If you’re looking for specialized sheet metal fabrication services in Chicago, you’re in the right place. At our metal fabrication company, we have years of experience and expertise in providing top-notch solutions for residential, commercial, and industrial needs.

We understand that each project is unique, and that’s why we offer a highly personalized service that can accommodate any type of requirements. Whether you need a one-time job or require ongoing fabrication services, we have the skills and resources to deliver high-quality results.

In this guide, we’ll provide insightful information about custom sheet metal fabrication services, the benefits of working with an experienced team, and how our company can help you achieve your goals.

But before that,this article first will explain what is sheet metal fabrication and what are its advantages in industry.

What is Sheet Metal Fabrication?

Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high precision and durability, especially for end-use applications like chassis, enclosures, and brackets.

Sheet metal manufacturing is suitable for various metals.

including:

- Stainless steel: Used for its strength and resistance to corrosion

- Cold-rolled and hot-rolled steel: Both of these are easily formed, but cold-rolled has a smoother finish and tighter size tolerances

- Aluminum: A lightweight metal with exceptional strength-to-weight ratio

- Copper and brass: These metals are easy to work with and look good in a fabrication

Custom sheet metal fabrication is the process of customizing metal parts or products to specific standards and needs. This process involves cutting, bending, shaping and welding metal sheets into specific shapes and sizes.

Sheet metal processing refers to processing flat metal sheets into various shapes and structures. The sheet metal processing method is not a single process, but a series of forming technologies that work together to produce the required parts. Metal processing is widely used in the automotive, aerospace and construction industries.

Custom sheet metal fabrication services are used for a variety of applications, including HVAC systems, architecture, industrial production, and decorative enhancements.

What Types Of Sheet Metal Fabrication Are Available?

There are many types of sheet metal fabrication services available, depending on the desired outcome. These can include:

- Cutting – as it implies, this involves cutting material down to exact length and specification.

- Forming and Shaping – this is where metal is coerced into a new shape, often through a press brake, or rolling it into a curved form.

- Machining – in this method, metal is removed from key areas, creating holes and other forms. This is done through various cutting tools, using hardened materials to cut the metal to specification.

- Grinding and Finishing – Grinding can be used to ensure a smooth, level shape or surface, while additional finishing techniques, such as coating or galvanising, can add the final qualities needed.

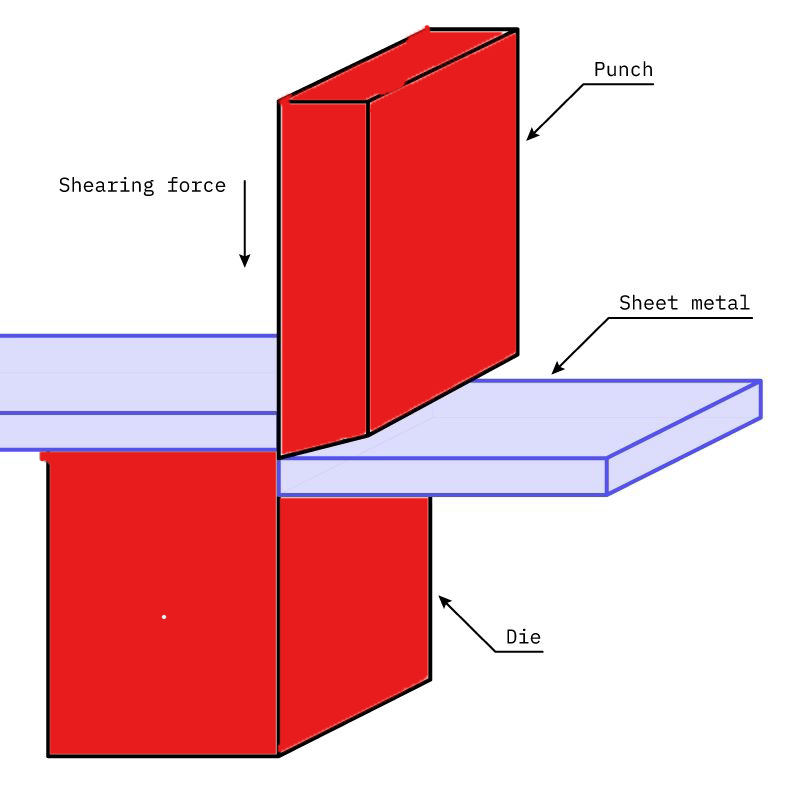

- Punching – this involves using specialised machines to punch shapes directly into sheet metal, creating the desired components quickly. This is ideal for batch orders.

- Welding – there are a number of techniques, including Mig and Tig, but welding nonetheless serves to join separate pieces of metal together.

