For precision milling, vertical and horizontal CNC milling machines are two basic machines. But which one will actually meet your needs in production? Vertical milling machines with vertical spindle and small body are superior in machining plates, discs, and complex curved surfaces, thus becoming a best machine in machining molds and medium and small-sized parts. Horizontal milling machines, with horizontal spindle and equipped with a precision rotary table, are capable of doing multi-faceted machining efficiently and are particularly suitable for mass production of box-shaped and large-sized workpieces, significantly improving efficiency.

The key to selecting the right machine is your basic workpiece type and size, precision need, batch size, and budget. LS, with its decades of CNC machining experience, doesn’t just provide the best vertical and horizontal CNC milling machines available, but also provides expert selection recommendations tailored to your specific application to ensure you get the most out of your investment and achieve optimal production efficiency. Contact us today and customize your ideal machining solution!

Vertical vs. Horizontal CNC Milling Machine Core Comparison Quick Reference

| Features | Vertical CNC Milling Machine (VMC) | Horizontal CNC Milling Machine (HMC) |

|---|---|---|

| Spindle Direction | Vertical | Horizontal |

| Structural Features | Compact, relatively small footprint | Complex, often equipped with a precision rotary table (B-axis), requiring a larger footprint |

| Typical Applicable Workpieces | Plates, discs, molds, small and medium-sized parts, complex curved surfaces | Boxes, large workpieces, parts requiring multi-sided machining |

| Machining Features | Suitable for single-sided, top-surface, and contour machining | Excels at multi-sided machining (machining multiple surfaces in a single clamping) |

| Production Efficiency | High efficiency for small and medium-sized batches | Extremely efficient for large-scale production (reduced clamping times) |

| Chip Evacuation | Relatively easy (gravity-assisted) | May require special chip removal devices (such as chain conveyors) |

| Machining Accuracy | High precision | High precision, typically with improved stability (better rigidity) |

| Operation and Programming | Relatively simple and intuitive | Programming and setup may be more complex (involving a rotary table) |

| Initial Investment Cost | Typically low | Typically high |

| Footprint | Typically small | Typically large |

| Core Advantages | High flexibility, low cost, easy operation, suitable for complex surfaces | Super high efficiency, good stability, suitable for large-scale box processing |

- Choose a vertical milling center (VMC): If you do a majority of small and medium-sized parts, plates, molds, or complex curved surfaces, you’re looking for low investment costs, versatile usage, and minimal floor space. Single-part or small-to-medium batch runs are your norm.

- Choose a horizontal milling machine (HMC): If you are manufacturing primarily large boxes and structural components, require multi-faceted machining in one setup, and want maximum high-volume production efficiency, high stability, and long-term machining consistency, you can afford a greater upfront investment and footprint.

Not sure what milling machine is appropriate for your manufacturing needs? LS experts can lead you to the best solution! Simply inform us on what kind of workpiece, how big, and precision level you require, as well as volume you would like to make and budget, and we will provide professional selection advice and optimal value solution.

Obtain free, customized milling machine selection planning!

Why Trust This Guide? Real-world Insight By LS Experts

Amidst the ocean of CNC milling machine choice data available today, you need reliable, field-tested information from hands-on experience. This guide and comparison chart rely on decades of hands-on experience from LS’s essential engineering personnel and industry application experts:

- Comprehensive Industry Knowledge: With over 20 years of experience in CNC machine tools, LS has been privileged to have worked with over 8,000 customers and has a firm understanding of the true application needs and issues in the wide-ranging industries of automotive parts, aerospace, molds, and general machinery.

- Extensive Equipment Application Experience: Our experienced personnel have directly participated in the commissioning, installing, process optimization, and production problem-solving of thousands of vertical and horizontal CNC milling machines and therefore have an intimate understanding of their performance limits, available applications, and best practices.

- Ongoing Technical Insights: LS does not just provide equipment but also focuses on process innovation. We monitor the new technology developments on a regular basis so that this guide reflects the current market trends and best practices for efficient production.

- Objective, Practical Guidance: Our sole aim is to help you make the right choice best appropriate to your production needs and economics. We don’t sell you; we match you.

LS’s seasoned guide will guide you through selection and guide you to successful production.

