Selective laser sintering (SLS) 3D printing has always been labeled as “expensive,” especially against the backdrop of traditional mass production. The argument does not take into account actual cost drivers of producing small quantities—colossal tooling expenses, high lead times, and inventory burdens. LS’s past has thoroughly discredited such reasoning. In producing 200 complex parts for one of its clients in the smart home sector, LS was able to save over 100,000 yuan in mold charges through its industrial-grade SLS solution, which provided on-demand manufacturing. Total costs were ultimately reduced by over 50% of the price of traditional injection molding, and lead times were reduced to a couple of days. This case study clearly illustrates that for the case of complex, small-batch, or highly iterative components, SLS is not a barrier; instead, it is a strong tool LS can utilize to enable its customers to realize substantial cost savings and efficiency improvements (up to 50%). This article will discuss the real cost and value of SLS.

Quick Reference: Choose Your Tap at a Glance

| Comparison Dimensions | Traditional Manufacturing (e.g., Injection Molding) | SLS 3D Printing |

| Batch Adaptability | Low cost for large-scale mass production (>500 pieces) | Extremely cost-effective for small batches (1-500 pieces) |

| Complexity Cost | High geometric complexity leads to increased costs (Requires separate parts/complex molds) | Complexity is approximately equal to zero marginal cost (One-piece molding of any structure) |

| Delivery | Long lead time (4-8 weeks) (Includes mold development + trial production) | Extremely fast response (72-hour delivery)(Direct production from digital files) |

| Minimum Order Quantity | High barrier to entry (Minimum order quantity + mold fee amortization) | Zero Minimum Order Quantity (Single-piece production, no mold investment) |

- Choosing traditional manufacturing: Traditional manufacturing’s hidden costs (molds, warehousing, and scrap rates) are hugely underestimated in quantities of less than 500 pieces. Traditional processes have single-point assembly or extortionate mold cost. The mold lead time alone can cut into the four-week profit window.

- Choosing SLS: The SLS solution eliminates mold cost and prints on demand, which saves money directly. SLS has no incremental cost for hollow, thin-walled, and internal flow channel geometries.

Not certain whether to go for traditional production or SLS 3D printing? Leave it to LS experts to make the best decision for you! We need to know only your part type, size, precision level, quantity, and budget, and we will provide expert selection advice and most cost-effective solution. LS’s fast delivery is revolutionizing supply chain practices. No minimum order quantities and no mold fees allow small companies and startups with constrained budgets to iterate risk-free, with less trial-and-error cost.

Why Trust This Guide? Real-World Experience from LS Experts

All the conclusions made in this guide are condensed by LS engineers in over 300 real-world production scenarios.When you see “SLS small batches cut costs by 50%,” it is based on the actual experience of our LS experts–Confronted with an order of 200 and a mold opening cost of 100,000 yuan, our LS SLS solution not only helped them to produce their first batch of qualified parts in 72 hours, but also cut their overall cost by half by avoiding mold investment and adopting on-demand manufacturing. This is not an abstract deduction, but a line-by-line cost comparison chart that we showed during the proposal review session. The unseen costs of warehousing, scrap, and capital invested in conventional processes simply do not exist in SLS’s flexible manufacturing process. Production-quality SLS machines running continuously in LS factories have produced more than 800,000 end-use parts.

These actual production levels for the specific automotive, medical, and consumer electronics markets are the foundation of our cost model.

