From the beach to the foundry, the difference between sand and metal parts

You might think that sand is sand, and that the sand in the backyard sandpit is no different from the sand in the foundry used to cast metal parts. After all, they look like inconspicuous particles. This is a common but extremely dangerous misconception.

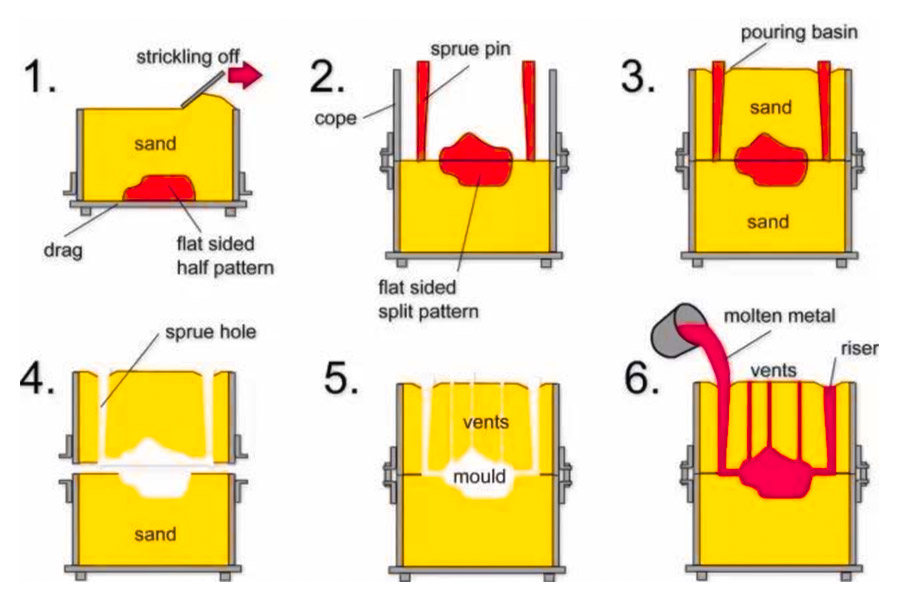

Imagine pouring the warm, fine beach sand that children play with into a casting mold to pour boiling, molten iron or steel at thousands of degrees Celsius – this scene itself is chilling. The consequences of using the wrong sand are not just as simple as “unsuitable”. At the very least, the carefully crafted castings will have a rough surface, be full of pores, or even be scrapped directly, resulting in a huge waste of time and materials; at worst, the moisture or impurities hidden in those seemingly harmless sand grains may cause a violent steam explosion when they encounter hot metal, threatening the safety of equipment and personnel.

