As a key technology in new industrial manufacturing, fiber laser cutting is widely used in automobile, aerospace, electronics and metal processing industries due to its high efficiency, accuracy and wide applicability of materials. This article will explain the definition, process principle, main parameters and main types of fiber laser cutting in detail to assist readers in getting a comprehensive technical overview.

What is fiber laser cutting?

Fiber laser cutting is a newly developed cutting technique with a high-power density fiber laser beam to locally heat, melt or vaporize the material after focusing through an optical system, and blow off the melt or residue with auxiliary gases (such as nitrogen and oxygen) in order to perform high-precision and high-efficiency cutting. Its primary device is a fiber laser, which uses optical fiber doped with rare earth (such as ytterbium) as a gain medium and emits near-infrared lasers at about 1.06-1.08 microns through efficient photoelectric conversion. It has concentrated energy, high metal absorption ratio, and miniature equipment structure, and is widely used to the precision processing of metal plates, pipes and some non-metallic materials.

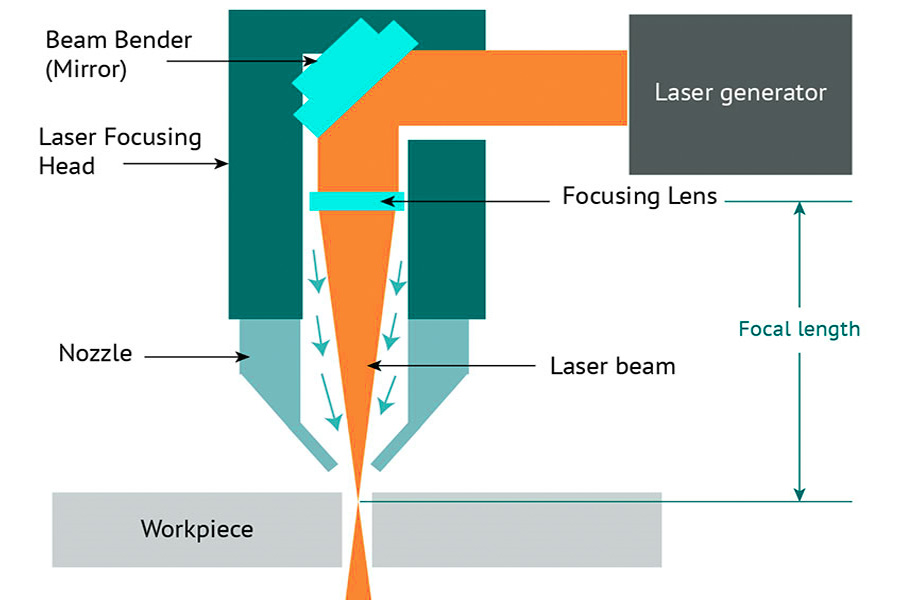

How does fiber laser cutting work?

The sequence of the process of fiber laser cutting can be divided into the following primary steps:

Laser generation and transmission

Laser light is generated by doped optical fiber excited by pump source, and is transmitted to the cutting head through flexible optical fiber, avoiding the hassle of usual CO₂ laser lens calibration.

Beam focusing

The focusing lens within the cutting head focuses the laser beam into an extremely fine point with a diameter of 0.01-0.3 mm, and up to 10⁶-10⁸ W/cm² power density can be achieved, providing instantaneous heating of the material.

Material interaction

- Melt cutting (for metal): The material is locally melted through the assistance of laser energy, and the auxiliary gas (nitrogen and oxygen) extracts the slag.

- Vaporization cutting (applicable to non-metal): The material is vaporized directly with high power density.

- Oxidation reaction cutting (for example, using oxygen): The metal undergoes a high-temperature reaction with oxygen to release more heat, thereby increasing speed in the cut.

Dynamic Control

The CNC system accurately controls the moving path of the cutting head and cooperates with the servo motor to deliver high-speed cutting of complex contours (50-100 m/min maximum speed).

