Have you ever marveled at the smoothness of wooden bowls, elegant table legs or exquisite wooden pens? Have you ever stopped to admire the round pillars and delicate bottle-shaped decorations on furniture? Even more curious is how a square, angular piece of wood can be magically transformed into these circular works of art full of rhythm and vitality? The answer is actually not complicated. It is hidden in a seemingly inconspicuous but powerful tool.

If you love wood and want to shape it, you must understand this confusion. Faced with a piece of simple logs or square materials, although you have the wonderful idea of rotational symmetry and smooth curves in your mind, you don’t know where to start. Saws can only cut straight lines, planes are good at flattening planes, and carving knives are fine at details but have limited efficiency. How to efficiently and accurately “spin” hard wood into a perfect circular cross-section? This magic of turning “square” into “round” requires a special stage.

This machine is a wood lathe. Simply put, it rotates wood at high speed so that you can cut and shape it with a fixed tool. This article will give you a comprehensive overview of a wood lathe – what it is, what parts it consists of, what tools it requires, what it can do, and how CNC turning works if you want to take this craft to industrial-grade precision.”

Here’s What You’ll Learn:

- The core “internal organs” of a wood lathe: Understand the functions of key components such as the bed, spindle box, tailstock, tool holder and power system, and understand the cornerstone of this “rotating art” machine.

- Spindle vs. face turning: The key basis for accurate selection: Decipher how the wood fixing method (supported at both ends vs. fixed at one end) and the direction of the wood grain (parallel vs. vertical) determine whether you can make table legs or dishes.

- “Diamond drill” list: Your first set of essential turning tool guide: Understand the six basic turning tools (roughing spatula, spindle spatula, bowl spatula, separation knife, scraper, bevel knife) and their dedicated tasks to shape wood safely and efficiently.

- From handmade prototype to mass production: Real case analysis: Follow a DIY wooden pen holder project to see how it can be accurately, efficiently and cost-effectively replicated on a large scale through CNC turning from a charming handmade product.

- The golden rule of safely harnessing the “power of rotation”: Keep in mind the key elements such as protective equipment, wood inspection, firm fixation, tool holder adjustment, two-handed operation, speed control and standardized dress to keep your creations away from harm.

- Decipher the myths and limitations of common alternatives: Analyze why methods such as electric drill “simple lathe” cannot replace the accuracy, safety and function of a real lathe, and clarify its applicable boundaries

- Authoritative answer: The ultimate FAQ for the purchase and application of woodworking lathes: Clarify the core differences between woodworking and metal lathes, choose the right size according to the target project (small objects vs. large items), and understand the true face of the learning curve.

Now, let’s explore in depth, unveil the mystery of the wood lathe, and master the essence of this skill of “turning logs into art”!

Why trust our analysis? From manual turning to CNC turning, we understand it all

I am Longsheng, an engineer at LS. My understanding of rotary machining began in the woodworking shop where I lived when I was a child. At that time, I held the turning tool in my own hands and felt the wood spinning and trembling under my fingertips. I watched the wood chips flying with full concentration, and let the shape be born in my hands with my touch, eyesight and experience. That pure sense of control and joy, as well as the deep understanding of the nature of materials, cutting forces and rotation, are engraved in my bones.

Today, I operate a precision CNC lathe. Many people think this is a huge leap, but for me, it is an evolution of understanding. The “intuition” from manual operation is precious-it allows me to “read” the subtle feedback (sound, vibration, chips) in CNC machining more keenly, convert experience into precise parameters, better control every detail, and foresee and avoid problems. I know how to balance efficiency and finish, and how to “tailor” for different materials. This ability is rooted in the most essential understanding of rotation.

At LS, our core advantage is that we have engineers and technicians with a knowledge system of the entire process from manual art to automated production. This is not only a superposition of technology, but also a penetration of the level of understanding.

Therefore, as a professional custom CNC turning manufacturing service provider, we provide far more than competitive CNC turning prices. We can truly understand you – whether you are facing challenges in the transition from traditional manufacturing or need high-precision custom parts. We understand your comprehensive considerations of precision, efficiency, and cost, and understand the pain points of materials and processes. Because our “rotation gene” flows with a deep understanding and love from the most basic to the highest level. This professionalism from the feel of the hand is the unique confidence of LS to provide you with excellent CNC turning solutions.

