5 Axis CNC Machining Services

Our 5 axis machining services meet the needs of high-precision and complex geometric parts in a wide range of applications, providing customers with reliable, efficient, high-quality machining solutions.

- Instant 5 axis parts online quotes

- Tolerances down to +/- 0.005mm

- Custom precise, complex parts

- All uploads are secure and confidential

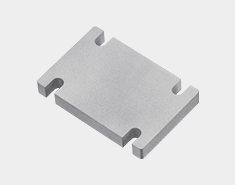

Our 5 Axis CNC Machining Capabilities

Our have a number of 5-axis machine tools, with high speed and efficiency, which can complete the precise machining of parts with extremely complex geometric shapes.With years of experience in the processing business and a thorough understanding of material properties, we have the ability to make your prototype and produce 5 axis parts in 3 days.

Simultaneous 5 Axis CNC Machining

When fast, efficient, and continuous 5-axis CNC machining is required to improve part transition and surface quality, our 5-axis machining center is the preferred choice. It can achieve uninterrupted continuous motion adjustment of all five axes and has intelligent functions to ensure efficient continuous processes and rapid conversions.

3+2 Axis CNC Machining

By adopting excellent 3+2 axis CNC machining technology, you can obtain high-precision complex CNC machining parts at lower costs and shorter cycle times without sacrificing quality and strict tolerance requirements. The 3+2-axis CNC machining process uses shorter and more robust cutting tools to ensure excellent dimensional stability of your parts.

From CNC Prototyping to Production

Our 5 axis machining services can be used for rapid prototyping as well as various production stages, including small and high volume production. This technique can be applied to a variety of materials, including metals, plastics, wood and composites

On-Demand Production

Accurately manufacturing complex geometric 5 axis parts according to customer requirements without the need for large-scale production, reducing the cost of large-scale manufacturing

Rapid Prototyping

Rapid prototyping is the cornerstone of design and development. 5 axis machining can play an important role in precision and fast production from multiple angles.

Small Lot Production

It can quickly handle smaller batch production tasks, help manufacturers produce more products in a shorter time, enhance competitiveness, and increase sales.

5 Axis CNC Machining Tolerances

Being an ISO 9001 certified company shows that our 5-axis CNC parts manufacturing process strictly complies with international quality management standards, and whether you need to manufacture complex metal parts or precision plastic parts, we provide parts with excellent dimensional stability.

| Type | Tolerance |

|---|---|

| Maximum Part Size |

400 × 300 × 200 mm

15.7 × 11.8 × 7.8 in. |

| Minimum Part Size |

2 × 2 × 2 mm

0.07 × 0.07 × 0.07 in. |

| Minimum Feature Size |

+/- 0.2mm

+/- 0.007in. |

| Standard Tolerances |

Metals: ISO 2768-f

Plastics: ISO 2768-m |

| Linear Dimension |

+/- 0.005 mm

+/- 0.0002 in. |

| Hole Diameters |

+/- 0.005 mm

+/- 0.0002 in. |

| Shaft Diameters |

+/- 0.005 mm

+/- 0.0002 in. |

| Edge Condition | Sharp edges are broken and deburred by default |

| Threads and Tapped Holes | LS Manufacturing can accommodate any standard thread size. We can also machine custom threads. |

| Lead Time | 3 Business Days |

Materials for Custom 5 Axis CNC Machining

Our 5-axis machining service has a wide range of material compatibility, you can choose from more than 40 production-grade materials we offer, no matter which material your application requires, LS Manufacturing will provide you with professional support to ensure that you get the most suitable materials and parts for your application.

Metals

Plastics

We offer customization based on your specific material requirements. If you need a material not listed here, our team can source and process it to meet your exact needs.

These are just a few examples of the materials we work with. If you have a specific material requirement, please contact us to discuss your needs.

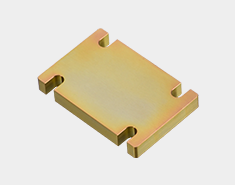

Surface Finishing for CNC Milling Machining

Our surface finishing allows you to customize the appearance and texture of your milling parts. Various textures, colors, and finishes are available to match the aesthetic requirements of your product or brand.

| Category | Description | Material | Color | Texture |

|---|---|---|---|---|

Anodizing

Anodizing

|

Anodizing is an electrochemical process used to enhance the corrosion resistance, appearance, and surface properties of metal parts, particularly aluminum. | Aluminum, Metals | Clear, black, grey, red, blue, gold | Rough, smooth, metallic |

Powder Coating

Powder Coating

|

Powder coating is a popular and environmentally friendly method of applying a protective and decorative finish to various types of metal and even some non-metal surfaces. | Metals | White, Black, RAL and Pantone | Glossy, fine, hardness |