Stuck choosing what’s right for you? Consult an LS expert today for a personalized review of your specific needs! Get special selection advice, courtesy of LS!

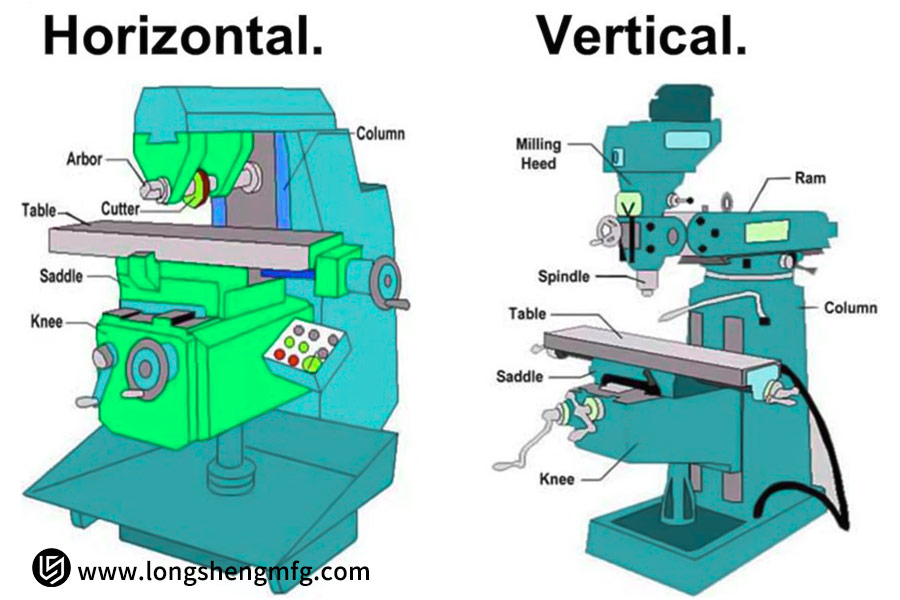

What Are Horizontal And Vertical CNC Milling Machines?

1. Vertical CNC Milling Machine

Structural Features:

This is the simplest and most common type of CNC milling machines. Its distinguishing feature is that the spindle axis (that is, the tool rotation axis) is orthogonal to the worktable.

- The spindle head is mounted on a vertical guideway (Z-axis) and can move up and down.

- The worktable can move horizontally (X and Y axes) forward, backward, left, and right.

- The workpiece is fixed to the worktable, and the tool cuts in a vertical downward direction from above.

Main Advantages:

- Simple structure and low cost: Since they are comparatively mature in design and production, new and small-and-medium-sized machines are usually less costly than comparable horizontal milling machines.

- Easy operation and monitoring: It is convenient for the operator to observe the workpiece, tool, and machining process from the top, and easy clamping, setting, and observation can be ensured.

- Low floor space utilization: Smaller than most horizontal milling machines, they have low floor space utilization.

- Simple clamping: For pieces such as plates, discs, and molds, clamping is relatively simple.

- Tool change at speed: Modern vertical machining centers are typically equipped with efficient tool magazines and tool changers (ATCs), which result in quick tool change times.

Main Disadvantages:

- Chip evacuation: Chips are prone to accumulate on the workpiece surface and in the machining area, which can affect machining accuracy, tool life, and surface finish. Any appropriate coolant flushing or air evacuation is essential.

- Machining capacity limits: One setup can machine the top and side surfaces of a piece of work (this can be in a rotary table or angle head, but that is not normal). This is not as efficient in machining the complex operations that have multiple vertical surfaces, such as box-type pieces.

- Rigidity Limitations: Cantilevered constructions (where the spindle is projecting beyond the worktable) are not always as rigid as the column base construction of a horizontal machine tool when subjected to very high cutting forces or in heavy cutting.

2. Horizontal CNC Milling Machine

Structural Features:

The spindle axis of this type of machine tool is parallel to the worktable (i.e., horizontal).

- The headstock is attached to a horizontal guideway (Z-axis) and has the ability to move horizontally in both directions.

- The worktable typically moves along the X and Y axes, and most importantly, the worktable (or spindle head) will generally rotate around the vertical axis (B-axis) (90 degrees, 180 degrees, or continuously). Most horizontal machining centers are also equipped with a pallet system, allowing one to clamp workpieces outside the cutting area, thus reducing the time consumption.