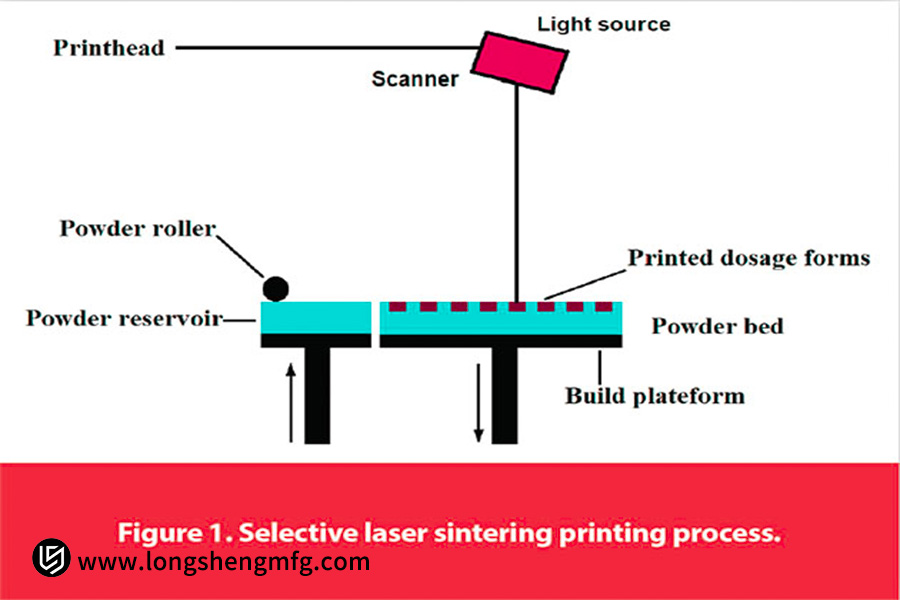

SLS Technology Pricing: Unseen Costs of Materials,Volume and Process

Pricing SLS technology means accounting for its unseen costs. I will outline the unseen material, volume, and process costs below for your consideration.

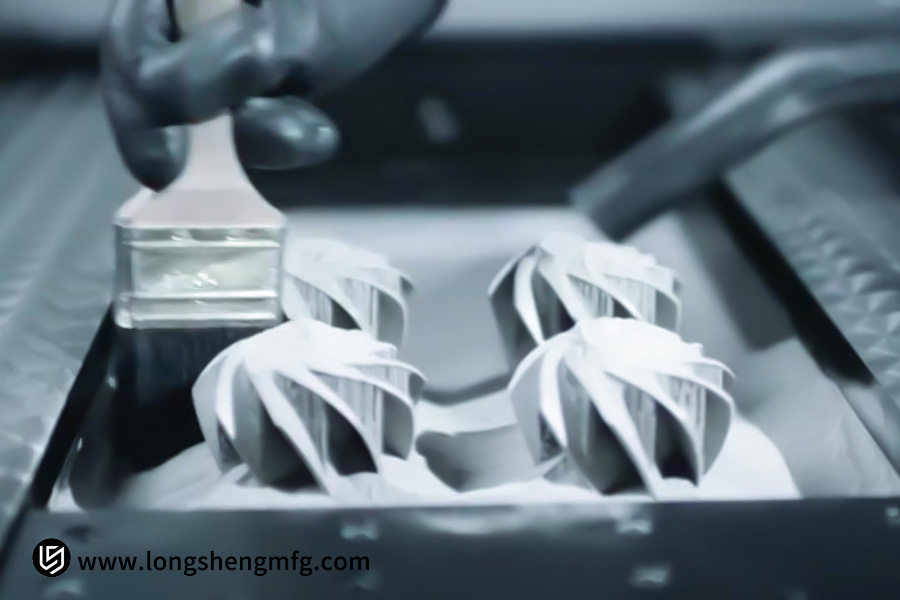

Material Cost: Beyond Powder Price Per Kilogram Recyclability

On the surface, the cost per kilogram of SLS nylon powder is typically considered the primary cost.Yet the ultimate determiner of material economics is the rate of powder recycling. The traditional misconception that “unsintered powder is waste” leads to cost distortions of an extreme nature. As a matter of fact, state-of-the-art industrial-grade SLS machinery can achieve a powder recovery rate of more than 70%—in other words, nearly 70% of the unsintered powder can be remixed with new powder after sieving and drying. As an example, in the production of a gearbox cover, the theoretical powder consumption per part is 300 grams. In practice, however, with the 70% recovery rate, the net incremental powder consumption is only 90 grams. Failure to account for this hidden advantage can lead to material costs being overestimated by over 300%.