Polishing

Polishing

|

The primary goal of polishing is to create a smooth and reflective surface by removing imperfections, scratches, and irregularities. | Metals | Silver gray | Bright, mirror, silk |

Chromate

Chromate

|

Chromate, commonly known as a chemical thin film, is a conversion coating used as a corrosion inhibitor on aluminum. | Aluminum | Clear/ Slight yellow tint | Satin |

Bead blasting

Bead blasting

|

Bead blasting, also known as abrasive blasting, is a surface preparation technique used to clean, finish, or texture a surface by forcibly propelling small, spherical abrasive materials, called "beads" or "media," at high speeds onto the surface being treated. | Aluminum, copper, stainless steel, steel | N/A | Grainy, slightly matte texture |

As machining

As machining

|

Machining is a subtractive manufacturing process in which a machine tool, typically a cutting tool, removes material from a workpiece to achieve the desired shape, dimensions, and surface finish. | Metals | N/A | Smooth, glossy finish |

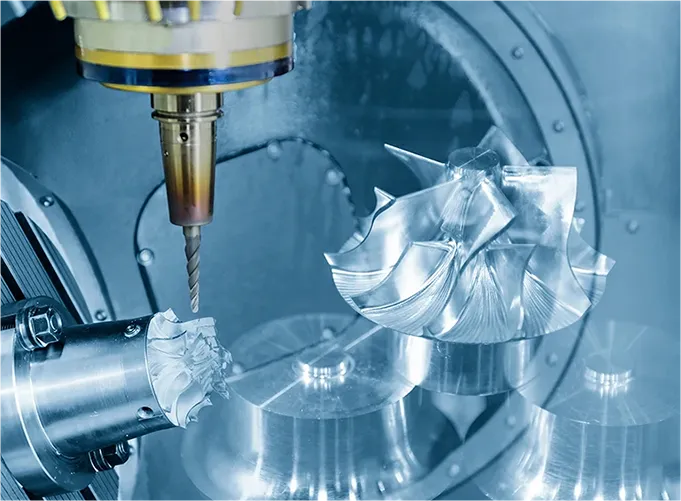

Applications of 5 Axis CNC Machining

Our 5-axis CNC machining services are the first choice for manufacturing complex, high-precision parts in a wide range of industries.

- - Aerospace parts: Aircraft engine parts, wings, flight control parts

- - Automotive parts: engine components, chassis components, brake components, transmission components

- - Medical devices: surgical tools, implants, medical equipment parts

- - Energy: Turbine components, power generation equipment components, gas turbine components

- - Electronic parts: electronic equipment casing, heat sink, connector, panel

Tour Our 5 Axis Machine

Check out our incredible range of functional 5 axis machining centers, our machinery includes HAAS and precision 5 axis CNC machines. With years of experience in the processing business and a thorough understanding of material properties, we have the ability to make your prototype and produce 5 axis parts in 3 days.

- All uploads are secure and confidential

Why Choose Our 5 Axis CNC Machining Service

LS Manufacturing is one of the most reliable manufacturing companies for complex geometry parts. We can turn your designs and ideas into real parts in just a few days.

Instant quote

Provide you with an instant quote, which means we will let you know your processing costs within 24 hours based on your needs

Rapid production

We can process parts with complex shapes, such as curved surfaces, complex structures, and spiral shapes. No matter how complex your design may be, we can provide high-quality processing services

Competitive pricing

We provide competitive prices and cost-effective solutions to ensure that customers gain the greatest advantage in cost control.

Rapid delivery

We have efficient production processes and flexible production plans, which enable us to timely deliver customer orders and meet urgent project needs.

Client's Reviews

Listen to our customers’ voices! We have received praise and satisfactory evaluations from many customers.

Put Your parts Into production Today

All information and uploads are secure and confidential.