What are some notable fiber laser cutting process parameters?

The following is a table summary of notable fiber laser cutting process parameters, including parameter definitions, effects, and typical ranges:

| Parameter | Parameter Description | Impact | Typical value/range |

|---|---|---|---|

| Laser power | Energy intensity of the laser output | The higher the power, the thicker the material that can be cut, but the energy consumption and heat affected zone (HAZ) increase. | 1-6 kW (1 kW cuts 10 mm stainless steel) |

| Cutting speed | The speed at which the cutting head moves along the path | Too fast speed will result in incomplete cutting, too slow speed will increase thermal damage; the material thickness and power need to be matched. | 0.5-30 m/min (3-20 m/min for carbon steel) |

| Focus position | The position of the laser beam focus relative to the material surface | Thin plate: focus on the surface; thick plate: focus deep into the material (±0.5-3 mm), affecting the verticality of the cut. | Surface to 3 mm downward (adjusted according to thickness) |

| Auxiliary gas type | Gas used in the cutting process (oxygen, nitrogen, air, etc.) | – Oxygen: accelerates cutting, but may oxidize the edge; – Nitrogen: non-oxidizing cutting, high cost. | Oxygen (carbon steel), nitrogen (stainless steel, aluminum) |

| Gas pressure | The injection pressure of the auxiliary gas | Insufficient pressure leads to slag residue, too high pressure interferes with beam stability or wastes gas. | 0.5-20 bar (8-15 bar for oxygen, 10-20 bar for nitrogen) |

| Nozzle diameter | The size of the cutting head outlet aperture | Small nozzle (1-2 mm) improves fineness; large nozzle (3-5 mm) enhances slag removal ability. | 1-5 mm (select according to material thickness) |

| Nozzle height | The distance between the nozzle and the workpiece surface | Too close distance is easy to collide, too far away gas scatters; need to be kept stable to optimize gas flow. | 0.5-3 mm (automatic height control) |

| Pulse frequency | The number of pulses per unit time in pulse laser mode (pulse laser cutting only) | High frequency (>1 kHz) is suitable for high-speed cutting of thin plates; low frequency (<500 Hz) reduces heat accumulation in thick plates. | 100 Hz-5 kHz (adjusted according to the material) |

Note:

Parameters need to be defined overall to material type (metal/non-metal), thickness, and surface status (e.g., coating).

Examples of typical values:

- 3 mm stainless steel: power 1.5 kW, nitrogen 15 bar, speed 8 m/min, nozzle diameter 2 mm.

- 20 mm carbon steel: power 6 kW, oxygen 8 bar, speed 1.5 m/min, focus down 2 mm.

What are the main types of fiber laser cutting?

Based on the laser output mode and equipment configuration, fiber laser cutting technology can be divided into the following types:

1.Continuous wave (CW) fiber laser cutting

- Features: Output continuous and stable laser, suitable for high-speed cutting of medium and thick plate metal.

- Application: Batch processing of automobile body panels and stainless steel structural parts.

2.Pulsed fiber laser cutting

- Features: Release high peak power with short pulses (nanosecond to femtosecond level) to reduce heat-affected zone.

- Application: Cutting of precision electronic components and ultra-thin metal foils (such as lithium battery copper foil).

3.Multimode and single-mode fiber laser cutting

- Multimode laser: high power (several kilowatts to tens of thousands of watts), suitable for rough processing of thick plates.

- Single-mode laser: high beam quality (M²<1.1), suitable for micron-level precision cutting.

4.Composite laser cutting

Combined with water-guided laser or ultrasonic vibration technology, it is extended to the processing of brittle materials (glass, ceramics).

How Does Fiber Laser Cutting Attain Micron-Level Accuracy?