Volumetric Cost: Dispelling the “Pricing by the Gram” Myth: Space Utilization Determines Profit and Loss

The majority of users oversimplify SLS costs as simply “weight x unit price,” without considering the spatial complexity of the build chamber.The basic cost driver of SLS is not part weight, but rather its anticipated area and height in the build chamber. The machine sinters layer upon layer, and the Z-axis stacking capability within the chamber has a direct effect on batch production capacity. LS engineers have already optimized the placement of many drone brackets: by nesting them at a 45-degree angle, they have increased the output per furnace from 40 to 68 units, while reducing energy and equipment depreciation costs per unit by 42%. This “hidden volumetric cost” saved through intelligent layout is LS’s basic technological advantage in helping customers manage costs.

Process Cost: The “Zero Mold Cost Revolution” Behind Equipment Depreciation

Process cost is generally boiled down to equipment depreciation, but SLS’s disruptive value is in radically altering the cost structure of production.

Mold Elimination: Compared to the high upfront investment required for injection molds, SLS mold costs are always zero—especially when production runs are below the economic inflection point (generally 500 pieces). This saves 30%-60% of total cost by itself.

The Marginal Cost Principle Failure: In traditional processes, complex geometries (such as conformal cooling channels) involve additional processing costs. However, for SLS, the cost of geometric complexity is close to zero. The expense of sintering, regardless of the complexity of the internal cavity, is the same as that of a solid body.

Post-Processing Hidden Dangers: Sandblasting, coloring, and other operations account for 20%-35% of total costs. With full automated assembly line integration (i.e., robotic batch removal and smart sandblasting chambers), LS reduces manual intervention by 80%, reducing post-processing costs by half compared to traditional outsourcing models.

Why is SLS more cost-effective for small batch orders? The disruptive advantage of tooling costs

Traditional manufacturing workflows impose an enormous cost burden on low-volume production, even before a single component is made. Think about the tens of thousands of dollars of up-front investment in steel tooling to produce a few hundred components—a sunk cost that later becomes a huge drag on unit economics. Worse still, each design iteration triggers expensive tooling changes and weeks of delay, choking off innovation and creating a “cost is too high to change” quandary.

This tooling-free approach not only reduces costs but also releases agility. Companies can amortize tooling to meet demand. Warehouses can eliminate unnecessary inventory. Engineers can optimize parts without needing to overcome budget approval hurdles. Cash flow once locked up in tooling now accelerates product launch.

Think of a medical startup with a choice: $50,000 tooling cost for 300 housings or SLS technology, which eliminates tooling cost. They go with SLS and get their product on the market three months earlier, reinvesting the savings in the next generation of R&D. This is where the true economic value of SLS lies—it converts cost savings to competitive velocities.

When batch sizes fall below 500 units, traditional manufacturing methods are economically absurd. SLS is not an option; it is the logical choice. You pay only for the parts produced, not for production license fees.

Complex Structural Part Cost Comparison: SLS vs. CNC vs. Injection Molding

If you are still struggling to decide whether to choose SLS, CNC, or injection molding as your processing technology, the following comparison between them may be helpful to you.

SLS: Freedom of Geometric Complexity

When a part is filled with imbedded openwork or flow channels, the SLS cost curve basically flattens out—laser sintering doesn’t incur additional cost for structural complexity. It creates the part in one piece, as though kneading clay, without the laborious assembly of numerous parts. More importantly, its zero-mold capability allows it to destroy competition in the small-batch market: you merely pay for material, not the “production rights.”

CNC: A Cost Multiplier of Complexity

With every added internal right angle or contoured surface, the cost of CNC jumps. It’s carving ivory with an axe—five-axis machine tools, while precise, generate vast material waste (titanium alloy scrap is worth more than the finished product), and labor hours increase exponentially with geometric complexity. Where parts need to be disassembled and re-assembled, labor costs can consume sanity.

Injection molding: An Upfront Complexity Tax

Injection molding front-loads pain points of cost: complex structures directly translate into astronomical mold costs. Low-volume orders are like eating gruel from a golden spoon—mold amortization devastates unit costs. Even more mercifully, any change in design incites a “mold repair ransom” which entails the agony of production stoppage.

