In precision manufacturing, CNC machining can produce components of geometric accuracy and inherent functionality, but metal surfaces are still yet to be challenged by wear, corrosion, and cosmetic imperfections. That is where anodizing comes in, whose worth cannot be overstated.

Not only does anodizing provide a surface finish that imparts lavish coloring to the parts but also a hard “inorganic armor” that significantly improves the surface hardness, wear resistance, and corrosion resistance of aluminum alloy parts, significantly enhancing the product life.

Consequently, its better insulation and enhanced dye absorption effect a complete shift from strength to appearance simultaneously. Choosing LS Precision Anodizing Services is the last step to provide your excellent CNC parts with strong protection and lasting beauty, thereby ensuring dependability in performance under extreme conditions and competitiveness. For your convenience, here’s a recap of the overall conclusions.

Quick Reference: Choose Your Tap At A Glance

| Project | Key Points |

| Principle | An electrolytic process creates a hard, corrosion-resistant oxide film on the aluminum surface, firmly bonding to the substrate. |

| Type II (Normal) | Decorative and basic protection. Thin films, rich colors, and low cost make them suitable for most exterior parts. |

| Type III (Hard) | Ultimate performance. Thick films, ultra-high hardness, and wear resistance make them suitable for parts subjected to high stress and harsh environments. |

| Color | Powerful customization capabilities. A variety of standard colors are available, and Pantone color matching is supported to meet brand needs. |

Anodizing well balances appearance improvement and performance improvement. Type II is suited to best color and overall protection, but Type III hard anodizing is for severe application conditions.

LS Precision Services uses the newest process and control technology to guarantee that not only do you select the best type of anodizing for your use, but you also receive precise, consistent, and diverse color solutions, which enhance the look and image of your product and make it worth twice as much.

Why Trust This Guide? Practical Experience From LS Experts

LS Precision has over 20 years of development experience in business, beginning with the initial stage of anodizing of aluminum alloys and gradually developing into the current integrated CNC machining and anodizing service leading provider.

Equipped with automatic anodizing production lines, state-of-the-art CNC machine tools, and a precision testing center, the company strictly adopts automotive industry standards in managing quality management systems, and the technology capabilities have strictly been certified by the world’s leading companies.

LS Precision always insists on making high-reliability and high-precision products, particularly on corrosion resistance, ultra-high vacuum, and cleanliness. LS Precision owns a large number of core patents, and it has good foundations for high-end manufacturing.

The proposals of LS Precision are based on numerous actual projects. For example, one aerospace technology company required a batch of aluminum parts that were lovely and long-lasting, with “full CNC machining and golden anodizing” called for. Not only did LS Precision’s crew perform the precision milling to completion, but they also tightly regulated anodizing process parameters to offer consistent color and corrosion as well as wear resistance for high-stress aerospace use, finally accomplishing successful delivery within 15 days.

Such case studies demonstrate the ability of LS Precision to utilize its extensive experience to generate consistent and stable outputs.

Why Is Anodizing Essential For Your Precision CNC-Machined Parts?

While at precision manufacturing cutting-edge CNC machining is just the beginning to making quality parts, master surface treatment is the key to realizing the ultimate performance and worth of the product. Especially with aluminum alloy parts, CNC anodizing is not just a process but a native technology that enhances the overall worth of the part. It is the one responsible for pushing product quality on three fronts:

1. Excellent Durability:

CNC anodizing imparts colossal surface hardness, increases wear resistance by 3-5 times, and considerably enhances corrosion resistance, hence making it capable of withstanding very aggressive environmental conditions and increasing product life.

2. Excellent Aesthetics:

Anodizing offers excellent color range, from classic black to a very extensive array of customized color options. Not only does this give the product a beautiful look, but also enhances brand awareness and value addition.

3. Enhanced Performance:

The oxide coating delivers enhanced electrical insulation and coating adhesion, giving more space for secondary processing and meeting the demands of individual applications.

High-grade pure CNC components must be the perfect combination of precision machining and expert surface finishing. LS Precision offers services from CNC machining to anodizing, offering quality assurance from substrate to final product, offering your products lasting protection and unmatched quality.

