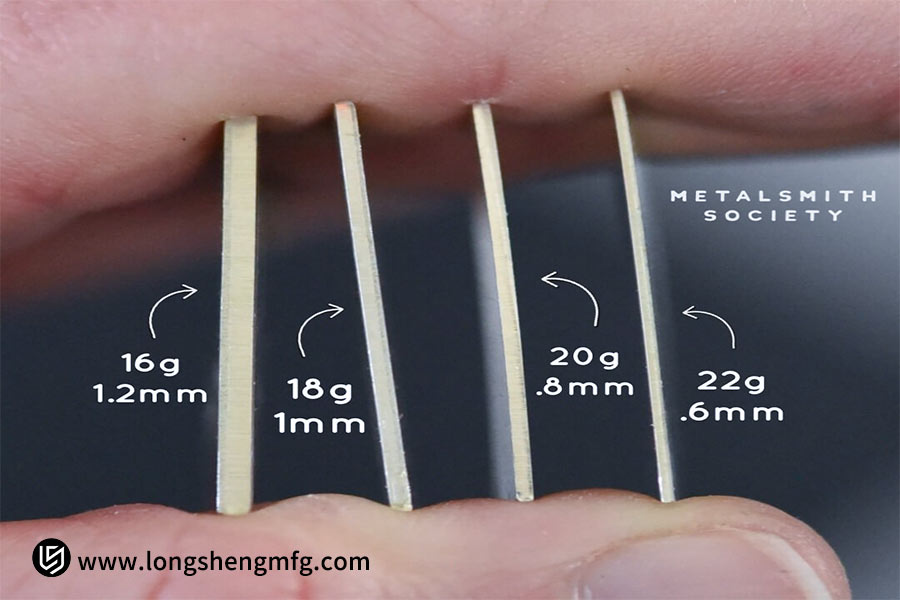

“Which is thicker, 18-gauge or 22-gauge sheet metal?”

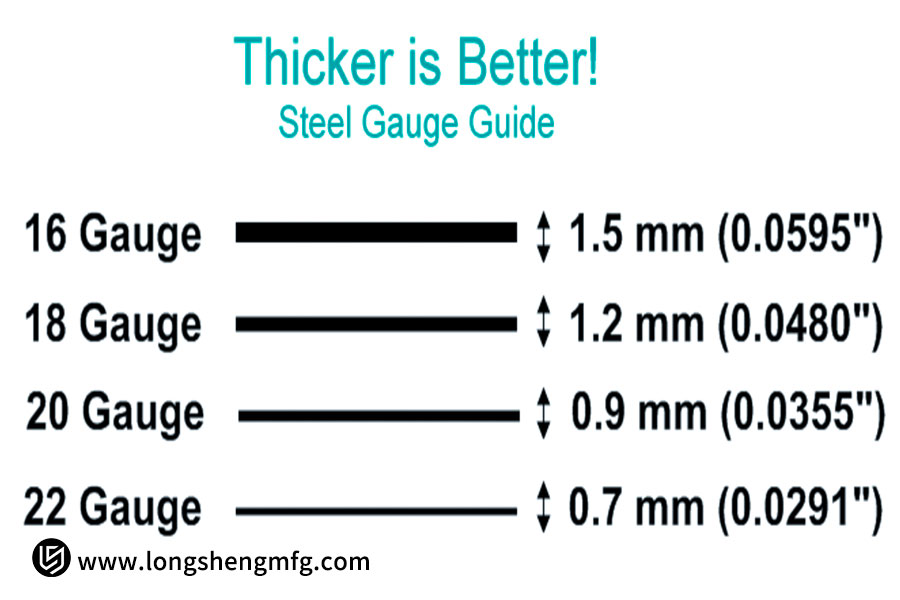

Your instinct would be to say 22-gauge, having a higher number, has to be thicker? That’s an illusion! Within the world of sheet metal (whether steel, galvanized sheet, or aluminum), standard gauge numbering systems (as per standards such as American Wire Gauge (AWG) or Birmingham Wire Gauge (BWG)) have one guideline: the higher the number, the thinner the actual thickness of the sheet.

So the moral is: 18-gauge sheet metal, for example, is considerably thicker than 22-gauge sheet metal. This seemingly innocent number difference directly affects a material’s strength, load-carrying capacity, cost, and application. The incorrect use of a gauge can lead to material waste and excessive cost at best, or even structural weakness or product failure at worst.

One must understand the “higher the number, the thinner the sheet” principle. This post will compare 18-gauge and 22-gauge sheet metal actual thickness measurements (millimeters/inches), describe their usage application differences, and demonstrate why accurately calculating gauge thickness is an important initial step to preventing errors in purchasing, designing, or fabricating.

