As a critical component in improving engine efficiency, turbochargers face extremely strict precision and reliability challenges in manufacturing. Internal components, such as the impeller and volute, not only feature complex geometries but must also provide long-term stability under harsh operating conditions of high temperature, high pressure, and high speed. Even a slight dimensional discrepancy or surface defect can lead to an instant loss of efficiency or even complete failure. Such strict demands make five-axis CNC machining technology a backbone of the manufacturing industry. How does the technology, with its high-precision molding and high-performance complex surface machining benefits, overcome traditional process bottlenecks and ensure the turbocharger’s high performance? The analysis follows. To save you time, here’s a quick overview of the core conclusions.

Quick Reference: Choose Your Tap at a Glance

| Aspect | Key Contributions of Five-Axis CNC Machining |

| Core Technical Advantages | Complex geometries can be machined in a single setup, eliminating errors caused by multiple positioning steps. |

| Solving Precision Challenges | Ultra-high geometric tolerances and surface finish are ensured for critical components like impeller blades, reducing the need for dynamic balancing. |

| Addressing Material Challenges | Highly efficient machining of difficult-to-machine materials like heat-resistant alloys meets the performance requirements of high-temperature turbocharger components. |

| Improving Production Efficiency | Reducing setup times, streamlining production processes, and achieving faster cutting speeds shortens lead times. |

| Ensuring Ultimate Performance | Precision airflow channels ensure aerodynamic efficiency, directly improving turbocharger response and engine performance. |

| Achieving Design and Manufacturing Integration | Advanced CAD design models are directly converted into high-quality physical parts, supporting product iteration and innovation. |

- Five-axis CNC machining technology, with its primary function of “one-step, complete forming,” has become the indispensable process for manufacturing complex high-performance turbocharger components such as impellers and volutes.

- Not only does it fully eliminate the manufacturing problems resulting from high precision, complex surfaces and difficult-to-machine materials, but it also plays an important role in improving product performance, reliability and production efficiency. It is one of the important manufacturing links connecting excellent design and excellent products.

Why Trust This Guide? Practical Experience From LS Experts

LS has accumulated extensive practical experience in five-axis CNC precision machining. For us, this means more than just possessing a few cutting-edge machines—more crucially, we have a team of truly knowledgeable engineers. Many of them have dedicated years to automotive component manufacturing, particularly complex components like turbochargers. They have a thorough understanding of everything from material properties and performance requirements to production bottlenecks. The technical solutions and process methods we provide are rooted in practical production line challenges and continuous optimization, resulting from repeated trial and error, rather than simply theoretical groundwork.

Our technical expertise has been recognized by numerous international clients. For example, we once collaborated with a British high-performance car manufacturer to machine a batch of turbocharger housings. This part featured a complex structure, numerous cavities, and highly variable surfaces. Furthermore, it was made of a high-strength, heat-resistant alloy, requiring extremely stringent tolerance control and surface consistency. Ultimately, through five-axis simultaneous machining and meticulous process control, we achieved high-quality product delivery, further demonstrating our capabilities in the precision machining of complex components.

The LS team delivered a custom five-axis machining solution, getting it exactly right first time, radically improving the performance and reliability of the product, and gaining excellent accolades from the customer.

What Is Five-axis CNC Machining? Why Is It More Powerful Than Three-axis?

