5-axis CNC machining overcomes the manufacturing obstacles of complex and precision parts. Unlike 3-axis machining, which is inefficient due to limited degrees of freedom, error accumulation, and multiple clamping operations, 5-axis technology enables omnidirectional cutting in a single setup. This fundamentally eliminates repetitive positioning errors and provides the ultimate solution for complex surfaces and stringent tolerances.

It is not only the technological upgrading but a strategic change in thinking of manufacturing; it therefore gives more space to optimization for the design of parts and turns the limitations that used to exist in machining into performance advantages. We will see how 5-axis machining, innovative in its capabilities, is giving every aspect the needed push toward successful and efficient production cost control.

5-Axis CNC Machining Quick Reference Table

| Modules | Key Points |

| Technical Definition | Refers to CNC machining technology where a machine tool can coordinate movements in at least five degrees of freedom for cutting. |

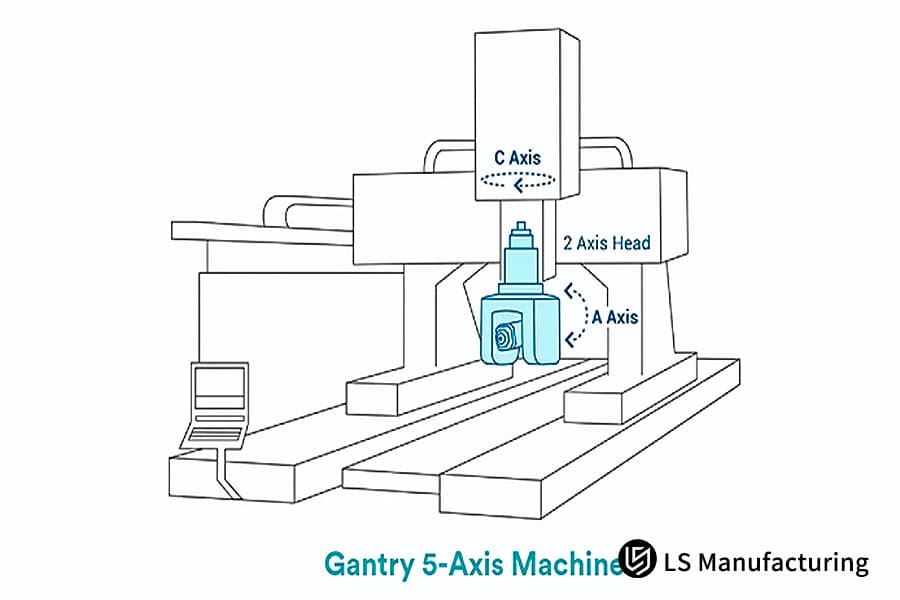

| Core Structure | Mainly divided into three common structural forms: double rotary table, double swivel head, and one rotary table and one swivel head. |

| Core Advantages | Complete multi-face machining of complex parts in a single setup, ensuring high precision and excellent positional accuracy. |

| Precision is Key | Reducing the number of setups fundamentally avoids the accumulation of repeated positioning errors. |

| Efficiency Improvement | Shorter tools can be used for complex curved surfaces, achieving high speeds and large feed rates, shortening the time per piece. |

| Cost Impact | Although the cost per machine is high, the overall manufacturing cost is reduced by decreasing processes, fixtures, and scrap rates. |

| Design Liberation | Enables engineers to design more complex, lightweight, and functionally integrated high-performance parts. |

| Applicable Fields | Complex parts such as aerospace impellers/blades, medical equipment manufacturing, automotive molds, and energy equipment. |

| Programming Challenges | Requires professional CAM software and post-processing, and consideration of tool interference and collision avoidance. |

| Success Factors | Relies on precision CNC machine tools, professional process planning, high-level programming, and experienced operators. |

| Selection Considerations | Requires a comprehensive evaluation of part complexity, precision requirements, batch size, and total return on investment. |

5-axis CNC machining involves more than just an upgrading of equipment; it represents a jump in manufacturing philosophy. The “one-time clamping, complete forming” systematically solves the trade-offs of precision, efficiency, and cost. As it requires higher technical expertise and initial investment, the gains in terms of accuracy, design freedom, and overall production economics make it a key tool for competition in high-end manufacturing. It means a pathway to sustainable excellence through technological advancement.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

Not only are they complicated drawings, but they are also a direct challenge to high-strength alloy materials, tight tolerances, and multi-dimensional surfaces. Herein, process knowledge has determined direct success or failure: the contour accuracy of the complex structural parts that we machine for aerospace guarantees flight safety; the surface quality of the implant surfaces we manufacture for medical devices affects patients’ recovery. Every cut is a severe test of reliability.