- The workpiece is held against the worktable, and the tool cuts horizontally from the side of the workpiece.

Main Advantages:

- Multi-Surface Machining Capability: This is the greatest strength of horizontal machine tools. A worktable that can be rotated (B-axis) enables more than one surface (top, side, and even bottom) to be machined within a single clamping, which is most applicable for complex parts such as boxes and housings. This significantly reduces the number of clampings, improving machining accuracy (reducing errors caused by multiple clampings) and efficiency.

- Good Chip Evacuation: Chips gravitate downwards naturally from workpiece and tool, maintaining machining area cleanliness and minimizing machining quality, tool life, and machine stability issues.

- Good Rigidity: The structure is stiffer (column-supported) and can withstand higher cutting forces and support heavy and high-speed cutting.

- Suitability to Automated Manufacturing: The pallet changer is part of the horizontal machine structure, hence an appropriate alternative for unmanned operation or flexible manufacturing cells (FMC/FMS).

Main Disadvantages:

- Complex Structure and High Cost: The structure is complex and higher in price than similar vertical machines.

- Long Footprint: Has a broader installation area, especially those with tall pallet changer.

- Somewhat Difficult to Operate and Observe: The machining area is less intuitive than in a vertical machine, and tool setting and internal machining operations may require the monitoring of a camera or dedicated window.

- Programming Could Be More Complex: Multi-axis correspondence (especially with B-axis rotation) and pallet control complicate programming and setup.

Processing Needs Dictate Machine Model Selection – Starting With Part Type

The basic reason for choosing a vertical or horizontal CNC milling machine is the processing needs (specifically the type of part). Here below we start from the part type and consider in detail how to make a model choice on the basis of the processing needs:

I. Typical part types and recommended machine models

1. Part types for vertical CNC milling machines

(1) Plate/disc parts

Features: Dimensions of width and length are significantly higher relative to thickness (such as mold inserts, end covers, flanges, PCB board fixtures).

Reason: Main processing surfaces are concentrated in one plane or shallow cavity. Top-down processing strategy of the vertical machine tool is highly effective and the clamping is self-evident.

(2) Molds (especially cavities/cores)

Features: Highly complex 3D surfaces, high material hardness (such as injection molds, die-casting molds, and stamping molds).

Reason: Convenient to observe tool paths and surface features in the vertical structure, and high-precision spindle can suit fine engraving; side milling heads are suitable for longer angle processing using the open structure.

(3) Simple small and medium-sized parts

Features: Simple structure, only 1-2 surfaces need to be machined (e.g., brackets, small enclosures, connectors).

Reason: Low cost and quick tooling change, good for prototype trials or small batches.

(4) Top surface as principal feature

Features: Features are centralized on the top (e.g., panel slots, surface engraving).

Reason: No need to turn over the workpiece, once clamping.

2. Part types that prioritize horizontal CNC milling machines

(1) Box/shell parts

Features: Some surfaces have holes, grooves, and bosses (e.g., engine cylinders, gearbox casings, hydraulic valve blocks, and pump bodies).

Reason: The biggest advantage of horizontal CNC milling machines! The top surface and the four side surfaces can be machined at once by way of the rotary table (B axis), with position accuracy and reduced clamping time.

(2) Parts which require high-precision matching on various surfaces

Features: There are stringent position tolerance requirements for every surface (such as precision fixture bases and robot joint components).

Reason: Prevent the reference error caused by multiple clampings and keep more than one surface in a processing in the relationship.

(3) Long parts

Features: High aspect ratio (such as guide rails, bushings, and long frames).

Reason: Horizontal clamping can achieve better stability, and long-distance milling can be completed by transferring the worktable.

(4) Parts produced in bulk

Features: continuous 24-hour operation and mature technology.

Reason: in conjunction with the pallet pool system, the workpiece can be clamped externally, the machine tool can process continuously, and the efficiency is doubled.

