Your design is complete, and a beautifully designed stainless steel product seems to be shining before your eyes. However, at this moment when the dream is about to be within reach, a key challenge lies before you: how to identify the reliable partner who can truly transform your precision drawings into perfect objects in the face of many factories claiming to be “professional” on the Internet? A simple search for “stainless steel sheet metal fabrication near me” returns a dizzying amount of results.

The reality is that finding the best fabrication plant is not as simple as finding the “nearest” on a map. It is more like a systematic evaluation that requires professional vision – you need to think like an experienced expert. Blind selection may not only lead to deviations from expectations and delays in delivery, but also unnecessary waste of costs. “Close” distance is convenient, but “close” ability is the core of success.

This guide will clear the fog for you and provide a clear and practical evaluation framework. We will guide you to go beyond the simple search list, systematically screen and build your own “Top 10” potential factory candidate list, and ultimately make the best decision from it. Take this crucial first step and let your perfect design move accurately from the drawing to reality.

Here’s What You’ll Learn:

- What “nearby” really means: A perspective that subverts cognition and reveals why location should not be your primary criterion for choosing a stainless steel sheet metal fabrication factory.

- Core hardware capability evaluation checklist: Accurately identify the 6 technical hard capabilities (cutting, bending, welding, materials, surface treatment, certification) that top factories must have.

- Service and cooperation soft power evaluation checklist: Insight into the 5 key service dimensions (engineering support, response, management, prototype, flexibility) that top partners go beyond processing.

- Real case analysis: When the “local” factory hit a wall, how LS Manufacturing achieved far more success than expected through capability-oriented selection.

- In-depth interpretation of the quotation: 5 key elements are analyzed to teach you to see through the truth and traps behind the “sheet metal processing price” and avoid pitfalls.

- Five key questions for final screening: “Interview” candidate factories like a professional purchaser to ensure that you find a partner that truly matches your needs.

- Authoritative answers to frequently asked questions (FAQ): A practical guide to quickly obtain accurate quotes, handle large and small orders, and solve common problems such as material selection confusion.

Now, let’s start this value-oriented exploration journey and accurately lock in the best stainless steel sheet metal fabrication partner for your project!

Why Trust Our Guide? We Solve This Problem Every Day

I am Longsheng, and I have been an engineer at LS for 15 years. Just this morning, I received an urgent request for help from a customer: they chose the wrong sheet metal supplier, which caused the parts to be deformed in welding, the tolerance was out of tolerance, and the production line was stopped. After hanging up the phone and looking at the aviation parts that we are precision-processing and about to deliver on time in the workshop, the contrast is shocking.

We encounter this kind of scene almost every day. After years of deep cultivation in the field of custom sheet metal fabrication and manufacturing, we have witnessed too many project delays, cost out of control, and parts failures caused by hasty selection of suppliers. A wrong decision consumes not only the budget, but also precious time and market opportunities.

But what is more gratifying is that we know more about how the right cooperation can achieve success. When customers work with us in depth, from design suggestions, material selection (such as stainless steel/aluminum plate characteristics), to precision bending, welding and cutting, to appropriate surface treatment, every step is based on professional capabilities, and the result is often efficient, high-quality and cost-controlled.

This “Supplier Selection Guide” is the result of our tempering and responsibility in thousands of projects. It embodies practical experience from simple cabinets to complex medical components, covering key knowledge such as material properties, process limits, tolerance control, etc. This is not theory, but a truly practical and practical guide that can help you avoid pitfalls based on success cases and failure lessons.

Our goal is pure: to help you make smarter and lower-risk choices in a complex market. Whether you ultimately choose LS as your sheet metal processing partner or not, we sincerely hope that this guide based on real engineering practice can help you avoid risks, save costs, and accelerate project success.

The value of this guide is verified every day in the workshop. It is worth your time to understand it, and it may solve your current or future key challenges.

