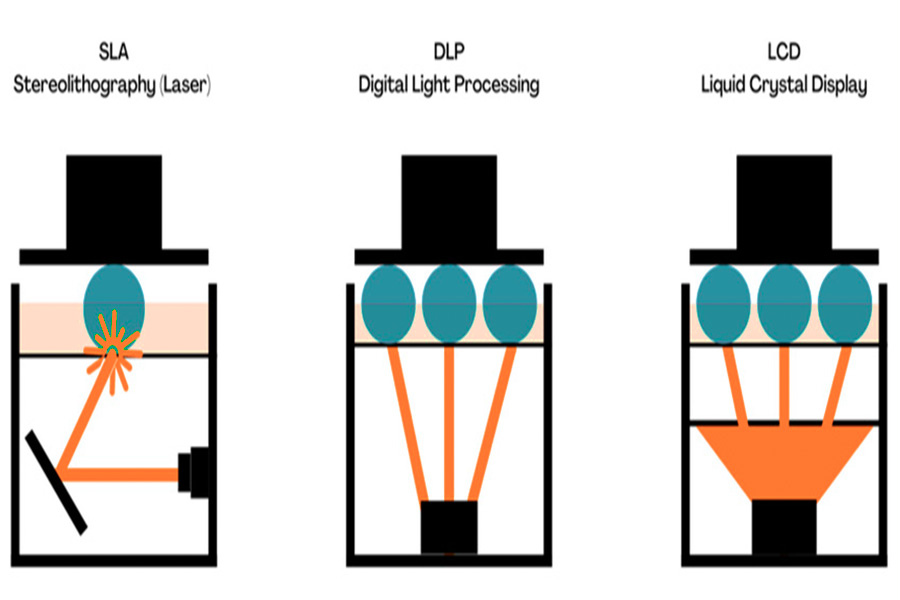

In the brilliant galaxy of resin 3D printing, SLA (stereolithography), LCD (liquid crystal photocuring) and DLP (digital light processing) are like three dazzling stars, shining together with the charm of photocuring technology. They all rely on liquid photosensitive resin as the basic material, which is triggered by light of a specific wavelength to instantly cure and shape. However, it is precisely this seemingly identical starting point that has led to completely different performance paths due to the vastly different curing methods – speed, precision, cost and even application scenarios are divided.

Among them, DLP technology stands out with its amazing printing speed and excellent detail expression, becoming the ideal choice for many professionals and companies pursuing efficiency and precision. But have you ever thought about what is the core fuel that drives this “high-speed precision engine”? The answer is DLP resin. Understanding how this material “tailored” for DLP technology, its unique chemical composition and physical properties work together with the projection light source, is the key to unlocking the full potential of DLP printers and achieving peak performance.

Comparison Of Stereolithography 3D Printing Technologies (DLP vs. SLA vs. LCD)

| Technical Features | DLP (Digital Light Processing) | SLA (Stereolithography) | LCD (Mask Stereolithography) |

|---|---|---|---|

| Light Source | Digital Projector (UV) | Single-point UV Laser | LED Array + LCD Screen (as Mask) |

| Curing Method | Whole Layer Curing – Projecting the Whole Layer Image Like a Movie | Scanning Point by Point – Drawing Finely Like Using a Laser Pen | Whole Layer Curing – LCD Screen as a “Mask” to Transmit the Whole Layer Pattern |

| Printing Speed | Very Fast (Especially Suitable for Large Area Layers) | Slower (Especially for Large Cross-section Models, Point by Point Scanning is Required) | Very Fast (Similar to DLP, Whole Layer Exposure) |

| Accuracy and Details | Very High (Depends on Projector Resolution/Pixel Size) | Highest (Laser Spot is Extremely Small and Can Be Precisely Controlled) | Good (Depends on LCD Screen Pixel Density/Resolution) |

| Light Source Life | Long (Projector Lamp Approximately 20,000+ Hours) | Longer (Laser Life is Longer) | Short (LCD screen is a core consumable, about 1,000 – 2,000 hours) |

| Equipment cost | High (common in industrial/professional grade) | Highest (traditional industrial standard, complex technology) | Lowest (mainstream consumer grade, relatively simple technology) |

| Applicable resins | UV resins that are sensitive to specific wavelengths of DLP equipment are required | UV resins that are sensitive to specific wavelengths of SLA equipment are required | Widest compatibility – most UV resins with a wavelength of 405nm are sufficient

|

- Pursuing extreme precision and details (such as jewelry, precision parts prototypes): SLA is the gold standard, but speed and cost are disadvantages.