II. Major Part Features and Machine Model Matching Analysis

| Part Features | Vertical Milling Machine Suitability | Horizontal Milling Machine Suitability | Choice Criteria |

|---|---|---|---|

| Number of Machining Surfaces | 1-2 Surfaces | ≥3 Surfaces | Horizontal milling machine for multi-surface machining |

| Structural Complexity | Medium-low complexity | High complexity | Horizontal milling machine for complex housings |

| Length-to-Diameter Ratio (L/D) | Low (plates/cubes) | High (long rods/housings) | Horizontal milling machine for long parts, more stable |

| Chip Removal Difficulty | Difficult (prone to accumulation) | Easy (gravity chip removal) | Horizontal milling machine for deep cavities/cast iron |

| Production Volume | Single piece/small batch | Medium-large batch | Batch + Automation Select Horizontal + Pallet System |

| Positioning Accuracy Requirements | Moderate | Extremely high (multi-surface matching) |

Horizontal milling machine is essential for high-precision multi-surface machining

|

Final Recommendation:

“Three plates and one mold, use vertical machine; multi-sided boxes, use horizontal machine; long, heavy cuts, hard to take out chips; horizontal machine, sure winner.”

(“Three plates and one mold”: plates, discs, panels + molds)

Machine Matchup Reasoning for Automotive/Aerospace/Medical Parts

For automotive, aero-space, and medical device manufacturing industries, vertical and horizontal CNC milling machine choice has to strictly adhere to part-specific needs, production levels, and quality required. A reason guide for matching machines to industry scenarios is given below:

1. Automotive Manufacturing

Typical Parts: Engine Blocks/Cylinder Heads, Transmission Housings, Chassis Structures

Pain Points and Requirements: High Volume Production, High Cycle Time, Multi-Surface Machining

Machine Choice:

Horizontal Milling Machine (First Option):

Benefits: Unmanned round-the-clock operation is achieved with the implementation of an Automatic Pallet Changer (APC) system, and five surfaces are machined (excluding the bottom) in a single fixture with over 40% cycle time reduction.

Case Study: Volkswagen EA888 engine block production line consists of a sequence of horizontal machining centers with a daily capacity of over 1,000 parts from a single line.

Vertical Milling Machine (Supplementary Role):

Applications: Small parts (e.g., sensor brackets), single-blank machining in repair shops.

2. Aerospace Industry

Typical Parts: Aircraft wing ribs, landing gear frames, engine components, titanium alloy assemblies

Pain Areas and Requirements: Complex structures, difficult-to-machine materials, and high stiffness requirements

Machine Selection:

Horizontal Milling Machine (Ideal for Heavy Parts):

Advantages: X-axis moving >5m, spindle torque >200Nm, adaptive for deep groove milling of high-temperature alloy and titanium alloy; stable workpiece center of gravity, avoiding vibration in machining of big-sized workpiece.

Case Study: Machining of Boeing 787 fuselage frame titanium alloy on Giddings & Lewis horizontal milling machine, deformation error <0.05mm.

Vertical Five-Axis Milling Machine (Supplementary for Curved Parts):

Applications: Precise contour machining of complex curved parts such as impellers and casings on A/C axis swing.

3. Medical Device Manufacturing

Example Parts: Orthopedic Implants (Hip/Knee), Surgical Instrument Housings, Imaging Device Parts

Pain Points and Requirements: Small Precision Parts, Biocompatible Materials (Titanium/Cobalt-Chromium), Mirror Polishing

Machine Selection:

Vertical Milling Machine (Absolutely Mainstream):

Advantages: Spindle speed > 20,000 rpm (to support very small tools), ±0.003mm accuracy positioning, and high-pressure coolant system for burr-free cutting of titanium alloy.

Case Study: Johnson & Johnson’s line of orthopedic implant products uses a Hermle five-axis vertical milling center with surface finish of <0.2μm (Ra).

Horizontal Milling Machine (Special Requirements):

Application: High-volume production of large medical device enclosures (e.g., CT gantry).

Horizontal machines are the option for automotive uses where efficiency is critical; horizontal machines are the option for aerospace uses where rigidity is critical; and vertical machines are the option for medical uses where precision is critical. The ultimate decision has to be made on a holistic basis of process focus, return on investment (ROI > 20%), and supply chain coordination requirements (e.g., just-in-time manufacturing).

How To Choose A Horizontal vs. Vertical CNC Milling Machine?

Whether to choose a vertical or horizontal CNC milling machine hinges largely on your particular machining application:

- Choose a vertical: If you machine primarily plates, plates, molds, and other features, are short on money and shop space, or if your machining jobs consist primarily of one side or more sides, and convenience of operation is of prime concern, a vertical machine is the cost-effective solution.