18-Gauge vs. 22-Gauge Metal Sheet Thickness Comparison Quick Reference

| Characteristics | 18-Gauge Metal Sheet (18 Gauge) | 22-Gauge Metal Sheet (22 Gauge) | Key Conclusions |

|---|---|---|---|

| Gauge Number Meaning | Metal Sheet Thickness Code (Gauge) | Metal Sheet Thickness Code (Gauge) | The lower the gauge number, the thicker the sheet |

| Relative Thickness | Thicker | Thinner | 18-Gauge sheet is significantly thicker than 22-Gauge sheet |

| Typical Thickness (US Standard Steel) | Approximately 1.214 mm (0.0478 in) | Approximately 0.759 mm (0.0299 in) | 18-Gauge sheet is approximately 1.6 times thicker than 22-Gauge sheet |

| Thickness Difference | Approximately 0.455 mm (0.0179 in) thicker than 22-gauge plate | Approximately 0.455 mm (0.0179 in) thinner than 18-gauge plate | Absolute difference is significant |

| Thickness percentage | Approximately 60% thicker (compared to 22-Gauge sheet) | Approximately 38% thinner (compared to 18-gauge) | 18-gauge plate is significantly thicker |

| Common Applications (Based on Thickness) | Structural parts requiring higher strength, frames, chassis, heavy-duty enclosures, load-bearing components | Lightweight covers, decorative panels, non-load-bearing enclosures, duct linings, where flexibility is required | Thickness determines the application |

| Key Points | Thick, stronger, heavier, more rigid, less prone to bending | Thin, lighter, more flexible, easier to form/bend. | Choice depends on required strength, weight, and rigidity |

Notes:

- Standard Basis: The values for thickness in the table are based on the most prevalent United States Standard (USS) for steel. It is among the most typical reference standards in industry.

- Material Variations: The actual thickness of different metals (e.g., stainless steel and aluminum) with the same gauge numbers may vary slightly, but the relative principle of “lower gauge number, thicker” always applies. For example, 18-gauge stainless steel or aluminum plate will still be much thicker than 22-gauge plate of the same metal.

- Actual Thickness: Always specify the actual material gauge sheet provided by the supplier when ordering, as there are small differences between standards (e.g., the British SWG) or between manufacturers.

- Conversion Relationships: Remember the useful principle: the larger the gauge number, the thinner the plate.

Why Trust This Guide? Leveraging The Practical Experience Of LS Experts

These thickness comparisons and these material selection suggestions don’t originate in cold books or web research. They are a direct consequence of decades of hands-on experience with metal materials by our LS engineering experts.

- Working at Sheet Metal Daily: My colleagues and I cut, test, and manufacture sheet metal in sizes from large storage tanks and pressure vessels to small precision machine parts. We compute, select, weld, and test them in-house. At what pressure does which thickness distort? For what process is which gauge optimum? What combination gives the best cost vs. life trade-off? These things are committed to memory.

- Handled Hundreds of “Improper Thickness Selection” Cases: We’ve had hundreds of jobs end up in rework, delay, and even loss due to incorrect initial material selection (i.e., specifying 22-gauge steel when we needed 18-gauge steel, resulting in insufficient strength, or the opposite, resulting in waste and excess weight). These experiences have intensely taught us the real-world impact of gauge differences.

- Derived from Real Customer Needs: The suggestions in this guide have been derived from the real-world experience of thousands of customers whom we’ve served. We know the underlying requirements and common pain points for sheet metal thickness for most industries (construction, machinery, chemicals, and energy).

- LS Internal Knowledge and Verification: Our results are based on LS’s rigorous internal technical specifications, extensive materials database, and frequent technical audits and experience sharing within our team of engineers. This ensures accurate and relevant information.

Whether you need 18-gauge or 22-gauge steel depends on your specific strength, weight, and budget requirements. Take this guide at its word—it’s derived from international standards and revised and reviewed regularly by LS engineers through actual construction projects to provide the most precise and helpful professional advice. LS is available for additional detailed material selection consulting.

What Do Sheet Metal Gauge Numbers Tell You?

The sheet metal common numbering system (for steel and galvanized steel, specifically) (e.g., 18 Ga., 22 Ga.) is derived primarily from the application of the Birmingham Wire Gauge (BWG) or the practically identical American Wire Gauge (AWG) to sheet metal. It is a very old, standard numbering system.

Fewer numbers mean thicker sheet metal: This is the key to remember! The logic behind this numbering system is in reverse. Different from sizes of apparel, where a higher number means larger size, a higher number means thinner material. Imagine a wire stretched out to be longer (a big number) and basically become thinner (thinner). This applies to sheet metal as well.

Numbers Represent Exact Thickness: Each number represents precisely a given thickness (usually in inches or millimeters). For example:

- 18 Ga. (18 gauge): The standard thickness is approximately 0.0478 inches or 1.214 mm.