Five-axis CNC machining

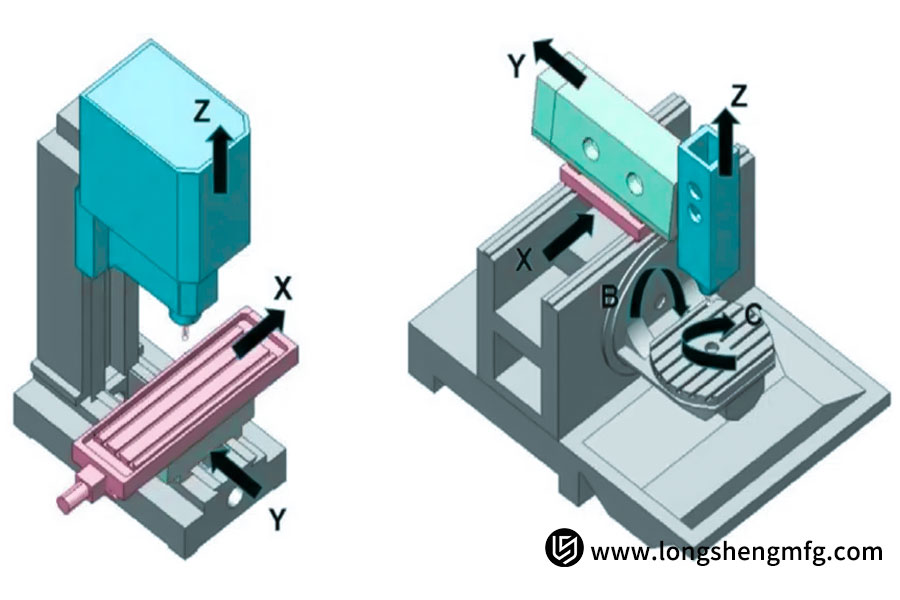

The basis of five-axis CNC machining is adding two rotary axes (commonly referred to as the A and C axes) to the three-axis (X, Y, and Z linear motion). This enables the machining tool not only to travel in three linear directions like a three-axis machine, but to also tilt and rotate the workpiece or the tool itself in multiple directions, enabling accurate milling of complex parts from nearly any angle.

Why it’s more powerful than three-axis machining

This additional degree of freedom delivers revolutionary advantages. Most obviously, it enables “five-sided machining in one setup.” Three-axis machines generally require a great deal of re-clamping to machine complex parts, and each setup brings with it new chances for error accumulation. Five-axis technology, by adjusting the tool’s angle, can easily approach all complicated surfaces and features of a part and complete all critical areas in a single operation. This greatly improves overall accuracy and consistency, and reduces production cycle time.

- Therefore, five-axis machining’s forte is its combination of excellent geometric freedom and high-quality manufacturing precision.

- Its merits lie in the manufacture of high-precision components with complex airflow passages, such as turbocharger impellers and turbine casings, which are difficult to achieve efficiently and with high quality using traditional three-axis machine tools. It is for this reason that it is a critical key technology for high-end manufacturing.

Why Is Turbocharger Manufacturing So Difficult?

Manufacturing challenges of turbochargers stem primarily from the harsh operating conditions and strict performance requirements of their major components. This is directly reflected in three aspects:

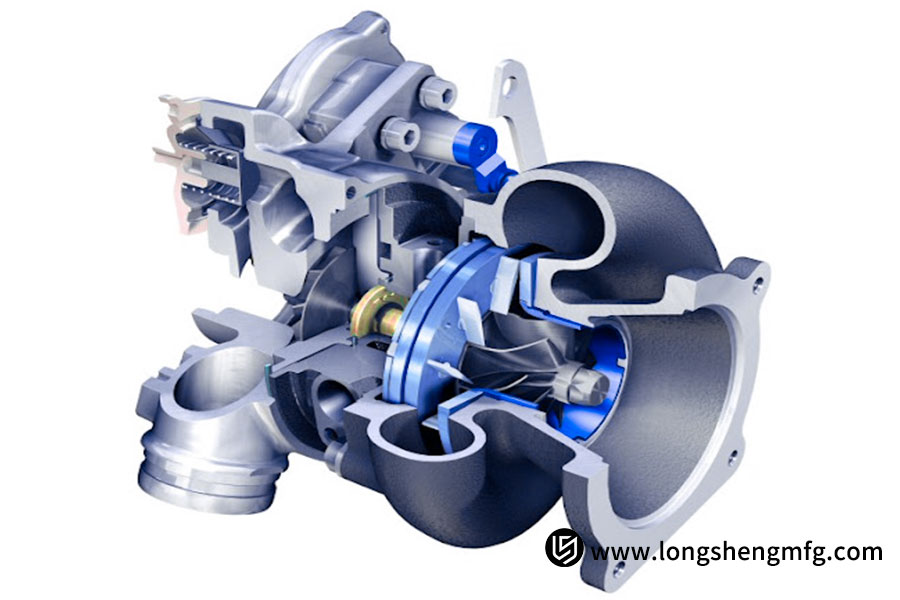

Extreme geometric complexity

Both the compressor impeller and the turbine casing contain a series of complex blades and flow passages with complicated aerodynamic curvature. These kinds of three-dimensional free-form surfaces must be machined with extremely high precision. Even a slight deviation can be expected to highly disturb the airflow, leading to reduced boost efficiency, noise, and even aerodynamic instability.