- Need high-speed printing, high precision (not extreme), equipment durability (industrial/professional): DLP is a good balance choice.

- Pursuing cost-effectiveness, entry-level/consumer level, high printing speed requirements, and expected LCD replacement costs: LCD is the most mainstream choice, thanks to its speed and extremely low equipment threshold, but you need to pay attention to the long-term consumption cost of LCD screens.

What Is DLP 3D Printing Technology?

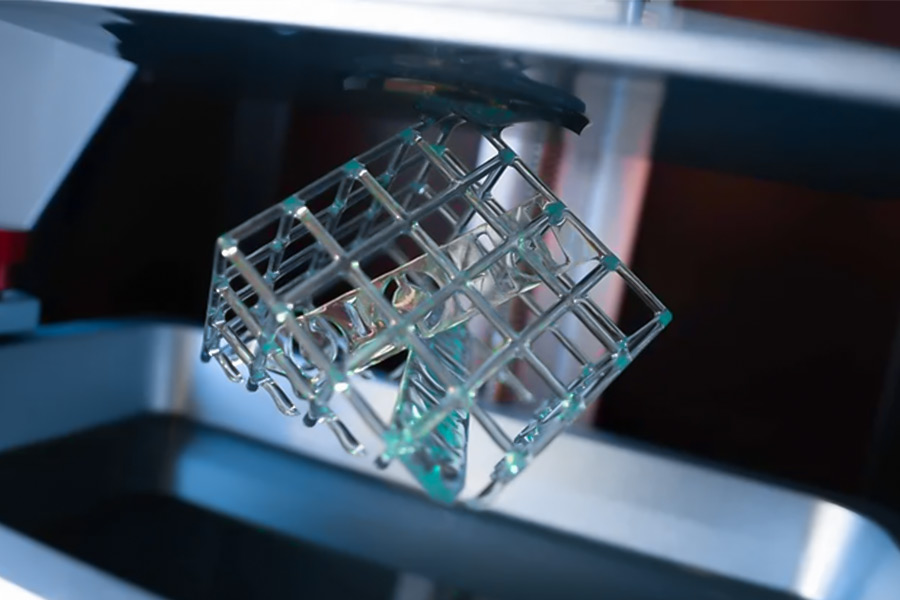

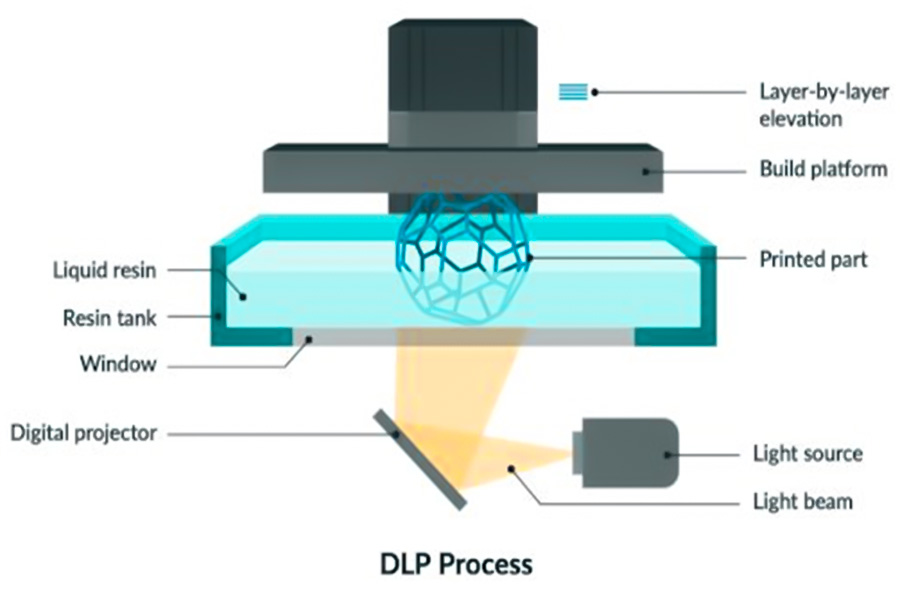

DLP (Digital Light Processing) 3D printing technology is a highly efficient Vat Photopolymerization additive manufacturing process. It uses digital light projection to selectively solidify liquid photosensitive resin, and builds up three-dimensional objects layer by layer.