- 22 Ga. (22 gauge): The standard thickness is approximately 0.0299 inches or 0.759 mm.

Why are the numbers not continuous? Historically, the wire gauge system developed based on the manufacturing needs of wires of various diameters. Over time, all the in-between numbers have been eliminated except in the sheet metal industry where frequently used numbers (18, 20, 22, 24, and 26) have been kept as standard thickness gauges.

Industry Standard: BWG/AWG is the most common application of sheet metal thickness specification (BS, CS, and SS sheet, specifically) in North America and in most of the world’s markets. It’s utilized extensively in construction, manufacturing, and appliance sectors.

Sheet metal gauge (gage) is a common system of numbers following the Birmingham Wire Gauge (BWG) or the American Wire Gauge (AWG). Its principle is the larger the number, the thinner the sheet. Thus, 18-gauge sheet metal (about 1.214 mm) is thicker than 22-gauge sheet metal (about 0.759 mm). Getting a handle on this counterintuitive principle—the larger the number, the thinner it is—is the key to grasping sheet metal gauge numbers. Practically, the best method of being precise in engineering is to refer to the standard and, if needed, take real measurements.

18-gauge vs. 22-gauge Metal Sheet: How Big Is The Measured Thickness Difference?

Primary Conclusion: 18-gauge metal sheet is considerably thicker than 22-gauge metal sheet. The measured thickness difference is approximately 0.50 mm (or 0.020 inches).

1. Definition of “Gauge”:

Normally, metal sheet gauges are Birmingham Wire Gauge (BWG) and American Standard Wire Gauge (AWG) (steel sheet is normally designated by BWG/SWG). The basic rule is: the larger the gauge, the thinner the thickness. 18-gauge is smaller than 22-gauge, so 18-gauge is thicker.

2. Thickness Measurement Values (Based on Common Standards):

- 18-gauge steel sheet: Typical thickness is normally between 1.20-1.25 mm (approximately 0.0478-0.0492 inches). Our standard measured value is 1.22 mm.

- 22-gauge steel plate: Typical thicknesses are normally between 0.70 to 0.75 mm (approximately 0.0276 to 0.0295 inches). Our standard measured value is 0.72 mm.

3. Measured Thickness Difference:

- Absolute Difference: 1.22 mm (18-gauge) – 0.72 mm (22-gauge) = 0.50 mm.

- Relative Difference: 18-gauge plate is roughly 69.4% thicker than 22-gauge plate (0.50 mm / 0.72 mm = 0.694).

4. Practical Significance:

- Strength and Rigidity: 0.50 mm is significant in sheet metal. 18-gauge plate is more resistant to bending, compressive strength, and rigidity in general than 22-gauge plate.

- Applications: 18-gauge plate would be the standard for structural parts, load-carrying components, chassis, heavy-duty enclosures, and other applications with increased strength demands. 22-gauge sheet metal is more suited to applications where weight is a concern or low-strength demands are required, i.e., light structures, internal brackets, non-load-bearing panels, and exterior shells.

- Cost and Weight: Increased thickness in 18-gauge sheet metal means increased material cost and increased weight of the finished product. The choice should be balanced based on design strength requirements, weight restriction, and cost factor.

- Manufacturing Process: Variation in thickness affects the processing techniques such as bending radius, formability in stamping, and welding parameters.

Machined data clearly shows that 18-gauge sheet metal (approximately 1.22mm) is approximately 0.50mm thicker than 22-gauge sheet metal (approximately 0.72mm). It is not a tiny discrepancy; it is a rather critical parameter that causes enormous differences in mechanical properties, fields of application, and cost. While designing and selecting the materials for LS products, engineers are required to precisely choose the right sheet thickness matching specific functional requirements and performance specifications.

Why Must Medical Device Housings Be Fabricated From 18-gauge Steel?

Medical equipment places extremely stringent requirements on chassis enclosures far beyond what is needed for typical equipment. The necessity for heavier 18-gauge laminate is largely a result of the following basic engineering and safety concerns:

1. Exceptional Structural Strength and Rigidity

Medical equipment (larger or wheeled units such as monitors, ultrasound machines, and workstation carts) goes through a lot of mechanical stress and shock when moved, operated (pushing, pulling, and bumping), cleaned, and serviced.

Heavier 18-gauge laminate is more resistant to bending, denting, and deformation, which enables the enclosure to effectively protect the delicate electronic and mechanical components within, from device failure or component mismatch due to deformation. 22-gauge laminate is not as resistant to deformation under the same conditions.

2. Excellent Electromagnetic Shielding Effectiveness:

Medical environments are filled with other causes of electromagnetic interference (EMI), including other equipment, cellular phones, and Wi-Fi. Even the devices can generate electromagnetic radiation.

