Plastic performance is the foundation of injection molding technology. Mastering the process performance and characteristics of various plastics is a basic professional knowledge that every injection molding worker must understand. The performance of plastics is the basis for setting “injection molding process conditions”, and it is also one of the factors that must be considered when analyzing quality problems and abnormal phenomena that occur during the injection molding process.

What is injection molding?

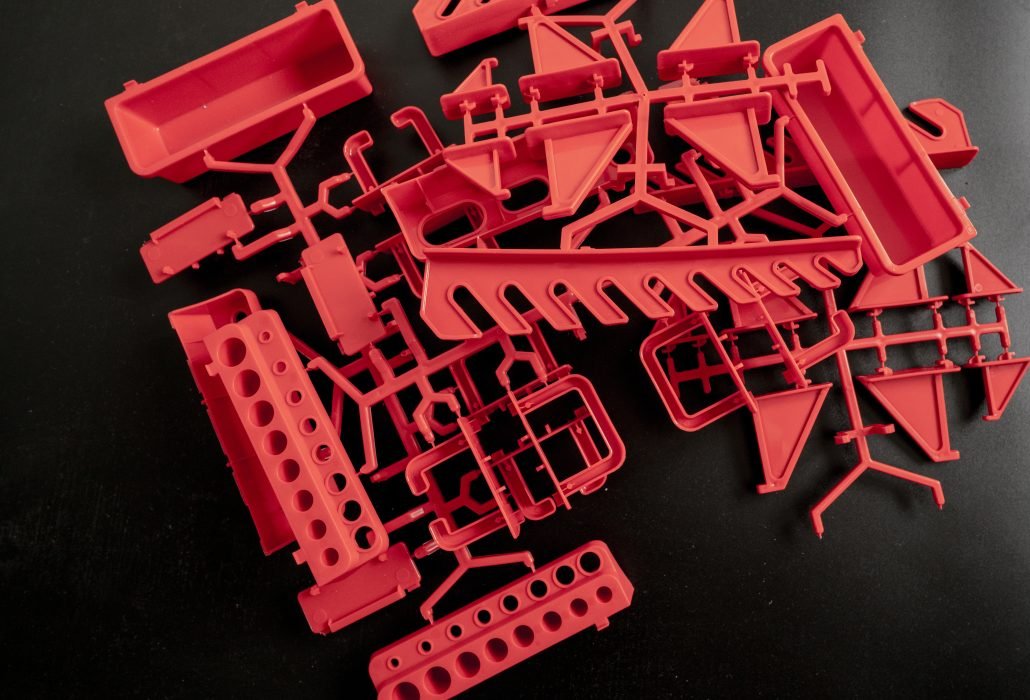

Injection molding, also known as injection molding, is a molding method that involves both injection and molding. The advantages of injection molding method are fast production speed, high efficiency, automated operation, multiple varieties of designs, shapes that can be simplified to complex, and sizes that can be large to small. Moreover, the product size is accurate, the product is easy to update and replace, and can form complex shaped parts. Injection molding is suitable for mass production and complex shaped products and other molding processing fields.

A method of obtaining a molded product by stirring fully melted plastic material with a screw at a certain temperature, injecting it into the mold cavity under high pressure, and cooling and curing it. This method is suitable for mass production of complex shaped components and is one of the important processing methods.

Injection molding processes for 5 types of plastics

In the process of injection molding, material selection and process optimization are crucial for the quality of the final product. Through reasonable material selection and process optimization, high-quality injection molded products can be produced.

Polypropylene (PP) injection molding process

Polypropylene, commonly known as PP or nicknamed “Bendy,” is a thermoplastic polymer known for its excellent impact resistance. It is semi-transparent, semi-crystalline in nature, and boasts several remarkable characteristics such as high strength, good insulation properties, low water absorption, high heat distortion temperature, low density, and high crystallinity. Modified fillers for PP typically include glass fibers, mineral fillers, and thermoplastic rubbers.

The flow properties of PP vary significantly for different applications, with the general flow rate falling between that of ABS and PC.