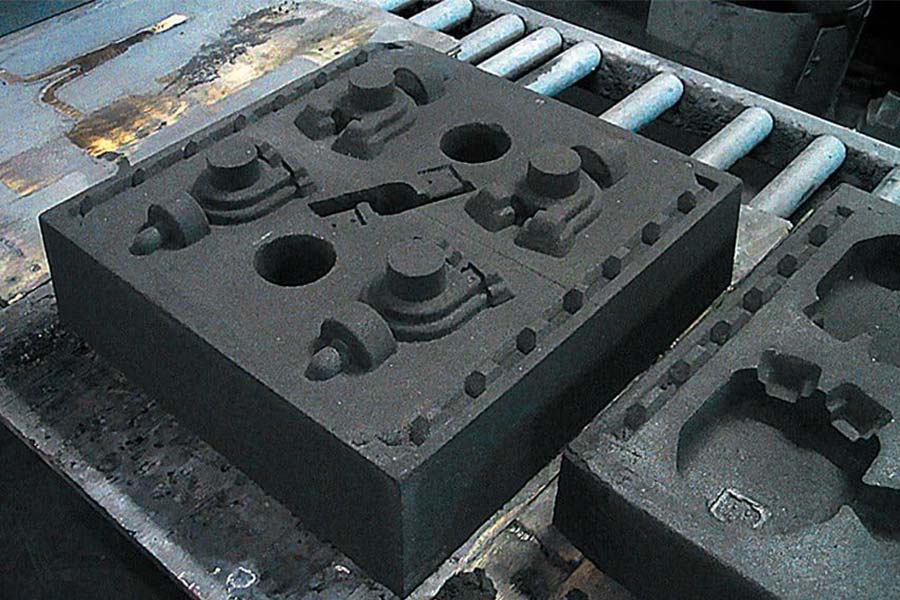

The sand in the foundry is far from the ordinary sand we see every day. They are carefully selected, processed, and even “formulated” engineering materials, called “molding sand” or “foundry sand“. They must be able to withstand extreme temperatures, shape precision, and discharge gases generated when metals cool. The sand on the beach that is rounded by waves and contains salt and organic matter is not only useless here, but also a potential safety hazard and quality killer.

Therefore, in the world of metal casting, the choice of sand is by no means a trivial matter, but a key starting point for the success or failure of castings, cost and even production safety. So, what kind of sand is this seemingly ordinary but responsible material – casting sand? What “superpowers” does it need to have? Let’s unveil the veil of this “sand” together.

Comparison Table Of Sand Core Information For Metal Casting

| Casting Sand Type | Core Composition/Principle | Key Advantages | Typical Application |

|---|---|---|---|

| Green Sand | Silica sand + bentonite (clay) + water | Extremely low cost, recyclable, highly versatile, easy and fast modeling | Most general castings such as iron castings, aluminum alloy castings, brass castings (especially suitable for mass production) |

| Resin / Chemical Sand | Sand + synthetic resin + catalyst (hardened by chemical reaction) | High dimensional accuracy, good surface finish, high strength, good disintegration, can manufacture complex sand cores | Complex sand cores, medium and large castings with high precision requirements (such as engine cylinders, gearbox housings, pump valve bodies, etc.), cast iron, cast steel, non-ferrous alloys can be used |

| Specialty Sand | Zircon sand, chromite sand, olivine sand, ceramsite sand and other high-refractory, high-density mineral sands | High refractoriness, excellent chemical stability, good thermal conductivity, low thermal expansion coefficient, strong resistance to metal penetration | Steel castings (especially stainless steel, high manganese steel, etc.), high temperature alloy castings (such as heat-resistant steel), thick and large-section castings or castings prone to sand adhesion defects, surface sand or local sand for key parts of castings |

This guide will take a deep dive into each of these foundry sands, their composition, pros and cons, suitable metals, and a real-life example of our selection process. Most importantly, we’ll tell you why you should never use regular sand for casting.

Here’s What You’ll Learn:

- The secret of the four core properties: a 60-second decision-making framework for quickly judging whether foundry sand is qualified or not—how refractoriness, air permeability, strength, and collapsibility determine success or failure.

- The ultimate comparison of three key sand molds: the design differences between green sand, resin sand, and special sand, and their disruptive impact on cost, precision, and surface finish.

- The golden rule for conquering difficult castings: a three-step process for sand mold selection for steel/aluminum/iron parts and complex inner cavities to avoid the catastrophic consequences of “sand-metal mismatch”.

- Real factory case disassembly: from the complex hydraulic valve body mixing process (resin sand core + green sand outer mold) to see how professional sand selection balances quality and cost.

- Dangerous misunderstanding crusher: answer fatal questions that even senior engineers are prone to make mistakes (such as “Can beach sand be used as a substitute?” “Why must silica sand be banned in cast steel?”).

Now, let’s uncover the engineering code for sand mold selection and become the master of casting materials.

Why Should You Trust Our Sand Selection Suggestions? We Cast Not Only Parts, But Also Experience

Hello everyone, I am Longsheng, and I have been a casting engineer at LS for more than 15 years. I face all kinds of complex sand casting part drawings from global customers every day. I know that perfect castings start with perfect sand molds, and half of the success or failure of molds depends on sand selection.

Sand selection seems simple, but it is not easy. In actual casting, different metals have different melting points and fluidity, and the structure and requirements of castings are also different. If you choose the wrong sand, the surface of the casting will have problems at the least, and the mold will be scrapped and the loss will be huge.