The metal casing is the main shield against electromagnetic interference (EMI) and radio frequency interference (RFI). 18-gauge, heavier laminate provides much more shielding than 22-gauge laminate. This is necessary to avoid disturbing sensitive circuits within the device (such as electrocardiograms, electroencephalograms, and low-level biosignal amplifiers) and to prevent disturbance of other devices by the radiation of the device itself (meeting strict EMC standards such as IEC 60601-1-2). Inadequate shielding can lead to incorrect measurements and even make diagnosis or treatment impossible.

3. Increased Protection and Longer Lifetime

Medical equipment enclosures must be capable of withstanding routine and active chemical disinfection (alcohol, chlorine disinfectants, peroxides, etc.) and physical cleaning. 22-gauge thinner steel is more susceptible to wear and perforation due to corrosion or repetitive stress.

18-gauge steel provides more material reserve, significantly increasing the corrosion resistance, wear resistance, and overall service life of the enclosure. This allows the enclosure to remain in integrity and sealing in harsh environments, preventing contaminants or liquids from penetrating the device.

4. High-Reliability Safety Grounding and Protection:

Medical devices are patient safety with extremely high electrical safety demands (IEC 60601-1). The enclosure is a critical component of the protective grounding of the device.

Thicker 18-gauge plate makes a more secure and stronger mechanical point of attachment when connecting to the ground wire, offering a low-impedance and stable ground path in case of a fault, which is critical to prevent hazards of electric shock. Thinner plate will experience issues with connections at the ground screw caused by stress or corrosion.

5. Professional Appearance and User Confidence

More substantial 18-gauge plate generally offers a more substantial, high-tech, and high-quality look and feel, which suits the professional presence of medical devices and makes medical staff and patients even more confident in their quality.

Although 22-gauge plate is thinner, lighter, and less expensive, its structural integrity, electromagnetic shield performance, long-time life, and protection against safety hazards cannot satisfy the high dependability, safety, and regulatory compliance requirements of medical devices. With its large thickness difference, 18-gauge plate provides a key mechanical barrier, electromagnetic interference shielding, and long-term safety assurance for medical device enclosures. It is an essential engineering choice to ensure the stable and safe operation of medical devices in mission-critical applications. In medicine, ruggedness and protection of the device enclosure surpass by far the demand for an ultra-thin design.

How Does PCB No. 22 Reduce Material Cost For Consumer Electronics By 30%?

Reducing material costs by far (targeting 30%) using 22-gauge (lighter) sheet metal rather than heavier sheet metal (e.g., 18-gauge) requires multi-angle collaborative optimization, not just material substitution. The following are key strategies and concepts:

1. Direct Raw Material Savings:

- Weight Reduction per Unit Area: Immediate effect. 22-gauge sheet metal is about 42% thinner than 18-gauge sheet metal. That means for the same area, used metal material weight is about 42% less. For consumer electronics products (such as smartphones, tablets, laptops, headphones, and smart speakers) involving a lot of metal in casings, brackets, shields, or battery covers, material cost is a major component of the bill of materials (BOM).

- Lower Cost of Purchase of Raw Material: Reduced material requirements directly reduce the cost of purchase of metal coils or sheets.

2. Cost Savings from the Optimization of the Manufacturing Process:

- Increased Stamping Speeds: Lighter sheet metal requires less punch force. This allows the stamping press to run at higher speeds, making more parts per unit of time, spreading fixed costs (equipment depreciation, plant space, and overhead) and thus reducing the cost per part.

- Less Die Wear: Forming thin sheet metal applies less wear and stress to dies, extending the life of expensive dies and reducing the frequency and expense of die maintenance and replacement.

- Higher Yield: Thin sheet metal, when properly designed, may be less prone to cracking or excessive springback than thicker sheet metal in certain complicated forming operations, reducing scrap rates and rework costs.

- Reduced Energy Consumption: Energy consumed in forming, stamping, and other processes is reduced.

3. Reduced Warehousing and Logistics Costs:

- Reduced Product Weight: Reducing the net weight of the finished product (especially for products that involve a large number of metal parts) can significantly reduce shipping expenses (air, sea, and ground freight are charged per weight/volume).

- Optimized Storing and Packaging: Slender parts provide more compact packaging, improving the space utilization in warehousing and shipping, and reducing logistic and warehousing costs per unit of product. Even the raw material coils/sheets used are lighter to store and manage.

4. Optimization of Design (Most Important!):

Reducing thickness alone without thinking in terms of design could result in poor structural stiffness or strength. The 30% cost reduction is based on smart design leveraging the properties of thin sheet metal:

- Structural topology optimization: CAE analysis allows for optimal material placement as needed, removing redundant elements, and meeting strength and stiffness demands with minimal material use.