CNC anodizing significantly improves part performance, appearance, and life, transforming precision-machined parts into high-performance finished components.

Anodizing is an investment and trust worth placing and an extremely important step in top-level manufacturing.

How Does Anodizing Protect Your Metal Parts?

Did you ever want to add a hard but light protection coating to your precision metal parts? Anodizing service makes it a reality by using a cutting-edge electrochemical process.

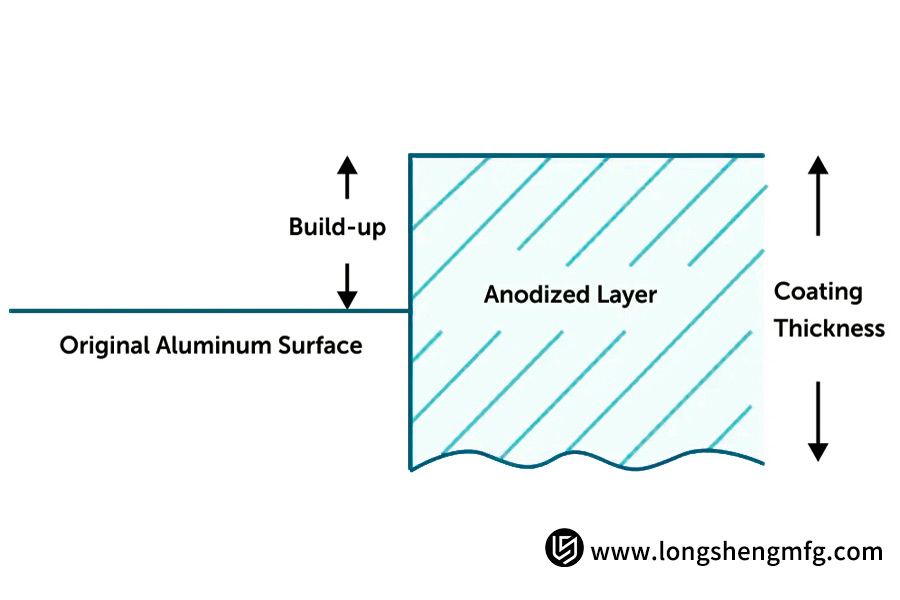

When aluminum is used as the anode in an electrolyte and current is applied, a close, uniform layer of aluminum oxide spontaneously forms naturally on its surface. It’s not a surface-applied coating, but a finished protective coating that spontaneously formed from within the underlying base metal below.

Unlike the other traditional surface finishing operations of painting and electroplating, the oxide film developed through anodizing has the enhanced strength of bonding to the base metal as a component. Because this oxide film is a metal overgrowth, it never peels or flakes off and becomes permanent to the article. This unique method of development creates a strong chemical bond between the substrate and the oxide film, where breaking will not happen even with extreme temperature fluctuations or mechanical shock.

This “protective layer,” developed from the inside outward, is harder in hardness, corrosion protection, and wear resistance, providing your precision parts long-term protection. Contracting professional anodizing services is contracting custom-designed “invisible armor” for your product.

Anodizing produces a heavy oxide film from the substrate, making metal parts extremely hard, non-flaking “protective coat.” That’s the overall description of its superior protective characteristics.

How To Choose The Most Appropriate Anodizing Type For Your Project?

Choosing the best anodizing process is a key consideration to achieving maximum product performance. There are many types of anodizing that address a wide range of requirements, ranging from appearances to ultimate protection. LS Precision offers full-service anodizing solutions to accurately address your project requirements.

1. Decorative anodizing (Type II):

This is the most widespread type, applied mainly for decorative and general corrosion resistance purposes. It is ubiquitous in consumer electronics, exterior parts, and domestic appliances and is available in several colors like black, gold, red, and blue.

2. Hard anodizing (Type III):

Hard anodizing is optimum when your parts encounter severe environments with high strength and wear. Hard anodizing offers rugged surface hardness (to HV500+), wear resistance, and heat resistance and is optimally suited where mission-critical aircraft, military, hydraulic equipment, and industrial applications are employed.