Why trust LS sand selection suggestions? Because we cast experience. LS provides top-level customized sand casting services and has a team of engineers who are deeply engaged in material science. We are familiar with the characteristics of various sand materials at high temperatures and have deeply studied their reactions with molten metals. The sand selection guide is the result of the team’s multiple tests, verifications and lessons learned. We know which sand is resistant to erosion, which sand makes the surface of the casting smooth, and which combination takes into account cost and molding needs.

So, when you hand over the sand casting project to us, please trust our judgment on the sand mold. Let’s start with the sand and together we’ll create your perfect part.

The “Four Great Kings” of Foundry Sand: Essential Properties For Successful Casting

| Property Name | Key Role | Common Issues If Inadequate |

|---|---|---|

| Refractoriness | Withstands the high temperature of molten metal without softening, melting or sintering. | Sand sticking, rough casting surface, and mold cavity deformation. |

| Permeability | Allows the gas (water vapor, combustion gas) generated during pouring to escape smoothly. | Porosity, choking, insufficient pouring. |

| Strength | Maintains the shape and size of the mold under molding, handling, pouring and metal liquid pressure. | Collapse, sand erosion, sand expansion, burrs. |

| Collapsibility | When the casting solidifies, cools and shrinks, the casting can give way or break in a timely and appropriate manner. | Hot cracking, cold cracking, excessive internal stress, and difficulty in sand cleaning. |

1.Refractoriness:

Key role: This is the most basic requirement for casting sand. The sand mold must maintain a stable structure under the scouring and heat radiation of high-temperature molten metal, without melting, softening or serious chemical reactions with the metal (such as sintering). High refractoriness ensures the integrity of the mold cavity and the clear outline of the casting.

Common problems: Insufficient refractoriness will cause sand particles to melt or sinter on the surface of the casting (sand sticking), making the surface of the casting rough and difficult to clean. In severe cases, it may even cause partial collapse and deformation of the mold.

2.Permeability:

Key role: At the moment of pouring, the evaporation of water in the sand mold, the combustion of the binder, and the air in the cavity will produce a large amount of gas. Good permeability provides a smooth discharge channel for these gases to avoid gas retention in the molten metal or the cavity.

Common problems: Poor permeability will prevent the gas from being discharged in time, resulting in the formation of pores (bubbles) inside or on the surface of the casting, unstable pouring process (choking), and even causing the molten metal to fail to fill the cavity (under-pouring).

3. Strength:

Key role: Sand molds need to have sufficient strength to withstand the test of multiple links: tightness during molding, vibration and impact during transportation and flipping, static and dynamic pressure of molten metal during pouring, and pressure generated during metal solidification. Strength ensures that the mold does not deform or break during the filling and solidification of molten metal.

Common problems: Insufficient strength can cause the sand mold to be damaged during transportation (collapse), washed away by molten metal during pouring (sand flushing), the mold wall to expand outward (sand expansion), or metal burrs (seam) on the parting surface and other parts.

4. Collapsibility:

Key role: The casting will shrink during solidification and cooling. If the mold is too hard and cannot be yielded or broken, it will hinder the free shrinkage of the casting. Good collapsibility allows the mold to collapse or become soft in a timely and appropriate manner when the casting shrinks, reducing mechanical obstacles to the casting.

Common problems: Poor collapsibility will hinder the normal shrinkage of castings, causing hot cracks (at high temperatures) or cold cracks (at low temperatures), increasing the internal stress of castings, and making sand cleaning extremely difficult, increasing production costs.

The four major properties of refractoriness, air permeability, strength and collapsibility complement each other and together constitute the core evaluation criteria for high-quality foundry sand. None of them can be missing and is the basis for ensuring the quality of castings and the smooth progress of the casting process.