Pure PP appears as a semi-transparent ivory white, but it can be dyed in various colors. Typically, coloration of PP involves the use of masterbatches, although some machines have independent plasticizing elements that aid in coloration using color powders. Products intended for outdoor use typically require the addition of UV stabilizers and carbon black fillers. The use of recycled materials should not exceed 15%, as exceeding this threshold can lead to reduced strength and color degradation. Generally, there is no need for special drying treatment before the PP injection molding process.

There are no specific requirements for the choice of injection molding machines. Due to PP’s high crystallinity, injection molding machines with higher injection pressure and multi-stage control are required. Locking forces are typically determined at around 3800 kg/m², with injection amounts ranging from 20% to 85%.

Mold temperatures typically range from 50°C to 90°C, with higher mold temperatures used for products with stricter dimensional requirements. Core temperatures should be at least 5°C lower than cavity temperatures. The runner diameter usually falls between 4-7 mm, while the pin gate length is set at 1-1.5 mm, with a diameter that can go as low as 0.7 mm. For edge gates, shorter lengths are preferred, at around 0.7 mm, with a depth equal to half the wall thickness and a width twice the wall thickness, increasing with the length of molten flow inside the cavity. Adequate venting is crucial for molds, with vent hole depths ranging from 0.025 mm to 0.038 mm and a thickness of 1.5 mm, aiming to avoid sink marks. To prevent sink marks, use larger, circular gates and round runners, with the thickness of reinforcing ribs kept minimal (approximately 50-60% of the wall thickness). Products made from homopolymer PP should not exceed a thickness of 3 mm, as thicker-walled products may experience bubbling (for thicker-walled products, copolymer PP is typically used).

PP’s melting point falls between 160°C and 175°C, with a decomposition temperature of 350°C. However, during the injection molding process, temperature settings should not exceed 275°C, and the optimal melt zone temperature typically hovers around 240°C.

To minimize internal stresses and deformation, high-speed injection is generally preferred, although some PP grades and molds may not be suitable for high-speed injection (which may result in bubbles or flow marks). If patterns on the surface show streaking caused by gate diffusion, resolving this issue may involve using low-speed injection and higher mold temperatures.

Typically, a melt-back pressure of 5 bar is used, with the back pressure for color powders adjusted as needed.

Higher injection pressure (1500-1800 bar) and holding pressure (around 80% of injection pressure) are employed. Transition to holding pressure usually occurs at around 95% of the full stroke, with an extended holding time.

To prevent shrinkage deformation caused by post-crystallization, products are generally subjected to a hot water immersion treatment.

PE (Polyethylene) Injection Molding Process

PE is a crystalline plastic material with extremely low moisture absorption, not exceeding 0.01%. Therefore, there’s no need for drying before processing. PE molecules exhibit excellent chain flexibility and weak intermolecular forces, resulting in low melt viscosity and outstanding flowability. Consequently, it can be molded into thin-walled, long-flow products without the need for excessive pressure. PE has a wide range of shrinkage rates, especially with LDPE at around 1.22% and HDPE at about 1.5%, exhibiting significant directional shrinkage tendencies. This can lead to deformation and warping, necessitating precise control of mold temperatures to ensure uniform and stable cooling conditions.

PE possesses high crystallization capability, and mold temperature significantly impacts the crystalline structure of the parts. Higher mold temperatures lead to higher melt crystallinity and increased strength but also result in greater shrinkage. Typically, mold temperatures for LDPE are controlled between 30°C and 45°C, while HDPE requires temperatures 10°C to 20°C higher.

Though PE has a relatively low melting point, its specific heat capacity is significant. Consequently, substantial heat is still required during plasticization. Therefore, it’s essential to have substantial heating power to enhance production efficiency. Furthermore, PE has a relatively narrow range of softening temperatures and is susceptible to oxidation in its molten state. Thus, it’s vital to minimize contact between the melt and oxygen during molding to maintain part quality.

PE components are usually soft and demold easily. Hence, a strong demolding force can be applied, especially when dealing with parts featuring shallow side recesses. PE melt exhibits non-Newtonian behavior, with changes in shear rate having a minimal impact on viscosity. Additionally, the influence of temperature on viscosity is relatively small. Therefore, thorough cooling is essential, necessitating molds with efficient cooling systems.