3. Electroless anodizing:

This process forms a consistent layer on complex geometry parts, including deep holes and inside surfaces, with wide coverage and no blind areas. It is particularly well adapted to complex precision parts.

The choice of the right mode of anodizing for your specific application—be it a consumer product with a focus on appearance or machinery in the industrial sector requiring ultimate performance—is critical.

LS Precision’s technical specialists will provide in-depth technical guidance to ensure you receive the most suitable surface treatment solution for your project.

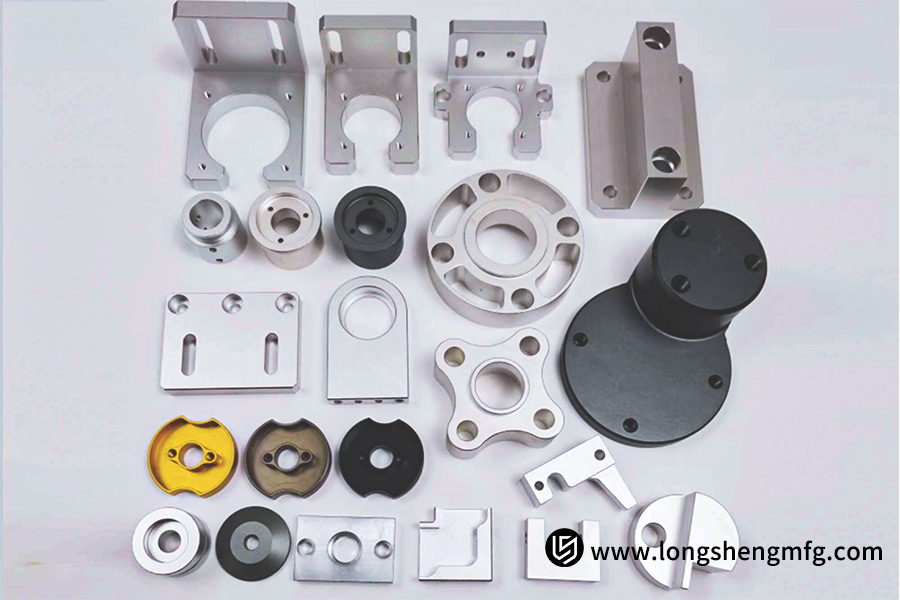

Can I Choose Other Colors For My Product Besides The Standard Black?

Yes! With modern anodizing technology, color options are virtually limitless. Anodizing is not a surface finish but a value-added beauty technology. LS Precision in-house custom anodizing can offer delicate color solutions to aid your product positioning and brand image so that your product will stand out visually.

1. Common Color Options:

By employing advanced adsorption dyeing and electrolytic dyeing, LS Precision offers color finishes including, but not limited to, the following:

- Classic Colors: Champagne Gold, Deep Black, Bright Silver

- Industrial Colors: Gunmetal Gray, Dark Blue, Military Green

- Fashion Colors: Sapphire Blue, Flame Red, Rose Gold

- Special Effects: Two-Tone, Gradient, Pearlescent

2. Factors Affecting Color:

It is advisable to add that anodizing color is reliant on the following factors:

- Substrate Composition: Different aluminum alloys (i.e., 6061, 6063, and 7075) possess different base colors.

- Anodizing Process Parameters: Voltage, temperature, and time must be tightly controlled.

- Concentration of Dye: Different combinations and concentrations of dyes produce different color effects.

- Sealing Process: Affects color durability and stability.

LS Precision maintains a commercial color lab and state of the art color matching system equipped with high-precision test instruments like spectrophotometers, color matching accuracy to ΔE<1.5. We also provide Pantone color matching and can duplicate special colors according to customers’ samples for the purpose of adjusting colors to be used for batch production.

LS Precision, technical expert team, new machines and equipment maintaining, strict quality control system, supplies accurate and stable color solution to your products, which create special visual value and brand reputation.