Redefining “Nearby”: Location VS. Capabilities

| Comparison dimensions | Local processing plants (geographic location “nearby”) | Online service providers (comprehensive capabilities “best”) |

|---|---|---|

| Core advantages | Physical convenience brought by geographical proximity | Professional advantages brought by breadth and depth of capabilities |

| Convenient communication | Strong: Samples can be viewed at any time, complex assembly details can be discussed face to face, and communication is intuitive and efficient. | Weak/Tool-dependent: Mainly rely on online communication (telephone, video, email), and on-site inspection is inconvenient. |

| Logistics costs and timeliness | Strong (for specific goods): Especially for large, heavy, and non-standard parts, local transportation costs are significantly lower and transportation time is short. | Weak/needs to be evaluated: Logistics costs increase with distance and cargo size/weight, and timeliness is greatly affected by geography. |

| Response speed (on-site) | Strong: Face-to-face problem solving is more direct and fast, especially for emergencies that require on-site coordination. | Weak: Remote diagnosis and resolution, response speed is affected by communication efficiency and whether someone needs to be sent on-site. |

| Scope of technical expertise | Limited: Limited to local or regional technical capabilities. It is difficult to cover very special or cutting-edge processes (such as specific precision laser welding, food-grade polishing, etc.). | Strong: Access to top national and even global experts and technical resources to match highly specialized and specific technical needs. |

| Equipment advancement and accuracy | Uncertain/may be limited: Equipment levels vary and may not be as good as top service providers. | Strong: Top service providers usually invest in the latest and most advanced equipment and have advantages in accuracy, efficiency and consistency. |

| Price competitiveness | May not have an advantage: Unit costs may be high due to scale and efficiency constraints. | Strong: Through economies of scale and highly optimized production processes, more competitive sheet metal processing prices can often be provided, especially in large-scale or standardized production. |

| Service coverage | Local/regional: Service scope is geographically restricted. | National/global: Service scope is not geographically restricted and has a wide range of choices. |

| Core value proposition | Physical accessibility, localized rapid response, specific logistics cost advantages | Top technical capabilities, advanced equipment, cost benefits brought by scale, professional resources without geographical restrictions |

The “best” partner is the one with the best capabilities for your project, not the one closest to you geographically. – The core of the decision should return to the project requirements themselves:

- If the project is extremely dependent on frequent face-to-face communication, involves oversized and overweight parts, or has a rigid demand for immediate on-site response, then a local high-quality supplier with a close geographical location may be a better choice.

- If the project requires special processes, pursues the highest precision/efficiency, is highly sensitive to costs (especially for non-oversized parts), or the local technical requirements cannot be met, then online service providers with strong comprehensive capabilities and technical expertise or remote professional manufacturers (even if they are geographically far away) are often the wiser “best” choices.

Your “Top 10” Candidate List: Core Technology Capability Assessment Checklist

“The core competitiveness of an excellent processing plant is rooted in a solid hardware foundation, superb process technology, rigorous quality management and an efficient production system.”