Difficulty in machining materials

To withstand exhaust gas temperatures of 1000°C and rotational velocities over 100,000 rpm, impellers are typically constructed from heat-resistant alloys (e.g., Inconel), and turbine housings are typically constructed from high-strength cast iron or heat-resistant steel. Such materials are extremely hard, wear-resistant, and corrosion-resistant but are, therefore, also hard to machine, placing very high demands on tools, equipment, and processes.

The quest for dynamic balance and reliability to the extreme

The high-speed rotating impeller components require extremely good dynamic balancing. Even minute mass differences in micrograms can get amplified into ferocious vibrations at high speed, generating noise and reducing bearing life significantly, with a potential for catastrophic failure of the entire turbocharger. Therefore, every process, right from material preparation to machining, must move towards perfection and consistency.

- The difficulty of producing turbochargers highlights the invincible status of five-axis CNC machining technology.

- Not only is it the only effective method of achieving complex geometries and material requirements, but also the essential technology foundation in ensuring the ultimate performance, efficiency, and reliability of the product.

How Does Five-axis CNC Overcome Turbine Impeller Manufacturing Difficulties?

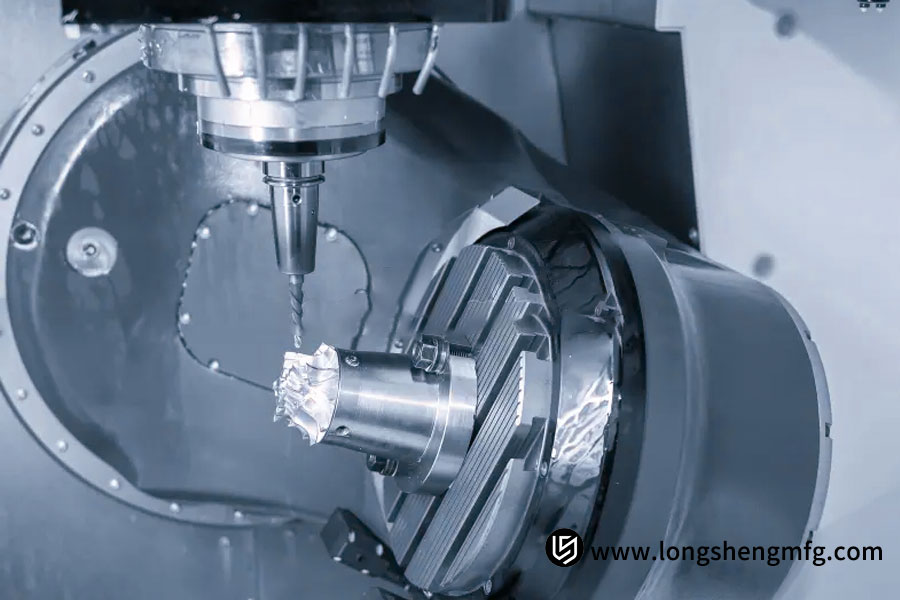

Five-axis CNC machining technology, characterized by the “five-axis simultaneous” feature, has become the ultimate solution for the issue of turbine impeller manufacturing. Turbine impellers are a summit of precision manufacturing. The inherent challenge lies in the complex curved surface of dozens of highly twisted and compactly distributed blades, requiring extremely high geometrical accuracy and mirror-like surface finish to gain the optimal aerodynamic performance and impressive speeds.

1. One-stop clamping completes entire machining process

The nature of five-axis technology is two basic advantages. First, it allows complete machining in a single set-up. Traditional three-axis machine tools require multiple re-clampings in order to achieve necessary blade angles, which is not only time-consuming but also results in accumulative errors due to datum transfers.

The five-axis CNC allows the tool to simultaneously alter the angles of the X, Y, and Z linear axes and the A and C rotary axes in continuous motion, maintaining the tool tip in the optimum cutting position with respect to the normal to the blade surface. This allows the entire impeller to be cut from the workpiece blank in a single pass, completely eliminating clamping errors and producing consistent geometric and positional tolerances on all of the blades.

2. Excellent precision and surface quality

Second, it has better accuracy and surface finish. Five-axis machining enables shorter tool lengths and optimum cutting contact points, which significantly reduces cutting vibration and achieves an excellent surface finish on difficult-to-cut materials. Moreover, it machines the tight “throat” area between the blade root and the hub perfectly, an area difficult to reach with traditional equipment.