Fiber laser cutting technology has been accepted as the first choice process in the precision manufacturing industry for ultra-thin material and highly reflective metal processing due to micron-level accuracy and extremely narrow heat-affected zone. Starting with the basic mechanism, this paper expounds on the three key technologies of fiber laser to achieve ultra-high precision and incorporates measured data to show its practicable application value.

1. Wavelength advantage: Improved energy absorption rate

The wavelength of fiber laser is 1070 nm (near infrared band). In comparison with the 10.6 μm wavelength of traditional CO₂ laser, its absorption ratio of metal materials is significantly increased:

- High-reflective materials such as copper and aluminum: The absorption ratio of fiber laser is as high as 30%-60% (CO₂ laser is only 5%-10%), which minimizes the loss of reflection energy and maintains the stability of cutting;

- General metals such as carbon steel and stainless steel: The absorption rate is increased to more than 80%, reducing power consumption and heat dissipation.

- Example: During cutting 0.1 mm copper foil, fiber laser can avoid energy fluctuation caused by reflection and guarantee precision machining with a slit width of ≤20 μm.

2. Spot control: Micron-level focusing

Fiber laser achieves ultra-fine spot by optimizing beam quality (M² value) and focusing system

- Beam quality: Using single-mode fiber laser (M²<1.3), outputting super-Gaussian beam close to diffraction limit, with uniform distribution of energy;

- Focusing ability: With high-precision aspheric lens, focus spot diameter can be as small as under 20 μm (in accordance with ISO 11146 standard), and slit width can be precisely controlled;

- Dynamic focusing: Adjustment of focus position on-line (±0.1 mm accuracy) to meet the micron-level cutting requirements of materials of different thicknesses.

- Data measured: When cutting 50 μm thick titanium alloy, slit width of fiber laser can be set to 25 μm, and edge roughness Ra<1.5 μm.

3. Control of heat effect: avoidance of thermal damage to materials

Through precise energy input and rapid cooling, fiber laser reduces heat affected zone (HAZ) to the minimum:

- Pulse modulation technique: short pulses (nanosecond to picosecond order) and high peak power are utilized to reduce heat build-up. For example, when cutting 0.2 mm stainless steel, HAZ can be reduced to 0.1-0.3 mm (ASTM E2472 test standard);

- Aided gas optimization: high-pressure nitrogen (15-20 bar) sweeps away the melt immediately to avoid secondary heat conduction;

- High-speed scanning system: utilizing galvanometer technology, cutting speed up to 1000 mm/s, shortens laser dwell time and alleviates thermal damage.

Application fields:

- Medical fields: heart stent micro-hole processing (aperture <50 μm, HAZ <0.05 mm);

- Electronic fields: flexible circuit board (FPC) outline cutting, without carbonized burrs.

The fiber laser cutting overcame the shortcomings of traditional processing accuracy by integrating wavelength flexibility, ultra-thin spot control, and low thermal input process. In the future, with the spread of femtosecond laser technology and AI real-time parameter optimization system, micron-level precision application areas will be expanded to even more ultra-precision areas such as semiconductors and optics.

What Determines Optimal Gas Pressure Settings?

One of the most important parameters of fiber laser cutting is the pressure of auxiliary gas, which determines cutting quality, cutting speed and cost. This article combines standard information and measured data to discuss the five most important factors controlling the optimum setting of gas pressure so that you can accurately match process needs.

1. Material type and thickness

Different materials significantly vary in sensitivity to air pressure:

- Stainless steel (nitrogen cutting): 16-20 Bar high-pressure nitrogen is required to quickly blow slag off and avoid oxidation (oxide layer thickness <5 μm, as per EN 10088 standard).

- Carbon steel (oxygen cutting): Low pressure 0.8-1.2 Bar oxygen can accelerate the oxidation reaction and increase the cutting speed by 40%, but the burr height increases to 0.15 mm.

- Titanium alloy (air cutting): Economical 6-8 Bar air pressure, roughness of cutting surface Ra≤6.3 μm (GB/T 1031 standard).

