Choosing the right acrylic determines whether your work is “fine” or “junk”

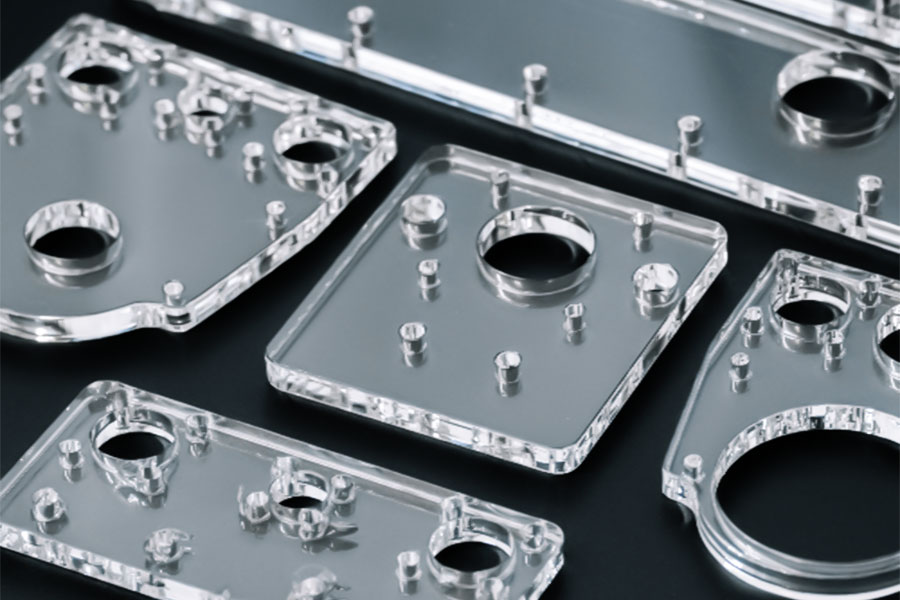

Have you ever cut an acrylic plate with great expectations, but the edges turned out to be rough, even white and sticky, not as smooth as glass as expected? Or, the carefully designed engraving pattern did not come out with a delicate and uniform frosted effect, but a blurry chaos accompanied by an unpleasant odor? I believe that many laser enthusiasts have deeply experienced the frustration of that moment.

Don’t rush to suspect that your laser machine has a problem! Many times, the real “culprit” may be hidden in the material you choose – you may have used the wrong acrylic!

Yes, not all plates marked “acrylic” are suitable for laser cutting and engraving. There are many types of acrylic on the market, but their composition and manufacturing process (mainly extrusion and casting) have a world of difference in the laser processing effect. If you choose the wrong type, no matter how precise your machine is and how you adjust the parameters, it is difficult to get the ideal effect. At the least, the effect is rough, and at the worst, the equipment is damaged and health is endangered, and the hard-made work instantly becomes “junk”.

Choosing the right acrylic is the first step to a successful laser creation. It directly determines whether your work is a stunning “fine product” or a “junk product” that can only be thrown into the trash. So, what kind of acrylic should be used for laser cutting and engraving? The key to the answer lies in understanding the advantages of “cast acrylic“.

Cast Acrylic vs. Extruded Acrylic Key Features

| Features | Cast Acrylic | Extruded Acrylic |

|---|---|---|

| Edge Quality After Cutting | Excellent – The edge is “ice crystal” smooth, clear, and almost burr-free, and usually does not require secondary polishing to achieve a high-quality appearance. | Good – The edge after cutting is relatively smooth and can be polished to a good effect, but the raw edge may have slight burrs or brushing, and usually requires polishing to achieve the best effect. |

| Laser Engraving Effect | High Contrast – The engraved area has a bright frosted/frost white effect, which creates a strong visual contrast with the transparent background. | Low Contrast – The engraved area maintains a high degree of transparency and has a lighter frosted effect with low contrast against the background. |

| Thickness Tolerance | Large – The tolerance range is usually around ±10%, and the thickness may not be uniform in different batches or within the same sheet. | Smaller – The tolerance control is very precise, usually within ±5%, and the plate thickness is extremely uniform. |

| Price | Higher – The production process is more complicated and takes longer, so the cost is higher. | Lower – The production process is continuous and efficient, and the cost is more advantageous and more economical. |

This guide will take you through the essential differences between these two types of acrylic for laser cutting, from manufacturing process to practical application, and through a real case study, show how this choice directly affects the cost and final effect of your project.