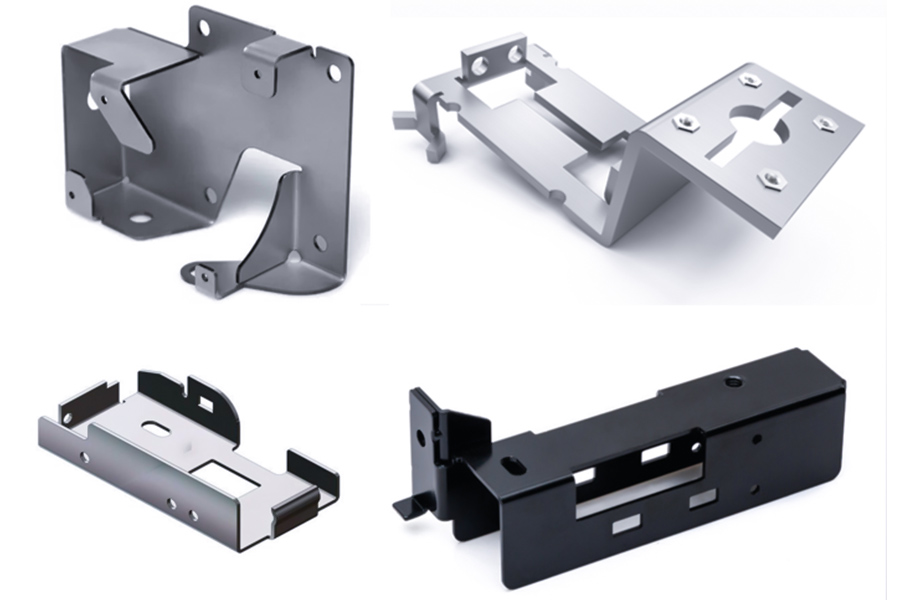

- High-precision cutting capability: Assess whether it has a high-power, high-precision fiber laser cutting machine, has experience in processing stainless steel of different thicknesses, and can control cutting accuracy, cross-section quality and efficiency.

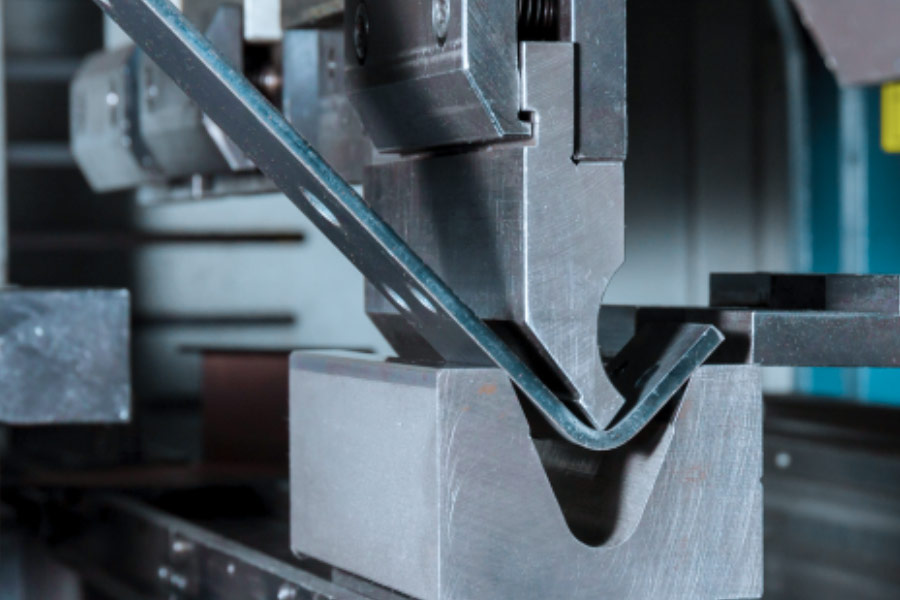

- Complex sheet metal forming capability: Investigate whether it is equipped with a high-precision, multi-axis CNC bending machine (with compensation function), whether it can perform complex bending sequences, and ensure angle accuracy, dimensional consistency and minimum bending radius control.

- Good welding skill: Determine whether it’s experienced in stainless steel TIG welding and laser welding procedures, make the weld be hard, beautiful (color, texture uniformity), dense, and have the respective post-weld treatment (grinding, polishing, passivation) capability.

- Material Science and Processing Expertise: Assess the extensive expertise in the properties (mechanical properties, corrosion resistance, processability) of typical stainless steel grades (e.g., 304, 316) and accompanying processing challenges (cutting heat effect, bending springback, welding thermal cracking), and pay attention to the credibility of raw material sources.

