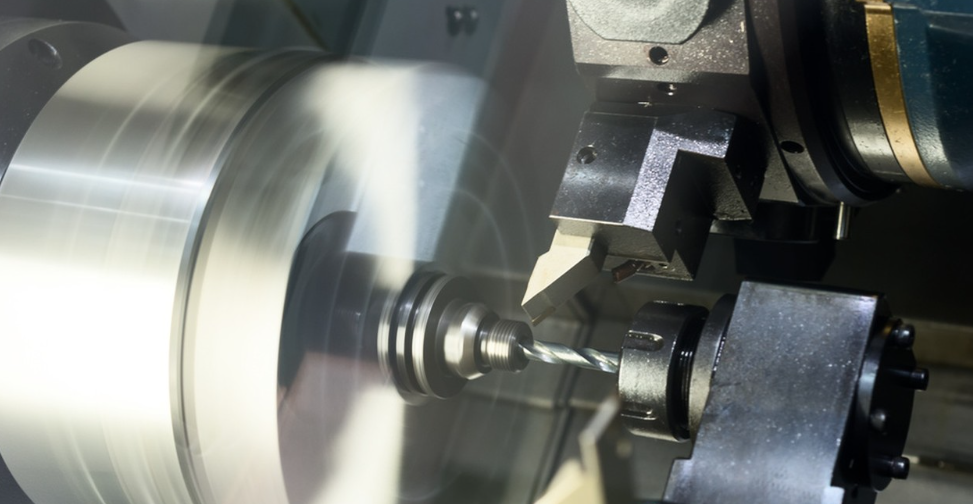

When it comes to manufacturing, there are two main methods of machining: traditional and CNC machining. While traditional machining has been the go-to method for many years, CNC machining has been gaining popularity due to its numerous advantages. In this article, we will discuss the advantages of using CNC machine equipment as opposed to traditional machining.

Precision

CNC machining offers a higher level of precision compared to traditional machining. CNC machines are programmed to make precise cuts and movements, leading to more accurate and consistent results. This precision can be especially important in industries such as aerospace and medical, where even the smallest error can have serious consequences. CNC machines are capable of producing parts with tolerances as tight as 0.005mm, which is much more precise than what traditional machines can achieve.

Efficiency

CNC machines are automated and can work continuously, which means they can produce a high volume of parts in a shorter amount of time compared to traditional machines. Additionally, CNC machines require less human intervention, reducing the risk of errors and increasing overall efficiency. This means that manufacturers can produce more parts with less resources, which is essential for staying competitive in today’s fast-paced manufacturing industry.

Flexibility

CNC machines can be programmed to produce a wide variety of parts, making them more flexible than traditional machines. This means that manufacturers can quickly switch production from one part to another without having to retool the machine. CNC machines also allow for more complex shapes and designs, which can be difficult or impossible to achieve with traditional machining. This means that manufacturers can take on more complex projects without having to invest in new machines or tools.

Cost-effectiveness

While the initial cost of CNC machines may be higher than traditional machines, they can save money in the long run. CNC machines require less labor and produce less scrap material, reducing overall production costs. They also require less maintenance, leading to lower maintenance costs. By reducing labor and material costs, CNC machines can help manufacturers improve profitability. Additionally, CNC machines can produce parts with higher accuracy and consistency, which can reduce the need for rework and scrap, further reducing costs.

Quality

CNC machines produce parts with higher accuracy and consistency compared to traditional machines. This means that the parts produced by CNC machines are of higher quality, which is essential for industries such as aerospace and medical. CNC machines can also perform quality checks during the production process, ensuring that the parts meet the required specifications. This means that manufacturers can produce parts with confidence, knowing that they meet the required quality standards.

Sustainability

CNC machines produce less scrap material compared to traditional machines, which means that they are more sustainable. Additionally, CNC machines can be programmed to optimize material usage, further reducing waste. This means that manufacturers can reduce their environmental impact while also improving their bottom line.

Conclusion

In conclusion, CNC machine equipment offers numerous advantages over traditional machining. These advantages include higher precision, efficiency, flexibility, cost-effectiveness, quality, and sustainability. As a result, many manufacturers are switching to CNC machining to stay competitive in their respective industries. If you’re looking to improve your manufacturing capabilities, consider investing in CNC machine equipment.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items