Here’s What You’ll Learn:

- Why professional experience matters: Insights from cutting acrylic every day to help you avoid common pitfalls.

- How manufacturing technology determines everything: A deep dive into the core differences between “cast” and “extruded” acrylic and how they affect material properties.

- The ultimate showdown between cutting and engraving: A clear reveal of which acrylic is the “king of cutting” and which is the “king of engraving”, and why the results are so different.

- The hidden pitfalls of thickness tolerance: Why it can ruin your precision design and how to choose wisely based on your needs.

- From prototype to boutique: A real-life example of a high-end cosmetics display stand, see how material selection determines product success and brand image.

- Explore the colorful world: The characteristics and precautions of special acrylics such as colored, mirrored, fluorescent, etc. in laser processing.

- The key to unlocking perfect results: The core parameter setting principles and testing points for laser cutting/engraving of cast and extruded acrylic.

- Clear the last doubts: Answers to key FAQs about toxicity, contraindicated materials (PVC/PC), thickness selection, and more.

Now, let’s get the scoop on acrylic and make your laser project go from “dumb” to “fantastic”!

Why Believe Our Analysis? Our Laser Cutters Cut Them Daily

Hello, I’m Longsheng, an LS laser engineer. Online in our company, there are plenty of online forums on the material choice, especially acrylic (PMMA), to cast or extruded one, and plenty of theoretical materials. But actually, the basis of our judgment at LS is never the content on the Internet or the technical manual parameters.

Our laser cutting machine literally cuts through these two materials on a daily basis. Day to day. Year by year.

As soon as the laser beam comes into contact with the cast acrylic, we see neater and smoother edges, notice a relatively “pure” and not as pungent smell of burning, and also the processed scrapings are thinner and powdery.

Snipping extruded acrylic, we can readily observe the edges will be more likely to exhibit minute ripples or melt marks, the smell will be more “pungent” and stronger, and the resulting scraps are tougher, more flaky or strip-like and even tacky at times.

It is something we actually sense each and every day when we operate machines, work with end products, and clean off workbenches. We sense it with our eyes, smell it, and wipe it away with our hands. It is not an educated guess, but the muscle memory and sensory awareness of tens of thousands of cuttings.

As an experienced laser cutting parts factory, our LS company has done thousands of orders and has been in touch with various designs and application environments. The recommendation we make to customers, be it material selection, processing conditions or design optimization, is based deep within the soil of these actual operations.

We share these experience things not to flaunt, but to help you genuinely. Help you to steer clear of the “traps” we have talked about and personally encountered ourselves – such as choosing the wrong material and receiving poor cutting performance, reduced yields, and even destroying costly molds or affecting the end product’s performance. We know that the application of the most suitable material can serve your design intent best and most efficiently at the lowest price of laser cutting, without any additional rework and cost wastage.

At LS, we do not just cut materials, we’re material experts. Let our practical experience lead your project.

Manufacturing Process Revealed: Why Is There Such A Huge Disparity Between Cast and Extruded Acrylic?

As “so that you can understand their performance, first you have to understand their manufacture,” the difference in cast and extruded acrylic performance comes from varying methods of how they are made. Casting is akin to baking the cake slowly in the mold, with a aim of molecular stability; extrusion is akin to squeezing out the paste from the toothpaste tube, with a focus on efficiency and consistency. These operations decide the molecular configuration of the material, which in turn affects its principal features such as hardness, chemical resistance, thickness, etc. To present it better, the following table provides a concise description of the principal comparison between the two processes:

| Manufacturing method | Manufacturing process overview | Result | Resultant properties |

|---|---|---|---|

| Cast Acrylic | Pour liquid acrylic monomer (MMA) between two glass molds and slowly solidify to form. | Higher molecular weight, random molecular chain arrangement, low internal stress. | Higher hardness, better chemical resistance, but uneven thickness. |

| Extruded Acrylic | Heat and melt acrylic particles, extrude through a mold, and then press with a roller. | Molecular chains are arranged along the extrusion direction, with high internal stress. | Softer, lower melting point, and very uniform thickness. |

Cast Acrylic: Manufacturing Process Revealed

The manufacturing process of cast acrylic is similar to “baking a cake in a mold”. First, liquid acrylic monomer (MMA) is poured between two glass molds to form a closed space; then, the monomer is cured into a solid sheet in the mold by slow heating or chemical catalysis. This process usually takes hours or even days to ensure uniform curing.