When feeding PE melt directly through the injection nozzle, it can increase stress and result in uneven shrinkage with distinct directional deformation. Therefore, careful attention should be paid to selecting nozzle parameters. PE has a broad molding temperature range, and slight temperature fluctuations during processing have little impact on injection molding. Moreover, PE exhibits good thermal stability and typically does not undergo significant decomposition below 300 degrees, having minimal effects on product quality.

Key molding conditions for PE include:

Barrel Temperature: The barrel temperature is related to PE density, melt flow rate, injection molding machine type, and part shape. Generally, the barrel temperature should be maintained at least 10 degrees above the melting point. For LDPE, barrel temperatures are typically controlled between 140°C and 200°C, while HDPE barrel temperatures are maintained around 220°C, with lower temperatures at the rear and higher at the front.

Mold Temperature: Mold temperature significantly affects part crystallinity. Higher mold temperatures lead to increased melt crystallinity and strength but also result in greater shrinkage. Typically, mold temperatures for LDPE are controlled between 30°C and 45°C, while HDPE requires temperatures 10°C to 20°C higher.

Injection Pressure: Increasing injection pressure aids in ensuring complete mold filling. Due to PE’s excellent flowability, lower injection pressures are generally preferred, typically ranging from 50 MPa to 100 MPa, except for thin-walled, elongated products. For more complex shapes with thicker walls, higher injection pressures may be necessary.

Polyvinyl Chloride (PVC) Injection Molding Process

Typical Applications: PVC material finds widespread use in various sectors, including water supply pipes, household plumbing, house siding panels, commercial equipment housings, electronic product packaging, medical devices, and food packaging, among others.

Chemical and Physical Characteristics: PVC is a non-crystalline material. In practical applications, stabilizers, lubricants, processing aids, pigments, impact modifiers, and other additives are often incorporated into PVC material. PVC exhibits excellent resistance to combustion, high strength, resistance to weathering, and outstanding dimensional stability.

| Property | Value |

|---|---|

| Chemical Name | Polyvinyl Chloride (PVC) |

| Molecular Formula | (C2H3Cl)n |

| Structure | -CH2-CHCl- (Repeat Unit) |

| Appearance | White or transparent solid, typically in the form of powder, particles, or resin |

| Density | 1.3 – 1.4 g/cm³ |

| Melting Point | 75°C – 85°C (Dependent on the type of PVC) |

| Glass Transition Temperature | 80°C – 105°C (Dependent on the type of PVC) |

| Tensile Strength | 50 – 80 MPa (Dependent on the type of PVC and processing conditions) |

| Flexural Strength | 50 – 100 MPa (Dependent on the type of PVC and processing conditions) |

| Hardness | 55 – 95 Shore D (Dependent on the type of PVC and processing conditions) |

| Chemical Resistance | Excellent resistance to acids, alkalis, solvents, and most chemicals |

| Thermal Stability | Stable within a certain temperature range but may decompose at high temperatures (PVC degradation temperature is approximately 200°C) |

| Insulation | Excellent electrical insulation properties |

| Flame Resistance | PVC can exhibit flame resistance, but may require flame retardants to meet fire resistance requirements |

| Processability | Easily processed through methods such as injection molding, extrusion, and blow molding |

| Applications | Construction, electrical wiring, pipes, medical devices, packaging, automotive components, etc. |

PVC demonstrates strong resistance to oxidizing agents, reducing agents, and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid, and it is not suitable for applications involving aromatic hydrocarbons or chlorinated hydrocarbons.

In the processing of PVC, the melting temperature is a critical process parameter, and improper settings may result in material decomposition. PVC’s flow characteristics are relatively poor, with a narrow processing range.

In particular, high molecular weight PVC materials are more challenging to process (typically requiring the addition of lubricants to improve flowability). Therefore, lower molecular weight PVC materials are commonly used. PVC exhibits a relatively low shrinkage rate, typically ranging from 0.2% to 0.6%.

Injection Molding Process Conditions:

Drying: Typically, drying treatment is not necessary.