1. Working principle: Projecting the whole layer for curing

- The core component of DLP is a high-resolution digital light projector (at its core, the DMD – Digital Micromirror Device), which functions like an office projector, but projects high-intensity UV light (usually 405nm).

- The software slices the 3D model into a series of extremely thin two-dimensional slices.

- The projector projects the entire image of the current slice at once onto the transparent bottom of the tank containing liquid photosensitive resin.

- The resin in the area irradiated by the UV light undergoes a photopolymerization reaction instantly, and the entire layer is cured and formed at the same time.

- The molding platform rises, allowing the new liquid resin to flow back to the bottom, then descends one layer, and the projector projects the next layer of image, and the cycle continues until the entire model is completed.

2. Core advantage: excellent printing speed

- The most significant advantage of DLP is its extremely fast speed. Whether the current layer on the printing platform contains one part or ten parts, the curing time of the entire layer is almost the same (only slightly affected by the light intensity and resin characteristics).

- This is in stark contrast to technologies such as SLA (laser point-by-point scanning), where the scanning time of SLA increases significantly as the area of a single layer increases.

- This feature makes DLP extremely efficient in producing the same or different parts in small batches. The total time required to print multiple parts is only slightly longer than printing one part (mainly the time for platform lifting and resin leveling), which is very suitable for scenarios that require rapid iteration of prototypes or small-scale manufacturing of precision parts.

3. Features: Pixelation effect and mitigation

- Since the image projected by DLP is composed of rectangular pixels, each cured layer is actually composed of countless tiny rectangular voxels.

- When printing curved or inclined surfaces, this discrete rectangular structure will form tiny step-like textures on the surface of the model, called “voxel lines” or pixelation effects. This may appear visually rough, or tiny steps may be observed at certain angles.

- Mitigation method:

- Anti-aliasing technology: This is the most commonly used method. When the software generates slice images, it intelligently adjusts the brightness (grayscale) of the pixel edges to make the solidification boundary transition smoother, effectively reduce the step effect, and significantly improve the surface finish.

- Improve resolution: Using a projector with a higher pixel density can reduce the size of a single pixel/voxel and make the steps more subtle.

- Optimize the placement angle: Adjust the direction of the model on the printing platform to minimize the situation where the large curved surface is parallel to the building platform.

DLP 3D printing technology uses a projector to solidify an entire layer of photosensitive resin at one time, achieving a printing speed far exceeding that of point scanning technology, especially in the field of small-batch production. Although its inherent rectangular pixels may cause surface voxel lines, they can be effectively improved through mature technologies such as anti-aliasing. DLP is one of the ideal choices for those who pursue efficiency, accuracy (especially Z-axis accuracy) and small-scale production.

Understanding DLP Resin: The Magic Liquid

DLP resin is a core consumable material dedicated to digital light processing (DLP) 3D printing technology. Its performance directly determines the quality and application range of the printed parts. The following are its key characteristics:

1. Core chemical composition: photosensitive polymer

DLP resin is essentially a liquid photosensitive polymer. Its formula usually contains several key components:

- Photoinitiator: absorbs light energy of a specific wavelength to initiate polymerization.

- Monomer: low molecular weight molecules that connect (polymerize) with each other under the action of photoinitiator to form the main body of the solid polymer network.

- Oligomer: short chain prepolymer, which constitutes the basic skeleton of the resin and affects the basic properties of the final material such as hardness, toughness, viscosity.

- Additives: used to impart or adjust specific properties, such as:

- Pigment: provides color.

- Toughener: improves the impact resistance and flexibility of the material.