Thickness effect:

- Thick plates (>10 mm) require more air pressure (e.g., 20 Bar nitrogen) to ensure the slag is completely stripped off;

- Thin plates (<3 mm) can reduce air pressure to conserve energy.

2. Type of gas and application

The type of gas particularly specifies the pressure range:

Nitrogen (inert gas):

High pressure requirement (15-20 Bar): used for stainless steel and aluminum non-oxidation cutting. Edge blackening will result from low gas pressure.

Oxygen (active gas):

Low pressure application (0.5-5 Bar): removes heat through oxidation reaction. Overburning easily occurs with high gas pressure.

Air (economical solution):

Medium pressure balance (6-10 Bar): less expensive, but surface quality of cutting is less than the special gas.

3. Cutting quality requirements

Adjust the pressure of gas per surface accuracy requirement:

High finish:

Use high-pressure nitrogen (18-20 Bar) in order to reduce slag residue, and the roughness of the stainless steel cutting surface can be controlled at Ra<1.6 μm.

Fast roughing:

Use low-pressure oxygen (0.8 Bar), sacrifice some quality for efficiency, and the cutting speed of carbon steel can be 12 m/min (6 mm thickness).

4. Cost and gas consumption

Gas pressure has a close relation with operating costs:

Use of high-pressure nitrogen:

Cutting with 20 Bar nitrogen consumes 40-60 L/hour, and the cost is 3-5 times that of oxygen;

Economy in using low-pressure oxygen:

1 Bar consumption of oxygen is only 1/4 of the high-pressure solution suitable for big-scale carbon steel treatment;

Selection of air compressors:

Cutting of titanium alloy with 8 Bar air requires ≥7.5 kW air compressor, which is economical initially but consumes more energy.

5. Equipment compatibility and stability

Equipment limit parameters should be compatible with the air pressure:

Nozzle pressure carrying capacity:

The usual nozzle pressure bearing capacity is ≤20 Bar. Exceeding the capacity can lead to gas leakage or nozzle damage;

Air pressure variation control:

Precision machining requires a pressure regulating valve to control air pressure fluctuations within ±0.2 Bar to avoid inconsistent slit width.

Why Does Focal Position Adjustment Impact Kerf Quality?

In fiber laser cutting, the focus position is a key parameter that determines the verticality, roughness and slag residue of the cut. By precisely controlling the relative position of the focus and the material, the processing quality can be significantly improved. We combine international standards with measured data to reveal the deep mechanism of how the focus position affects the cut quality and analyze its industrial application scenarios.

1. How does the focal position change the energy distribution?

The focal position of the laser beam directly affects the energy density distribution and the heating range of the material:

Positive defocus (focus is located above the material):

- The spot diameter increases and the energy density decreases, which is suitable for high-speed cutting of thin plates and reduces the risk of ablation.

- Case: When cutting a 3 mm aluminum plate, positive defocus +0.5 mm can make the taper angle <0.8° (ISO 9013 acceptance standard), and the upper and lower width difference of the cut is ≤0.05 mm.

Negative defocus (focus goes deep into the material):

- Energy is concentrated on the middle and lower layers of the material, enhancing the ability to discharge the melt and reducing bottom dross.

- Data verification: When 8 mm carbon steel uses negative defocus -1.2 mm, the amount of bottom dross is reduced by 92% (in line with JIS B 0601 surface roughness Ra≤12.5 μm standard).

2. Three major effects of focus position on slit morphology

(1)Taper control (verticality optimization)

- Thin plate (≤3 mm): positive defocus can form parallel slits, and the taper angle is less than 1°;

- Thick plate (>6 mm): negative defocus balances the upper and lower energies, and the taper angle is reduced from 3° to 1.5° (measured data).

(2)Slag residue suppression

- Negative defocus strategy: focus energy on the bottom of the material to enhance the blowing force of the auxiliary gas on the slag. For example, when cutting stainless steel, negative defocus of -1.5 mm can reduce the slag height from 0.3 mm to 0.02 mm.