The end product is an impeller with near-perfect dynamic balance that requires minimal post-processing manual polishing, directly benefiting the final pursuit of the turbocharger for performance and reliability.

Why Can A Five-axis Machining Center Achieve High-precision Production Of Turbine Housings?

The production challenge of turbine housings is their complex internal vortex exhaust flow channels and various mounting interfaces at varied angles. Five-axis machining centers, through their excellent kinematic flexibility, offer a perfect solution to the challenges. Their intrinsic benefits are reflected in the following:

1. Single-stage clamping for multi-angle feature machining

Traditional three-axis machine tools require multiple re-clamping when machining flanges, interfaces, and flow channels at varied angles. Each re-clamping introduces new positioning errors, which lead to cumulative tolerances and even scrap.

A five-axis machining center uses the rotation of the machine table or tool head (A/C axes) to easily orient the workpiece surface to the optimal tool engagement angle. This means that all of the external flanges, internal flow channels, and side interfaces of the entire housing can be machined in a single setup, effectively eliminating the repeat clamping errors and assuring positional accuracy between all of the features.

2. Rapid and precise machining of complex three-dimensional flow channels

The core of the housing is the spiral vortex flow channel of continually changing cross-section. Its surface finish and dimensional accuracy have a direct influence on exhaust gas flow efficiency and boost response.

Five-axis machining enables the end mill to always cut in the normal direction of the flow channel surface in a uniform manner, with the most stable cutting conditions and optimum chip evacuation efficiency. The tool is enabled to penetrate deep into the flow channel in an optimum inclination without colliding with the workpiece. This allows direct and efficient machining of complex three-dimensional flow passages with high precision and high finish without the need for special fixtures or EDM electrodes.

3. Improving efficiency and preserving quality

By reduction in setup, simplification in fixture design, and consolidation of machining operations, five-axis technology radically lowers the production cycle times. More importantly, by offering extremely good machining consistency and geometric integrity, it gives outstanding performance reliability and yield for turbine casings, which meets the high requirements of these critical parts for modern high-performance engines.

In short, five-axis machining centers transform turbine casing manufacturing from a multi-positioning, multi-process labor-intensive operation into a continuous, smooth, and highly reliable digital precision manufacturing operation.

LS Precision Manufacturing Case Study: Custom Turbocharger Components for a British High-Performance Marque

1. Client challenge:

LS Precision Manufacturing recently partnered with a British luxury high-performance automobile brand to design and mass-produce a high-temperature alloy turbine housing assembly for its next-generation variable geometry turbine (VGT) system.

There were a few challenges the customer faced in the development process:

- The turbine housing needed to be made of a high-strength, heat-resistant material with a complex variable-geometry air passage structure.

- The thin-wall structure was susceptible to machining deformation, and the multi-angle sealing faces required extremely high precision (tolerance ±0.05mm).

- Traditional manufacturing techniques were pushed to their limits in an attempt to meet the sealing, heat resistance, and aerodynamic performance requirements concurrently.

2. LS’s innovative solution:

To meet this difficult task, the LS team utilized its five-axis CNC machining center’s technical advantages to devise an integrated, innovative solution.

- Through five-axis simultaneous machining, the housing achieves single-setup high-precision machining of all air passages, sealing surfaces, and mounting holes, essentially eliminating datum conversion errors caused by multi-setup.

- To resolve the problem of thin-walled structure deformation, the team innovatively used a layered cutting and stress relief process, in combination with a special tooling system, to actively inhibit machining deformation.

- In the meantime, a customized tool path and cooling solution were developed based on the characteristics of the high-temperature alloy, ensuring the seal surface roughness of Ra0.8μm, fully meeting the sealing requirements under high-temperature working conditions.

3. Final results and value:

There were significant enhancements in this project:

- The VGT housing assembly supplied by LS achieved a 100% pass rate and enhanced the customer’s boost response by 15% and significantly optimized low-speed engine torque.

- The product survived 1,500 hours of aggressive durability testing without loss of performance or leakage.

- Moreover, the mass production cycle was reduced by 30% and significantly improved the stability of the customer’s supply chain.

This success story best demonstrates LS’s complete technical competency, from material processing, precise machining, to quality control, and turns the company into a leading technology provider in the high-end manufacturing of auto parts.

How Does Manufacturing With Five-axis CNC Drive Turbocharger R&D And Iteration?