As a result, this slow curing method leads to higher molecular weight (longer molecular chains) and random and disordered molecular chains, resulting in minimal internal stress.

The resulting characteristics are: significantly improved material hardness (such as more scratch resistance) and stronger chemical resistance (resistant to solvent erosion), but due to slight deformation of the mold or uneven curing, the thickness often fluctuates slightly (for example, the edge may be slightly thicker than the center), which limits its use in precision applications.

Extruded acrylic: the manufacturing process revealed

The manufacturing process of extruded acrylic is like “squeezing toothpaste from a tube”. After the acrylic particles are heated to a molten state, they are forced through a slit die to be extruded into sheets; then the molten material is pressed by a set of rollers to quickly cool and set. The whole process is continuous and efficient, usually only a few minutes.

As a result, high-speed extrusion causes the molecular chains to be highly aligned along the extrusion direction (i.e. the direction of machine operation), but the internal stress is large (the molecular chains are stretched).

The resulting characteristics are: the material is softer and easier to process (such as easier to bend or cut), the melting point is lower (more likely to deform when heated), but the thickness control is extremely precise (the roller system ensures extremely small tolerances and uniform thickness), making it suitable for large-scale production, such as advertising signs or display cover plates.

The dramatic difference in properties between cast and extruded acrylic—cast is harder and more chemically resistant but has uneven thickness, extruded is softer and more uniform but has high stresses—ultimately stems from the fact that their manufacturing processes solidify in very different ways and align their molecular chains.

Laser Cutting Showdown: Who Is The King Of Cutting? Who Is The King Of Engraving?

“Now, let’s put them on the laser cutting machine and see what happens.” The encounter between the laser beam and different acrylics will play out completely different wonderful chapters. The outcome of this duel has long been determined by the inherent genes of the materials.

Comparison of laser processed acrylic characteristics

| Characteristics | Extruded acrylic | Cast acrylic | Winner |

|---|---|---|---|

| Cutting effect | Flame polished edge, bright as a mirror | Clean edge, frosted/satin texture | Extruded acrylic (King of cutting) |

| Cutting principle | Low melting point, melt recondensation polishing | – | – |

| Engraving effect | Shallow trace transparency, low contrast | Bright frosted white, high contrast | Cast acrylic (King of engraving) |

| Engraving principle | – | Internal bubbles scatter light | – |

| Core advantages | Cutting edge beauty | Engraving pattern clarity | – |

| Typical applications | Light boxes, display racks, parts that require clear and smooth edges | Medals, signs, nameplates, fine artworks | – |

Cutting: A battlefield where the edge is sharp and the finish is king

- Extruded acrylic (King of Cutting): When the heat of the laser acts on extruded acrylic, its relatively low melting point brings unexpected advantages. The material melts at the cutting point and then quickly cools and solidifies. This process is like a delicate magic of fire, and the final result is an edge effect called “flame polishing“. This edge is extremely smooth and transparent, like a mirror, and almost no secondary processing is required. For cutting applications that require the ultimate edge finish and transparent visual effects – such as delicate light boxes, display frames or any parts that require perfect light transmission – extruded acrylic is the undisputed king. Its cut surface itself is a beautiful sight.

- Cast acrylic: Cast acrylic can also be cut cleanly and neatly by the laser. However, its molecular structure is more “loose” and disordered, resulting in a higher melting point and less fluidity in the molten state than extruded acrylic. As a result, its cut edge presents a uniform matte texture or soft satin effect. It’s just as clean, but lacks that crystal-clear sheen. It’s a solid player in the cutting realm, but it’s a bit less radiant than extruded acrylic.