Actually, we have made tens of thousands of high-precision parts using 5-axis CNC in the last decade alone. Our process has been refined with countless successes and early trial-and-error processes. It always considers appropriate operational safety and environmental compliance, always strictly following all requisite safety protocols such as Occupational Safety and Health Administration(OSHA) and all environmental guidelines from the US Environmental Protection Agency(US EPA).

That means every recommendation you read in here has been checked and rechecked with chips, coolant, and dial indicators. By choosing this guide, you tap into the cumulative, practical wisdom that lets you directly bypass the common pitfalls and robustly and efficiently turn your designs into robust, precision parts.

What is 5-axis CNC machining? How does it achieve one-time machining of complex parts?

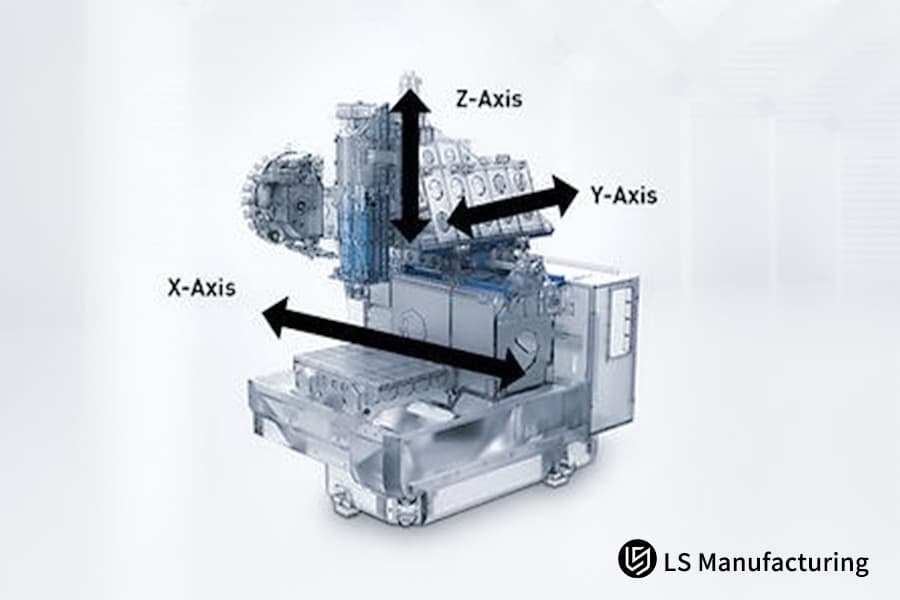

Compared to the conventional 3-axis machine tool, 5-axis CNC machining combines basic X, Y, and Z linear motion axes with two additional rotary axes, generally two out of the A, B, and C axes, enabling cuts to the workpiece surface from almost any direction. This multidimensional linkage ability is the basis for “one-time clamping, complete forming” of complex geometries. The very core advantage of 5-axis CNC machining emanates from its working method:

- Performing Complex Surface Machining: This will enable it to machine parts with deep cavities, steep walls, or a continuous smooth free-form surface efficiently and accurately, which is difficult to achieve with a traditional 3-axis machine tool. Typical examples of such applications are impellers, turbines, and precision moulds.

- Ensuring ultra-high overall precision: One-time clamping is the revolutionary significance of 5-axis CNC machining, which completely avoids the repeated positioning error brought about by multi-clamping and lays the foundation for ensuring the relative positional accuracy of complicated features on the part while greatly reducing specialized fixture usage and clamping adjustment time.

- Optimizing Machining Efficiency and Quality: Due to the flexible adjustment of the tool orientation in a cut, a shorter and more rigid tool can be used, thus increasing stability and speed; hence, better surface quality and longer tool life can be attained.

5-axis CNC machining, often introduced by the question, “what is 5-axis CNC machining?,” is a manufacturing method that, through two added rotary axes, enables complete part processing in a single setup. This achieves an optimal balance of precision, efficiency, complex shape capability, and total cost, making it a key enabling technology for transforming advanced designs into realizable products.

5-axis or 3-axis machining? What are the key decision factors?