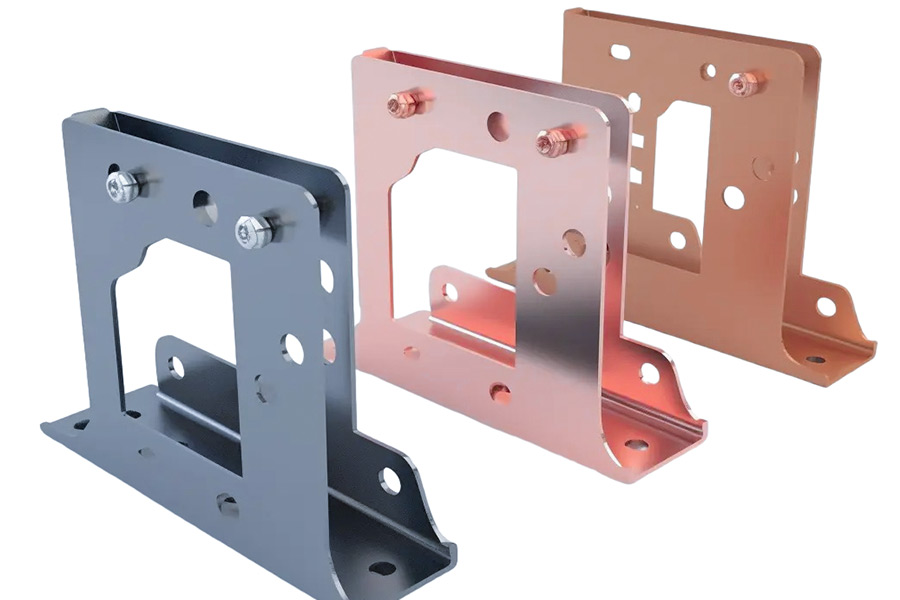

- Diversified Surface Treatment Capabilities: Check if varied stainless steel surface treatment processes (e.g., brushing, sandblasting, polishing, pickling passivation, electrolytic polishing, powder coating) can be supplied or processed, and appearance, durability and batch consistency after treatment can be guaranteed.

- Precision Machining Ability: Assess whether the company has a CNC machining center/lathe with precision turning, milling and other secondary processing capabilities, and is able to perform precision surface, groove and hole processing on sheet metal products to meet tight tolerance requirements.

- Stamping and Mould Ability: Investigate whether there is CNC punching machine/precision stamping equipment and mold (especially continuous mold) design and production capability to handle economically and efficiently large-sized or special shape parts production.

- Quality assurance system and certification: Check if it possesses ISO 9001 and other quality management certifications, maintains a complete-process inspection system from raw materials to finished product, and possesses available and calibrated test equipment (e.g., three-coordinate measuring machines and flaw detectors).

- Engineering support and design optimization: Verify whether it has manufacturing design analysis capabilities, can provide optimization suggestions during the design phase, has good communication skills from engineers, and is responsive to quick production of high-quality samples.

- Production planning and scheduling efficiency, rate of on-time delivery, significant equipment capacity coordination, raw material purchasing and outsourcing ability and plans for handling fluctuations, and maintenance status of equipment.

Service And Cooperation Capability Assessment Checklist

“The value of a top partner lies in the ability to convert processing needs into surefire solutions.”

- Engineering Support (DFM): Evaluate whether it can positively provide manufacturability analysis prior to the design phase to help achieve cost savings and improved mass production viability through optimization of structure, process or material choice.

- Speed of Response: Review the response speed of inquiries, technical guidance and problem feedback (e.g., responding in 24 hours) to ensure effective and smooth channels of communication.

- Project Management: Verify whether a specific full-time project manager can track the progress of the order through the process, handle internal and external resources, and coordinate the delivery nodes in relation to the specifications.

- Prototype Service: Verify the feasibility of quick sample-making (e.g., 3-7 days delivery), to enable design, process and function verification through physical samples, and reduce the risk of mass production.