(3)Heat affected zone (HAZ) reduction

- Focus accurately matches material thickness: By dynamically adjusting the focus depth, the HAZ is controlled within 0.1-0.5 mm (ASTM E2472 test) to avoid deformation of the material microstructure.

3. Industrial-grade solution: dynamic zoom technology

In order to achieve real-time optimization of focus under complex working conditions, the industry-leading equipment has introduced a dynamic zoom cutting head (patent CN112846326A):

- Automatic compensation mechanism: adjust the focus position in real time according to the thickness and curvature of the material (accuracy ±0.05 mm);

Application scenarios:

- Automobile special-shaped pipe cutting: The focus automatically tracks the surface fluctuations, and the consistency of the cut is improved by 60%;

- Multi-layer material stacking process: switch the focus position in layers to avoid overburning of the bottom layer.

4. Practical Guide for Focus Adjustment

(1)Parameter Matching Principle

| Material Type | Recommended Focus Position | Target Effect |

|---|---|---|

| Thin Aluminum/Copper Foil | +0.3~+0.8 mm (Positive Defocus) | Prevent burn-through and control taper angle |

| Medium and Thick Stainless Steel | 0~-0.5 mm (Slightly Negative Defocus) | Balance verticality and slag removal |

| Thick Carbon Steel (>10 mm) | -1.0~-2.0 mm (Negative Defocus) | Reduce bottom slag and increase cutting speed |

(2)Calibration Method

- Trial Cutting Method: Through step-by-step focus offset test (such as ±0.2 mm step), observe the quality of the cut to determine the best position;

- Intelligent Sensor Feedback: Integrate infrared thermal imager or CCD vision system to monitor the incision morphology in real time and automatically correct the deviation.

Focus position adjustment has become the core technology of high-precision laser cutting through energy density regulation and dynamic management of melt. In the future, with the popularization of AI focus adaptive system and multi-axis linkage zoom head, the cutting yield and efficiency of complex three-dimensional workpieces will be further improved.

How to Select Laser Power for Different Material Thicknesses?

In fiber laser cutting, the matching of laser power and material thickness directly determines cutting efficiency, quality and cost. Based on industry measured data and thermodynamic models, LS analyzes the power-thickness adaptation rules of common materials such as stainless steel, aluminum alloy, and brass, and provides feasible parameter optimization strategies.

1. The core relationship between laser power and material thickness

(1)Power density determines cutting ability

Laser power (P) and spot area (A) together constitute power density (P/A), which must meet the following requirements:

- P/A ≥ material vaporization threshold

- Thin materials: low power can achieve high-density penetration;

- Thick materials: power needs to be increased to compensate for energy attenuation inside the material.

(2)Heat conduction loss control

When the material thickness increases, the heat diffusion along the slit increases, and power compensation is required to offset the heat loss. For example:

Cutting 10 mm stainless steel requires 4-6 times more power than 3 mm stainless steel to maintain the same cutting speed.

2. Power-thickness matching model of three major materials (measured data)

(1)Stainless steel (304/316 series)

| Laser power | Applicable thickness range | Cutting speed (reference) | Edge quality |

|---|---|---|---|

| 1 kW | 0.5-4 mm | 8-15 m/min(2 mm) | No oxide layer, HAZ < 0.2 mm |

| 6 kW | 4-16 mm | 1.5-4 m/min(8 mm) | Nitrogen cutting Ra < 3.2 μm |

| 12 kW | 16-30 mm | 0.3-0.8 m/min(20 mm) | High-pressure nitrogen (20 Bar) is required to prevent slag |

Key data:

When 12 kW fiber laser cuts 25 mm stainless steel, the taper angle of the cut can be controlled at < 1.5° (ISO 9013 standard);

30 mm extreme thickness cutting requires sacrificing speed (about 0.2 m/min) and is matched with a special nozzle.