Five-axis CNC machining technology is more and more a vital source of innovation and iteration in turbocharger R&D. Its advantages are particularly vital in the rapid prototyping process, where it speeds up the cycle from design concept to physical evidence dramatically.

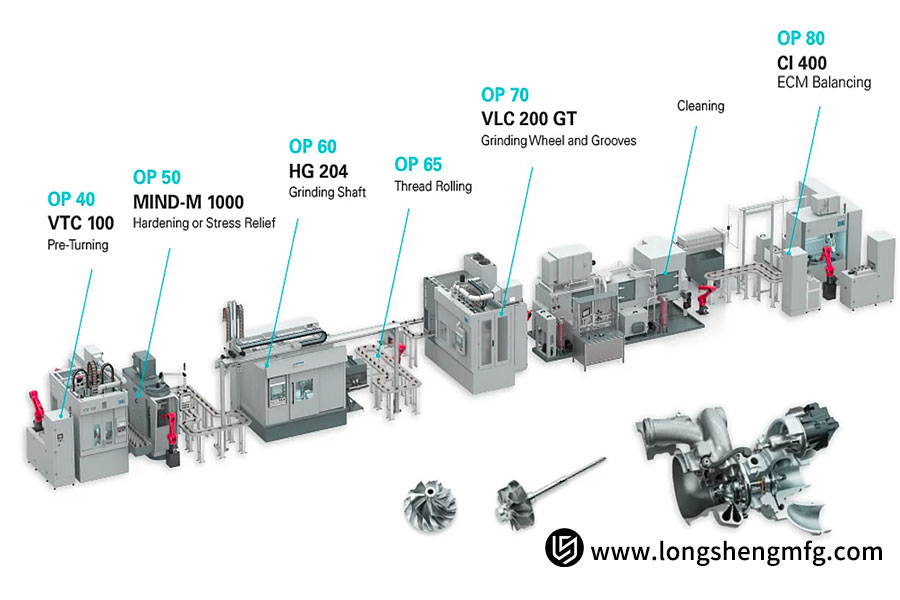

Innovative manufacturing processes

Five-axis CNC machining, compared to traditional manufacturing methods, eliminates the need for special tooling and fixture design and development and skips CAD models directly to precise parts. R&D personnel can build functional prototypes in a few days that simulate the performance of the completed product accurately for airflow testing, durability testing, and assembly inspection. If design updates are necessary, the engineers simply update the computer model to rapidly produce new models, with a fast closed-loop “design-manufacture-test” process.

Agile manufacturing capabilities

This flexible manufacturing cell is well-paired for the production of complex parts such as turbochargers. Key features like the aerodynamics of the impeller and casing flow path geometry can be precisely achieved through five-axis machining, enabling designers to verify innovative concepts.

Furthermore, because all machining operations can be performed in a single setup, prototypes are as precise and good in quality as production parts, making test data reliability and R&D efficiency shine.

By dramatically reducing iteration cycles and costs of trial production, five-axis CNC technology allows engineers to try more ideas, speed up product optimization, and ultimately allow manufacturers to get innovative and optimized turbocharger products to market sooner.

What Are The Factors To Consider In Choosing Five-axis CNC Machining Services?

When choosing a five-axis CNC machining service company, businesses must carefully take into account a few important factors in order to produce high-quality precision parts.

Pay close attention to the equipment capacity and technical skills of the supplier

A capable supplier should be equipped with high-level five-axis machine tools with international reputations (e.g., LS uses five-axis machining centers from Germany or Japan) and have specialized technical experience in hard-to-machine material machining like high-temperature alloys. Especially for the manufacturing of such complex parts as turbochargers, whether the supplier has successful experience in similar industries or not is extremely important.

Check the quality control system

The potential supplier should have a developed quality management system and be willing to make an investment in sophisticated test equipment such as coordinate measuring machines and laser scanners for the provision of consistent quality from first piece to series production. As an example, LS’s application of an ISO 9001 quality management system ensures traceability and back-up for all processes within the manufacturing process.

Evaluate the overall service potential of the supplier

Their capacity collectively needs to be considered in an overview of engineering design assistance, quick response capability, and large-scale production capacity. The ideal collaborator would not only offer precision machining services but also recommendations at the design phase for manufacturing feasibility to reduce costs and make products easy to structure.