- Adding ribs, flanges, and concave-convex contours: Precisely detailing ribs, flanges, and concave-convex profiles into 22-gauge sheet metal can significantly increase the moment of inertia of the section, significantly improving stiffness and strength, making up for lost performance with thinning, while maintaining total material usage well below the equivalent thicker sheet metal.

- Material consolidation: The easier formability of thin sheet metal allows product formerly constructed of a number of stamped, welded, or riveted parts to be produced with fewer, or even a single, piece, reducing process steps and joining costs.

- Integration with other elements: Using less costly non-metallic materials (engineering plastics and composites) in non-critical structural elements or where special properties are needed (insulation or appearance) with 22-gauge metallic components.

5. Supply Chain and Economies of Scale:

- Mass procurement and better raw material price discounts can be achieved through large-scale applications of No. 22 steel sheets.

- Manufacturing becomes more economical with higher capacity usage.

- Reduced scrap generation and disposal costs.

Baked-in 22-gauge thinning is directly converted into raw material savings and potential efficiencies in processing, and that’s what cost savings are founded on. However, the attainment of a material cost savings of up to 30% requires the combination of highly advanced engineering design (topology optimization and structural reinforcement design) and optimized processes of manufacturing to fully utilize thin sheet without compromising product performance and quality. This is a well-coordinated effort requiring close coordination among engineering, design, manufacturing, and procurement. We have successfully adopted thinner sheet metal for various consumer electronics projects at LS, where huge material cost savings have been achieved in an integrated fashion.

What Are The Chain Effects Of Receiving The Incorrect Specifications For Sheet Metal Fabrication Costs?

Receiving the incorrect sheet metal gauge on a sheet metal fabrication project (e.g., using 18 gauge when you should have used 22 gauge, or vice versa) can cause a chain reaction that significantly increases total manufacturing costs. This is an analysis of the specific chain effects of receiving the incorrect gauge on fabrication costs:

1. Direct Raw Material Cost Increase

Choosing Thick Plate (e.g., having 18-gauge when 22-gauge):

- Material Waste: 18-gauge plate is approximately 42% heavier than 22-gauge plate for the same area, directly increasing material purchase prices.

- Overdesign: Using thick plate when excess strength is unnecessary is paying for useless performance.

Choosing Thin Plate (e.g., having 22-gauge when 18-gauge):

- Higher Scrap Rate: Thin plate can generate more deformation and cracking during processing, with increased scrap rates and indirectly raising the unit price of effective material.

2. Process cost vicious cycle

(1) Rises in equipment and energy prices

| Error type | Impact on processing | Cost increase |

|---|---|---|

| Incorrect use of thick plates | Stamping requires a larger tonnage press | Equipment rental/energy costs ↑30%~50% |

| Laser cutting speed decreases, gas consumption increases | Unit labor cost ↑, auxiliary material cost ↑ | |

| Incorrect use of thin plates | Bending requires more precise control, multiple trial and error adjustments | Debugging time ↑, production capacity ↓ |

| Welding is prone to burn-through, requiring power reduction and multiple passes of welding | Labor time ↑, argon gas consumption ↑ |

(2) Die maintenance and life expenses

- Incorrect application of heavy plates: Punching heavy plates generates die stress overload, speeds up wear or chipping, and raises die repair frequency by 2-3 times.

- Abuse of thin plates: Thin plate blanking requires higher clearance (generally 8%-12% of plate thickness) and traditionally prepared dies are more prone to burrs, requiring special die repair.

→ Chain costs: Die repair cost (↑) + loss of time (↑) + emergency custom die cost (up to 2 times traditional dies).

3. Lowered Yield and Rework Expense

| Specification Errors | Typical Defects | Hidden Costs |

| Using Thick Plate as Thin | Excessively Large Bend Radius, Interference in Assembly | Secondary Processing (Grinding/Cutting) + Delays in Structural Design Revisions |

| Using Thin Plate as Thick | Bending Cracks, Rivet Stripping, Welding Deformation | Rewelding/Scrap + Risk of Customer Returns + Cost of Quality Claims |

→ Total Impact: For every 10% loss of yield, total costs increase by approximately 15% (including material, labor, and administrative losses).

4. Snowball Effect of Supply Chain and Time Costs

Production Delays:

- Slow thick plate processing → Order shipment delays → Risk of liquidated damages

- Thin plate high scrap → Urgent replenishment → Increased procurement cost (small batch raw material unit prices may be 20% higher)

Design Rework:

- Upon failure of product testing due to low strength (due to misuse of thin plates), the following is compelled:

- Design change → Re-mold → Second trial production → Delayed launch

- Cost Impact: Overall project costs will be in excess of 50%, and loss of opportunity costs of missed markets is harder to quantify.