Four Core Advantages Of LS Precision Manufacturing’s Anodizing Services

Choice of anodizing service company company, LS Precision Manufacturing, is based on the fortitude of the following four key advantages and consequently is a long-term partner of the most reputable companies:

1. Superior Quality Consistency:

LS Precision created a beginning-to-end quality control system, with precise parameter control at each stage, from pretreatment to oxidation and sealing. With our latest automated production lines, we have high-quality colour constancy, film thickness, and performance parameters in every batch of parts to your high standards of quality.

2. Professional Technical Expert Support:

LS Precision’s over a decade of seasoned engineers are at your disposal for free technical consulting and solution. According to your application of the product and performance requirement, we can recommend the most appropriate type, color, and process combination for you to create the anodizing effect most appropriate.

3. One-Stop Integrated Service:

LS Precision Manufacturing provides one-stop processing from anodizing to CNC precision processing. One model reduces over 15% of the whole production process without raising the cost of communications and risks of quality in the intermediate links, and delivering more genuine delivery schedules to you.

4. Rapid Response Mechanism:

Regardless of the size of the project, LS Precision ensures you with a 24-hour full quote and official technical proposal within 48 hours. We provide you with a special customer service channel for timely reporting of the production schedule and offer you stable production cycles and emergency order process functions.

Our anodizing business of LS Precision Manufacturing is founded on outstanding consistency of quality.

Supported with technical specialists, one-stop service model, and rapid response mechanism, LS Precision offer full-service solutions with high technology, stable quality, and timely delivery.

How Did LS Precision Solve The Heat Dissipation And Wear Resistance Challenges Of Motor Housings For A Well-Known Drone Manufacturer?

Actual technical proficiency in the high-end production industry is finding solutions for the most challenging and complicated customer issues. The following case study describes how a top drone maker solved the issue of motor casing heat dissipation and wear resistance successfully. It illustrates how LS Precision Manufacturing heavily integrates hard anodizing and CNC precision machining technologies to provide an overall, innovative solution.

1. Customer Challenge:

A preeminent global drone manufacturer faced a tough technical challenge: the situation of its top-selling product’s high-power motor needs to meet three primary specifications simultaneously: effective heat dissipation, utmost weight reduction, and strong surface wear resistance. Existing processes could not meet these specifications, leading to surface wear and appearance inconsistency, directly impacting product life and business reputation.

2. LS Precision’s Innovative Solution:

After stringent scrutiny, the technical team at LS Precision Manufacturing devised a new, systems-integrated solution:

- The housing was high-precision cut from aerospace-grade 6061 aluminum alloy material in CNC to achieve light-weight design and dimension accuracy.

- A controlled hard anodizing (Type III) was done. By exact control of electrolyte temperature and current density, a hard oxide layer with more than 50μm thickness was created on the component’s surface.

3. Outstanding Results:

This specially designed anodizing process yielded excellent results:

- Surface hardness was greater than HV500, and wear resistance was greater than three times that of normal anodizing.

- The oxide film possessed high thermal conductivity with a 40% efficiency increase in thermal dissipation over traditional spray coating methods.

- The surface finish was a uniform deep black that enhanced the high-quality appearance.

- The weight reduction provided the motor housing with 25% reduced weight.

Results: LS Precision Manufacturing’s entire process for CNC anodizing withstood 200 hours of continuous, high-heat, full-load testing without losing its initial brilliance. The process proceeded to enter mass production, with orders per year exceeding 100,000 units.

With the perfect synergy of CNC precision machining and hard anodizing, LS Precision Manufacturing provides customers with innovative solutions that meet heat dissipation, wear resistance, and lightweighting requirements, showing our problem-solving capability and technical capabilities in surface treatment of complex components.

Looking For High-Quality Anodizing Services Near You? Why Is LS Precision The Smart Choice?

When you type in “anodizing services near me,” you’re not searching for location convenience only; you’re searching for good quality, trusted surface treatment services. LS Precision Manufacturing, with our cutting-edge technical competency and full-service system, is your top choice, offering the nearest value even if we’re beyond your area.

- LS Precision has established an efficient nation-wide logistics network for secure and timely sample and batch delivery.

- With efficient online communication procedures, we provide 24/7 expert technical support and real-time order tracking with remote collaboration as easy as interpersonal collaboration.

- Strictly standardized production processes ensure routine delivery cycles free from uncertainty.