Green Sand: Evergreen in the Foundry Industry

In the complex casting process, Green Sand is known as the “evergreen in the foundry industry” for its enduring vitality. It is worth noting that the “green” here does not refer to its physical color, but rather vividly describes its core feature of being in a wet state (containing water). As the most commonly used and most economical molding material to date, Green Sand forms the basis of casting production.

| Characteristic category | Description |

|---|---|

| Core features | A mixture of sand, clay (bentonite), water and additives (such as coal powder); the name comes from the “wet state” rather than the color |

| Main advantages | Extremely low cost, high reusability, environmentally friendly (materials are natural and recyclable) |

| Main limitations | Relatively low dimensional accuracy, general surface finish of castings, extremely strict requirements on moisture content control |

| Applicable metals | Most common metals such as cast iron, aluminum alloy, brass, bronze, etc. |

Advantages and Disadvantages Analysis

1. Advantages:

Extremely low cost: Raw materials (silica sand, bentonite, coal powder, water) are easy to obtain and cheap.

Reusable: After pouring, the sand mold can be crushed and processed (remove old sand blocks, replenish losses, adjust ingredients), with a high recycling rate, significantly reducing costs and waste.

Environmentally friendly: High recycling rate reduces waste sand, the main component is natural minerals, and the environmental impact is usually lower than chemical binder sand.

2. Disadvantages:

Low precision and finish: Compared with precision casting or resin sand, the dimensional accuracy and surface finish of castings are poor (limited by sand mold strength, compactness and sand grain size).

Moisture control key: Insufficient moisture leads to low sand mold strength (easy to collapse); excessive moisture reduces permeability (easy to produce pores, bulging sand), and is not easy to compact. Moisture and related performance parameters (wet compressive strength, permeability) need to be strictly monitored and controlled.

Applicable metals

Green sand casting has a wide range of applications, especially for metals with low melting points, small shrinkage or less demanding surface requirements:

Main applications: cast iron (gray iron, ductile iron), aluminum alloy, brass, bronze.

Not applicable: metals with high melting points (such as cast steel), metals that are easily oxidized or require extremely high precision/finish.

With its excellent economy, excellent recyclability and relatively environmentally friendly characteristics, green sand has firmly established itself as the mainstream molding material for casting and is a well-deserved “evergreen tree”.

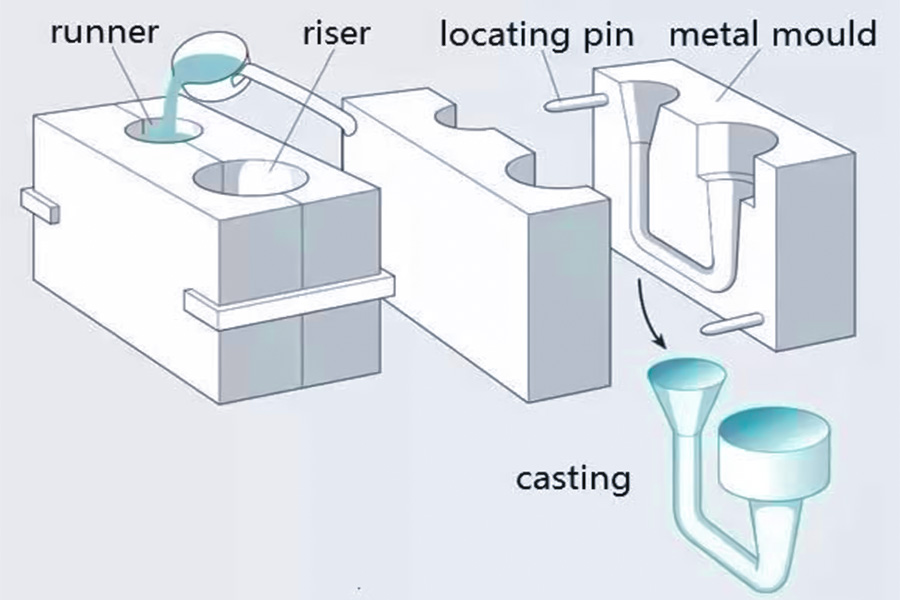

Chemically bonded sand: a casting tool for precision and finish

When casting design requires tight dimensional tolerances and smooth internal cavity surfaces (such as hydraulic valve bodies and engine cylinder waterways), chemically bonded sand becomes the preferred process due to its excellent replication ability.