Engraving: Details matter, contrast matters

- Cast acrylic (the king of engraving): Engraving is where cast acrylic really comes to the fore! When the laser beam etches the surface of cast acrylic, it acts on tiny bubbles and molecular structures inside it. These structures scatter the laser, instantly transforming the transparent material into a vivid, opaque frosty white. This change creates extremely high visual contrast, making every detail, every fine line, and every word clear and sharp, jumping off the “board”. Making medals, signs, delicate artwork, need a clearly legible nameplate or graphic information? Cast acrylic is the undisputed king of engraving, and it can present the design intent in the most eye-catching and professional way.

- Extruded acrylic: When lasers try to engrave on extruded acrylic, the results are often disappointing. Laser engraving mainly produces slight melting depressions or fine cracks due to its close molecular arrangement, homogeneity and minimal bubbles. The engraved area remains basically transparent, and only a faint trace may be seen at a certain angle or light. The contrast is extremely low, and the pattern or text is difficult to clearly identify, far from meeting the requirements of logo or decoration. If the core of your design lies in the engraving effect, then extruded acrylic is a material to avoid.

Laser processing acrylic, extrusion is the king of cutting (smooth and transparent), casting is the crown of engraving (clear and eye-catching) – choosing a material is choosing the way to show the magic of laser.

Thickness And Tolerance: Why It Matters To Your Design?

Thickness tolerance is often overlooked, but it is the “invisible killer” of precision design – small deviations can lead to assembly failure, functional failure and even cost surge.

Comparison of thickness tolerance between extruded acrylic and cast acrylic

| Attributes | Extruded acrylic | Cast acrylic |

|---|---|---|

| Thickness tolerance | Very small (usually within ±5%) | Large (up to ±10%) |

| Advantages/disadvantages | Small tolerance, suitable for precision splicing and snap-on structure, high reliability | Large tolerance may lead to uneven thickness, which is not conducive to precision matching |

| Applicable scenarios | Structural parts that require high precision, such as boxes and mechanical housings | Designs that require larger tolerances, or applications with lower tolerance requirements |

| Potential risks | Low: Good tolerance control reduces the risk of assembly failure | High: Thickness changes (such as 3mm plate measured 2.7-3.3mm) are prone to assembly problems |

Tolerance is the lifeline of precision assembly

1. Tolerance refers to the allowable deviation range of material thickness (such as ±5%).

Fatal impact: In snap-on, splicing or sliding parts, out-of-tolerance will lead to:

Loose clearance (too small thickness → loose assembly)

Interference jamming (too large thickness → forced assembly cracking)

Case: Cast acrylic nominal 3mm plate, measured 2.7–3.3mm, if the slot is designed as 3mm, the entire line assembly may fail.

2. Material selection is directly related to tolerance risk

Extruded acrylic (±5%):

Advantage: uniform thickness (such as 3mm plate actual 2.85–3.15mm), ensuring that the snap-on/splicing is tight.

Applicable: high-precision scenes such as medical equipment housings and electronic boxes.

Cast acrylic (±10%):

Disadvantage: large thickness fluctuations, different areas of the same plate can differ by 0.6mm, resulting in skewed structure and stress concentration.

Trap: Although the optical performance is excellent, tolerance problems are often exposed during mass production, causing batch rework.

3. Countermeasures: Design must be pre-tolerated by tolerance management

Reserve expansion gap:

When using a casting plate, the slot width = nominal thickness + 20% (such as a 3mm plate with a 3.6mm slot).

Choose extruded plates for key components: Extruded acrylic is preferred for precision structures (such as sliding rails).

Cost awareness: Tolerance out of control causes the scrap rate to soar, and early reservation of tolerance can reduce costs by 30%+.

Tolerance is not a “detail”, but the pillar of design implementation. Choose extruded acrylic to ensure accuracy, and choose a casting plate to leave a margin – if you ignore this, even the best design may become scrap. Only by controlling tolerance can we move from “paper creativity” to “reliable products.”