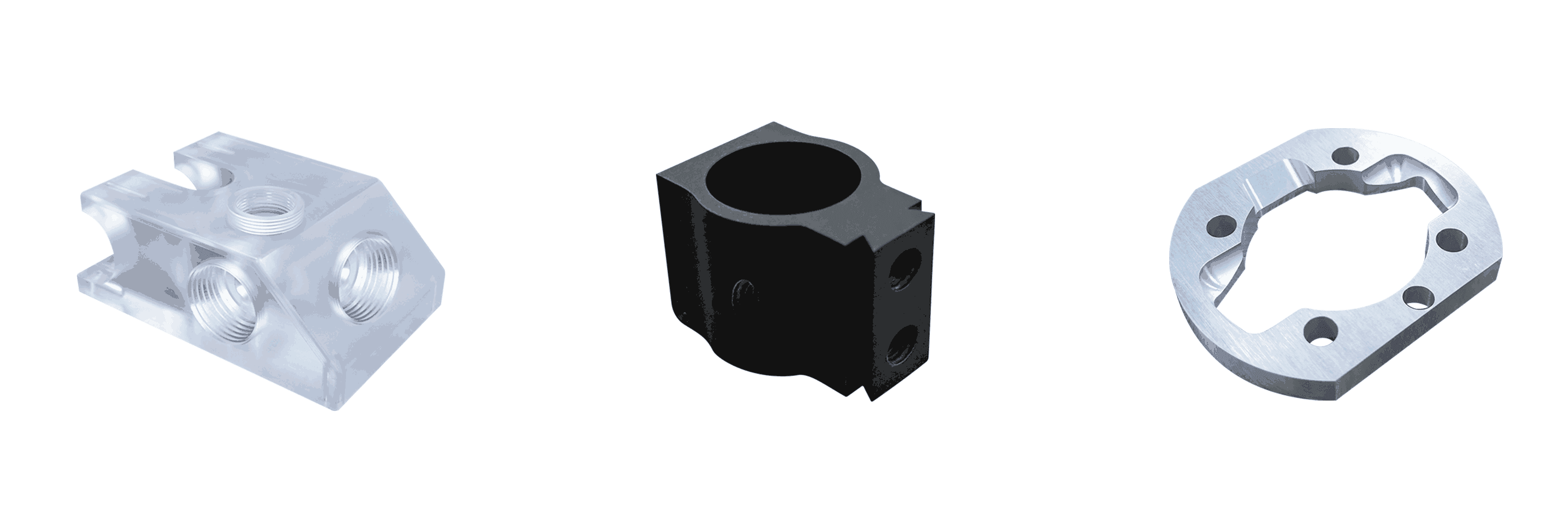

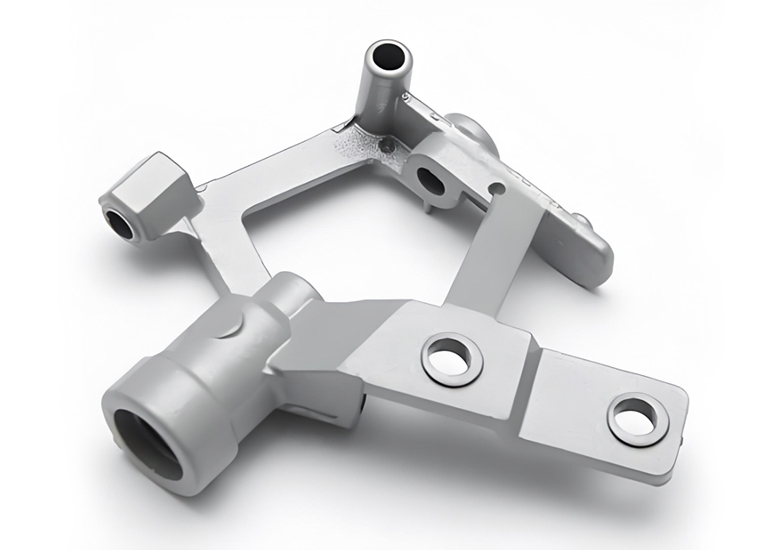

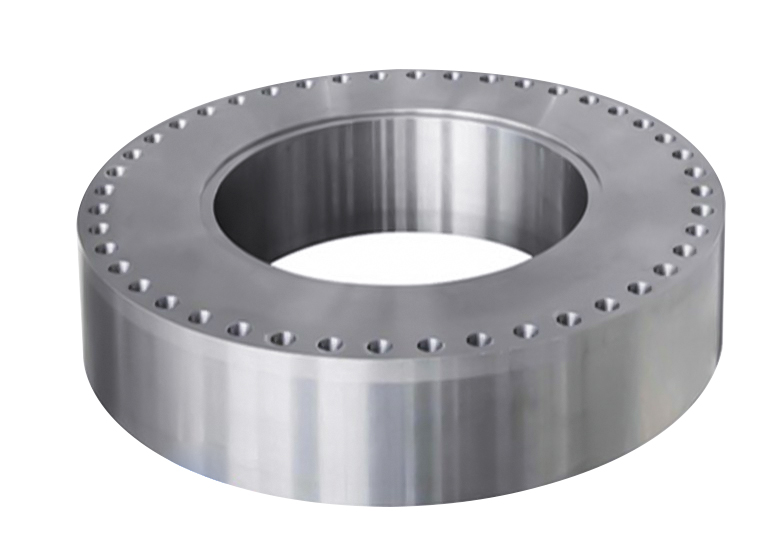

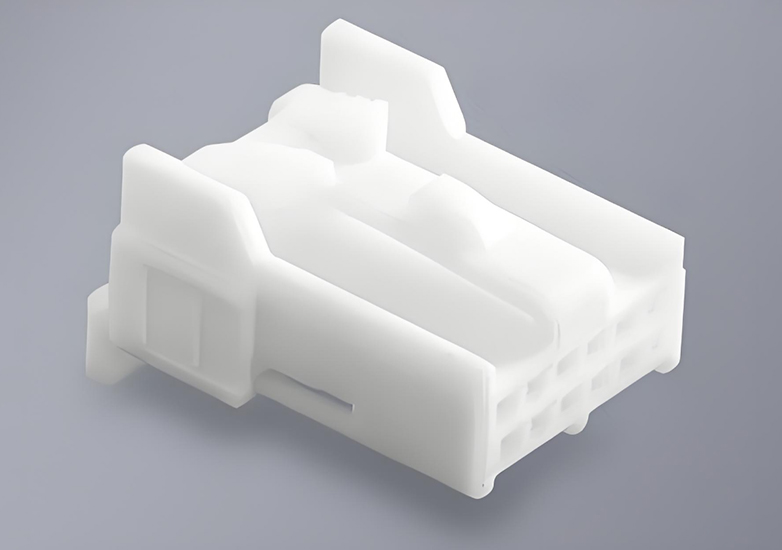

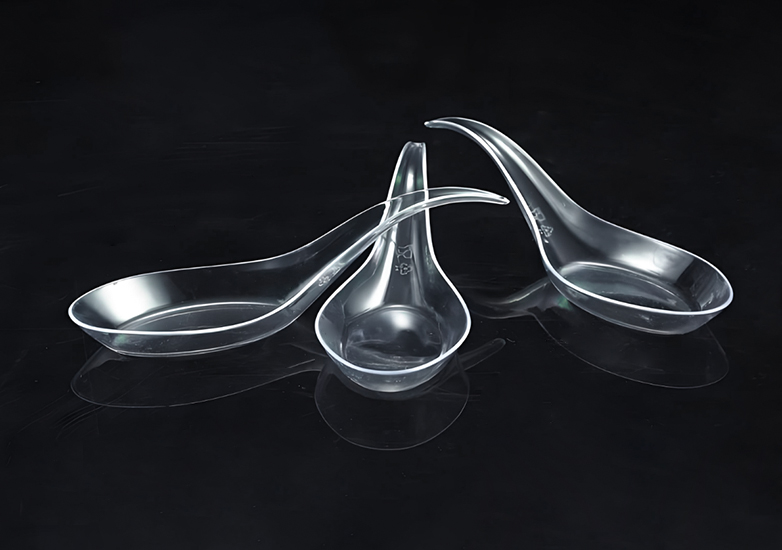

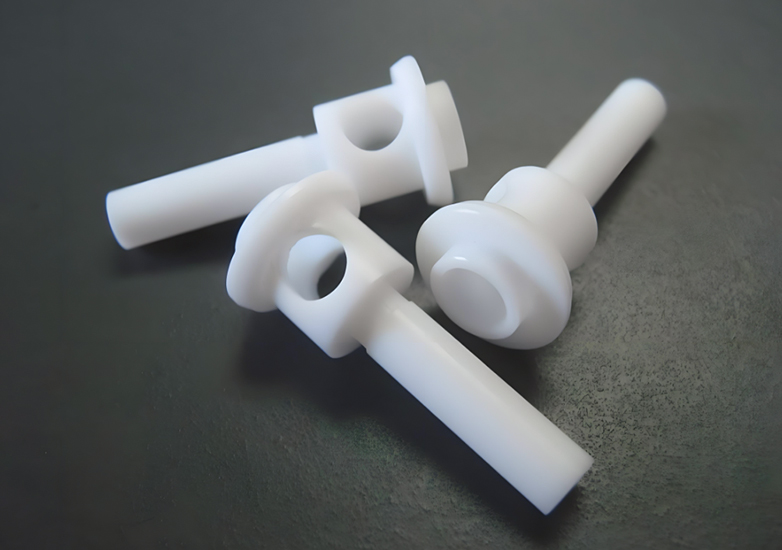

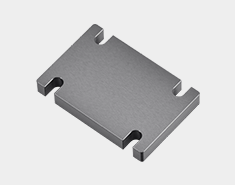

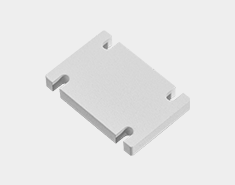

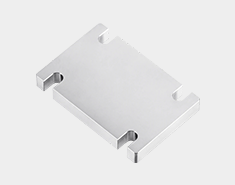

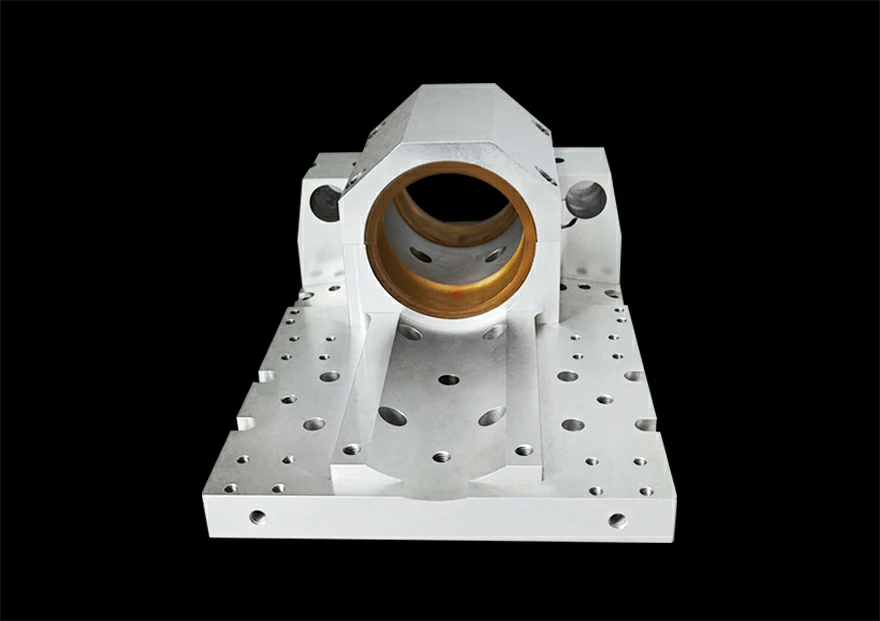

Gallery of 5 Axis Machining Parts

View the custom 5 axis parts we process for customers, from rapid prototyping, small batch production to batch production orders.

Our 5 Axis CNC Machining for Various Industrial Applications

Crossing numerous industries, LS Manufacturing uses highly advanced technology, from prototype production to on-demand manufacturing, and then to large-scale production, to ensure the excellent quality and reliable performance of parts, ensuring the success of your project.

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

![]() We respect your privacy and will not use your information for other purposes.

We respect your privacy and will not use your information for other purposes.

5 Axis CNC machining FAQ