Melting Temperature: It is recommended to maintain it within the range of 185°C to 205°C, while mold temperature should be kept between 20°C and 50°C.

Injection Pressure: It can go as high as 1500 bar.

Holding Pressure: Up to 1000 bar.

Injection Speed: To prevent material degradation, a relatively high injection speed is generally required.

Runners and Gates: Various standard gates can be used. For smaller components, it is advisable to use pin-point gates or submerged gates, while for thicker parts, a fan gate is preferred. The minimum diameter for pin-point gates or submerged gates should not be less than 1mm, and the thickness of fan gates should not be less than 1mm.

Chemical and Physical Characteristics: Rigid PVC is one of the most widely used plastic materials.

Polystyrene (PS) injection molding process

Common Application Areas: PS materials find extensive use in various sectors, including product packaging, household items (such as cutlery and trays), and electrical equipment (such as transparent containers, light diffusers, and insulating films).

Chemical and Physical Properties: Commercially available PS is typically non-crystalline and transparent. It boasts excellent geometric stability, thermal stability, optical transparency, electrical insulating properties, and minimal moisture absorption tendencies. PS can resist water and most diluted inorganic acids, but it can be corroded by strong oxidizing acids like concentrated sulfuric acid. It may also undergo expansion deformation in some organic solvents. The typical shrinkage rate ranges from approximately 0.4% to 0.7%.

| Property | Value |

|---|---|

| Chemical Formula | (C8H8)n |

| Molecular Weight | 104.15 g/mol |

| Physical State | Solid |

| Density | 1.04 g/cm³ (20°C) |

| Melting Point | 240-270°C |

| Glass Transition Temperature | 90-105°C |

| Tensile Strength | 55-75 MPa (tensile) |

| Flexural Modulus | 2.1-3.1 GPa |

| Hardness (Rockwell) | M70-M95 |

| Impact Strength (IZOD) | 2-5 J/cm (23°C) |

| Thermal Conductivity | 0.15-0.20 W/(m·K) (23°C) |

| Linear Expansion Coefficient | 70-90 x 10^-6/°C |

| Water Absorption | 0.1-0.3% (24 hours in water) |

| Optical Transparency | Transparent or semi-transparent |

| Flammability | Combustible, but not self-igniting |

| Major Uses | Plastic containers, optical discs, household items, electronic components, toys, packaging materials, etc. |

Injection Molding Process Conditions:

1.Drying: Generally, unless material storage conditions are inadequate, drying treatment is not necessary. If drying is required, it is recommended to use drying conditions at 80°C for 2-3 hours.

2.Melting Temperature: The melting temperature range for PS materials is from 180°C to 280°C. For flame-retardant materials, the upper limit should be kept below 250°C.

3.Mold Temperature: Typically set between 40°C and 50°C.

4.Injection Pressure: The recommended injection pressure range is from 200 to 600 bar.

5.Injection Speed: It is advisable to use a relatively fast injection speed for improved molding results.

6.Runners and Gates: All conventional types of runners and gates can be used during the injection molding process for PS.

These are key details about the injection molding process for Polystyrene (PS). Depending on specific projects and products, adjustments and optimizations may be necessary to suit individual requirements. We hope this information proves helpful in your injection molding work.

ABS Injection Molding Process

Common Application Areas: Automotive interiors (such as dashboards, door panels, wheel covers, mirror housings, etc.), household appliances (especially refrigerators), high-strength tools (including hairdryers, mixers, food processors, lawnmowers, etc.), communication equipment housings, printer keyboards, leisure and recreational vehicles like golf carts, and snowplows, among others.