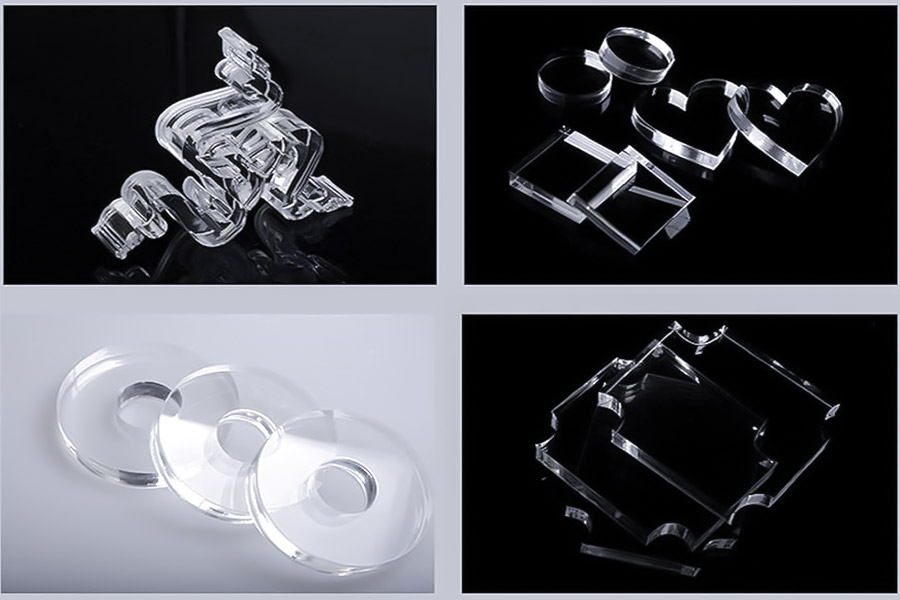

Case Summary: Material Optimization For Customizing A High-quality Cosmetics Display Stand For A Luxury Brand

1. Project background:

We were commissioned by a well-known luxury cosmetics brand to customize a high-end countertop display stand for it. The core requirements were: to show a crystal-like transparent texture and to achieve clear and delicate brand logo engraving.

2. Early plan and problems:

(1) Material selection (initial version): Due to costs, the initial plan utilized extruded acrylic.

(2) Prototype checking and feedback: We made an extruded acrylic prototype according to the standard procedure for testing.

Verified benefits: The cutting edge can achieve the desired bright effect.

Key issues revealed: The engraving effect of the logo is far from the norm – it has a fuzzy and rugged texture, and its overall appearance looks cheap, which is far from the high-end positioning of the brand. This proves that extruded acrylic has its limits in conveying fine engraving.

3. Professional solution analysis and optimization

(1) Identification of the problem: Following the assessment by the engineering team, it was confirmed that extruded acrylic’s non-uniform internal structure was the fundamental reason for its substandard engraving effect, which was unable to meet luxury-level detailing demands.

(2) Solution to optimize: We skillfully recommended and submitted a second version of the prototype using cast acrylic for comparison.

Performance advantages: Cast acrylic is denser and more uniform.

Findings of testing the prototypes:

Cutting edge (same as extruded plate): Possess a clean and transparent crystal texture.

Logo engraving (appreciably improved): A highly clear, sharp-edge, and elegant matte effect was achieved, immediately enhancing the product level.

(3) Cost concerns: We clearly informed the customer that the unit price of laser processing per piece would increase by approximately 20% due to material enhancements.

4. Final decision and results:

(1) Customer choice: Based on the preliminary intuitive comparison of the two prototypes and professional description of the performance difference, the customer clearly made the choice of the cast acrylic solution.

(2) Project outcome: The final product completely achieved the design requirements:

The crystal texture was maintained.

The brand logo engraving effect was excellent and exquisite.

The general look was highly consistent with that of a premium brand and was welcomed in the terminal market.

Summary from the perspective of the LS engineers:

This project completely illustrates the essential influence of material selection on the final quality of high-end display products. Whereas extruded acrylic surpasses in low-end optical quality and cost, it cannot match the high-precision engraving detail and is therefore not up to the high-end standards of high-end brands. Through means of rigorous prototype comparison tests and technical review from a material science point of view, we essentially guided the customer to comprehend the unreplaceable value of cast acrylic in achieving high-end engraving clarity and texture. Even if the unit price increased, the leap in final product quality and brand worth fully justifies the precision of this material optimization decision. This is a testimony to LS’ key value to properly comprehend customer needs, exercise professional expertise to solve problems and manufacture products at high-end positioning.