5. Ultimate Financial Impact: Loss of Price Competitiveness

Suppose the initial target cost of a sheet metal component is $100 per unit:

| Cost Item | Cost Increase After Selecting the Wrong Specification | Final Unit Price |

|---|---|---|

| Raw Materials | +15%~25% | $115~125 |

| Processing Energy Consumption | +10%~20% | $126~150 |

| Molding/Maintenance | +5%~15% | $132~173 |

| Yield Loss | +8%~12% | $142~194 |

| Total Cost Increase | +42%~94% | $142~194 |

Solution: How to Avoid Specification Misselection?

1. DFM (Design for Manufacturing) Review:

During the drawing stage, process engineers verify compatibility of material specifications with the structure (e.g., minimum bend radius formula: Rmin ≥ plate thickness × coefficient).

2. Rapid Prototyping:

Use laser cutting and hand bending to make functioning prototypes and verify assembly and strength (only 1/10 of the cost of mold making).

3. Cost Simulation Software:

Import ERP system data to compare automatically full-process costs (material + processing + loss) by plate specification.

4. Supplier Interaction:

Transfer design requirements to plate suppliers and leverage their database to recommend the most cost-effective specifications (e.g., 22-gauge plate with localized reinforcements vs. 18-gauge plate).

In sheet metal processing, material specs are the key to cost control. Misselecting incorrect specifications not only causes direct material loss but also creates a vicious cycle with equipment wear and tear, collapse of yields, and delay in deliveries. LS has reduced cost overruns because of incorrect selection of specifications to less than 5% through standardized Design for Material Functionality (DFM) procedures along with computer-based cost forecasting. It is recommended that 10% of initial development time should be spent on specification verification so that 90% of future cost overruns can be avoided.

5 Tricks To Find Duplicate Spec Suppliers

When purchasing metal sheet, specifications are a crucial consideration, having a direct impact on cost, performance, and safety. Alas, it is by no means uncommon to encounter unscrupulous vendors who pad specifications (i.e., selling thin 22-gauge sheet as 18-gauge). As seasoned engineers at LS, we’ve compiled the following five tips to assist you in avoiding these dangers:

Tip 1: Understand the rules of the gauge number and understand thickness.

- Key Knowledge: Remember the American Standard rule of “the higher the gauge number, the thinner the thickness” (for typical metal sheets such as steel).

- Key Comparison: As mentioned at the beginning, 18-gauge sheet (approximately 1.31mm) is significantly thicker than 22-gauge sheet (approximately 0.80mm). Be highly suspicious if a supplier is evasive or implies that a larger gauge number means thicker.

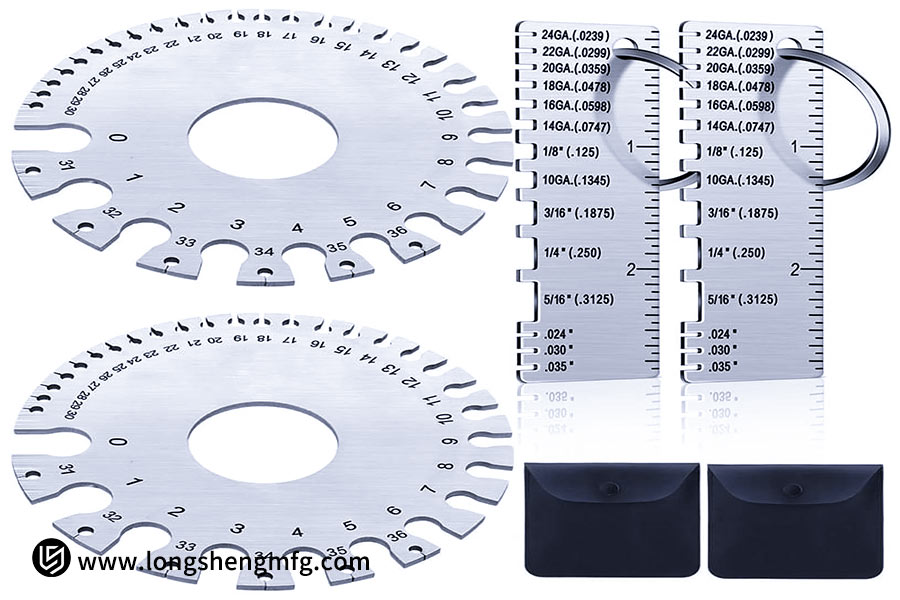

- Verification Tools: Bring or order a standard “Metal Sheet Thickness-Gauge Number Comparison Chart” for on-site validation.

Tip 2: Must-Have Tool – Bring Your Own Precision Measuring Tools for On-Site Measurement

The most straightforward and efficient approach! Don’t presume on test reports or verbal assurances offered by suppliers.

Tool Selection:

- Digital Micrometer: Ideal, with high precision (0.01mm) and simple operation. Reliable brands like Mitutoyo and Starrett are recommended.

- Vernier Caliper: Decreases precision (0.02mm or 0.05mm), but sufficient to observe noticeable differences between #18 and #22 gauges.