- Choose a horizontal: Machining complex boxes or housings: If you require high-precision machining of multiple sides in a single setup, and you desire increased productivity and automation (e.g., with FMS), and your budget and floorspace allow it, the advantages of multi-face machining and overall efficiency benefits provided by a horizontal machine are immense, especially in large volumes.

In brief: Need multi-sided machining, chip removal, stiffness, and automating? Choose a horizontal machine. Cost-saving, simplicity, and the ability to machine relatively complex parts wanted? Choose a vertical machine.

LS Actual Case Sharing: Customers Save And Optimize In What Ways?

Case 1: A car part supplier chose a horizontal milling machine (HMC) to mass produce efficiently.

Pain point: High-volume (200,000 pieces a year) production of multi-sided aluminum alloy engine brackets. Multi-setup vertical machining was not economical and not consistent.

LS recommended solution: Single horizontal machining center with automatic pallet changer.

Efficiency savings:

- Efficiency up high: Time per piece decreased by >60%, doubling capacity.

- Manpower savings: Operator decreased by 50%.

- Quality improvement: Scrap rate decreased by ~70%.

- Long-term savings: While the upfront cost was significant, the payback period was 18 months of labor savings, reduced scrap, and added capacity. The total cost of ownership over the long term was far lower than that of a number of vertical machining centers.

Major reasons for selection: Multi-sided + high-volume machining → The “single setup” advantage of a horizontal machining center is attractive, and automation provides justification for the high price.

Case 2: A Precision Medical Component Manufacturer – Choosing a Vertical Milling Machine (VMC) to Support Flexible and Variable Needs

Pain Points: Low volume of production, wide mix of high-precision medical parts, rapid design changes, and limited budget. Horizontal mill is expensive and time-consuming to modify and thus uneconomical.

LS Recommended Solution: High-speed vertical machining center (optional fourth axis).

Cost-Saving and Efficient:

- Controllable Investment: Equipment cost is merely ~40% of high-end horizontal milling machines, without idle capital.

- Flexibility and Efficiency: Simple changeovers allow for simple processing of small series and mixed order lots, and simple addition of new parts.

- Space-Saving and Ease of Use: Perfect for small workshops, simpler operation and programming, and lower technical entry barrier.

- Critical Selection Reasons: Small lots + high mix + flexibility first + budget-conscious → Low cost and high flexibility of a vertical milling machine are perfect, optimizing capital efficiency.

In conclusion of the cost-cutting and efficiency key points:

- Think about the part & lot size:

- Multi-sideded + high-volume → Horizontal MNC (buy expensive, use cheap): Automation and single-clamping save labor and time, improve quality, and levelize costs.

- Small batch sizes/double/single-sided or numerous varieties → Vertical MNC (buy cheap, use efficiently): Avoid horizontal networks of over-investment and under-use by MNCs and create flexibility to respond to change easily.

- Think in terms of total cost and not unit cost: It is a balance of initial investment + labor + loss of efficiency + costs of quality + costs of space. A horizontal MNC will have greater unit cost but lesser cost overall, and a vertical MNC gives lesser initial load.

- Everything fits: There is no such as absolute good or bad; it’s a matter of what works best for your part details, amount of manufacturing, price segment, and business model.

LS Precision: Your Best CNC Machining Partner

Purchasing high-end CNC equipment, such as horizontal machining centers, can be an enormous investment. With professional CNC machining services, you can gain world-class manufacturing capability and production solutions that are tailored to your needs without the excessive acquisition and maintenance expenses.

LS Precision is your partner. Not only do we possess our own in-house state-of-the-art CNC machining facility (with vertical, horizontal, and multi-axis precision equipment), but we also possess a team of veteran engineers who are well versed in global manufacturing standards and process optimization. We machine more than to print; we apply Design for Manufacturability (DFM) to refine your design, select material, and develop the most cost-effective and efficient machining processes, providing you with peace of mind and cost savings.

Benefit from the speed and convenience of LS Precision:

- Professional Process Optimization: Upload your CAD design, and our engineers will examine and provide optimization proposals to reduce your costs and achieve maximum yield.