LS Precision Manufacturing fully understands that true proximity is to possess constant and uniform quality, convenient service, and prompt and seamless communications. We provide value-added benefits over geographical closeness to all our customers so that they can enjoy better surface finishing as if they were there.

Geographic proximity is far from make-or-break in choosing an anodizing service company.

LS Precision Manufacturing uses its national distribution network, virtual operations, and secure delivery capabilities to provide “value proximity”—an experience greater-than-“geographic proximity.” That is, a quality, productive partnership experience—the smart choice.

How Much Does Anodizing Increase Your Costs? How Can LS Precision Optimize Your Budget?

Anodizing expense is not fixed; it is an estimation on the basis of material characteristics, process intricacy, and order quantity. Innovative producers understand the value addition and enhanced performance through the surface treatment are much higher than the cost of the initial investment.

1. Cost Analysis:

- Material Base: Variations in oxidation behavior of various aluminium alloys (e.g., 6061 and 7075) influence process time and intricacy.

- Process Choice: Simple anodizing (Type II) is inexpensive while hard anodizing (Type III) is expensive due to the complicated and time-consuming process.

- Volume Impact: Large quantities can significantly reduce unit cost and provide economies of scale.

2. LS Precision Budget Optimization Solutions:

LS Precision provide complimentary design optimization consultations to our engineering staff and recommend the following should be taken into account during the design process:

- Simplify part form, remove deep grooves and holes, and improve oxidation uniformity.

- Use correct film thickness specifications to avoid costly over-specifying.

- Use pre-approved color sets to keep custom dye cost to a minimum.

- Volume pricing discount tiered pricing of 15% or more available.

More importantly, though anodizing is more costly to do initially, its long-term worth well justifies the initial outlay exponentially:

- Extends part life by 3-5 times, significantly reducing replacement frequency and maintenance expense.

- Enhance the quality of products and brand value to enhance market competitiveness.

- By our one-stop service model, we eliminate intermediaries and persist in lowering overall costs.

Anodizing is extremely cost-effective. LS Precision provides you with expert technical consulting, design optimization, and volume discounting in an effort to allow you to attain the best surface treatment solution at your budget and achieve ultimate cost-effectiveness.

FAQs

1. How long does anodizing typically take?

The standard process is 3-5 business days depending on the part complexity, batch, and type of anodizing. Expedited service can be provided. By utilizing efficient scheduling of production and batch processing, LS Precision Manufacturing can ship in 24 hours, meeting your urgent needs without compromising quality.

2. What part sizes can you process?

LS Precision deep anodizing tanks, 2 meters deep, have the capability to anodize up to 1.5-meter-long and up to 200-kg components. Our unique hanger design and proprietary mixing process ensure even anodizing films on heavy and complex parts to achieve the highest aerospace-grade quality.

3. Can the anodized color be completely consistent?

Yes. LS Precision possess a fully automated constant temperature control system and spectrum analyzer for precise measurement of electrolyte parameters, temperature, and dye concentration to provide superior color consistency (ΔE ≤ 1.5) within batches and between batches to ensure consistent and stable color quality to you.

4. How can I get an accurate quote?

Just provide a sample or a sketch, and LS Precision’s master engineers will assess the process within two hours. Depending on parameters such as material, size, and requirement for the process, we will provide a detailed, clear, and competitive quotation without an additional cost, so you can cope with your budget.

Conclusion

Anodizing not only serves as the last process of producing a product, but it is also the most critical aspect that will establish the final value of a product. It adds corrosion resistance, wear resistance, and aesthetics of metal components considerably, enhancing them to be more viable in the market.

With LS Precision Manufacturing, you not only receive the world’s top-of-the-line CNC anodizing technology, but a reliable manufacturing ally as well. With years of industrial experience, rigorous quality control system, and one-stop service, your products will definitely surpass in performance and look, become market leaders.

Act now and let experience pave the path! Submit your part drawings or contact LS Precision directly for free personalized surface treatment consultation and competitive pricing. Let LS Precision Manufacturing give your products the strongest and most striking finishes in the market, and work together to create the next blockbuster!

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.