Key Measurement Guidelines:

- Make at least 3-5 measurements across different points on the plate (edges, middle), and average out to eliminate local irregularities or edge warping.

- Clean the surface being measured and position the gauge correctly to zero.

Comparison Standard: The test mean value should be within a reasonable tolerance (typically ±0.05mm or as agreed) of the purchased specification (say #18 ≈ 1.31mm). If the test value is close to #22 (≈ 0.80mm), the report clearly must be incorrect!

Tip 3: Sharp Eyes – Check Original Labels and Warranties

Require Verification of Raw Material: Demand to check the original mill marks (steel stamp or inkjet print) on the actual plate, not merely the “Quality Assurance”/”Material Certificate” (MTC) supplied with shipment.

Key Information Verification:

- Gauge Number: Clearly display whether it is 22ga or 18ga.

- Measured Thickness: The MTC should include actual thickness readings from the steel mill or a reputable testing agency.

- Manufacturer and Heat Batch Number: Make this information legible and traceable.

Avoid Discrepancies: If the label or the warranty details do not correlate with the order (e.g., order number 18, label number 22), or if the warranty details are ambiguous or absent, probe deeply.

Tip 4: Weight Estimation – Easy and Prompt Secondary Check

Basic Principle: For the given material and sizes (width and length), thickness varies directly with weight. No. 22 plate is considerably lighter than No. 18 plate.

Estimation Method:

- Use the actual width and length of one plate sheet (in meters).

- Check the material density (e.g., approximately 7850 kg/m³ for ordinary steel).

Calculate the theoretical weight:

- Weight of No. 18 plate (kg) ≈ Length (m) x Width (m) x 1.31 (mm) / 1000 x 7850

- Weight of No. 22 plate (kg) ≈ Length (m) x Width (m) x 0.80 (mm) / 1000 x 7850

Take a single sheet of plate or a randomly selected plate from the entire batch and measure it with a calibrated balance.

Judgment: If the real weight is considerably smaller than theoretical weight for No. 18 plate and close to theoretical weight for No. 22 plate, the specifications are likely inflated.

Tip 5: Professional Third-Party Inspection – The Gold Standard for Dispute Resolution

When Doubts Can No Longer Be Dispelled: If doubts persist after the initial four steps, or in case of a significant investment or a pivotal project, hiring an independent, experienced third-party inspection agency for a re-inspection is the most reasonable course of action.

Content of Inspection: Requires special inspection of the plate thickness (performed by multi-point measuring standards), and a legally enforceable report of inspection can be required.

Value: This report is sound evidence for future supplier negotiations, claims, and even lawsuits. While the cost is expensive, it is a worthwhile investment in comparison to potential product failure, rework, or safety hazard from non-conformance.

LS Company’s Commitment:

As a good supplier of metal materials, LS Company understands the importance of accurate specs. We ensure:

- All plate specs are accurately marked, and we provide full, traceable, original warranty records.

- We support on-site thickness measurement using professional measuring instruments.

- We enforce an unrelenting incoming and outgoing materials inspection program to provide for the prevention of release of non-conforming products.

- We welcome third-party testing, establishing trust by being open.

Metal plate specifications are the building blocks of quality. Remember the “18 gauge is thick, 22 gauge is thin” rule. Add the following five steps to it: doing it yourself with your own gages, checking the original label and warranty, verifying weight estimates, and performing third party testing when necessary, you can make a decent firewall, effectively establishing and preventing suppliers from inflating the specs, getting value for money and a safe and sound project.

Future development: Hybrid specifications in custom sheet metal fabrication

While in today’s quest for extreme cost reduction and creative design, the traditional single-gauge sheet metal production model is being turned on its head, as lead engineers at LS, we believe that the hybrid gauge method will be the future of bespoke sheet metal production. By creatively combining multiple sheet thicknesses without sacrificing functionality and strength, we can produce a revolutionary break-through, reducing costs by over 15% and weight by over 20%!

I. Pain Point Drivers: Why is the hybrid gauge strategy necessary?

- Cost Dilemma: Using only thick sheet metal (e.g., all 18-gauge) results in significant material waste, while thinner sheet metal (e.g., all 22-gauge) requires additional structural reinforcement.

- Weight Bottleneck: The conflict between lightweighting demands (e.g., in new energy vehicles and aerospace) and traditional strength requirements.

- Design Rigidity: Engineers are forced to choose between overdesign and performance compromise.

- Supply Chain Risk: Increased demand for a particular gauge subjects it to price volatilites and stock-outs.

- Case inspiration: A new energy battery box firm replaced the outside casing (non-pressure-bearing portion) from No. 18 to No. 22 plate, keeping No. 18 internal brackets intact. Total cost decreased by 18%, weight decreased by 23%, and the battery withstood the vibration test.