The Core Anatomy Of A Wood Lathe: Understanding The “Internal Organs”

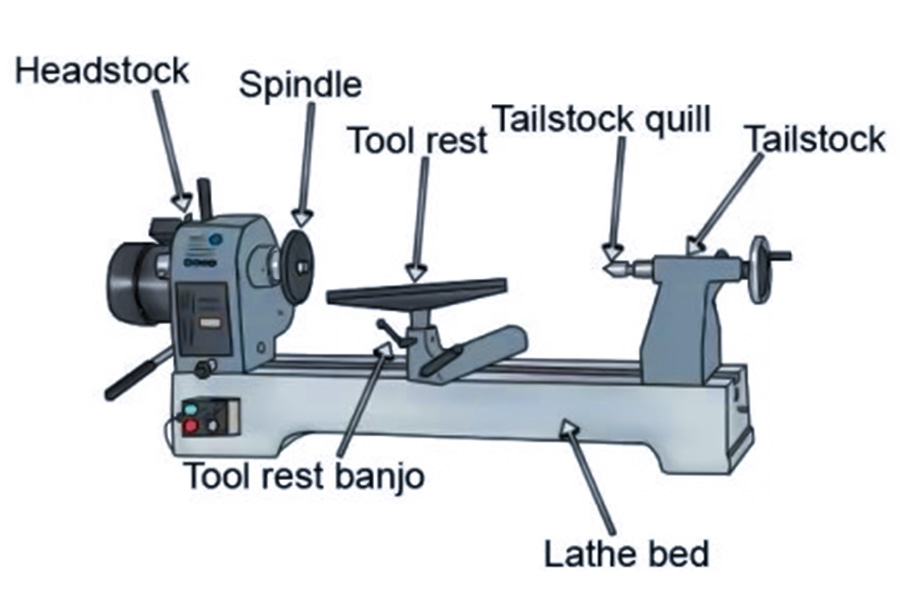

The magic of a woodworking lathe comes from the precise cooperation of its core components: the bed, the spindle box, the tailstock, the tool holder and the power system. Together, they support, drive, stabilize and control the cutting process.

- Bed: The backbone of the machine. It is usually made of solid cast iron, like a straight, steady track. The bed provides a solid mounting base and a precise movement path for all other parts on the lathe, and is the cornerstone of the rigidity and precision of the entire machine. Without its solid support, precision turning is out of the question.

- Headstock: The rotating heart. Located at one end of the bed, the drive motor and transmission mechanism (such as pulleys or gears) “beat” inside. The core of the spindle box is the extended spindle, where the lathe chuck or drive center is installed. It is responsible for clamping one end of the wood and spinning it at high speed, and is the source of power for the entire machine.

- Tailstock: The flexible support arm. It is located at the other end of the bed and can slide and lock its position on the bed according to the length of the wood. The top of the tailstock is equipped with a retractable center (such as a movable center or a dead center). Its core function is to use the center to firmly support the other end of the wood after moving into position, clamp the workpiece together with the spindle box, provide crucial axial support, ensure rigidity and safety during processing, and prevent the wood from flying off during rotation.

- Tool Rest: A safe operating platform. This is a metal crossbar with flexible height and angle adjustment, installed on the bed, located on the lower side of the rotating workpiece. It is the direct support point for the turning tool. During operation, the turning tool must be stably against the tool rest for cutting. The position adjustment of the tool rest directly affects the cutting angle and operating comfort. It is not only the support for achieving precise turning, but also a key barrier to ensure the safety of the operator’s hands and prevent the tool from jumping out of control.

- Power System (Motor & Pulleys): The source of power. It is mainly composed of an electric motor and a pulley speed change mechanism. The motor provides the core power; the main and driven pulleys of different diameters (usually located in the spindle box) are connected by belts to change the rotation speed of the spindle (wood). Different wood materials, diameters, and processing stages (such as rough turning, fine turning, and grinding) all require matching appropriate turning speeds. The design and adjustment range of the power system directly determine the adaptability and processing effect of the lathe.