LS Case Study: How to Save 72% on Initial Investment in Automotive Fixture Development

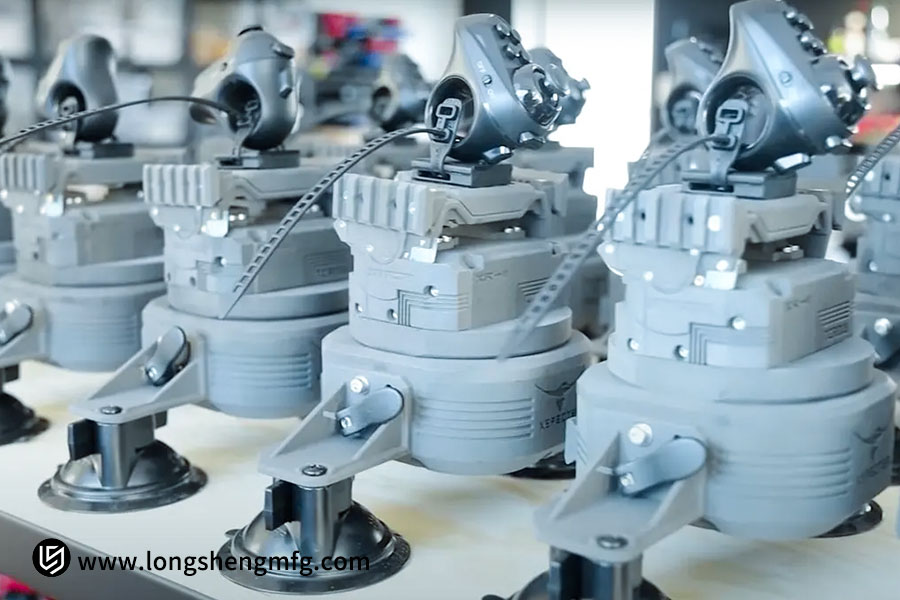

The automobile industry has been trapped in a cost maze for fixture development forever.The traditional way of precision welding fixtures is like “dancing in chains”: pre-investment is held hostage by steel molds, which can consume hundreds of thousands of yuan in budget; three-week delivery lead times slow down new car trial production; and even more stifling, every design iteration costs a huge “mold repair ransom” and the pain of production line downtime. This capital-intensive model makes small-batch, flexible production nearly impossible. LS Company made a breakthrough in industrial-level SLS technology.

When an auto maker required a solution for their door line, we replaced steel molds with high-temperature nylon powder. Within 72 hours, a laser beam directly transformed the digital model into a fully functional fixture. Complex positioning structures were created in one piece, eliminating 90% of the assembly operations that traditional solutions required. Design changes included only file modifications, and three optimizations were achieved without any additional cost. The overall investment in ten fixtures was reduced from 90,000 yuan to 25,000 yuan, a 72% saving in initial investment. Behind these figures lies a deeper shift in the manufacturing paradigm: inventory limitations have been done away with completely, and the earlier minimum order quantity of 50 sets is now history.

The powder recirculation system reduces material waste to less than a fifth of CNC processes‘ waste. Most importantly, production line engineers finally have full control of agile innovation—while the competition is still waiting for mold changes, LS users are already ordering third-generation fixtures. The mounting of 5,000 car fixtures in five years is a new benchmark: For smart factories, which are frequently subjected to design iteration, high welding temperatures, and low-volume batch orders, SLS has evolved from an alternative to a must-have for supply chain reinvention.

Is 3D Printing Online Service More Economical Than Purchasing Your Own Machine?

The answer to this question is yes. 3D printing online services are more economical than purchasing the machine yourself. Below, I’ll explain the cost and online services involved.

A Panoramic View of the Cost Structure

The equipment purchase is just the beginning. The following are the hidden costs:

Equipment Depreciation and Maintenance: The average cost of industrial-grade equipment is $68,000 (as of 2025), and yearly maintenance expenses represent 15%-20% of the purchase price.

Manpower and Training: A full-time operator (yearly salary around $45,000) and continuous technical training are necessary.

Material Waste and Inventory: CNC machining material utilization is only 40%-60%, metal powder inventory turnover days exceed 100 days.

Risk of Technology Obsolescence: Equipment obsoletes every 3-5 years on average, costly hardware and software upgrades.