- Other additives such as leveling agents, inhibitors, etc. are used to optimize the printing process and final performance.

2. Key features that distinguish them from SLA/LCD resins

- Higher reactivity: DLP resins generally require higher reactivity (photosensitivity) than SLA or LCD resins. This is because DLP projectors cure the entire layer at once, and the light is dispersed over a larger area, and the light intensity per unit area is generally lower than the focused laser spot of SLA or some high-power LCD light sources. High reactivity ensures fast and sufficient layer curing even at relatively low light intensities.

- Gigantic wavelength sensitivity: The photoinitiator of DLP resins must be exactly matched to the specific wavelength of UV light produced by the specific DLP projector it is being used with. The most common wavelength is ~405 nm (violet), and some industrial models use ~385 nm. This extremely tight match is a requirement for curing the resin properly, in contrast to some SLA resins that will accept a slightly wider wavelength range.

3. A large family of materials

DLP resins are far from being “one” material, but a highly heterogeneous family designed for all kinds of requirements of applications:

- Normal resins: General-purpose, good surface finish and straightforward mechanical properties, for models and show pieces.

- Engineering resins: Mimic engineering plastic-like behavior, such as ABS-like resins (good impact strength, toughness), PP-like resins (good fatigue life, chemical resistance, flexibility), high-temperature resistant resins, high-rigidity resins, etc., for functional models, snap-on parts, fixtures, etc.

- Dental resins: Meet demanding biocompatibility requirements and are used in the production of crowns, bridges, models, guides, etc.

- Resins used in casting jewelry: For investment casting, with virtually no ash remaining after burning, yielding a clean cast metal component surface.

- Others include biocompatible resins, flexible resins, filled ceramic resins, etc., which continue to expand the areas of application of DLP technology.

In short, DLP resin is a highly precise photosensitive liquid. Due to its high reactivity and stringent wavelength matchability requirements, it is made suitable for the unique curing process of DLP technology, while its large family of materials gives this technology vast application potential ranging from concept models to end product functional parts.

The Great Debate: DLP vs. SLA vs. LCD

Table 1: DLP vs. SLA

| Features | DLP (Digital Light Processing) | SLA (Stereolithography) | Core Differences |

|---|---|---|---|

| Core Principle | UV light source projects an entire layer of image through the DMD chip to cure the resin | UV laser beam scans point by point to cure the resin | Surface projection vs. point scanning |

| Speed | Fast – entire layer is exposed at once | Slow – laser needs to scan the path point by point | DLP is significantly faster |

| Accuracy/Detail | High accuracy – resolution is determined by the micro-mirrors of the DMD chip | Extremely high accuracy – laser spot is extremely small, allowing for fine detail | SLA has a higher theoretical limit |

| Trade-off Focus | Pursuing speed while maintaining high accuracy | Sacrificing speed for extreme accuracy | Speed vs. accuracy |

| Typical Applications | Dental models, hearing aids, precision parts that require speed | Jewelry prototypes, high-precision industrial parts, fine art models | |

| Equipment cost | Usually high | Usually very high |

Table 2: DLP vs. LCD

| Features | DLP (Digital Light Processing) | LCD (Mask Photocuring) | Core Differences |

|---|---|---|---|

| Core Components | DLP Projector + UV Light Source | LCD Screen (as Mask) + UV LED Array | Projector vs. LCD Screen |

| Cost Positioning | Professional/Industrial – Higher Equipment | Cost Consumer/Desktop – Significantly Lower Equipment Cost | LCD Cost Advantage |

| Light Uniformity | High – Optimized Light Path Design for Professional Projectors | Medium/Variable – Affected by LCD Panel Quality and Backlight | DLP is Usually Better |

| Service Life | Long – DMD Chip and Light Source Have Long Life | Relatively Short – LCD Screens are Prone to Aging/Burning | DLP is More Durable |

| Details | May Be Finer/Consistent – Precise Micromirror Control | High resolution is possible – but uniformity and edges may be less | DLP has slightly higher potential |

| Market Positioning | Professional applications, areas requiring high reliability and consistency | Consumer market, hobbyists, education, small studios | Professional vs. Popular |

SLA is an “artist” pursuing perfection, DLP is an “engineer” of efficiency and precision, and LCD (mSLA) is a “popularizer” promoting the popularization of technology.