It is the precise coordination and respective functions of the five core components, namely the bed, spindle box, tailstock, tool holder and power system, that together constitute the powerful and reliable “body” of the woodworking lathe, laying a solid foundation for every safe and efficient turning creation.

Two Major Schools Of Turning: Spindle Turning vs. Face Turning (Bowl Type)

“Although both are rotating”, the way the wood is fixed and the direction of the grain fundamentally determine the turning technology, tool use and final product form, thus clearly dividing it into two major schools: spindle turning and face turning.

Spindle Turning vs. Faceplate Turning (Bowls) Core Comparison

| Features | Spindle Turning | Faceplate Turning |

|---|---|---|

| Wood fixing method | Two-end fixation: Spindle box + tailstock center | Single-end fixation: Spindle box panel/chuck (tailstock is usually not used) |

| Wood grain direction | Parallel to lathe axis/bed | Perpendicular to lathe axis/bed (end face facing the operator) |

| Main cutting surface | Wood circumferential side (parallel to the axis) | Wood end face (perpendicular to the axis) |

| Main tool movement direction | Move along the bed/axis direction | Move in a plane perpendicular to the axis, with significant radial feed |

| Typical products | Slender, axisymmetric, columnar objects: table/chair legs, baseball bats, pens, candlesticks, spindles | Flat, hollow, disc-shaped objects: bowls, plates, dishes, boxes, vases, objects with bases |

| Structural features | Mainly solid or bas-relief | Often have concave curved surface or hollow structure |

| Source of stability | Support at both ends provides high rigidity | Rely on chuck/panel clamping force, cantilever structure, stability is a challenge (especially large diameter/deep cavity) |

| Core technical challenges | Maintain straightness/symmetry (slender parts), cut along the grain to avoid tearing | Handle end face texture cutting (easy to tear), control vibration, and safely remove workpieces |

| Fixed conversion requirements | Usually fixed in one time | Bowls often need to be reversed and fixed (turn the outside first, then fix the outer circle and turn the inside) |

- Spindle turning: The wood is fixed at both ends (spindle + tailstock), and the wood grain is parallel to the lathe. Focus on processing the side profile of slender rotating bodies, such as table legs and pens.

- Face turning: The wood is fixed at one end (panel/chuck), and the wood grain is perpendicular to the lathe. Focus on cutting on the end face of the wood to make disc-shaped or hollow containers, such as bowls and plates.

“You Can’t Do A Job Without A Diamond Drill”: Your First Set Of Essential Turning Tools

A lathe is not enough, you also need a set of sharp ‘brushes’ to create shapes.

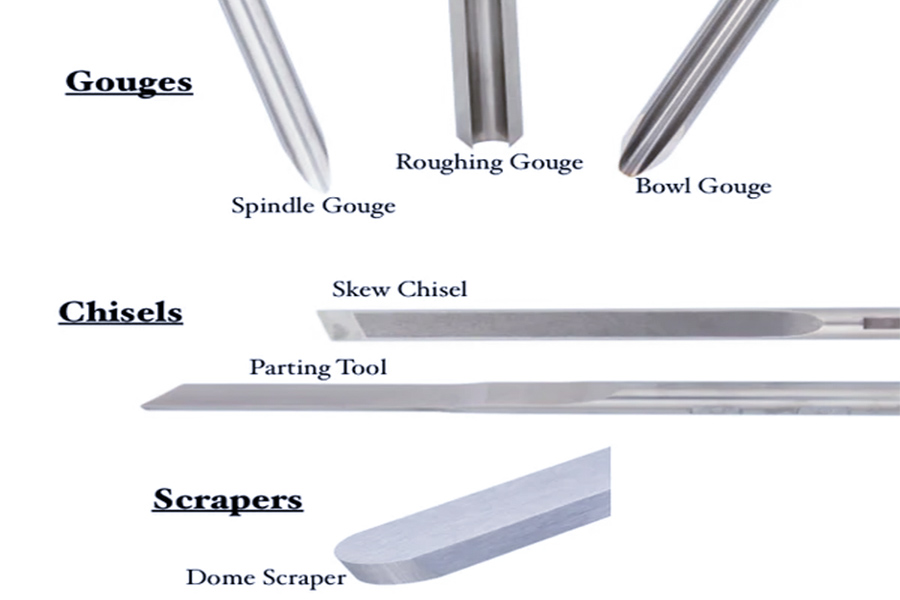

Quick reference table of the functions of the six basic turning tools

| Tool name | Main function | Typical application scenario | Learning difficulty |

