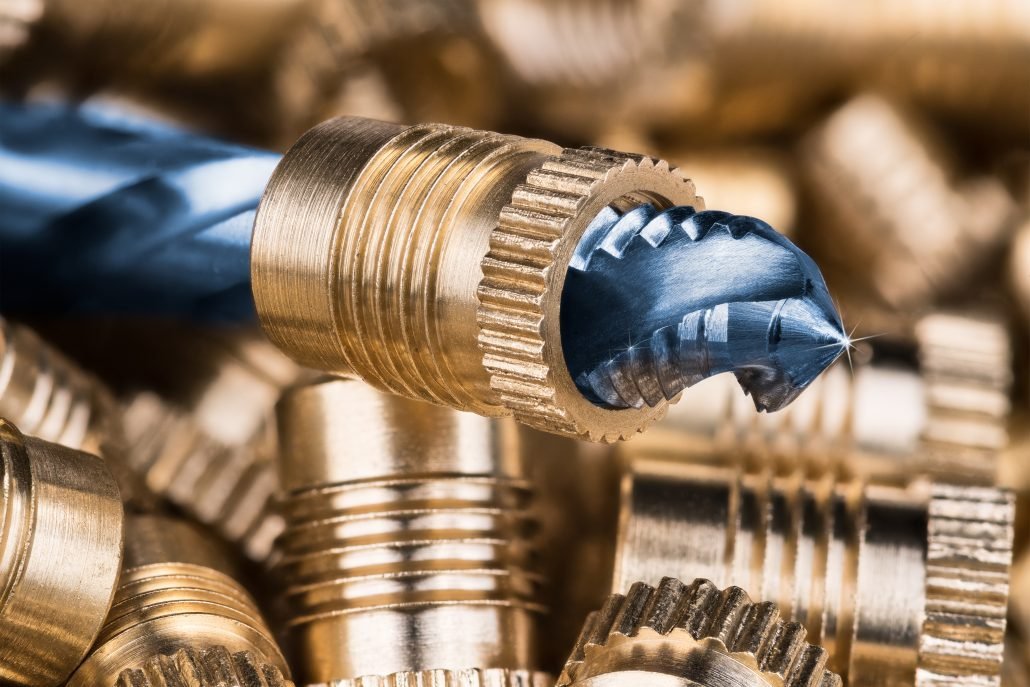

Precision CNC machining has been widely used in automotive, aerospace, medical and electronic manufacturing industries. In these areas, workpiece accuracy and surface finishing requirements are very high.

These days, customers often ask me whether you can meet the accuracy requirement of 1~2um for products? Our answer is no, precision CNC machining in the final analysis is machine processing, the machine itself will have errors, it is impossible to ensure that every size to reach such a standard, perhaps a position with a special secondary finishing may be able to achieve, such as holes or shafts. But Longsheng technology will not easily promise customers, we will say that our best accuracy is 4~8um. Rather than set too high expectations for customers, it is better to be real and do what we can do.

If you are looking for parts to be machined using a CNC machine, there are some very important factors to consider. These include materials, shape, size, complexity, and use. Therefore, it is very important to choose a suitable CNC machining scheme

In real life, there are not many products with accuracy up to u level. Such precision parts are generally used in precision testing equipment. The equipment for processing these parts is often for processing a certain kind of parts, and can not do more categories of products. And precision CNC machining is suitable for more precise parts processing, its processing advantages are: many categories, complex, flexible quantity, etc. Cost is very important for every customer, for different parts choose different processing methods can save a lot of costs.

When considering whether it is suitable for precision CNC machining, we also need to consider the following:

The shape and size of the part

Any shape or size of part can be CNC machining, but as the size of the part increases, so does the cost of machining.

Part complexity

Complex parts will require more time and resources for CNC machining. Therefore, additional time and cost need to be taken into account when designing complex parts.

Purpose of parts

Different uses require different ways of designing and manufacturing. Therefore, in the selection of the appropriate CNC machining scheme, should take into account the specific use and needs.

Parts processing requirements

Precision CNC machining is often used to manufacture high-precision, complex models of parts. In the process of processing, need to consider the following aspects: machining accuracy, surface finish, processing time, tool selection and service life, etc

Finally, to ensure that your parts quality and schedule are met, you should choose an effective, experienced and professional CNC machining service provider. They can provide you with first class manufacturing services to ensure that your project goes smoothly.

Longsheng Technology precision CNC processing, not only the precision can reach 4~8um, we can also help you test materials, do a variety of surface treatment, assembly, etc., your design once you give us, we can provide you with finished products! Precision CNC processing, only do their own, only do customer satisfaction, only do win-win products!