Advantages of sheet metal fabrication

- Durability: Sheet metal is strong and durable, and sheet metal parts can often withstand more pressure and heat than plastic parts. In addition to this, aluminum, stainless steel or surface treated steel are resistant to pressure, corrosion and wear. While methods like casting offer these advantages, the durability of plastic decreases over time.

- Replaceability: One of the biggest advantages of using sheet metal is that the parts are replaceable. If several metal parts are used to make an assembly, instead of making the whole part out of one substance, the individual components can be removed and replaced without having to replace the entire assembly. This can save money on repairs and even allow for modifications and upgrades.

- Sustainability: As far as materials go, metal is by far one of the most sustainable materials. Metal is a natural resource that is both environmentally and economically strategic. When the parts are no longer needed, they can be recycled indefinitely and turned into other parts. Plastic has a limited ability to be recycled and cannot be easily and safely disposed once it reaches its end point. Metal manufacturing is a much more responsible and sustainable option.

- Cost-Effectiveness: Tooling costs for plastics can be very expensive, making sheet metal a more economical choice. Many companies move from cast or molded parts to sheet metal because of the overall reduction in costs and material waste. Material lifespan and longevity must also be considered when evaluating the cost of material. The cheapest material is not necessarily the most cost-efficient option if it will not serve you well for a long period of time and has to be consistently replaced or maintained. The strength and durability features of sheet metal make it a more cost-effective option.

Why Choose our Custom Sheet Metal Fabrication Services?

There are several benefits to choose our professional custom sheet metal fabrication services, including:

| Rapid Prototyping | On-Demand Production | Functional Prototype |

|---|---|---|

| Manufacturing sheet metal prototypes at low cost in a short period of time, quickly validating design concepts and making design revisions, can help accelerate the product development cycle. | Produce the required quantity of sheet metal parts according to your specific needs, without the need for large-scale manufacturing and storage of large quantities of inventory. | A physical model or sample used to validate and test product design helps designers and engineers test and validate the design before the product enters actual production. |

long Sheng Sheet Metal Fabrication Tolerance Standard

following the ISO 2768-m standard, your custom sheet metal fabrication service can more easily ensure the manufacturability and accuracy of parts, reducing errors and unnecessary manufacturing issues.

| Types | Tolerance |

|---|---|

| Bend edge straightnes | +/- 0.2 mm +/- 0.008 inches |

| Edge to edge, single side | +/- 0.1 mm +/- 0.004 inches |

| Edge to hole, single side | +/- 0.1 mm +/- 0.004 inches |

| Hole to hole, single side | +/- 0.1 mm +/- 0.004 inches |

| Bend to edge/hole, single side | +/- 0.2 mm +/- 0.008 inches |

Edge to feature, multiple sides | +/- 1.0 mm +/- 0.040 inches |

Overformed parts, multiple sides | +/- 1.0 mm +/- 0.040 inches |

| Bend angle | +/- 1° |

| Weld joint location | +/- 0.2 mm +/- 0.008 inches |

| Surface finish thickness | +/- 0.05 mm +/- 0.002 inches |

Sheet Metal Parts In As Fast As 3 Day

Can’t wait to complete your sheet metal project? No need to wait for a long cycle, we promise to provide you with customized sheet metal parts as soon as 3 days! From prototype design to efficient production throughout the entire process, our efficient team will quickly respond to your needs, escort your project, and ensure that you take the lead in the market!

Our Sheet Metal Fabrication For Various Applications

Longsheng’s sheet metal fabrication services provide critical support for enterprises in various industries, whether it is metal automotive components or electronic equipment components.

How Can Our Custom Sheet Metal Fabrication Services Help You?

At our company, we provide comprehensive custom sheet metal fabrication services for Chicago that can meet any need, from simple to complex. Some of our services include:

- Quatation: Just upload your design file and configure the materials, finishing options, and requirements. Our engineers analyze your part geometry and provide real-time and competitive pricing as well as comprehensive DFM feedback.

- CAD Design: We utilize the latest computer-aided design (CAD) software to create precise and accurate designs for your project.

- Cutting and Bending: We use state-of-the-art machinery to cut and bend metal sheets to your exact specifications.

- Welding and Assembly: Our experienced welders and assemblers can provide expert welding and assembly solutions to ensure the final product meets all the required standards.

- Finishing: We offer a range of finishing options to enhance the look and durability of your custom-made parts and products.

- Delivery: From prototype design to efficient production, we deliver high-quality sheet metal parts within our standard delivery time of 3 days.

fAQs

How to Avoid Damage to Sheet Metal Fabrication Parts?

What processes are used in sheet metal?

How do you manufacture sheet metal?

What Materials are Often Used in Sheet Metal Fabrication