|---|---|---|---|

| Roughing Gouge | Quickly remove large amounts of wood and turn square blanks into cylindrical shapes. | Roughing blanks | Primary |

| Spindle Gouge | Turning fine curves, grooves and details. | Spindle-type workpieces (pens, legs, spindles) | Intermediate |

| Bowl Gouge | Turning the inner and outer surfaces of containers such as bowls and plates (especially side cutting). | Bowls, plates, hollow parts | Intermediate and advanced |

| Parting Tool | Cut grooves of precise depth, define boundaries, and cut workpieces off from waste. | Grooving, splitting workpieces | Primary |

| Scraper | Finishing the surface, scraping to achieve a smooth and flat effect. 。 | Finishing, flattening | Primary |

| Skew Chisel | Multifunctional: produces very smooth surfaces, turning planes, V-grooves, bead-shaped decorations, cones, etc. | Finishing, detail decoration | Advanced |

- Roughing Gouge: This is your workhorse for the roughing phase. It’s strong and has a wide blade, so it can quickly and safely turn square wood into cylindrical shapes, removing a lot of excess wood and laying the foundation for fine processing. It deals with “faces” rather than fine “points”.

- Spindle Gouge: This is the most commonly used fine shaping tool when doing spindle turning (such as making table legs, railings, pen barrels, etc.). It has a narrow and deep “flute” and is particularly good at turning smooth curves, grooves (such as the grooves between beads) and convex surfaces (such as the beads themselves). It allows you to “draw” the outline of the workpiece.

- Bowl Gouge: Designed for end turning (such as making bowls and plates). It is heavier and stronger than the spindle chiseling shovel, with a longer shank (for cantilever operation) and an optimized blade shape (usually with a deeper notch and a specific grinding angle), which can effectively resist torsional forces and safely cut the inner and outer curved surfaces of the bowl wall.

- Parting Tool: The blade is slender and the blade is thin and straight. Its main function is to make precise cuts: one is to turn a groove of precise width on the workpiece (often used to measure the diameter or position for subsequent operations); the other is to finally cut the finished product cleanly from the waste material (wood chuck) connected at both ends.

- Scraper: Generally has a negative rake angle or near zero cutting angle. Is not used to “cut” wood but to “scrape” the wood’s surface like a shovel. It removes knife marks fine after coarse and fine processing, makes the surface flat (especially the end texture or hard spots) and pre-grinds. The procedure is quite safe and simple.

- Skew Chisel: Its cross-section is diamond-shaped and its blade long and oblique (normally 45 degrees). It is the most convenient but the most difficult “master-level” lathe tool. When used correctly, it can produce a mirror-smooth surface (far smoother than a scraper effect), precise planes, tidy edges and beautiful V-shaped decorative cuts. It is easy to “bite the knife” or “fly away” if it is not done well, and lots of practice is needed to get it right.

These six basic lathe tools perform their respective jobs, from coarse processing and cutting (rough processing chisel), fine shaping (spindle/bowl chisel), cutting and cutting with accuracy (separation knife), polishing on the surface (scraper), to the pursuit of ultra-smoothness and detailed work (skew knife), together constitute the “core brush library” of woodworking lathe creation and are indispensable tools for operating lathes and manifestation of creativeness.

Case Study: From Handmade Wooden Pen Holder to Bulk Production

Client Background: A designer planned to engrave a set of special wooden pen holders with advanced grooves for his workshop, and initially used handmade mockups.

Challenges:

- Limitations of manual mockups: Even after successfully converting the first sample manually, the designer faced significant bottlenecks:

- Poor uniformity: The depth and interval of the grooves were difficult to accurately control, resulting in variations among individual pens in each pen holder.