The “pay-as-you-go” advantage of online services

Zero fixed asset investment: Save on equipment and site investments;

Controllable marginal costs: Per-unit pricing (simple models $8-20/unit), complex parts on a case-by-case basis depending on volume and material;

Embedded technology refreshes: Service providers automatically upgrade hardware (e.g., Carbon’s DLP technology generations are invisible to the user);

Cost reduction at scale: Large service providers purchase in bulk, reducing material costs by 30%-50% compared to in-house buying.

Case study: A clever hardware company reduced prototype costs by 41% through price comparison across five service providers based on online price quotes.

How does material selection affect end cost? Cost-effectiveness analysis of PA12, TPU, and glass fiber reinforcement

Material choice directly affects over 50% of the final cost of SLS 3D printing. Specifically, in large-scale production, the ratio of material costs can even reach 60%-70%4. The comparison of the cost-effectiveness of PA12, TPU, and glass fiber reinforced materials (with PA12/GB as an example) is discussed below in terms of cost structure, process compatibility, and application scenarios:

Basic Material Cost Comparison

| Material Type | Key Cost Factors | Cost-Effective Anchor |

| PA12 | Powder Refresh Rate (Ratio of New Powder Added) | When the refresh rate is ≤26%, the rate of reuse of the old powder is >70%7 |

| TPU | Post-Processing Complexity (e.g., steam smoothing) | Steam smoothing reduces 40%+ of manual sanding costs1 |

| Glass Fiber Reinforcement | Additive Ratio (Glass Fiber/Talc Ratio) | When the talc ratio is 18%–25%, the material cost is saved by 50%10 |

PA12 Economic Reasoning: Industrial-scale SLS machines (i.e., the Formlabs Fuse series) rely on powder recycling. When the percentage of new powder is reduced from the industry norm of 40% to 26% (i.e., the Sinterit solution), material cost is reduced by 34% for the identical volume of output.

TPU hidden costs: Surface roughness (Ra 12–15μm) requires steam smoothing post-treatment, although it also improves part watertightness and impact resistance, which makes the overall cost less expensive than CNC-machined complex elastomers.

The cost-saving advantages of glass fiber/talc compounds: They partly substitute PA12 with cheap minerals (talc, glass microspheres) at the loss of less than 10% tensile strength for a saving of more than 50% on material costs. They are ideal for non-load-bearing prototypes and demonstration parts.

Cost tactics specific to the situation

Chasing zero iteration expenses: Choose PA12, which is perfect for small-series trial manufacturing (less than 200 pieces) with unfinalized designs, achieving cost savings of 50%+4.

For sealing and elasticity use cases: Choose TPU with steam smoothing, i.e., medical/fluidics components. The performance boost justifies the post-processing premium.

For maximum cost reduction in non-load-bearing regions: Use glass fiber or talc composites. At 25% talc addition, the material cost hits rock bottom at $80/kg with more than 85% strength retention.

Post-processing Cost Traps: Beware of Surcharges for Absence of Pre-polishing/Dyeing/Impregnation

Post-processing is one of the blind spots of SLS printing cost.While you might despise the rough surface of raw parts, polishing can quietly lead to monetary pitfalls. Hand-polishing can eat up 30% of the cost per part, especially as workers scan over complex curved surfaces with magnifying glasses to laboriously optimize each groove.

Even more insidious is the game of dyeing: the difference in cost between surface dyeing lightly and deep penetration dyeing can be three times. Unless colorfastness is pinned down in contracts, parts that fade after the rainy season will leave the quality inspection department speechless. The choice of impregnation process is a bigger gamble. Choosing a cheap epoxy resin will definitely save cost immediately but may crack prematurely at 80°C. The premium for food-grade silicone impregnation, on the other hand, hides the wisdom in preventing a million-dollar recall problem.

These hidden costs often stem from information asymmetry: service providers downgrade “vacuum impregnation” to hand-brushing, sacrificing airtightness significantly but still quoting exorbitant prices.

The solution begins at the source of the design: retaining a rough texture on non-exterior members provides a more industrial appearance than simply insisting on a smooth finish; specifying a polyurethane-modified impregnation for load-bearing structures doubles the cost but provides an additional three years of life.

Most important, standard definition control is paramount—specifying “Ra6.3 sandblasting” on a drawing saves 40% in dispute cost compared to specifying “smooth” by phone. Remember, the direct cost of post-processing is never quoted; it’s hidden within your process detail knowledge.