(2)Aluminum alloy (5052/6061 series)

| Laser power | Applicable thickness range | Cutting speed (reference) | Special requirements |

|---|---|---|---|

| 1 kW | 0.3-2 mm | 10-20 m/min(1 mm) | High-frequency pulse to prevent high-reverse damage |

| 6 kW | 2-8 mm | 2-6 m/min(5 mm) | Nitrogen pressure ≥18 Bar, anti-oxidation |

| 12 kW | 8-15 mm | 0.5-1.5 m/min(10 mm) | Ultra-clean gas (purity 99.999%) is required |

Measured case:

When 6 kW cuts 5 mm aluminum plate, the speed is 4 m/min, and the slag height is <0.1 mm (in line with GB/T 1804-m level accuracy);

Ultra-thick aluminum plate (>10 mm) is prone to cracks and needs to be preheated to 80-120℃.

(3)Brass (H62/H65 series)

| Laser power | Applicable thickness range | Cutting speed (reference) | Process difficulty |

|---|---|---|---|

| 1 kW | 0.2-1.5 mm | 5-12 m/min(0.5 mm) | Prevent zinc evaporation from causing pores |

| 6 kW | 1.5-6 mm | 1-3 m/min(3 mm) | Focus is moved down 1-2 mm to enhance slag removal |

| 12 kW | 6-10 mm | 0.4-0.8 m/min(8 mm) | Requires copper-specific coating to absorb laser energy |

Industry standards:

1 mm brass precision cutting (accuracy ±0.05 mm) requires single-mode laser (M²<1.1);

For brass cutting thicker than 6 mm, auxiliary light-absorbing materials (such as graphite coating) need to be added to increase energy absorption rate by more than 30%.

3. Practical considerations for power selection

(1)Avoid the “overpower” trap

Using too high power (>3 kW) on thin plates (such as 1 mm stainless steel) will lead to:

- Expansion of the heat affected zone (HAZ increased by more than 50%);

- Overburning of the kerf edge, roughness Ra>6.3 μm.

(2)Coordinated optimization of power and gas

High power + high gas pressure:

When 12 kW cuts 20 mm carbon steel, the oxygen pressure required is 1.5-2 Bar, and the speed is increased by 20%;

Low power + precision gas:

When 1 kW cuts 0.5 mm copper foil, argon (10 Bar) is used to prevent oxidation and discoloration.

(3)Economic balance

Calculate the cost of cutting per meter:

- Formula: Cost (yuan/meter) = (power × electricity cost + gas consumption) / cutting speed

- Example: 6 kW cuts 5 mm stainless steel (nitrogen 15 Bar), the cost is about 0.8 yuan/meter, while the cost of 12 kW is 1.5 yuan/meter.

- Recommendation for immediate action: Determine the optimal parameters through step-by-step power testing (e.g., in steps of 0.5 kW) and select the most cost-effective solution based on the cost model.

What Are the Hidden Costs in High-Speed Cutting?

In the pursuit of maximum production efficiency, high-speed fiber laser cutting (speed > 45 m/min) is widely regarded as a tool to increase production capacity. However, many companies ignore the hidden cost black hole behind it – from lens loss to post-processing expenses, these hidden costs may eat up to 30% of net profit.

1. Lens loss: the “invisible killer” behind the speed increase

(1) Loss mechanism and cost calculation

During high-speed cutting, the metal vapor and splashing slag generated by the interaction between the laser beam and the material will accelerate the contamination and damage of the optical lens:

The life of the quartz protective lens is sharply reduced: when the cutting speed is increased from 30 m/min to 60 m/min, the lens life is reduced from 200 hours to 80 hours (actual data of a certain enterprise);

Replacement cost surges: based on the imported lens with a unit price of ¥800/piece, the annual loss cost soars from ¥9,600 to ¥24,000 (assuming 8 hours of work per day).