The key to choosing between 5-axis vs 3-axis CNC lies in clearly defining the project’s needs, rather than comparing technologies. Any time complex surfaces, multi-angle features, or stringent overall tolerances are part of a design, selecting a 5-axis CNC machining service becomes a core decision that directly impacts project success and total cost.

| Decision Dimensions | 3-Axis CNC Machining | 5-Axis CNC Machining |

| Geometric Complexity | It is suited for parts with simple geometric features like prisms, planes, and simple cavities. | Intricate 3-D geometries, such as multi-faceted features, free-form surfaces, deep cavities, and inclined holes can be completed in one clamping operation. |

| Production Batch | Much cheaper to make medium-sized to large batches of standard parts as fixture costs will be well spread. | In relation to producing in small batches, multi-variety, high-value, complex parts such as molds and medical implants are very advantageous and enable fast changeover. |

| Accuracy and Tolerance Requirements | While it is possible to get high precision on one surface, the sum of repetitive positioning errors resulting from multiple clamping operations in the course of processing directly impinges on the relative positional accuracy between a number of surfaces. | Most features can be completed with the assurance that one clamping operation fundamentally avoids the repetitive positioning error, ensuring rigorous overall geometric relationships and high demands with regard to tolerance. |

| Surface Quality | Performs well on planes and regular curved surfaces, while in the case of complex curved surfaces, machining efficiency and surface finishing are limited. | Because of optimization of tool angles, shorter tools can be used for efficient finishing and hence provide better surface quality and consistency. |

| Total Cost Consideration | Generally, equipment, programming, and labor costs are lower; however, on complicated parts, many machines are needed, with several clamping operations with increased time for dedicated specialized fixtures, besides debugging time to turnaround the project. | Although unit cost is higher, it may considerably reduce the overall manufacturing cycle of complicated parts, such as an aerospace structural component from 5 hours to 1.5 hours and decrease the need for specialized fixtures, which on the whole helps make it cost-effective. |

The selection of 5-axis CNC services balances part complexity with precision and total cost. While 3-axis machining is generally suitable for most conventional parts, 5-axis excels in dealing with complex geometries, tight multi-face tolerances, or small-batch rapid delivery. It often achieves superior overall economics because of shorter lead times, higher first-pass yield, and lower tooling costs, all because this technology allows the reliable translation of innovative designs.

What are the major purposes of 5-axis CNC machining in aerospace and medical devices?

Traditional manufacturing cannot meet either the geometrical complexity or performance requirements of today’s precision parts. 5-axis CNC machining is designed to solve these issues by enabling the creation of multiple facets in one clamping. Looking deeper into 5-axis CNC applications,, it becomes obvious that, in particular, aerospace and medical devices find this not an option but a necessity for core performance and extreme reliability.

| Application Domains | Key Functions and Typical Applications |

| Aerospace | While manufacturing impellers and blades of complex aero-engines, the high precision forming of the complicated aerodynamic surface is implemented, with guarantees regarding the thrust-to-weight ratio and extreme reliability. |

| Perform machining for large fuselage structural parts and lightweight frames. Finish cutting multiple-angle features in one clamping to assure the integrity and strength of the part structure. | |

| Manufacturing flight control components to high precision, like linkages and joints, falls under tight tolerances in both dimension and performance of materials. | |

| The field of medical devices | The fabrication of artificial joints, such as acetabula and femoral stems, allows the realization of complex biomimetic surfaces perfectly matching those of the human skeleton and ensures the biocompatibility of implants. |

| Processing high-precision, multi-axis, movable surgical instruments and orthopaedic tools that can meet extreme requirements of flexibility and reliability with minimally invasive surgery. | |

| Manufacturing customized medical components, such as personalized craniofacial implants, uses 5-axis CNC machining to fabricate highly accurate replications of patient anatomy. | |

| Materials and Performance Contributions | It meets the requirements of weight reduction and strengthening in the aerospace field by giving full play to the performance potential of advanced materials represented by titanium alloy and high-temperature alloy. |

| Ensuring medical devices have implant-grade materials with a mirror finish, such as cobalt-chromium alloys and titanium alloys, while sterility and biocompatibility are maintained. | |

| Demonstrated LS Manufacturing Capabilities | It has demonstrated its mature 5-axis CNC machining technology in complex parts through real-world machining examples of complicated curved bladed disks and personalized artificial joints. |

5-axis CNC machining redefines high-precision manufacture, from assuring extreme reliability and performance in aerospace applications to translating sophisticated engineering into life-enhancing solutions in medical devices. In any case, the mastery of this 5-axis capabilities will be necessary for companies aiming to keep pace globally in turning cutting-edge design into realizable, high-value products.