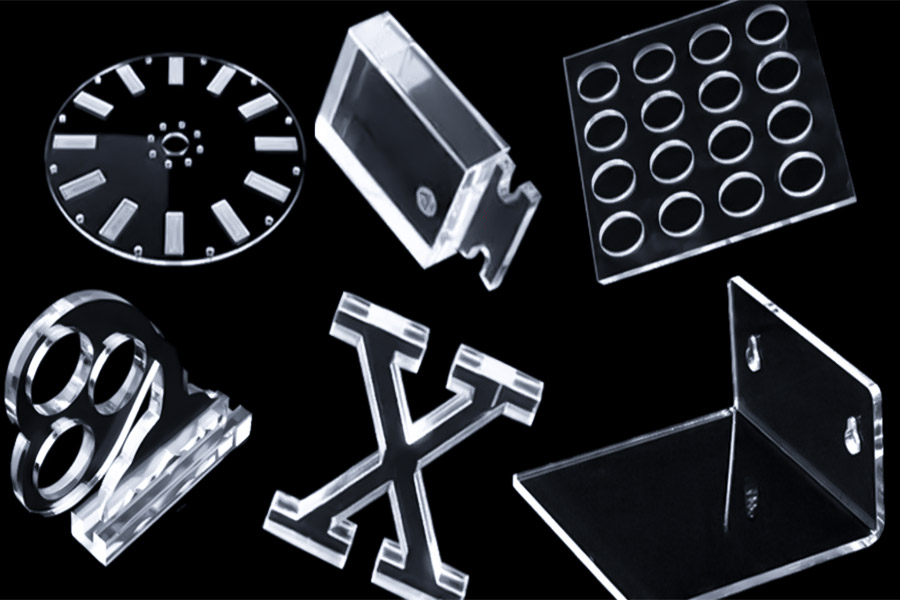

Specialty Acrylics: Colored, Mirrored and Fluorescent Acrylics

“The acrylic world is far more than clear.”

Comparison table of three special acrylic materials

| Characteristics | Colored acrylic | Mirror acrylic | Fluorescent acrylic (Edge-Lit) |

|---|---|---|---|

| Material type | Usually cast acrylic | Usually extruded acrylic (substrate) + mirror film layer on the back | Special cast acrylic |

| Production process | Add pigment during casting | Mirror film on the back of transparent extruded plate | Special formula casting, with photoluminescent properties |

| Core features | Full color, rich colors | Highly reflective mirror effect | Edges emit bright fluorescence under light |

| Processing points | Good engraving effect, debris forms contrast | Must be cut/engraved from the back, and parameters need to be finely adjusted to protect the mirror layer | Focus on fine processing and lighting design of the edges |

| Typical applications | Colored signs, decorative pieces, crafts, displays | Mirror decoration, reflective signs, fashion displays, props | Illuminated signs, backlit decoration, atmosphere creation, artwork |

1. Colored acrylic:

Core: Coloring is achieved by adding pigments during the casting process. This process can evenly disperse the pigments to ensure the overall color saturation and consistency of the material.

Advantages: Provides a very rich color selection to meet various design and branding needs.

Processing characteristics: Excellent performance when laser engraved. The acrylic at the engraving is vaporized and removed, revealing the underlying white or different colored inner layers (depending on the pigment distribution and engraving depth), which forms a sharp and beautiful contrast with the surface color, especially suitable for making graphic logos and fine patterns.

Application: Widely used in color signs, display boards, trophies and medals, indoor and outdoor decoration, retail displays, crafts, etc.

2. Mirror acrylic:

Core: Essentially, a layer of metal film (usually aluminum) is vacuum-coated on the back of the transparent extruded acrylic sheet to give it a high reflective effect similar to a mirror.