- Inefficiency: Hand operations were too time-consuming and entirely powerless against a batch order of 50 pen holders’ delivery demands and time cost.

LS Company Solution:

- Technology Transformation: After evaluating the situation, we proposed and implemented a shift from hand machining to CNC turning.

- Design Engineering: Our engineering team took the designer’s drawings and converted them into precise CAD digital models to ensure the geometry, the size and position of the grooves were parametric and standardized.

- Automated Programming Production: Based on the CAD model, we produced correct CNC machining programs and scheduled production through our web-based CNC turning service platform. The CNC lathe follows the program rigidly to ensure perfect reproduction of every groove in the design.

Achievements:

- Accuracy and repeatability: The groove dimensions of the 50 pen holders produced successfully are completely uniform, with dimensional accuracy and geometric repeatability not possible with manual processes.

- High quality: The product finish is significantly improved, better than the handmade prototype.

- Effective delivery: The entire mass production process was executed effectively within a few days, meeting the customer’s tight delivery schedule.

- Cost optimization: The overall cost of production (particularly with regard to the value of the designer’s own time) is significantly less than the customer’s do-it-yourself approach.

Key value of the case:

This case clearly demonstrates the capability of LS Company to transform the designer’s creative idea and handmade prototypes into professional engineering conversion (CAD) and high-end digital manufacturing (CNC) capabilities to achieve rapid, accurate, and cost-efficient mass production. We could eliminate the inherent pitfalls of manual production – efficiency and consistency, and enable customers to enjoy seamless and dependable transition from “creative prototype” to “commercial-grade mass production”.

Safety First! The woodturning golden rule

High-speed rotating wood combined with cutting tools can produce beauty or injury. Kindly take care to observe the rules below.

- Safety goggles first! Always use a mask or goggles.

- Inspection of the wood! Well inspect the wood for cracks, big knots, loose pieces or things that are not there (like nails).

- Safe! Pre-rotate the wood by hand to ensure smooth, vibration-free rotation and the clamp to be secured.

- Shut the tool holder! Position the tool holder as close to the wood as possible (about 3-6mm), but never touching it when the machine is running.

- Hold the tool with two hands! Always hold the turning tool in both hands (one hand forward to control the tool, and one hand at the back to hold it steady).

- Be slow! Start with the lowest speed and gradually increase the speed after the wood has turned around and stopped vibrating.

- Dress code! Loose garments and gloves are not allowed, and long hair should be tightly tied up.

- Concentrate on operation! Be very concentrated during operation and avoid distraction.

- Clean environment! Maintain a clean working area and clear wood chips and rubbish on schedule.

Security is the condition to enjoy the happiness of turning! Please make sure to inspect each one before operating the machine!

“Can I Turn Wood Without A Lathe?” – Analysis Of Alternatives And Limitations

Do not possess a wood lathe, but would like to try and create round wooden parts? The short response is ‘technically yes, but with certain limitations. This article will review several of the most common ‘homemade approaches’ and focus on the analysis of their limitations and potential dangers.

DIY alternatives:

Drill simulation (firmly not advised):

- Method: Clamp an extremely powerful electric drill firmly in a vise, and clamp an extremely dense and extremely small bit of wood in the drill bit. Turn it on and try to cut the rotating wood with a hand tool.

- Essence: Simulates the “workpiece rotation” operation, with very poor results.

Manual shaping (not turning):

- Method: Hand-cut and hand-grind wood with equipment such as band saws, sanders, and files into almost a circular shape (such as a rough rolling pin).

- Essence: Static shaping/grinding, not really turning.

Innermost limitations and dangers:

Extremely low accuracy:

- Drill method: Drill bit shakes and rebounds, producing elliptical/irregular shapes and no concentricity.

- Shaping method: A circle is difficult to achieve with a hand.

Extremely dangerous (especially the drill method):

- Wood missile: Drill chuck does not limit side forces, and wood is highly likely to become a high-speed missile.

- Tool loss of control: Hand tools are highly likely to be tossed around or damaged.

- Risk of entanglement: Hair and apparel have a tendency to become entangled easily.

- The risk of shaping method is reasonably normal but still there.