As a professional five-axis CNC machining center manufacturer and service provider, LS leverages its abundant technical experience and industry know-how to provide customers with one-stop services from rapid prototyping to mass production, helping them to realize rapid time-to-market as well as long-term competitiveness.

Where Is There A Five-axis CNC Machining Center Close By?

In case you are looking for a five-axis CNC machining center nearby, LS is your optimum choice. We are based at Unit 101, No. 3, 1st Tuanjie Road, Shutian, Humen, Dongguan City, China, and are strategically located and very accessible. In addition, our vast international logistics network ensures timely delivery and secure shipment, meaning that your workpieces or equipment are delivered to your doorstep in a timely manner wherever you may be.

LS provides total five-axis machining solutions to customers of any size:

- We provide large five-axis machining centers that can machine large and complex pieces in markets such as aerospace and automotive manufacturing.

- We also provide mini five-axis CNC machining services, which are most ideal for designers, research institutes, and universities for prototyping, low-volume trial production, and practice teaching.

- Range of machining covers a huge variety of materials such as steel, copper, aluminum, and plastic.

- No matter if you require machining for heavy machinery or solutions for smaller precision parts, LS can provide you with expert support.

- Do not hesitate to contact us to learn more about the potential and advantages of our five-axis machining solutions.

FAQs

1. Is five-axis CNC machining of turbine parts extremely costly?

Five-axis CNC machining of the components of a turbine is relatively expensive at the beginning, primarily due to the fact that equipment cost and technology requirements are extremely high. However, as it possesses the capability to consolidate processes, reduce the need for special tooling, and significantly improve product yield, it can effectively reduce overall manufacturing costs and institute a higher return on investment over the entire project duration.

2.What types of materials does LS Precision Manufacturing provide five-axis machining services?

LS offers full five-axis machining services for aluminum alloys, stainless steel, titanium alloys, and high-temperature nickel-based alloys, which are commonly used in turbochargers. We provide customized machining processes based on material properties to accommodate diverse demands from prototyping to large-lot production.

3. How to select a reliable five-axis CNC machining service provider?

While selecting a reliable five-axis machining service provider, you must take notice of the brand and high level of equipment, project experience of the technical team, previous case studies, and quality control system. LS Precision Manufacturing possesses all the necessary qualifications, complete quality management system, and abundant industry experience. We welcome you for an audit.

4.Does LS offer small-batch or prototype production services?

Indeed. LS takes advantage of five-axis machining technology to provide customers with one-stop service, from single-piece prototype verification to small and medium-volume production. Through rapid response and flexible production, we significantly accelerate product development and meet customers’ manufacturing needs at different stages.

Conclusion

Five-axis CNC machining technology has become an important procedure for the production of high-end turbochargers.

- Apart from solving the problems involving production limitation in intricate geometry, difficult-to-machine materials, and high accuracy, it is also a strategic choice to improve product performance, reliability, and competitiveness in the market.

- By executing a complete machining operation in one set, five-axis technology is able to ensure utmost aerodynamics performance and life of the turbine parts while cutting development cycles and overall cost considerably.

Choice of professional service provider of five-axis machining is the core of success:

- LS Precision Manufacturing takes advantage of first-class equipment, extensive industry experience, and rigorous quality control system to provide global customers one-stop service from rapid prototyping to mass production.

- Situated in Dongguan, we sell to the world, and enjoy superior local technical support and international logistics system, thus enabling each customer to enjoy timely and effective service!

To learn more about how to enhance the performance of your turbocharger products through five-axis CNC machining, contact LS team for a technical evaluation by specialists customized solutions and CNC machining quote. Let us work together and drive technology and excel.

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

What’s Happening i’m new to this, I stumbled upon this I have found It absolutely useful and it has aided me out loads. I hope to contribute & help other users like its aided me. Great job.

I have not checked in here for some time since I thought it was getting boring, but the last few posts are great quality so I guess I’ll add you back to my daily bloglist. You deserve it my friend 🙂

Your comment means a lot to me. Thank you so much for giving me another chance and sharing your honest thoughts! Adding my blog back to your daily reading list is the best gift I could receive today. I will do my best to ensure that future content is worthy of your return. Welcome back, friend!

Welcome, new friend! Your message makes me so happy. It’s most gratifying to know that my content can help those new to this field. I also strongly support your future contributions to the community. We welcome every enthusiastic member here! Keep it up!

Well I truly liked reading it. This subject offered by you is very effective for correct planning.