What are the types of sheet metal forming

Sheet metal forming is a process that allows for the creation of three-dimensional objects from a two-dimensional piece of metal. The processes involve stretching, bending, or stamping the metal to achieve the desired shape. This type of manufacturing is often used in the production of cars, appliances, and even medical equipment. In this blog post, we will explore the different types of sheet metal forming and how they are used to create various products.

Sharing

Shearing is a cutting process that uses sharp blades to cut through sheet metal. This process can be performed using manual or powered shears. Manual shears are typically used for small, thin pieces of sheet metal, while powered shears can cut through thicker and tougher materials.

There are two types of shearing processes: cold shearing and hot shearing. Cold shearing is the most common type of shearing process and uses a cutting tool that is cooled with a refrigerant. This type of shearing process is typically used to cut through softer materials, such as aluminum or brass. Hot shearing, on the other hand, uses a cutting tool that is heated with an electric current. This type of shearing process is typically used to cut through harder materials, such as steel or stainless steel.

Bending

There are three main types of sheet metal forming: bending, stretching, and drawing.

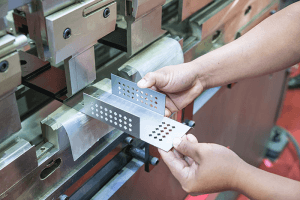

Bending is a process that changes the shape of a piece of sheet metal by deforming it along a linear axis. This can be done using a variety of methods, including:

-Manual bending, using a hammer or other tool

-Machine bending, using a press brake or other machine

-Hydraulic bending, using high-pressure fluid to deform the metal

Stretching is a process that changes the shape of a piece of sheet metal by deforming it along a non-linear axis. This can be done using a variety of methods, including:

-Manual stretching, using a hammer or other tool

-Machine stretching, using a press or other machine

-Hydraulic stretching, using high-pressure fluid to deform the metal

Drawing is a process that changes the shape of a piece of sheet metal by pulling it through dies of various shapes. This can be done using:

-A draw bench

Embossing

Embossing is a sheet metal forming process in which a design is raised above the surface of the metal. This can be done using a variety of tools, including a die, a roller, or a stamp. The raised design can be used for decoration or to add strength to the metal.

Drawing

There are many types of sheet metal forming processes. The most common are:

-Rolling: Rolling is a process that uses a pair of rolls to form the metal into its final shape. This is one of the most common methods for shaping sheet metal, and can be used to create everything from simple bends to complex shapes.

-Bending: Bending is a process that uses a die to force the metal into a desired shape. This method is often used to create 90-degree bends in sheet metal.

-Drawing: Drawing is a process that uses tension and/or pressure to stretch the metal into its final shape. This method can be used to create both simple and complex shapes.

-Stamping: Stamping is a process that uses dies and/or molds to stamp shapes into sheet metal. This method is often used to create complex shapes or patterns in sheet metal.

Coining

Coining is a type of sheet metal forming in which the workpiece is compressed between two dies. The dies are usually made of tool steel, and they can be either cylindrical or flat. Coining can be used to form complex shapes, including internal threads, external threads, and gear teeth.

Spinning

There are various types of sheet metal forming processes, each with its own advantages and disadvantages. The most common types are spinning, stamping, and bending.

Spinning is a process where a sheet of metal is formed into a cylindrical shape by rotating it on a lathe. This method is often used to create objects such as vases and bowls. Spinning is relatively quick and easy, making it a popular choice for mass production. However, it is limited to shapes that can be created by rotating the sheet around an axis.

Stamping is a process where a die is used to shape the metal into the desired shape. This method can be used to create complex shapes, but it requires more expensive equipment than spinning. Stamping is also slower than spinning, making it less suitable for mass production.

Bending is a process where the metal is bent into the desired shape using tools or machines. This method can be used to create both simple and complex shapes. Bending is typically slower than spinning or stamping, but it does not require specialized equipment.

Hydroforming

Hydroforming is a process that uses high-pressure

There are numerous types of sheet metal forming processes, each with its own advantages and disadvantages. Perhaps the most versatile of these is hydroforming. Hydroforming uses high-pressure fluid to form metallic shapes. This process can be used to create both simple and complex parts, making it ideal for a wide range of applications.

There are two main types of hydroforming: die and punch. Die hydroforming uses a die to shape the metal into the desired shape. Punch hydroforming uses a punch to push the metal into the desired shape. Each method has its own benefits and drawbacks, so it’s important to choose the right one for your project.

Die hydroforming is well suited for creating large, complex parts. The downside is that it can be expensive and time-consuming. Punch hydroforming, on the other hand, is faster and less expensive but is limited to simpler shapes.

No matter which method you choose, hydroforming can produce parts with superior strength and accuracy. It’s an excellent choice for projects that require intricate shapes or high precision.

fluid to form metal into complex shapes. This process is often used to create metal parts with thin walls and complex geometries. Hydroforming can be used to form both ferrous and non-ferrous metals.

Conclusion

Sheet metal forming is a process where thin sheets of metal are bent or shaped to create various parts and components. There are many different types of sheet metal forming, each with its own advantages and disadvantages. The most common type of sheet metal forming is stamping, which is often used to create car body panels and other complex shapes. Other types of sheet metal forming include roll forming, hydroforming, and deep drawing. Each of these processes has its own unique set of benefits that can be utilized depending on the application.