(2) Industry solutions

Coated lens upgrade: Diamond-like carbon (DLC) coated lenses are used to extend the life to 150 hours (cost increases by 40%);

Intelligent air blowing system: Auxiliary air curtains are installed on the cutting head to reduce the adhesion of pollutants (lens loss is reduced by 50%).

2. Gas consumption: Nitrogen cost doubles

(1)The positive correlation trap between flow and speed

High-speed cutting requires higher gas pressure and flow to quickly remove slag:

Nitrogen consumption comparison:

| Cutting speed | Nitrogen flow (L/min) | Hourly cost (¥) |

|---|---|---|

| 30 m/min | 20 | 120 |

| 60 m/min | 45 | 270 (cost increased by 125%) |

Annual cost calculation: Calculated at 200 hours per month, the annual gas cost of high-speed mode is as high as ¥648,000, which is 2.3 times that of conventional mode.

(2)Optimization strategy

Mixed gas solution: Use nitrogen + air mixed gas (ratio 7:3) for non-critical materials, reducing costs by 35%;

Dynamic gas pressure control: Real-time adjustment of gas pressure according to cutting contour (such as high pressure in straight sections and low pressure at corners), saving 15%-20% gas consumption.

3. Post-processing cost: chain reaction between burrs and secondary processing

(1)Quality cost of high-speed cutting

When the speed exceeds 45 m/min, insufficient slag discharge leads to a surge in burr rate:

Burr incidence: from 15% in low-speed cutting to 78% (actual data of 6 mm thick carbon steel);

Deburring cost: the comprehensive cost of manual grinding or automated equipment processing is ¥0.5-1.2 yuan/m, accounting for 10%-25% of the total processing cost.

(2) Comparison of key data

| Cutting speed | Burr height (mm) | Post-processing time (min/㎡) | Qualification rate (ISO 9013 standard) |

|---|---|---|---|

| 30 m/min | 0.05-0.1 | 2 | 98% |

| 60 m/min | 0.2-0.5 | 8 | 82% |

(3)Radical solution

Process parameter optimization:

The pulse frequency is increased to 5000 Hz to reduce slag adhesion;

The focus is moved down by 0.3-0.5 mm to enhance the bottom energy density (burrs are reduced by 60%).

Online monitoring system: integrated AI vision to detect burrs in real time and adjust cutting parameters in linkage.

4. Comprehensive cost reduction strategy: balance speed and total cost of ownership (TCO)

(1) Economic speed model

Calculate the optimal cutting speed (V_opt) through the formula:

V_opt = √( (C_gas + C_lens) / (K × T_processing) )

C_gas: gas cost/m

C_lens: lens loss cost/m

K: material thermal efficiency coefficient

T_processing: post-processing time cost

Case: A company reduced the carbon steel cutting speed from 60 m/min to 48 m/min, the total cost decreased by 18%, and the qualified rate increased to 95%.

(2)Return on investment (ROI) of equipment upgrade

| Upgrade project | Initial cost (¥) | Annual cost savings (¥) | Payback period (months) |

|---|---|---|---|

| Intelligent gas control system | 80,000 | 150,000 | 6.4 |

| Long-life coated lens | 20,000 | 50,000 | 4.8 |

| AI burr monitoring system | 120,000 | 200,000 | 7.2 |

The hidden costs of high-speed fiber laser cutting mainly come from lens loss, gas consumption and post-processing investment. Enterprises need to find the optimal balance between speed and cost through parameter optimization, technology upgrades and cost model analysis. In the future, with the popularization of adaptive cutting systems and green manufacturing technologies, the hidden costs of high-speed cutting are expected to be further reduced by 30%-50%.