Key point: Processing direction is crucial! Any cutting, engraving or drilling operations must be performed from the back of the sheet (the coated side) and the laser power, speed or mechanical tool parameters must be precisely adjusted. The front (smooth) side is the viewing side, and any processing from the front side will directly damage the mirror layer, causing the reflection effect to fail or produce unsightly defects.

Advantages: Provides a modern, high-gloss mirror effect, which is lighter, safer, and easier to process than glass mirrors (when following the rules).

Applications: Used for decorative panels, cosmetic display stands, prop production, logos (reflective characters), interior design elements, fashion installations, etc. that require mirror reflection effects.

3. Fluorescent Acrylic (Edge-Lit):

Core: A specially formulated cast acrylic containing fluorescent substances.

Unique phenomenon: When light (especially LED light source) enters from its edge, the light is transmitted through total reflection inside the acrylic, stimulating the fluorescent substances inside, causing the edge of the entire plate or the engraved pattern to emit bright and saturated fluorescence. This effect is particularly shocking in a dark environment.

Advantages: Create an attractive and technological dynamic luminous effect with a strong visual impact.

Processing and Application: The key is to polish the edges with high quality and design a reasonable installation method for the light source (usually LED light strips) to ensure that the light can be efficiently introduced to the edge of the plate. It is widely used in high-end luminous signs (especially backlit characters, contour lights), bar/restaurant decorations, stage scenery, art installations, creative light boxes and other places that require eye-catching luminous effects.

Colored, mirrored and fluorescent acrylics have greatly expanded the application boundaries of acrylic with their unique visual effects (full color, highly reflective mirrors, edge luminescence) and processing characteristics, perfectly interpreting the truth that “the world of acrylic is far more than just transparent”.

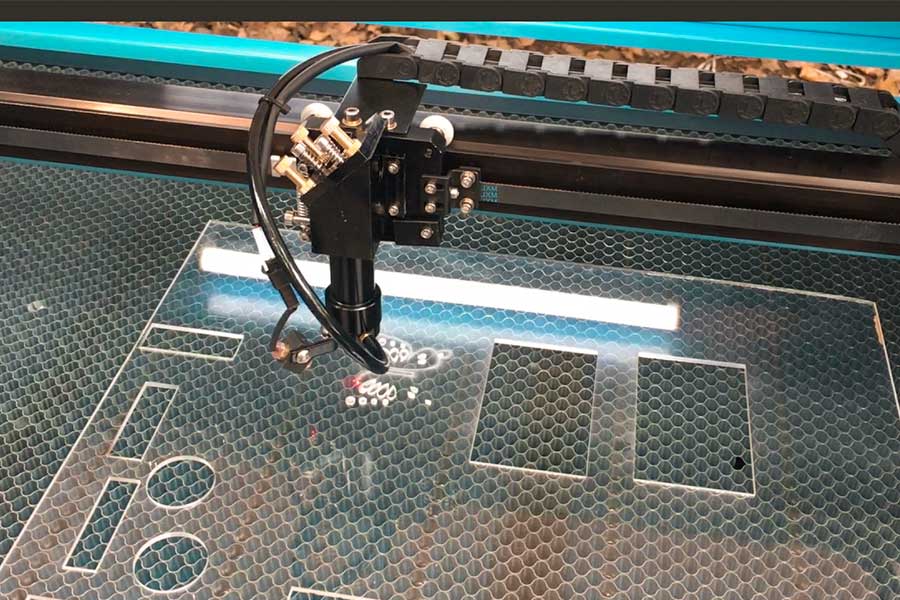

How To Set The Right Parameters For Your Laser Cutting Machine?

Choosing the right material is only the basis, accurate parameter setting is the key to successful cutting. Especially when dealing with acrylic, the parameters vary greatly:

- Extruded acrylic: Looking for a smooth edge of flame polishing? Use relatively high speed with low power. This can quickly melt the surface of the material to achieve a polished effect, while avoiding over-melting that will cause edge collapse or deformation.

- Cast acrylic: Aim for clean cuts and clear engraving details? You need a relatively low speed combined with high power. Sufficient power ensures thorough penetration, and slow speed ensures a smooth and vertical cut with less dross.