Why Choose DLP for Professional Applications?

DLP technology has become the first choice for professional applications (industrial manufacturing, medical dentistry, jewelry casting, etc.) due to its unique advantages:

1. Ultra-high efficiency and mass production capacity:

DLP cures the resin by exposing the entire layer at the same time. Whether the platform is placed with one part or full of parts, the single-layer printing time is the same. Compared with point-by-point scanning technology (such as SLA/SLS), it can significantly improve mass production efficiency, reduce unit cost and delivery cycle, and has revolutionary significance for online services and large-scale production.

2. Excellent precision and surface quality:

Industrial-grade high-resolution projectors (4K/8K) achieve pixel-level precise exposure (accuracy of 25-100 microns), which can manufacture parts with fine details, strict tolerances, and smooth surfaces to meet the high requirements of engineering coordination, medical anatomy and jewelry models.

3. Excellent reliability and long life:

- Long light source life: The LED light source used by DLP has a life of up to tens of thousands of hours.

- Durable core components: The core digital micromirror device adopts a physical reflection mechanism, and its anti-ultraviolet light aging ability far exceeds that of LCD screens.

This greatly reduces maintenance costs and downtime, ensuring continuous and stable production.

4. Extensive material compatibility:

The mature 405nm photochemical system has attracted many material suppliers to develop high-performance resins specifically for DLP, including:

- Engineering resins: high temperature resistant, high toughness, flame retardant, and engineering plastic-like.

- Biocompatible resins: Meet medical standards and are used for surgical guides, dental instruments, and hearing aids.

- Casting resins/elastomers/ceramic slurries, etc. DLP’s uniform light field ensures the reliability and predictability of material performance.

With its high efficiency of full-layer exposure, micron-level precision, ultra-long life reliability, and excellent compatibility with high-end engineering and special materials, DLP perfectly meets the professional field’s stringent requirements for mass production capacity, precision manufacturing, stable operation, and material performance, making it an ideal choice for precision dentistry, customized medical, jewelry casting, and high-value-added industrial parts manufacturing.

Common Types of DLP Resins and Their Uses

Overview of common DLP resin types and their uses

| Resin type | Material properties | Main application areas | Typical industries | Key advantages |

|---|---|---|---|---|

| Standard Resin | High precision, smooth surface | General prototypes, display models, artwork | Product design, education, entertainment | Low cost, good detail performance |

| Tough/Durable Resin | High toughness, impact resistance, ABS-like | Functional prototypes, snap-ons, housings, fixtures | Engineering, manufacturing, consumer products | Simulate the mechanical properties of engineering plastics |

| Flexible Resin | Elastic, bendable, rubber-like | Seals, gaskets, flexible joints, protective covers | Industrial, consumer products, medical (non-implantable) | Simulate the elasticity of rubber/TPU |

| Castable Resin | High precision, no ash after burning | Investment patterns for casting (lost wax method) | Jewelry, dental (casting) | No residue after casting, high precision |

| Dental/Biocompatible Resin | Biocompatible, high precision | Surgical guides, temporary crowns/bridges, models | Dental, medical | Certified biocompatible, medical-grade precision |

DLP technology provides accurate and efficient solutions for prototyping, functional testing and final product manufacturing in different industries by providing a variety of specialized resin materials, from high-precision display models, tough functional parts, elastic seals to residue-free casting molds and biocompatible medical devices.

Case Summary: DLP 3D Printing Accelerates Medical Device Prototype Development

1. Customer Project: Our LS team recently assisted a medical device startup to develop a high-precision housing prototype for its innovative handheld diagnostic device.

2. Core Challenges: The customer faced three key requirements:

Fine feature presentation: The housing needs to include fine surface textures and functional snap-on structures.

Rapid iteration capability: Multiple design iterations and physical testing are required in a very short time.

Functional Verification: The prototype needs to meet the requirements of appearance evaluation and structural (especially snap-on) durability testing.

3. LS Solution:

Core Technology Choice – Digital Light Processing (DLP) 3D Printing:

Based on its high printing speed, it meets the customer’s essential need for fast iteration cycles.