How to assess the real capability level of a 5-axis CNC machining service provider?

Choosing a 5-axis CNC machining service means evaluating a supplier’s actual capability, and not just the ability to make parts but meet performance, reliability, and cost goals. An ideal supplier acts as a solution partner, integrating advanced equipment, process expertise, and engineering insight. For structured guidance on this process, how to choose 5-axis CNC services is thoroughly outlined in the LS Manufacturing 5-axis guide. Below are key dimensions to assess when choosing a collaborative partner.

- Equipment and Technical Strength: Verify their 5-axis machine tools, with brand and model, quantity, condition, whether equipped with Renishaw online probes, tool setters, tool magazine capacity, and multi-axis CAM software. Advanced hardware is the basis while the advanced online inspection technology guarantees “processing is qualified” closed-loop quality control.

- Industry Experience and Process Accumulation: Review past success stories within your specific industry, such as aerospace or medical devices, where projects involve the machining of intricate, high-value components. The fact is, this directly reflects a team’s practical ability to handle material properties, geometric challenges, and tolerance requirements quite well-an aspect much highlighted in the LS Manufacturing 5-axis guide.

- Engineering Support and Design Optimization Capabilities: The excellent suppliers will not only go through the drawings but provide optimization suggestions in the DFAM phase, including enhancing manufacturability, optimizing the tool paths to reduce vibration, and increasing efficiency. This controls the quality and cost from the source and represents one of the core distinguishing features between ordinary machining plants and technical partners.

- Quality Control and Certification System: Verify if the supplier has in place a valid quality management system, such as ISO 9001/AS9100/ISO 13485, and if the supplier has final inspection capabilities, including coordinate measuring machines and laser scanners. Full process control, right from setup through final inspection, is the ultimate source of confidence in delivery.

All in all, choosing a 5-axis CNC machining service involves a highly critical and technical selection process. The idea behind this LS Manufacturing 5-axis machining is to take you deeper than just “asking for a price,” but to carry out an in-depth investigation in four dimensions: equipment, experience, engineering, and systems; thus finding the strategic partner who will truly protect the success of your project.

Case Study: 5-Axis Machining of Aerospace Engine Impellers: How LS Manufacturing Overcame Vibration and Efficiency Challenges

The manufacturing of aerospace engine impellers represents a typical top-tier challenge in the area of precision manufacturing, which combines complicated surfaces with tight tolerances and very high reliability requirements. We will show below, using an industrial case study, how the advantages of 5-axis CNC machining are translated from design to real performance, as it embodies a systematic problem-solving approach emphasized by the LS Manufacturing 5-axis machining guide.

Customer Challenge

The customer, from the aerospace industry, urgently needed a high-strength aluminum alloy impeller for auxiliary power units. Their previous supplier used the conventional multi-clamping process, which led to poor consistency in blade profile, substandard dynamic balance, and huge risks of big vibration during operation. Besides, the machining cycle for a single part took more than 40 hours, severely hindering the development progress of the whole project.

LS Manufacturing Solution

By making an in-depth analysis of the root cause of vibration, we concluded that the key lay in ensuring the aerodynamic surface consistency of all blades and the relative positional accuracy between flow channels. For this purpose, a high-end 5-axis machining center was utilized by adopting the strategy of accomplishing all surface finishing in one clamping. The optimum toolpath and combination of side milling with trochoidal machining effectively controlled the cutting force and deformation to ensure blade uniformity and surface integrity. Precise online measurement technology guaranteed real-time closed-loop control of critical dimensions.

Results and Value

The delivered impeller eventually achieved a dynamic balance rating of G2.5, which far exceeded the customer’s expectations and fundamentally eliminated the risk of vibration. Machining cycle time was greatly reduced from 40 to 15 hours, hence tremendously improving efficiency. In all, part performance has been improved by some 20%, passing the most stringent ground durability test on the first try, helping the customer’s project move forward with key milestones successfully.