We provide new product developers with engine machining parts suitable for functional testing or final use of engineering -level materials. Get your required CNC machining services support by reading FAQ.

What 5 axis CNC machining services do you offer?

We offer all types of 5 axis CNC machining services, including aluminum alloy machining, copper machining, stainless steel machining, titanium alloy machining and composite machining. We can also tailor the service according to your requirements, if you need custom processing, please contact our customer service personnel

What is the maximum size for 5 axis CNC machining?

The size of 5 axis CNC machining mainly depends on the working area of the machine and the size of the processed materials. We can provide various sizes of machining to meet your specific needs.

Why choose 5 axis machining?

5 axis machining can handle some complex parts, such as curved surfaces, complex convex shell parts, and parts requiring very high precision. At the same time, 5 axis machining can complete the machining of multiple faces through a single clamping, thus improving work efficiency.

What are the main advantages of 5-axis CNC machining compared to 3-axis machining?

Can you machine parts with complex curved surfaces and intricate details using 5-axis CNC?

Yes, 5-axis CNC machining is ideal for producing complex curved surfaces and intricate details that are difficult or impossible with traditional 3-axis machines.

How do you ensure the stability and precision of parts during 5-axis machining?

We use advanced fixturing and multi-point clamping techniques to securely hold parts. Additionally, our machines are regularly calibrated, and we perform in-process inspections to maintain precision.

Are there any material limitations for 5-axis CNC machining?

While 5-axis CNC machining can handle a wide range of materials including metals and plastics, very soft or extremely hard materials may require specialized tooling or processes. Please consult us for specific material inquiries.

What file formats do you accept for 5-axis CNC machining projects?

We typically accept CAD files such as STEP, IGES, and native formats like SolidWorks, CATIA, and NX. Please provide detailed 3D models to ensure accurate programming of the 5-axis machine.

Put your parts into production today

- All information and uploads are secure and confidential.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.