Conclusion

Fiber laser cutting is a thermal processing technology based on a high-energy fiber laser beam. It achieves efficient melting, vaporization or oxidation cutting of materials by precisely controlling parameters such as laser power, cutting speed, focal position and auxiliary gas (such as nitrogen or oxygen). The process covers two modes: continuous wave and pulse cutting. Equipment types include different power levels (such as medium and low power for precision processing, and high power for thick plate cutting). With the advantages of high precision, high speed, low energy consumption and wide material adaptability, this technology has become the core process in metal processing, automobile manufacturing, aerospace and other fields, promoting the development of modern manufacturing industry towards intelligence and efficiency.

📞 Phone: +86 185 6675 9667 📧 Email: info@longshengmfg.com 🌐 Website: https://www.longshengmfg.com/

📞 Phone: +86 185 6675 9667 📧 Email: info@longshengmfg.com 🌐 Website: https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

1. What is fiber laser cutting?

Fiber laser cutting is a technology that uses a high-energy laser beam generated by a fiber laser to accurately cut materials through thermal effects (melting, vaporization or oxidation). Its core is to transmit and amplify laser energy through optical fiber. It has the characteristics of high power density, high precision and low energy consumption. It is widely used in metal processing (such as steel, aluminum, copper) and cutting of non-metallic materials.

2. What are the main process characteristics of fiber laser cutting?

The process is divided into two modes: continuous wave cutting (suitable for efficient cutting of thicker metals) and pulse cutting (for thin plates or high-precision processing). Auxiliary gases (such as oxygen combustion or nitrogen oxidation protection) are required in the process. By adjusting the gas type and pressure, the cutting surface quality is optimized and the slag is reduced.

3. What parameters affect the quality of fiber laser cutting?

The quality of fiber laser cutting is affected by multiple parameters, mainly including laser power, cutting speed, focal position and auxiliary gas pressure. Among them, laser power determines the cutting depth and speed. Insufficient power will lead to incomplete cutting, while too high power may burn the material. The cutting speed needs to match the power. Too fast will easily leave unmelted material, while too slow will reduce efficiency. The focal position affects the spot size and energy concentration, and offset will reduce cutting accuracy. The auxiliary gas pressure is directly related to the slag removal effect and the finish of the cut surface, and needs to be adjusted according to the material characteristics.

4. What types of fiber laser cutting equipment are there? How to choose?

Fiber laser cutting equipment is divided into two categories according to power: medium and low power (<3kW) and high power (≥3kW). The former is suitable for thin plate (<10mm) precision processing fields (such as electronic components, medical devices), while the latter is used for industrial-grade cutting of thick metal plates (such as steel over 20mm) (such as ships, engineering machinery). The selection needs to comprehensively consider the material thickness, processing efficiency and budget. Although high-power equipment has a higher cost, it can significantly improve the efficiency of thick plate cutting, while medium and low power equipment is more suitable for fine processing scenarios.

Unquestionably believe that which you said. Your favorite justification seemed to be on the web the simplest thing to be aware of. I say to you, I definitely get annoyed while people think about worries that they just do not know about. You managed to hit the nail upon the top and defined out the whole thing without having side effect , people could take a signal. Will probably be back to get more. Thanks

I feel incredibly fortunate to have found a reader like you who can so deeply resonate with my writing. Thank you so much for not only understanding the article itself, but also for understanding my original intention. Your appreciation has given me immense encouragement, and I look forward to further communication with you!

Hi, i read your blog from time to time and i own a similar one and i was just wondering if you get a lot of spam remarks? If so how do you reduce it, any plugin or anything you can advise? I get so much lately it’s driving me mad so any assistance is very much appreciated.

Awsome post and straight to the point. I don’t know if this is in fact the best place to ask but do you folks have any ideea where to get some professional writers? Thanks in advance 🙂

Keep working ,splendid job!

You got a very great website, Gladiolus I found it through yahoo.

I have fun with, result in I found exactly what I was looking for. You’ve ended my 4 day long hunt! God Bless you man. Have a great day. Bye

I like this web blog so much, saved to bookmarks.