Functionality is significantly limited:

- Limited to very minute size (electric drill approach), very basic shape (simplified column/cone).

- Low efficiency, cannot machine subtle contours, internal detail, threads.

- Requirements of material are exacting (small, uniform hardwood).

Only form quasi-circular effects under highly limiting conditions (very small, simple parts, high-risk endeavor) and cannot be replaced by wood lathes.

- Accuracy, safety and use are fatal defects.

- Only suitable for emergency requirements, rough prototypes or lathe roughing out.

For whoever needs precision, security or speed, or wants to actually do (bowls, pens, etc.), a solid wood lathe is an absolutely necessary essential tool. Consider second-hand or shared workshops, which is much safer than dodgy attempts.

FAQ – Final Questions on Wood Turning

1. What is the difference between a wood lathe and a metal lathe?

Wood lathes are relatively plain and light, with very high spindle speeds (around 500-4000 RPM). These are designed for turning relatively soft wood and are operated with a light tool holder or a turning tool held in the hand. Metal lathes are stronger and heavier with less speed but greater torque. They possess high precision feeding systems and rigid tool holders to machine hard metals. The chucks, tools, and their fixing methods are completely different from each other. Wood lathes focus on high-speed rotation controlled by flexibility, whereas metal lathes are focused on precision cutting and measurement by using low speeds.

2. How big of a lathe should I buy?

Lathe size depends on the size of your project and your budget for space. Small to medium-sized lathes (rotation diameter of below 300mm and about 1m in length) are best suited for making bowls, pens, small ornaments, etc. They are cost-effective and space-efficient. Large lathes (swing diameter ≥ 400mm, more than 1.5m long) can be used to turn large bowls, legs of tables, columns, etc., but they require sufficient space and a higher budget. New starters are recommended to work with medium-sized lathes (e.g., swing diameter 330mm × length 800mm), based on flexibility and applicability, and pay attention to the diameter of the spindle hole (determining the workpiece passing capacity) and the motor power (≥500W is appropriate).

3. Is wood turning difficult to learn?

Turns of basic skills are not hard to master, and simple shapes such as cylinders and curves are easy to teach by short-term instruction. But proficiency requires constant practice, with ability in advanced shape making, accuracy grinding and specific methods (hollowing and inlaying). Safety is the primary issue and safety gear must be fitted snugly and used in an agreed manner. Practice can start with straight lines and progress to arc surfaces. In the first phase, wood grain vibration or ripping may occur due to unsuitable tool angles, which can be overcome by adjusting patiently. Online tutorial classes or local woodworking classes can significantly reduce the learning curve, and hobbyists can complete hands-on works independently within a few months.

Conclusion

Essentially, wood turning is about tapping the power of rotation. Traditional wood lathes are the key to artistic expression, allowing you to infuse life and warmth into wood with your own hands. Where precision, speed, and dimension determine tasks for industrial purposes, CNC turning is the new wave of this ancient art form, ensuring fine detail and mass production to precise standards to the finest detail.

Whether inspiration springs from creating a hand-made wooden bowl that’s one of a kind, or producing tens of thousands of parts to very close tolerances, the essence of unleashing “rotation” is the same.

Choose LS and let rotation inspire!

LS fosters profound appreciation of your needs for “rotation” – whether the charm of handcraft or the precision of CNC.

- Handcraft enthusiast? LS provides tried-and-true “traditional” lathes and tools.

- Need precision turning? Upload your drawings today and get an instant CNC turning quote!

Leave it to LS. We know the art of spinning and are committed to making every idea of yours – from art making to industrial design – a reality with precision and efficiency.

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Some genuinely interesting info , well written and generally user pleasant.

wonderful points altogether, you just gained a brand new reader. What would you recommend in regards to your post that you made some days ago? Any positive?

you are really a good webmaster. The website loading speed is incredible. It seems that you are doing any unique trick. Moreover, The contents are masterwork. you have done a wonderful job on this topic!

Just a smiling visitor here to share the love (:, btw outstanding layout.

Great write-up, I am normal visitor of one?¦s site, maintain up the nice operate, and It’s going to be a regular visitor for a lengthy time.