This case demonstrates that 5-axis CNC machining goes beyond producing complex parts—it offers a process philosophy that systemically addresses precision, efficiency, and reliability through “one-time clamping, integral forming.” The LS Manufacturing 5-axis machining guide embodies this commitment, integrating advanced equipment, deep process expertise, and rigorous engineering to deliver consistent value.

Are your complex parts facing precision and efficiency challenges? Contact LS Manufacturing 5-axis machining experts today for solutions!

What are the main advantages of 5-axis CNC machining reflected in commercial value?

The real benefits of 5-axis CNC machining are not technical specifications but core business benefits. A shift in view from cost-focused to value-driven will then show that 5-axis is not just a more expensive process but actually a value-added system that enhances quality, speed, innovation, and total cost efficiency to reshape the outcomes of manufacturing.

From “high precision, one-time machining” to “reduced quality costs and improved performance

A single setup for multi-face completion of machining eliminates repetitive positioning errors from multiple setups. This directly reduces scrap rates and rework costs, hence assuring better overall consistency for such parts as engine impellers and precision valve bodies, enhancing the reliability and efficiency and prolonging the life of the final product for heightened competitiveness.

From “Shortening Manufacturing Cycles” to “Accelerating Product Launch and Capital Turnover

This type of 5-axis CNC machining can greatly reduce the overall time from design to finished product by integrating multiple processes and saving clamping and debugging time. Given that in the making of a complex part, the production time is reduced from 5 days using traditional multi-process methods down to 1.5 days, apart from the quick response to the market demand, the work-in-process inventory is greatly reduced, which also accelerates the capital recovery.

From “Achieving Complex Geometry” to “Empowering Design Innovation and Reducing Total Cost of Ownership”

It frees design constraints and allows the engineers to integrate several components into one to reduce weight and numbers of components. Or else, one can design for more efficient internal flow channels and lightweight structures. Although this may raise the price per unit, because later steps of connection and assembly are reduced and product performance considerably improved, the overall ownership cost throughout its lifetime is normally lower, realizing a leap in basic value.

The advantages of 5-axis CNC machining are rooted in its core business logic: transforming technical strengths into certainty, speed, and innovation freedom. It reduces risk costs through higher quality, creates time value by shortening cycles, and lowers total system costs through functional integration. Investing in 5-axis CNC machining means investing in a more resilient supply chain, faster market response, and more disruptive product competitiveness.

What does the general workflow look like for a 5-axis machining project with LS Manufacturing?

LS Manufacturing translates the expertise in its LS Manufacturing 5-axis guide into a reliable project strategy. We follow a clear, structured process designed to maximize risk control and cost optimization from the start. For those considering how to choose 5-axis CNC services, it begins with understanding our collaborative steps, which include:

1. Requirements Communication and Solution Demonstration

Starting from your input of 3D data and technical specifications, we provide free DFM analysis by our engineering team, identify potential points of optimization, and go back to you with a technical solution and quotation that will include process routes, quality control points, and an initial timeline based on our experience base. This is key in translating your needs into a feasible and economic manufacturing plan.

2. programming, production, and end-to-end quality control

After confirmation of the solution, all the procedures will be done precisely by process engineers through 5-axis programming and full-path simulation to confirm safety and the collision-free state of machining. On production-from the first piece to batch production-the whole process will strictly follow the quality plan, continuously feeding back the key milestone data so that everything goes according to the set standards.

3. Delivery and Ongoing Support

Before making the arrangement for safe delivery, we make final inspections, which normally include a comprehensive dimensional report along with material certification. Our cooperation does not end at shipment. We will also provide the required after-sales technical support and summarize experience in projects to build a foundation for our continuous improvement and deepening of cooperation in the future.

It is not only about a checklist on selecting 5-axis CNC machining services; more than anything else, it is a closed-loop system-from technology alignment and risk prevention all the way to value delivery. In choosing to partner with LS Manufacturing, you will be gaining a reliable manufacturing partner, supported by a deterministic process; every complicated part idea you will have in mind turns into high-quality reality, with high efficiency and accuracy.

Is the investment in 5-axis machining too expensive? How to validate the real return on investment?

Is investing in 5-axis CNC machining too costly? While the initial investment surpasses 3-axis machines, the real decision requires a holistic ROI analysis. The advantages of 5-axis CNC machining are most apparent for complex, precision parts, where its systemic benefits—such as significantly reduced clamping, leading to direct cost savings—often make it the more economical choice in overall production.