Comparison table of chemical bonded sand core features

| Features | Resin sand/self-hardening sand | Remarks |

|---|---|---|

| Bonding method | Synthetic resin (furan, phenolic, etc.) + catalyst | Chemical polymerization reaction to form a bond |

| Hardening method | Room temperature hardening (no baking required) | Also known as “self-hardening sand” (No-Bake Sand) |

| Core advantages | Extremely high dimensional accuracy, excellent surface finish | Especially good at complex cavities |

| Mold strength | High | Support for large castings |

| Process energy consumption | Low (no baking process) | |

| Main disadvantages | High cost, one-time use of sand | High cost of resin and catalyst |

| Environmental impact | Produces chemical gases | Ventilation and exhaust gas treatment should be noted |

| Sand regeneration | Difficult/usually not recycled | Increase material costs |

| Typical applications | Complex cavities (sand cores), large castings, high-precision parts | Meet stringent geometric and surface requirements |

1. Working principle: The core is to mix raw sand, liquid synthetic resin (such as furan resin, phenolic resin) and catalyst. At room temperature, the resin and catalyst react chemically (polymerize), firmly bond the sand particles and quickly harden and form them without additional heating.

2. Advantages:

Precision and finish: Provide top dimensional stability and surface quality in the casting field.

High strength and no baking: The mold strength is sufficient to support large and complex castings, and the high energy consumption baking step is eliminated.

3. Disadvantages:

Cost pressure: The cost of resin and catalyst is significantly higher than that of binders such as clay, and sand is usually not regenerated.

Environmental challenges: Chemical gases such as formaldehyde are released during the sand mixing and pouring process, which need to be effectively collected and treated.

4. Applicable scenarios: It is an ideal choice for manufacturing castings with complex cavities or sand cores, large structural parts (such as machine tool bases, gear boxes), and castings with extremely high requirements for dimensional accuracy and surface finish (such as aerospace and precision hydraulic parts).

Chemically bonded sand has become the core technology for casting high-demand complex cavities and key precision parts with its unparalleled precision and smoothness. Although it is relatively expensive, it is indispensable in fields where quality is paramount.

Wisdom of Selection: How to Match the Right Sand Mold for Your Metal?

“The wrong match can lead to disastrous consequences: sticking sand, rough surface, dimensional deviation, and even mold collapse. Here is a quick selection guide.”

Sand Mold Selection Quick Reference Guide

| Casting Metal Type | Recommended Sand Mold System | Key Notes |

|---|---|---|

| Casting Aluminum | Green Sand | Extremely cost-effective, suitable for most aluminum castings. |

| Oil sands (such as Petaling Sands) | Particularly suitable for fine, complex small aluminum castings, providing better surface finish and detail reproduction. | |

| Casting Iron/Copper | Green Sand | Industry standard, widely used in various types of iron castings and copper alloy castings, with good cost-effectiveness. |

| Resin sands (such as furan, phenolic) | For large, complex-shaped or high-dimensional precision castings, they can provide excellent stability and strength. | |

| Casting Steel | Special sands such as zircon sand and chromite sand | Ordinary silica sand and green sand are absolutely prohibited!The high temperature of molten steel will cause silica sand to melt. Special sand with high refractoriness must be used, usually chemically bonded (such as resin self-hardening sand and water glass sand). |

1. Casting Aluminum:

- Green Sand: Aluminum casting temperature is relatively low (~700°C), green sand has the highest cost performance and is the most widely used.

- Oil Sand (such as Petbon Sand): Suitable for small and fine parts with high requirements, providing excellent surface finish and details.

- Casting Iron/Copper:

Green Sand: At the casting temperature of iron (~1200-1400°C)/copper (~1000-1200°C), silica sand and green sand are still a reliable and economical choice.

Resin Sand: Used for large, complex or high-precision iron parts, providing higher strength, stability and surface quality.

2. Casting Steel:

- Absolute warning: ordinary silica sand and green sand are prohibited! The temperature of molten steel is extremely high (>1500-1600°C), far exceeding the limit of silica sand, which will cause severe melting and sand sticking.

- Special high-refractory sand must be used:

- Zircon sand/chromite sand: It has extremely high refractoriness (>1800-2000°C) and is the preferred aggregate for casting steel.