With its extremely high resolution (usually up to 25-50 microns), the fine textures and intricate snap-on geometries on the housing are replicated flawlessly.

Strategic material use:

- Initial iteration (appearance/grip verification): Normal DLP photosensitive resin was selected to quickly and cheaply produce prototypes with a focus on morphology, ergonomics, and texture verification.

- Functional test iteration (clip durability verification): Switching to high-toughness DLP photosensitive resin with excellent impact resistance and fatigue resistance can truly simulate the mechanical properties of the final product clip, and perform repeated opening and closing tests.

4. Key results:

With the speed of DLP technology and the coordination of the LS team, up to 5 rounds of shell prototype versions were successfully completed in one week.

This efficiency greatly reduced the R&D cycle of the customer and effectively accelerated the design verification and optimization process.

The project fully realized the huge value of DLP technology in customized 3D printing manufacturing, especially in the development of medical device prototypes with extremely high requirements on accuracy, speed and frequency of iteration.

Through the precise selection of materials step by step and quick printing, with the functionality of the prototype ensured, the cost of 3D printing during the early stage of the project was successfully controlled.

5. Value realization of LS: This case clearly demonstrates how LS utilizes advanced DLP 3D printing technology and professional material selection strategies to solve complex prototype problems of innovative medical device customers, achieve fast, high-precision, and low-cost prototype iteration, and ultimately accelerate their product launch process.

FAQs

1. Is DLP resin toxic? How do I handle it?

Yes, DLP resin is toxic in liquid form and can cause skin and eye irritation. Use goggles and gloves when handling to avoid direct contact. Cured samples are harmless and nontoxic to work with. For waste resin, always cure it completely under UV light before disposal to prevent environmental contamination and health risk. At the same time, ensure good ventilation in the working area to reduce potential risks of inhalation. The entire handling process should be cautious to ensure personal safety and environmental safety.

2. Is it possible to use LCD resin in a DLP printer?

It is not recommended to use LCD resin in a DLP printer. Although the two’s wavelengths may be compatible, the DLP resin formula is uniquely optimized for projector light intensity, and LCD resin is optimized for screen light sources. Mixing can cause print failure, loss of detail, or mechanical property compromise, such as weak interlayer bonding or rough surface. For consistent printing results and high-quality final products, always utilize printer-compatible special resins to avoid wasting time and material.

3. Why are DLP printers significantly more costly than LCD printers?

The increased price of DLP printers mainly results from differences in light source systems. There are certain characteristics each one has that should be matched with the kind of print you are doing. DLP uses industrial-grade digital light projectors, which are more expensive but long-lasting and very precise and are, hence, well-suited for professional applications. LCD printers, on the other hand, use consumer-grade LCD displays and LED arrays, which are cheaper components but are prone to aging and low resolution. This hardware difference creates a higher initial expense for DLP, but one which is offset by advantages in speed, lifespan, and detail performance that make it well-suited for high-demanding applications.

4. What do I need to do after printing?

After printing, post-processing is necessary to get model quality. First, wash the print with isopropyl alcohol (IPA) to eliminate the excess liquid resin. Then, take off the support structure gently to prevent model damage. Lastly, secondary curing is done under UV light to completely harden the resin and enhance the final mechanical properties like strength and wear resistance. All these steps are crucial, and omission of any step can lead to a brittle model, rough surface, or functional defects.

Conclusion

DLP resin is a photopolymer resin for Digital Light Processing (DLP) 3D printing technology. It represents the perfect combination of speed, accuracy and reliability, and is a serious professional tool. The primary advantage of DLP technology is that it cures an entire layer of resin at a time via a projected light source, and does so at print speeds much faster than most other technologies.

Choosing the right materials and technologies, such as DLP resin and its technology, is crucial to efficiently transform design ideas into solid, high-precision parts in your hands – whether for rapid prototyping or small batch production.

If you are not sure which DLP, SLA or other 3D printing process is best for your project needs, take action now! Upload your CAD file to our secure online platform. Our team of experts will analyze your design, recommend the best 3D printing solution, and provide an instant quote. Let our expertise accelerate your innovation!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.