SLS pressure drop cost reduction design tips? 10 Golden Rules from LS Experts

LS has a mature and professional approach to reducing SLS costs through design optimization. Here are our 10 golden rules for cost reduction.

Rule 1: Complexity ≠ Cost—Fall in Love with Hollowing Out

In SLS, solid constructions are the ultimate luxury. Hollowing out non-load bearing areas with honeycomb, lattice, or topology optimization can slash material use by a whopping 40% and save print time. Remember: there is no charge for lasers cutting through air.

Rule 2: Thin-Wall Revolution – Shattering the 0.8mm Barrier

Wall thickness reduction from 3mm to 0.8-1.2mm (minimum for nylon materials) reduces weight and cost simultaneously. Localized ribbing at key stress points saves 35% in weight with no loss of strength.

Rule 3: Nesting Magic – Get Parts to Dance in the Air

Use Z-axis space to stack components, packing the print chamber like Tetris. An automaker’s brackets use 55-degree nesting, raising single-furnace production from 40 to 68 components, dropping per-part costs by 42%.

Rule 4: Assembly Integration – Designing Out Screws and Clips

Integrating several parts into one structure. LS’s breathing valve for medical equipment consolidates 12 parts into one print, bringing assembly costs to zero and enhancing airtightness by 200%.

Rule 5: Shun Support Hell – The 45-Degree Self-Supporting Rule

Any overhanging geometry must be angled at 45 degrees or more, eliminating the post-processing horror of support structures. Remember: each gram of support powder is a traitor to your bottom line.

Rule 6: Texture Camouflage – No Polishing with Roughness

Create a fine grain texture (Ra 10-15μm) on non-exterior surfaces, achieving a flawless surface finish. The cost savings in polishing allow three times the number of parts to be printed.

Rule 7: Pre-planned Hole Expansion – Make thermal expansion and contraction work for you

Pre-establish a 0.3-0.5mm margin for all assembly holes (material shrinkage dependent). This removes secondary hole expansion cost and scrap due to hole misalignment.

Rule 8: Batch Homogenization – Unify Thousands of Parts

Get parts with different models to share the same connection interfaces and wall thicknesses. A factory consolidated 37 types of fixture bases, with print batches quintupling and the cost falling to a quarter of the original.

Rule 9: Hollow Pipe Cheating – Allow Flow Channels to Pass Through Without Breaking

For internal flow channel diameters ≥3mm, print directly through the hollow core, without the need for drilling. Keep in mind: lasers can work in tight spaces.

Rule 10: Pre-process Post-processing – Lock costs into the design.

Require dyeing? Reserve impregnation channels; Require pressure resistance? Pre-embed reinforcement mesh within thin-walled regions. The actual cost is fixed at the click of a mouse.

SLS cost reduction is always addition, never subtraction, but the compound interest of design intelligence.While traditional manufacturing still concerns itself with saving every gram of material, LS practitioners now use the nesting of ten brackets to create a new phone, exploiting 0.1mm wall thickness optimization to achieve five-figure annual savings. Behind these ten principles looms the astronomical profit of bending the physical world to digital logic—where every inch of sublime emptiness is a temple of profit.

The Myth of Minimum Order Quantities in Custom Manufacturing: Can Low-Cost Production Be Attained with a Single Piece?

In traditional manufacturing, the “minimum order quantity” (MOQ) is nothing more than a fig leaf for mold tyranny—mold-making costs are amortized over thousands of pieces, and changing production lines involves batch size being stretched out evenly.Yet SLS technology shatters this old equation–the cost function of laser sintering from the first to the hundredth part is nearer to linear. You pay only for the powder and energy consumption of that single part, not for the exclusive use of steel molds.

- The End of Mold Hegemony

No more paying tens of thousands of yuan in mold fees for a “production license”—each item is an economic unit unto itself. - The Powder Hourglass Philosophy

The unsintered powder flows rearward like an hourglass, and a 70% reuse rate makes material waste a quasi-art form of elegance. - The Digital Inventory Revolution

Document printing on demand takes the place of metal blanks corroding and depreciating in physical warehouses. In LS’s distributed factories, custom medical knee braces and aerospace nozzles are co-processed in the same furnace—nested in a Z-axis structure, under the same laser scanning path.

