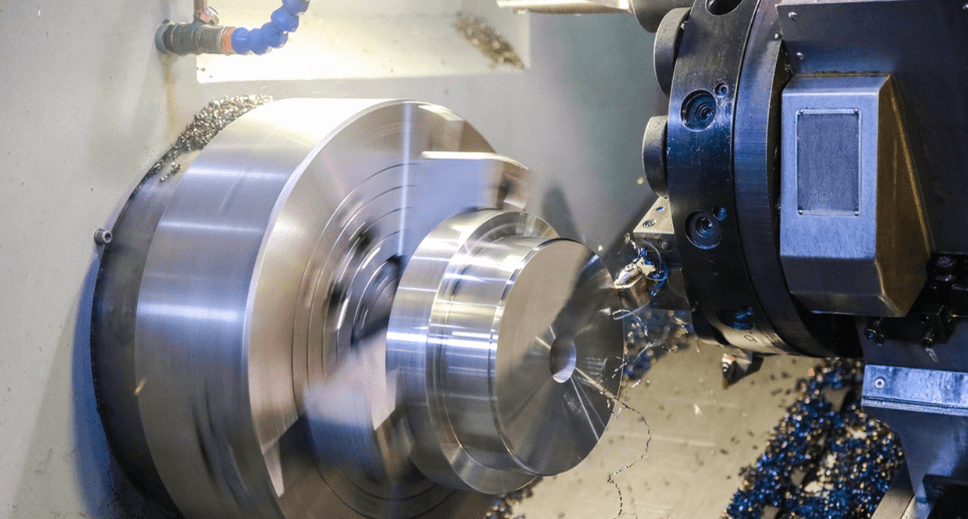

CNC milling machines have become an integral part of modern manufacturing processes, as they offer a range of advantages, including precision, versatility, consistency, and efficiency. However, the quality of the parts used in CNC milling machines plays a crucial role in determining the quality of the final product. In this article, we will explore the importance of using high-quality CNC milling machine parts in manufacturing processes.

Precision and Accuracy

CNC milling machines are known for their ability to deliver high levels of precision and accuracy. However, the quality of the parts used in the machine is critical in achieving this level of accuracy. High-quality CNC milling machine parts are essential for producing precise and accurate components that meet the necessary specifications. Low-quality parts can result in component failure and compromise the quality of the final product.

Efficiency and Productivity

High-quality CNC milling machine parts can significantly improve the efficiency and productivity of the machining process. These parts are designed to withstand high speeds and loads, reducing the need for frequent maintenance and repairs. This not only saves time and money but also improves the overall efficiency of the machining process.

Consistency and Quality Control

High-quality CNC milling machine parts produce components with the same level of accuracy and precision every time, ensuring consistency. This consistency is crucial in the manufacturing industry, where components must meet strict quality control standards. Using high-quality parts reduces the risk of defects and ensures that the final product meets the necessary standards.

Cost-Effectiveness

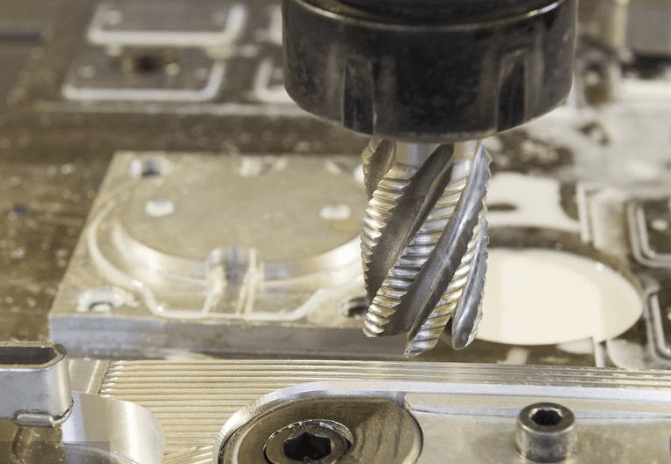

Using high-quality CNC milling machine parts can be cost-effective in the long run. While these parts may be more expensive initially, they last longer and require less frequent maintenance and repairs, reducing overall costs. Additionally, high-quality parts produce high-quality components that have longer lifespans, reducing the need for frequent replacements.

The Impact on Competitive Advantage

High-quality CNC milling machine parts can give manufacturers a competitive edge in their respective industries. By producing high-quality components with precision and accuracy, manufacturers can establish themselves as industry leaders. Additionally, by reducing the need for frequent maintenance and repairs, manufacturers can save time and money, making them more competitive in the market.

Conclusion

In conclusion, high-quality CNC milling machine parts are essential for producing high-quality components with precision and accuracy. They improve efficiency and productivity, ensure consistency and quality control, and can be cost-effective in the long run. By investing in high-quality parts, manufacturers can improve the overall quality of their products and remain competitive in their respective industries. Choosing the right CNC milling machine parts can be a daunting task, but it’s essential for achieving the desired results. Manufacturers must consider the material to be machined, the dimensions, and the level of precision required when selecting the appropriate CNC milling machine parts.

At the end of the day, the quality of the final product depends on the quality of the parts used in the CNC milling machine. By using high-quality parts, manufacturers can deliver the precision, accuracy, and consistency that their customers demand. In today’s highly competitive market, it’s more important than ever for manufacturers to invest in the right CNC milling machine parts to stay ahead of the competition.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items