- Intelligent Instant Quotes: Through our user-friendly online manufacturing platform, upload your file and get a clear quote in no time based on the optimized solution.

- End-to-end quality control: Founded on our own factory’s strict quality control system and advanced equipment, we ensure every product up to your high standards.

FAQs

1. Are horizontal CNC milling machines more advanced than vertical ones?

Horizontal CNC milling machines are not necessarily more advanced than vertical ones, as they are designed for different processing requirements: horizontal machines are suitable for large-volume, multi-sided processing (e.g., automotive parts), improving efficiency and precision; vertical machines are suitable for small-volume, simple parts (e.g., molds), offering greater flexibility and lower costs. There is no such thing as absolute superiority or inferiority; the key is to match specific requirements of production, i.e., part complexity, volume, and budget, to achieve the best value for money. One should carefully choose, not necessarily looking for “higher-end” equipment.

2. I only have some small parts. Is a horizontal machine a worthwhile investment?

A horizontal CNC milling machine is not a worthwhile investment. For a limited component range and small batch sizes, vertical CNC milling machines offer a lower initial investment (starting at over 100,000 yuan for the entry level), operational costs (e.g., electricity and maintenance), and space. Vertical machines are straightforward to operate and highly flexible, making them ideal for small-scale production. Although horizontal machines are productive, they are expensive (starting in the millions for low-end mid-range machines) and require complex maintenance and thus are cost-effective for high-volume production alone. We recommend concentrating on vertical machines for return on investment maximization.

3. What is the cost range for vertical and horizontal CNC milling machines?

Prices vary widely, depending on specifications, make, and configuration. VMCs start at an entry level of around 100,000 RMB, with mid-range standard machines costing hundreds of thousands. HMCs are considerably more costly (entry-level prices start in the hundreds of thousands), and mid-range standard machines will typically be millions or greater. Twice that can be anticipated for premium models or specialized configurations (e.g., automatic tool changers). During buying, negotiate with the supplier according to your specific need to obtain a fair quote.

4. Does LS provide selection guidance and equipment support solutions?

In fact, LS provides single-source selection consulting and equipment support services, including needs assessment, equipment selection (e.g., vertical vs. horizontal consideration), machining process planning, ancillary tooling (e.g., fixturing and software), and technical support. Our personnel adapts solutions to your part type, production level, and budget to help maximize production efficiency and control costs, so your equipment investment is optimally aligned with your actual needs.

Conclusion

Choosing a vertical or horizontal CNC milling machine is more than a simple equipment comparison; it’s a strategic decision that impacts production efficiency, cost control, and long-term competitiveness. Through the analysis in this article and real-world cases from LS Precision, we clearly see the following:

- Vertical Machining Centers (VMCs): Their advantages lie in flexibility, cost-effectiveness, and a small footprint. They are best suited for small-batch, high-mix, complex curved surfaces, and single- and double-sided machining (such as prototypes and precision parts). They offer low initial investment and convenient operation.

- Horizontal Machining Centers (HMCs): Their core value lies in the efficiency and superior rigidity of “one-setup, multi-sided machining.” They are irreplaceable for the large-scale production of large-volume, multi-faceted parts (such as housings and valve bodies). While the initial investment is high, the long-term cost per part is lower .

LS Precision Insight: The secret to cost-saving and efficiency lies in a deep understanding of part characteristics, production scale, and total cost of ownership (equipment, labor, efficiency, and quality), rather than simply comparing equipment prices.

Choosing LS means more than just equipment or services. We offer manufacturing optimization experts:

- Professional selection consultants: Data-driven, helping you make accurate decisions.

- Design, Function, and Manufacturing (DFM) optimization: Reduce costs and improve efficiency from the source.

- Top-tier CNC machining services: No need to purchase machines. Enjoy high-end equipment, sophisticated craftsmanship, and optimized production solutions, achieving true cost savings and efficiency.

Contact an LS expert today or submit your design online to receive your customized, efficient solution!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

I simply could not go away your web site prior to suggesting that I really enjoyed the standard info a person supply on your guests Is going to be back incessantly to investigate crosscheck new posts

Its like you read my mind You appear to know a lot about this like you wrote the book in it or something I think that you could do with some pics to drive the message home a little bit but instead of that this is fantastic blog An excellent read I will certainly be back