shrinkage prediction and compensation, we lower scrap from shrinkage cavities and porosity at the source, reducing your material and production costs and project risk.

- Excellent dimensional consistency and stability: In volume production, we have excellent dimensional homogeneity between parts and lots. This is a solid foundation for your automated assembly process, with significantly improved manufacturing efficiency and yield.

- Optimized Machining Allowances and Efficiency: The machining allowances in the castings we produce are controlled to the best and most homogeneous condition possible. This directly lowers your own machining time and tool wear, shortening the overall part production cycle.

- Significantly Shortened Development Cycles: With high-level simulation analysis and database functions, we are able to eliminate or diminish unnecessary mold trial and rework due to dimensional issues, expediting the introduction of your products to the marketplace.

Choosing LS Precision means having the guarantee of a precision casting and absolute dimension control specialist.

We are committed to freeing you from non-controllable process risk and working together with you to achieve the strategic goals of cost reduction, efficiency, and enhanced quality.

FAQs

1. Is the shrinkage rate of castings of the same material constant?

Not at all. Even for the same material, shrinkage can be widely different due to factors like the casting structure (uniformity of wall thickness, for example), mold material yield properties (sand/metal mold), pouring temperature, and gating and riser design. The behavior of simple thick-walled section shrinkage can be far different from that of a complex thin-walled rib. This is where the ability of LS Precision, in the form of accurate judgment and active compensation, comes into play. Design to the exact fixed shrinkage value of the material is far short of the target.

2. How do you verify the accuracy of your calculated shrinkage compensation?

LS Precision assures accuracy through an extremely strict closed-loop process of “digital verification and physical inspection.” After trial casting, we use high-accuracy 3D scanning equipment to measure the first part’s full size, accurately matching resultant point cloud data to our theoretical model design. By examining deviations, we not only directly verify the correctness of the current compensation, but also feed this data into our process database for continuous optimization of the algorithms, thus ensuring dimensional consistency in subsequent mass production.

3. What is your success rate for castings with particularly complex structures?

Advanced castings demonstrate the strengths of LS Precision technology. Leveraging advanced simulation technology, we can accurately predict the solidification sequence, thermal distribution, and shrinkage resistance of each part of the casting before mold manufacturing. Through the development of customized compensation solutions and targeted process measures (e.g., redesigned chiller layout) for these “trouble spots,” we have been able to cast many challenging castings, such as large frames and pump casings with multi-stream internal flow path features, with an extremely high first-time success rate.

4. Can we provide a preliminary shrinkage analysis during the quotation stage?

Yes, certainly. In quotation process, as long as you provide preliminary part drawings, our engineering team will make the first review for processability. Based on material information, significant wall thicknesses, and structural information in drawings, LS Precision will make use of its internal database and empirical formulas to incorporate a critical shrinkage analysis and first process feasibility estimate into the quotation. It helps you catch possible risks of shrinkage early and provide meaningful reference for project decision-making.

Choose LS Precision Control to Ensure Casting Project Success

In metal casting, project success or failure is directly determined by being able to effectively control shrinkage behavior. LS Precision Manufacturing System codifies this crucial technology: Not only do we possess our own proprietary database of eight of the most critical metal types and decades of field-proven know-how, but we apply advanced simulation technology to leapfrog from empirical guesswork to computer-based prediction.

This means that LS Precision can provide you with differentiated compensation solutions that fully considering material properties, casting structure, and process conditions. This whole solution for casting does so much more than provide exact dimensional control—it fully ensures your project’s stability in schedule, cost, and quality.

Choosing LS Precision means choosing a reliable partner committed to your project’s success. Let us leverage our technology strengths as marketplace competitive strengths.

Conclusion

Shrinkage control of casting is at the heart of the cost and quality of the castings. We strongly believe that true value lies not in the post-processing but in accurate predictions. We now offer a free, exclusive, and professional evaluation. Simply send us your part drawing, contact LS Precision and LS Precision specialists will calculate an initial shrinkage estimate and feasibility analysis to help you be successful in the first place.

Upload your design drawings now and get an instant metal casting quote ( metal casting price), let LS Precision be your strong backing in pursuit of ultimate metal casting precision!

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.