What processes are used in sheet metal?

The sheet metal forming process is instrumental in the fabrication and manufacturing of parts and components. A sheet metal forming process involves reshaping a metal while it is still in its solid state. The plasticity of certain metals makes it possible to deform them from a solid piece into a desired form without losing the structural integrity of the metal. The 6 more common forming processes are bending, curling, ironing, laser cutting, hydroforming, and punching. Each process is accomplished through cold forming without heating or melting the material first to reshape it.

Bending

Bending is a method used by manufacturers to form metal parts and components to a desired shape. It is a common fabrication process where force is applied to plastically deform metal on one of its axes. Plastic deformation changes the workpiece to a desired geometric shape without affecting its volume. In other words, bending changes the shape of the metal workpiece without cutting or subtracting from any of the material. In most instances, it does not change the thickness of the sheet metal. Bending is applied to impart strength and stiffness to the workpiece for the functional or cosmetic appearance and, in some cases, to eliminate sharp edges.

Curling

Curling sheet metal is a forming process that removes burrs to produce smooth edges. As a fabrication process, curling adds a hollow, circular roll to the edge of the workpieces. When sheet metal is initially cut, the stock material often contains sharp burrs along its edges. As a method of forming, curling de-burrs otherwise sharp and rugged edges of sheet metal. Overall, the process of curling improves strength to the edge and allows for safe handling.

Ironing

Ironing is another sheet metal forming process done to achieve uniform wall thickness of a workpiece. The most common application for ironing is in forming material for aluminum cans. Stock aluminum sheet metal must be thinned in order to be rolled into cans. Ironing can be accomplished during deep drawing or performed separately. The process uses a punch and die, forcing the metal sheet through a clearance that will act to uniformly reduce the entire thickness of the workpiece to a certain value. As with bending, the deformation does not reduce volume. It thins the workpiece and causes the part to lengthen.

Laser Cutting

Laser cutting is an increasingly common fabrication method that employs a high-powered, focused laser beam to cut and subtract material from a workpiece into a desired shape or design. It’s used to produce complex parts and components without the need for custom-designed tooling. A high-powered laser burns through metal with ease—faster, with precision, accuracy, and leaving smooth-edged finishes. Compared to other conventional cutting methods, parts cut with laser precision have less material contamination, waste or physical damage.

Hydroforming

Hydroforming is a metal forming process that stretches a blank workpiece over a die utilizing highly pressurized fluid to press room-temperature working material into a die. Lesser known and considered a specialized type of die-forming metal parts and components, hydroforming can create and attain both convex and concave shapes. The technique employs high-pressure hydraulic fluid to force the solid metal into a die, the process is best suited to shape malleable metals like aluminum into structurally strong pieces while retaining the properties of the original material. Due to the high structural integrity of hydroforming, the automotive industry relies on hydroforming for the unibody construction of cars.

Punching

Metal punching is a subtractive fabrication process that forms and cuts metal as it passes through or under a punch press. The metal punching tool and accompanying die set shape and form custom designs into metal workpieces. Simply put, the process cuts a hole through metal by shearing the workpiece. A die set consists of male punches and female dies, and once the workpiece is clamped in place, the punch passes through the sheet metal into a die that forms the desired shape. Though some punch presses are still manually operated machines, most of today’s punch presses are industrial-sized CNC (Computer Numerical Control) machines. Punching is a cost-effective method for forming metals in medium to high production volumes.

Types of Sheet Metal Fabrication Materials

There are numerous types of sheet metals available that are suitable for various fabrication processes. The primary metals available include:

Steel-all four classifications of steel are prominent for robust strength, ductility, and resistance to corrosion

Aluminum- a relatively lightweight metal with high strength

Magnesium-a shiny, lightweight, and strong metal with low density making it adequate for structures that require stiffness

Bronze-a very high ductile metal with a low melting point

Copper- a soft and malleable metal with heat and electrical conductivity

In the manufacturing industry, sheet metal is used for automobile components, heavy machinery, floors and more. When making sheet metal, we often use one or more of the above forming processes.

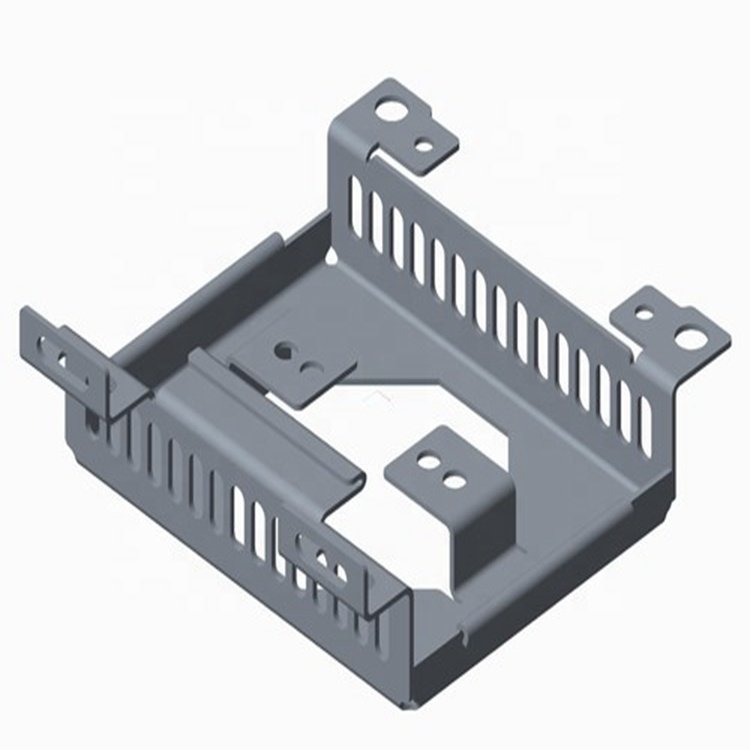

Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high precision and durability, especially for end-use applications like chassis, enclosures, and brackets.

Longsheng Technology also provides sheet metal services to our customers in a wide range of industries. If you are interested in using sheet metal in manufacturing, please contact us and we would be happy to help.