II. Four Core Benefits of the Mixed Specification Solution

| Advantage Dimensions | Traditional Single Specification | Mixed Specification Solution | Value Enhancement |

|---|---|---|---|

| Material Cost | High (Redundant Thick Plate) | ↓ 15%-30% | Thin Plate Replaces Non-Critical Areas |

| Product Weight | Heavy | ↓ 20%-40% | Lightweight Competitiveness Enhanced |

| Structural Performance | Overdesign or Insufficient Strength | Precisely Match Load Requirements | Strengthen Critical Areas, Optimize Redundant Areas |

| Supply Chain Resilience | Reliance on Single Specification Supply | ↑ Multiple Specifications in Parallel Operation: Greater Risk Resilience | Avoiding Material Shortages and Production Suspension Crisis |

Mixed-gauge technology is not just “thin plate + thick plate”, but a reshaping of value system. The companies who grasp this trend will achieve triple competitiveness in cost, innovation, and sustainability. Not choosing LS is just choosing a sheet metal manufacturer, but also a strategic partner to break through mixed-gauge technology and achieve a win-win outcome in product innovation and cost savings. Let’s build the future together!

FAQs

1. Is it possible to tell the gauge of metal sheets just by inspecting them?

Not on your life! 18-gauge and 22-gauge metal sheets differ by a mere 0.44 mm, making it impossible to detect reliably by sight. Visual inspection can have an error rate as much as 90%, which readily results in gauge errors, production delay, and waste materials. To ensure accurate measurements, LS utilizes advanced laser thickness gauge technology with a level of measurement accuracy at the millimeter level, reducing the factor of human error. Therefore, we strongly recommend that all clients utilize equipment professional enough to test gauges rather than risking visual inspection to ensure quality and cost control.

2. Are different materials of the same gauge thicknesses the same?

Gauge numbering systems typically only apply to steel. For other metals and aluminum, thickness requirements may vary and must be converted to avoid processing errors. The same equivalent thickness of 22-gauge steel sheet may not be the same as that for aluminum sheet, for example. LS has a free conversion software on-line. Consumers simply input the material type and gauge code into the website, and the system will give exact thickness data within seconds, which ensures material compatibility, streamlines the process, and reduces on error risk.

3. Does thin sheet metal translate to lower sheet metal fabricating costs?

Not necessarily. Even though thin sheet metal, such as No. 22 sheet metal, costs less in materials, deformation increases as much as 15% in welding and other operations, leading to increased rework and scrap and thus total cost. LS utilizes intelligent process compensation technologies, such as optimized welding parameters and adaptive equipment, to accurately control deformation and optimize total cost. This saves customers materials cost without sacrificing quality or productivity.

4. How can I quickly obtain a quote for custom specifications?

Visit the “Online Sheet Metal Fabrication Services” page on the LS website and upload your design drawing file (supports common formats such as Jpg, PDF, PNG, BMP, Doc, Zip, Rar, DWG, Xisx, and Excel). The system will automatically generate an accurate quote within 10 minutes, including recommended specifications, detailed cost breakdown, and optimization solutions. This process requires no manual intervention, making it efficient and convenient, enabling customers to make quick decisions and saving time and resources. It is suitable for a variety of custom needs.

Conclusion

18-gauge metal sheet is thicker than 22-gauge metal sheet. The “gauge” number for metal sheet is a commonly used thickness designation system in North America (such as Birmingham Wire Gauge (BWG) or American Wire Gauge (AWG). The core principle is: lower gauge numbers represent thicker metal sheet, while higher numbers represent thinner metal sheet. This is the key to understanding the relationship between gauge number and thickness.

18-gauge: Its thickness is typically around 1.20 mm (approximately 0.0478 inches) (the specific value depends on the adopted standard, such as ASTM).

22-gauge: Its thickness is significantly smaller than 18-gauge, typically around 0.79 mm (approximately 0.0313 inches).

Therefore, based on the definition of this gauge system and the standard thickness comparison table, the absolute thickness of 18-gauge metal sheet is significantly greater than that of 22-gauge metal sheet. When selecting materials, if higher structural strength or load-bearing capacity is required, thicker 18-gauge plate should be prioritized. If lightweighting or cost savings are desired while still meeting strength requirements, 22-gauge plate is a thinner, lighter option. Be sure to confirm the exact thickness based on specific application requirements and refer to relevant material standards.

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Hello i think that i saw you visited my weblog so i came to Return the favore Im trying to find things to improve my web siteI suppose its ok to use some of your ideas

I just wanted to drop by and say how much I appreciate your blog. Your writing style is both engaging and informative, making it a pleasure to read. Looking forward to your future posts!

Hi i think that i saw you visited my web site thus i came to Return the favore I am attempting to find things to improve my web siteI suppose its ok to use some of your ideas