Chemical and Physical Characteristics: ABS is synthesized from three distinct chemical monomers—acrylonitrile, butadiene, and styrene. Each monomer brings its own unique properties to the table: acrylonitrile provides high strength, heat stability, and chemical resistance; butadiene imparts toughness and impact resistance to ABS; styrene contributes to ease of processing, high gloss, and strength. ABS material is non-crystalline in nature.

| Property | Value |

|---|---|

| Chemical Composition | Acrylonitrile, Butadiene, Styrene |

| Structure | Two-phase structure: Styrene-Acrylonitrile continuous phase, Polybutadiene dispersed phase |

| Morphology | Amorphous |

| Density | 1.04 – 1.07 g/cm³ |

| Melting Point | 215 – 240 °C |

| Environmental Stability | Good |

| Heat Stability | Medium to High |

| Chemical Stability | Good |

| Flexural Strength | 60 – 80 MPa |

| Modulus of Elasticity | 2,100 – 2,500 MPa |

| Tensile Strength | 40 – 60 MPa |

| Impact Resistance | Medium to High |

| Surface Finish | Low to High |

| Flame Resistance | Varies with formulation, adjustable |

| Moisture Absorption | Low |

| Electrical Insulation | Good |

| Heat Distortion Temperature | Medium to High |

| Creep | Low |

| Processing Temperature Range | 210 – 280 °C |

The copolymerization of these three monomers results in ABS’s two-phase structure, with one phase being continuous styrene-acrylonitrile and the other phase comprising dispersed polybutadiene rubber. The performance of ABS is primarily influenced by the ratios of these three monomers and the molecular structure of the two phases. This flexibility in material composition has led to the market offering a plethora of ABS grades, each with varying properties, such as impact resistance ranging from medium to high, glossiness from low to high, and resistance to high-temperature distortion, among other attributes.

ABS material is characterized by its exceptional processability, aesthetic qualities, low creep, outstanding dimensional stability, and high impact strength.

Injection Mold Process Conditions:

1.Drying: Due to ABS’s hygroscopic nature, it requires pre-drying before processing. It is recommended to dry at a minimum of 80-90°C for at least 2 hours to ensure material humidity is below 0.1%.

2.Melting Temperature: Typically falls within the range of 210-280°C, with a recommended setting of 245°C.

3.Mold Temperature: Usually set between 25-70°C, with mold temperature selection impacting the surface gloss of the molded part; lower mold temperatures may result in reduced glossiness.

4.Injection Pressure: Generally maintained between 500-1000 bar, adjusted as needed for specific conditions.

5.Injection Speed: Employ medium to high speeds, depending on mold and product requirements.

These well-calibrated process parameters are crucial for the successful injection molding of ABS, ensuring the quality and performance of the final product.

Characteristics and Applications of Injection Molding

Injection molding technology has demonstrated strong adaptability and can efficiently manufacture plastic products with complex shapes, precise dimensions, and metal or non-metallic inserts. It has the advantages of high productivity and easy automation, making it an important method in the field of thermoplastic processing.

The injection molding process is constantly developing rapidly, and in addition to being suitable for thermoplastic injection molding, it has also been successfully applied to some thermosetting plastics, which have the characteristics of high efficiency and stable product quality. In addition, plastic products with excellent cushioning, sound insulation, and thermal insulation properties can be produced by injection molding using low anti foaming plastics (density range 0.2-0.9g/cm3). Multicolor injection molding technology can produce colorful and beautifully crafted plastic products.

In addition, the application of hot runner injection molding technology has significant advantages in manufacturing large plastic parts and reducing or eliminating solidification in the gating system. Injection molding technology is also one of the important process methods for manufacturing hollow plastic products.

conclusion

Different plastic materials have different physical and chemical properties, so different process parameters need to be used during injection molding. This paper introduces five common plastic materials and their injection molding process points. With an in-depth understanding of the characteristics and process points of different materials, you can better optimize the injection molding production process, improve production efficiency and product quality.

Have you already completed the mold design work? If you’re encountering difficulties in selecting the appropriate type of plastic injection mold for your project, we, at Longsheng, are here to assist you.

Our expertise covers mold manufacturing, mold design analysis, and plastic parts production. We can manufacture high-quality injection molds for you, enabling the production of durable and reliable plastic molded parts. Our engineering team possesses extensive experience and skills to provide you with the best injection molding solutions.

When you are ready, simply upload your design files to our contact form, and you’ll receive a quotation and a free Design for Manufacturability (DFM) analysis from our engineers. This will help ensure that your project achieves optimal performance and quality during the manufacturing process.

Mobile:+86 185 6675 9667 (Gloria Wu)

E-Mail:gloria.wu@longshengmfg.com