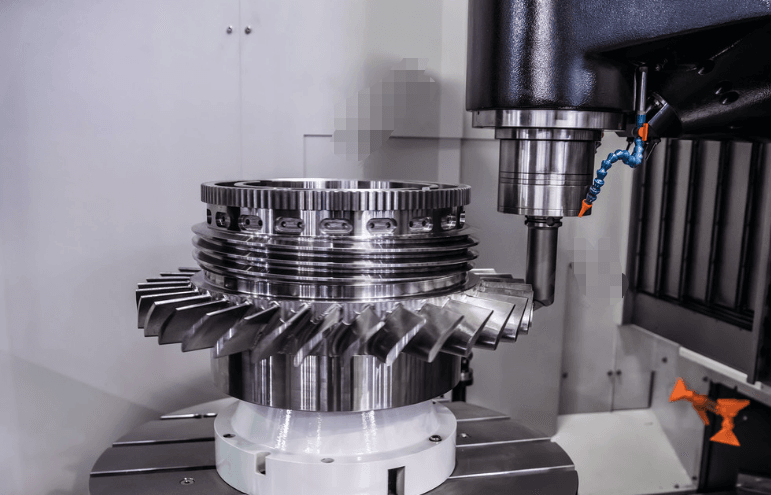

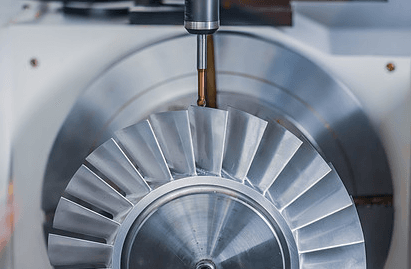

CNC milling machining is a rapidly evolving field, with new technologies and trends emerging all the time. Here are some of the key trends and technologies that are shaping the future of CNC milling machining.

1. Automation and Robotics

Automation and robotics are becoming increasingly common in CNC milling machining. By automating certain tasks, such as loading and unloading workpieces, manufacturers can increase efficiency and reduce labor costs. Robotics can also improve safety by reducing the need for human operators to be in close proximity to the cutting tool.

2. Additive Manufacturing

Additive manufacturing, or 3D printing, is another technology that is changing the face of CNC milling machining. By using 3D printing to create complex shapes and structures, manufacturers can reduce waste and increase efficiency. Additive manufacturing is also well-suited to creating custom parts and prototypes.

3. Internet of Things (IoT)

The Internet of Things (IoT) is a network of connected devices that can communicate with each other and exchange data. In CNC milling machining, IoT can be used to monitor machine performance and identify potential issues before they become major problems. By using IoT, manufacturers can improve efficiency and reduce downtime.

4. Artificial Intelligence (AI)

Artificial Intelligence (AI) is also starting to make its mark on CNC milling parts machining service. By using AI algorithms to optimize tool paths and machining parameters, manufacturers can increase efficiency and reduce waste. AI can also be used for predictive maintenance, allowing manufacturers to identify potential issues before they arise.

5. Advanced Materials

With the growing demand for high-performance materials, CNC milling machining is also advancing in the use of advanced materials. These materials include composites, ceramics, and metals, which offer superior strength, durability, and wear resistance. CNC milling machines are capable of handling these materials with precision and accuracy, opening up new possibilities for industries such as aerospace, defense, and medical.

6. Virtual Reality (VR) and Augmented Reality (AR)

Virtual Reality (VR) and Augmented Reality (AR) are becoming increasingly relevant in CNC milling machining. By using VR and AR simulations, manufacturers can visualize and test designs before they are manufactured. This allows for greater precision and accuracy, while reducing the risk of errors and waste. VR and AR can also be used for training purposes, allowing operators to familiarize themselves with machines and processes in a safe and controlled environment.

7. Sustainability

Sustainability is an increasingly important consideration in CNC milling machining. By reducing waste and energy consumption, manufacturers can reduce their environmental impact and improve their bottom line. CNC milling machines can be designed to minimize waste and optimize material usage, while also using energy-efficient technologies such as regenerative braking and variable frequency drives.

Conclusion

In conclusion, the future of CNC milling machining is exciting, with new technologies and trends emerging all the time. By embracing automation and robotics, additive manufacturing, IoT, AI, advanced materials, VR and AR, and sustainability, manufacturers can stay ahead of the curve and meet the growing demand for high-quality, high-performance products. Whether you are a manufacturer, engineer, or hobbyist, the future of CNC milling machining offers endless possibilities for innovation and creativity.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items