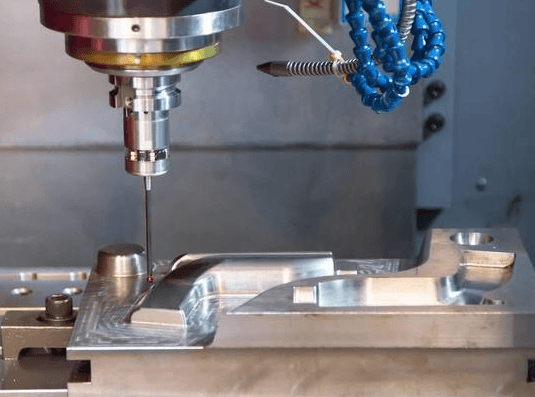

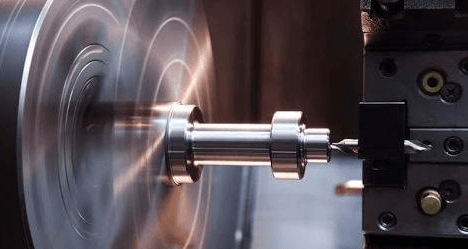

CNC machining has revolutionized the manufacturing industry, and the food industry is no exception. With its ability to produce high-quality parts with precision, CNC machining is an excellent option for creating parts used in food production. In this article, we’ll explore the top applications of CNC machining parts in the food industry.

Food Processing Equipment

Food processing equipment requires parts that are durable, easy to clean, and can withstand harsh environments. CNC machining can produce parts from a wide range of materials, including stainless steel and food-grade plastics, that are well-suited for these applications. CNC machines can also create parts with complex shapes and intricate designs, which can improve their performance and lifespan.

Packaging Equipment

Packaging is a critical component of the food industry, and CNC machining is used to produce parts for packaging equipment. CNC machines can produce parts with high precision, ensuring that they fit together seamlessly and function as intended. Additionally, CNC machining can create parts with intricate designs that improve their performance and durability.

Dispensing Equipment

Dispensing equipment is used in many food applications, and CNC machining is used to produce parts for these machines. CNC machines can produce parts with tight tolerances, ensuring that they dispense the correct amount of product every time. CNC machining can also create parts with complex shapes and designs that enhance their functionality and reliability.

Bakery Equipment

Bakery equipment requires parts that are durable, easy to clean, and can withstand high temperatures. CNC machining can produce parts from a wide range of materials, including stainless steel and heat-resistant plastics, that are well-suited for these applications. CNC machines can also create parts with intricate designs that improve their performance and longevity.

Conclusion

In conclusion, CNC machining offers a range of benefits for producing parts used in the food industry. Its ability to produce precise, consistent, and durable parts makes it an excellent choice for food processing, packaging, dispensing, and bakery equipment. Additionally, its ability to create parts with complex shapes and designs, as well as its flexibility in producing parts from different materials, makes it an attractive option for food manufacturers. By utilizing CNC machining in the food industry, manufacturers can achieve high-quality parts that meet exact specifications and perform reliably over the long term.

In summary, CNC machining is an essential manufacturing process for the food industry. By producing high-quality parts with precision, CNC machining can improve efficiency, reduce waste, and enhance the safety and quality of food products. As the food industry continues to evolve, CNC machining will undoubtedly play a crucial role in meeting the demands of this rapidly growing industry.

Benefits of Using CNC Machining Parts in the Food Industry

CNC machining offers several benefits for manufacturers in the food industry. Here are some of the top benefits:

Precision

One of the primary benefits of CNC machining is its ability to produce parts with high precision. This is especially important in the food industry, where even the slightest deviation from the intended specifications can impact safety and quality. CNC machines are capable of producing parts with tight tolerances, ensuring that they meet the exact specifications required for food processing, packaging, dispensing, and bakery equipment.

Consistency

Another advantage of CNC machining is its ability to produce consistent parts. This is important for the food industry where multiple parts must work together seamlessly to achieve optimal performance. CNC machines can produce identical parts with high consistency, which reduces the risk of errors and improves overall performance.

Durability

The food industry requires parts that are durable and can withstand harsh environments. CNC machining can produce parts from a wide variety of materials, including stainless steel and food-grade plastics, that are well-suited for these applications. CNC machines can create parts with complex shapes and intricate designs, which can improve their durability and performance.

Hygiene

Hygiene is a critical concern in the food industry, and CNC machining can help manufacturers produce parts that are easy to clean and maintain. CNC machines can create parts with smooth surfaces and minimal crevices, reducing the risk of bacteria and other contaminants. Additionally, CNC machining can produce parts with food-grade materials that meet strict hygiene standards.

Conclusion

In conclusion, CNC machining is an essential manufacturing process in the food industry. Its ability to produce high-quality parts with precision, consistency, durability, and hygiene makes it an attractive option for food manufacturers. By utilizing CNC machining for food processing, packaging, dispensing, and bakery equipment, manufacturers can achieve high-quality products that meet exact specifications and perform reliably over the long term.

As the food industry continues to evolve, CNC machining will undoubtedly play a critical role in meeting the industry’s demands. By leveraging the benefits of CNC machining, manufacturers can improve efficiency, reduce waste, and enhance the safety and quality of food products.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC Milling Parts Machining Service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items