The essence of 5-axis machining is “one clamping, multiple faces completed”

It saves directly in cost due to multiple machines, multiple debugging sessions, and a large number of specialized fixtures. For instance, in the case of a complicated box that needs to be machined on 5 sides, the 5-axis machining center can reduce the 4-5 clamping operations involved in using multiple 3-axis machine tools to just one, saving tens of hours of labor and avoiding the risk of scrap due to the accumulation of errors.

From “Improving Precision and Consistency” to “Reducing Quality Costs

Clamping done only once, right at the beginning, avoids the problem of accumulated repeating positioning errors and finally pushes the yield rate near 100%. Consequently, it will directly drastically reduce material and labor losses due to scrap and rework, besides subsequent quality screening costs. Its value is particularly high in the processing of high-value materials.

From “Shortening the Overall Cycle Time” to “Accelerating Cash Flow and Market Response”

It is a fact that integrated processes can allow fantastic compression in the overall manufacturing cycle time. Suppose the delivery cycle of a critical component comes down from 2 weeks to 3 days. That will mean companies get paid sooner, are able to serve their customers’ needs quicker, and invest that saved time into more orders or R&D; thus getting a chance to create more opportunities for business and revenues.

Therefore, evaluating 5-axis CNC machining requires a “total cost of ownership” view. Its higher upfront cost secures three productivity gains: certainty, efficiency, and flexibility. Altogether, this translates into overall cost savings and competitive advantages on complex, high-value, or time-sensitive 5-axis CNC parts, making it a strategic and high-value investment.

FAQs

1. What is the MOQ of the 5-axis CNC machining?

We adopt the flexible production model in 5-axis machining, with no fixed MOQ. If an MOQ is needed, the actual MOQ will be confirmed case by case, taking comprehensive consideration of geometric complexity, material, and post-processing requirements of the part. Whether you have a need for a single-piece sample or bulk order, we will offer you the optimal production solution.

2. What range of tolerance is generally to be expected?

Based on high-precision equipment and mature processing, we can ensure that the tolerance in our normal 5-axis machining reaches ±0.025mm constantly. For special features and special materials, the allowance will be controlled even more strictly. Specific indicators will also be clearly stated in the quotation after technical evaluation.

3. How long does it take to get a quotation from the date one receives the drawings?

For standard 5-axis machining requirement, we can guarantee a detailed technical review and quotation within one working day.If the part is very complicated, we’ll be in contact with you instantly, too, to make sure an answer in the shortest time possible-usually no more than two days.

4. Do you provide quality inspection reports in the course of machining?

We provide full-process quality documentation, which includes the first article inspection report (FAIR), online inspection records for critical dimensions, and the final shipment inspection certificate. All inspection data is traceable for complete quality transparency and process control.

5. Do my design files need special preparation for 5-axis machining?

You just need to provide a complete STEP, .). IGES 3D design file. We will run the free DFM (Design for Manufacturing) analysis for you and optimize manufacturability without professional 5-axis programming knowledge.

6. Is 5-axis machining suitable for all kinds of materials?

5-axis machining boasts a wide range of applications in various materials. We treat a wide range of metals, including aluminum alloys, titanium alloys, and stainless steel, along with engineering plastics. We support you in choosing the best material solutions based on your needs for strength, weight, corrosion resistance, among others.

7. How Do I Protect My Design Intellectual Property?

We consider the intellectual property of our clients as top secret. All design documents are kept on encrypted servers right from the time the NDA has been signed, with tight access controls in place for full protection of your design at every stage.

8. How can new customers initiate their first 5-axis machining project?

CAD data and requirements can be submitted via our website, by e-mail, or by calling us. A dedicated project engineer will be assigned to the client for one-on-one professional support, from technical clarification and process planning through to production follow-up, so as to guarantee a smooth project launch.

Conclusion

5-axis CNC machining is no longer some unreachable high-end technology but rather an important tool for dealing with complicated precision manufacturing problems and ensuring product competitiveness. Choose LS Manufacturing means you’ve selected a partner with deep industry experience, state-of-the-art equipment, and an unshakeable commitment to quality.

Overcome bottlenecks in your designs’ manufacturing right now! Click “Get Free 5-Axis Machining Solution Consultation” and upload your part drawings. Professional engineers from LS Manufacturing will provide one-on-one DFAM analysis for you and grant a highly competitive quote. Now, let us join hands and bring your innovative thoughts into reality.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.