- Bonding method: It must be used with chemical binders (resin self-hardening sand, water glass sand, etc.) to meet the requirements of high-temperature strength and stability.

The key to selecting sand molds for metal castings is to match the pouring temperature of the metal with the refractoriness and strength requirements of the sand mold: Aluminum parts are preferably economical green sand or fine oil sand; iron and copper parts are reliable green sand or upgraded resin sand; and for cast steel parts, high-refractory aggregates such as zircon sand and chromite sand must be used at all costs with chemical bonding systems to avoid the catastrophic consequences of silica sand melting.

Case summary: Complex hydraulic valve casting solution that balances quality and cost

Challenge: We recently undertook a very challenging project: to produce a cast iron hydraulic valve body for a customer with an extremely complex internal flow channel structure and extremely high critical dimensional accuracy requirements. The customer clearly required that if a single traditional green sand process was used, the surface finish and dimensional accuracy of the complex inner cavity could not be guaranteed, which would directly affect the performance and reliability of the valve body.

LS solution: In response to this core challenge, our engineering team innovatively adopted a “hybrid process” casting solution. The core of this solution lies in the refined material selection and matching the optimal process for different parts of the mold:

- Core component (sand core): The sand core responsible for forming the complex internal flow channel is manufactured by resin self-hardening sand process. After curing, this material has high strength and excellent dimensional stability. It can perfectly replicate the complex flow channel design, ensure its inner wall is smooth and dimensionally accurate, and fully meet the stringent technical indicators.

- Main mold (external mold): For the external shape of the valve body, we use the mature green sand process. Green sand has good plasticity and cost-effectiveness. While ensuring the integrity of the external shape, it effectively controls the overall mold cost.

Results and Value: This “hybrid process” strategy has achieved remarkable results:

- Accurate compliance: Successfully met the customer’s stringent requirements for key dimensional accuracy and surface quality of the internal flow channel.

- Cost optimization: Under the premise of ensuring core quality, the overall sand casting production cost is significantly reduced by using more cost-effective green sand in the outer mold.

- Professional value: This case fully demonstrates that the LS engineering team can flexibly use innovative solutions based on a deep understanding of materials and processes to create maximum economic benefits for customers while ensuring the highest quality. This is the value of our professional casting knowledge and engineering experience.

FAQ – Debunking Dangerous Myths About Foundry Sand

1. Can I use regular beach sand or children’s play sand?

Absolutely not! There are three reasons: 1) Too many impurities, unpredictable chemical reactions are prone to occur at high temperatures; 2) The water content is uncontrollable, and a large amount of water vapor is instantly generated after the molten metal comes into contact, resulting in violent splashing or even steam explosions, which is extremely dangerous; 3) The particle shape and size are uneven, the air permeability is poor, and the casting will be full of pores and of poor quality. Using professional foundry sand is a guarantee of safety and quality.

2. What is a sand core? Is it the same as mold sand?

A sand core is an independent component used to form internal holes or complex cavities in a casting, and is placed in the main mold cavity. Because it is completely surrounded by molten metal and the working environment is more severe, it usually requires higher strength and better collapsibility than the outer mold (easy to clean after pouring), so it is often made of specially formulated chemically bonded sand such as resin sand, which is different from the requirements of outer mold sand.

3. Where can I buy foundry sand?

You can buy from specialized casting material suppliers. But for most projects, the wiser choice is to work directly with a full-service professional foundry (such as LS). They not only have all types of strictly processed foundry sands, but more importantly, they have the expertise and experience to select the most suitable sand type according to your specific project needs and apply it correctly to ensure the quality and safety of your castings.

Conclusion

In sand casting, sand is not just a simple filler, it is a core engineering material that is as important as metal. Choosing the right sand mold has a decisive impact on the quality, safety and cost of the final product.

Don’t take risks and guess! Leave your design problems to LS. Upload your CAD file now, and LS’s experts will not only provide a transparent sand casting quotation, but also scientifically analyze and recommend the most suitable sand mold system for you, ensuring that your project is built on the best solution from the beginning!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.