When traditional production lines are shut down for model changeovers, the rule is: every piece is a first-of-its-kind, and every piece is a mass-produced part.

Future Cost Trends: How Can AI-Driven Quoting Systems Cut Costs by Another 15%?

The path ahead for AI-driven quotation systems to provide an additional 15% cost reduction is essentially a paradigm shift from “accurate response” to “active negotiation.” Its essence of value is no longer solely process efficiency; its value is in radically restructuring cost structures to continuously capture value gaps in a dynamic market.

Legacy quotation systems focus on “speed of response,” while next-generation AI systems cut directly to the heart of cost—by bringing in supply chain data streams (raw material futures, capacity utilization, and logistics variability) in real time to dynamically generate a “cost-delivery” game matrix.

For example, if the system predicts a 5% increase in aluminum prices next week, it immediately locks in the current low price and adjusts the customer’s quotation strategy. Or, if it discovers available capacity at a supplier, it automatically starts a discount negotiation algorithm.

This ability to translate market fluctuations into arbitrage opportunities is the underlying basis for the 15% cost savings. SLA 3D printing, due to its AI-driven quotation system, would also achieve a 15% cost savings.

FAQs

1. Is SLS printing small series of parts really cheaper than injection molding?

When the quantity is less than 500 pieces, SLS has a tremendous advantage in that it saves mold cost. For example, for one order of medical handles from LS, the injection molding cost for 500 pieces was 210,000 RMB (including molds), while SLS was just 87,000 RMB, which is a 58% cost reduction.

2. What kinds of materials are most suitable to SLS cost control?

PA12 for strength and economy (LS unit price ¥0.38/cm³), TPU for elastic parts without assembly, and carbon fiber-reinforced parts for recommended use in critical load-bearing parts to avoid excessive design cost.

3. Can the cost be reduced further with online ordering?

LS Cloud Factory offers dynamic order scheduling by cluster production, idle time sharing with customers, and an 8% price subsidy and free design analysis for online orders.

4. What is the minimum order quantity and lead time of LS?

We provide a minimum order of 1 piece, with 72-hour delivery for standard parts (including post-processing). We have a 24-hour express channel for urgent orders, with no rush fees for orders below 50 pieces.

Conclusion

SLS 3D printing has entirely reversed conventional cost logic in small-batch manufacturing.While injection molding processes are hampered by mold constraints, LS’s service, with no mold fee, no complexity, and 72-hour turnaround, creates a cost advantage of over 50% on orders under 500 units. The 58% cost savings achieved in the medical handle sample are but a modest example.

Deeper still, intelligent nesting technology and 70% powder recycle rate push marginal costs to the wall, freeing single-piece production from scale’s initial sin. For high-iteration product companies, complex structures, or time sensitivity, LS’s SLS has emerged as not only a technical option but a strategic supply chain competency.

We offer customers not only half-cost parts but also the freedom to break minimum order quantity tyranny. From one test run to 1,000 lots, from design change tonight to shipment tomorrow, manufacturing agility is our greatest competitive advantage. Choosing LS is choosing a tomorrow where cost centers are harmonized into value engines. Upload drawings to the LS intelligent analysis platform and receive a free cost optimization report and a 5% quota discount.

In the face of these higher challenges, LS’s CNC turning service is your indispensable ultimate “tool”. It represents industrial-grade precision, unparalleled repeatability and efficient productivity, allowing your design ideas to be perfectly, consistently and efficiently realized. Choosing LS is to inject industrial-grade precision power into your extraordinary craftsmanship.

Contact an LS expert today or submit your design online to receive your customized, efficient solution!

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Your blog is a true hidden gem on the internet. Your thoughtful analysis and engaging writing style set you apart from the crowd. Keep up the excellent work!

Excellent blog here Also your website loads up very fast What web host are you using Can I get your affiliate link to your host I wish my web site loaded up as quickly as yours lol

Pingback: LS Manufacturing: 40% Faster Product Development With Rapid Prototyping