Don’t rely on “universal parameters”! Before you officially cut expensive materials, always test on a small piece of scrap. This is an indispensable step:

- System test: Test the combination of power, speed, frequency (PPI).

- Observational evaluation: Carefully check the cut quality (smoothness, verticality, dross), engraving depth/clarity, and back-side effect.

- Fine-tuning lock: Fine-tune based on test results to find the parameters that perfectly match your specific machine, material batch and desired results.

Powerful air assist is the “guardian angel” of cutting acrylic. It quickly blows away the melt, significantly suppresses the flame generated by the cutting, and directly leads to cleaner, carbon-free quality cuts, which is essential for professional results.

The key to successful cutting is to deeply understand the material characteristics (such as differentiating between extruded and cast acrylic), find the best balance of power, speed and frequency through rigorous scrap testing, and always enable powerful air assist to turn parameters into perfect cutting results.

FAQ – Final Questions About Acrylic Laser Cutting

1. Is laser cutting of acrylic toxic?

When laser cutting acrylic (PMMA), it mainly decomposes into low-toxic monomers (such as methyl methacrylate), but it produces a strong irritating odor. Long-term inhalation may cause respiratory discomfort. Therefore, a strong ventilation and smoke exhaust system must be equipped to ensure air circulation in the operating environment. This is a core measure to ensure the health and safety of operators and cannot be omitted.

2. Why can’t PVC and polycarbonate (PC) be cut with laser?

Laser cutting of PVC is strictly prohibited because it contains chlorine, which will release highly toxic and highly corrosive chlorine gas at high temperatures, which is harmful to health and seriously damages laser equipment. Polycarbonate (PC) is not resistant to high-temperature lasers. When cutting, it will burn violently, produce a lot of smoke, and severely yellow/carbonize, making it almost impossible to obtain a usable cut. Both are laser cutting restricted materials.

3. How thick should I choose acrylic?

The thickness selection depends on the specific purpose: 3mm is commonly used for signs/decorations, and ≥5mm is recommended for load-bearing structural parts. Note: Increased thickness will significantly increase the difficulty of processing – requiring higher laser power and slower cutting speed (to prevent uneven melting), resulting in increased processing time and cost. Be sure to weigh the load-bearing requirements against your budget.

Conclusion

For laser cutting, should you choose cast acrylic or extruded acrylic? The answer is not a simple distinction between good and bad, but a precise match to your design needs.

- Pursuing fine engraving, extreme transparency and artwork-like texture? Cast acrylic is your best choice.

- Need cost-effective, easy-to-bond structural parts or large cutting parts? Extruded acrylic is a more economical and efficient choice.

Choose casting for engraving and extrusion for splicing. A deep understanding of the essential differences between these two materials is the most critical cornerstone to ensure the success of your laser cutting project, whether it is the stunning presentation of visual effects or the stability and reliability of functional structures.

Don’t let the confusion of “Which acrylic should I choose?” hinder the perfect realization of your creativity!

LS’s professional team is here to provide you with accurate navigation!

Take action now:

- Upload your design files to our safe and convenient online platform.

- Get double value:

A highly competitive laser cutting quotation.

Professional material recommendations from our senior engineers! We will carefully analyze the details of your design (is it focused on fine engraving or structural cutting? Is it a decorative display or functional application?) to accurately recommend the type of acrylic (cast or extruded) that will best achieve the desired effect.

Say goodbye to guesswork and welcome to professionalism! Upload your design now and experience a truly project-based expert laser cutting service brought by LS!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Oh my goodness! an incredible article dude. Thank you However I’m experiencing subject with ur rss . Don’t know why Unable to subscribe to it. Is there anyone getting similar rss problem? Anybody who is aware of kindly respond. Thnkx

Thank you for reading, but we regret that you are unable to subscribe. You can contact our professionals to help you complete the subscription at info@longshengmfg.com

Loving the information on this web site, you have done outstanding job on the posts.

hi!,I like your writing very much! share we communicate more about your article on AOL? I require a specialist on this area to solve my problem. Maybe that’s you! Looking forward to see you.

I?¦ve recently started a website, the information you provide on this site has helped me greatly. Thank you for all of your time & work.