CNC machining has become an indispensable manufacturing process in the electronics industry due to its ability to produce high-quality parts with precision. In this article, we’ll explore the top applications of CNC machining parts in the electronics industry.

Printed Circuit Boards (PCBs)

Printed circuit boards (PCBs) are a crucial component of electronic devices, and CNC machining plays a vital role in their production. CNC machines can create precise and intricate patterns on the board, allowing for the creation of complex circuits that are essential for modern electronic devices.

Enclosures

CNC machining is also used to produce enclosures for electronic devices. Enclosures protect electronic components from damage and provide a platform for mounting the components. CNC machines can create enclosures with precise dimensions, ensuring a perfect fit for the electronic components.

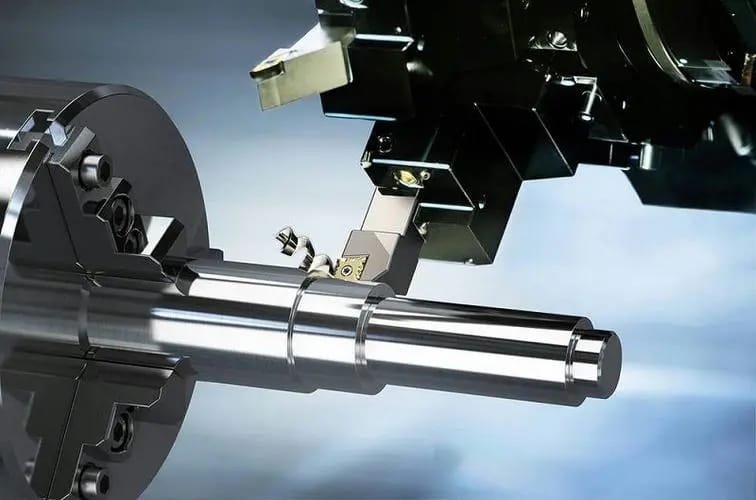

Connectors

Connectors are another essential component of electronic devices, and CNC machining is used to create them. CNC machines can produce connectors with precise dimensions and complex shapes, allowing for the creation of connectors that are tailored to specific applications.

Heat Sinks

Heat sinks are used to dissipate heat generated by electronic components, and CNC machining is used to produce them. CNC machines can create heat sinks with intricate designs that maximize their cooling efficiency, ensuring that electronic components operate at optimal temperatures.

Sensors

Sensors are used in a wide range of electronic devices, and CNC machining is used to produce them. CNC machines can create sensors with precise dimensions and complex shapes, allowing for the creation of sensors that are tailored to specific applications.

Conclusion

In conclusion, CNC machining plays a vital role in the production of electronic devices. Its ability to produce high-quality parts with precision makes it an indispensable manufacturing process in the electronics industry. By utilizing CNC machining for the production of PCBs, enclosures, connectors, heat sinks, and sensors, manufacturers can achieve high-quality electronic devices that meet exact specifications and perform reliably over the long term.

Benefits of Using CNC Machining Parts in the Electronics Industry

CNC machining offers several benefits for manufacturers in the electronics industry. Here are some of the top benefits:

Precision

One of the primary benefits of CNC machining is its ability to produce parts with high precision. This is especially important in the electronics industry, where even the slightest deviation from the intended specifications can impact performance. CNC machines are capable of producing parts with tight tolerances, ensuring that they meet the exact specifications required for electronic devices.

Speed

CNC machining can produce parts quickly, which is essential in the fast-paced electronics industry. The ability to produce parts quickly reduces lead times, allowing manufacturers to bring products to market faster.

Cost-Effective

CNC machining can be a cost-effective option for producing parts for electronic devices. While the initial investment in CNC equipment can be significant, the ability to produce consistent, high-quality parts can ultimately reduce costs over the long term. CNC machines can also produce parts quickly, which can further reduce costs and lead times.

Flexibility

CNC machining is a flexible manufacturing process that can produce parts from a wide range of materials, including metals and plastics. This flexibility allows manufacturers to choose the best material for a specific application, ensuring that electronic devices perform optimally.

Conclusion

In conclusion, CNC machining is an essential manufacturing process in the electronics industry. Its ability to produce high-quality parts with precision, speed, and cost-effectiveness makes it an attractive option for manufacturers. By utilizing CNC machining for the production of PCBs, enclosures, connectors, heat sinks, and sensors, manufacturers can achieve high-quality electronic devices that meet exact specifications and perform reliably over the long term.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC Milling Parts Machining Service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items.