- Order flexibility: Determine whether it can absorb order requirements ranging from individual prototypes to batch orders of thousands of units and adapt to quantity fluctuations at each stage of product development.

- Value-added services extension: Determine whether the company goes beyond expectation in extending service, such as supply chain integration support (e.g., outsourcing coordination of surface treatment, logistics solution optimization) or research study of technical pain points (e.g., anti-fingerprint processing technology).

The core of this list is to discover that a truly great manufacturing partner must be an extension of your R&D and supply chain. Not only can they “make it”, but also help you to optimize products, accelerate listing, control risks, save cost, and ultimately bring commercial success through professional expertise, effective communication, stringent management, and flexible response. When selecting and evaluating, be sure to venture beyond hardware specifications and unit prices and deeply interrogate their “soft power” and “service genes”.

Case Overview: LS Manufacturing High-end Food Equipment Shell Purchasing Experience

As project engineer for the aforementioned project within LS Manufacturing, we just encountered serious challenges when purchasing an order of high-end food processing equipment shells.

Core specifications: The shell must be manufactured out of food-grade 316L stainless steel, and the welds must meet strict hygienic standards – smooth finish, no dead corners, easy cleanability, and extremely high surface treatment quality demands.

Dilemma of localization effort: We first tried to contact some local processing facilities. Although the first price quote was tempting, after extensive communication and sample testing, we saw that they generally had bottlenecks:

- Reluctant to assure weld quality: Lack of access to state-of-the-art welding technology and stringent quality control made it difficult to give the quality of flawless hygienic welds as desired.

- Shoddy surface treatment: The samples provided were not able to surpass our top-grade equipment standards of finish and evenness.

The project was therefore delayed for some time, and finding a certified supplier became an imperative.

Breakthrough solution: We ultimately chose to work with LS, a talented online sheet metal manufacturing solutions company. Its advantages are:

- Front-end design optimization (DFM): LS engineers were brought in during the design review process early on and tuned some key bending angles by applying design manufacturability analysis, effectively reducing the amount of welding and reducing risks early on.

- Greater process guarantee: They used automated laser welding technology to ensure the accuracy and consistency of the weld, and followed it up with exquisite professional polishing technology to achieve the required hygienic surface finish to perfection.

- Smooth remote cooperation: Geographical distance is not “close by” but the entire cooperation process smoothly works out and efficiently through its transparent online information exchange interface, open process management and secure logistics system.

Results and value: The final delivered product far surpassed our expectations and fulfilled or even exceeded the stringent food-grade quality and hygiene requirements. This instance clearly shows that in the context of high-precision and high-standard manufacturing demands, the supplier’s professional technical competence, process level, and collaboration efficiency are much more essential than geographical convenience alone. Choosing the right partner with underlying professional capability is the decisive key for the project’s success.

Reading The Sheet Metal Working Quotation: How To Penetrate The Secrets Of The Price

The notice – “the lowest quotation usually conceals the highest risk” – is far from being alarmist in sheet metal fabrication. A seemingly cheap low price usually goes at the cost of quality, delivery or service. To be able really to unveil the quotation’s secrets, the point is to take its build-up apart and learn about the value logic:

1. Essential cost components:

- Material cost: This is the building block. Prices of plates of different grades (e.g., 304 and 201 stainless steel) and different thicknesses can vary by dozens of dollars. Be careful against vendors using low-quality or non-standard material in an attempt to reduce cost.

- Processing hours: Includes every process such as laser cutting, bending, welding, and grinding. Complexity of process, accuracy requirement, and batch size all directly influence working hours. Efficiency can be increased by skilled labor but the labor cost is also greater.

- Equipment depreciation: High-precision laser cutting machines and CNC bending machines are equipment that require massive investments, and their cost of use has to be inevitably transferred to the quotation. Reasonable valuation: High-precision equipment may achieve higher precision, efficiency and yield rate, although its unit cost is high.

- Surface treatment: Powder spraying, electroplating, wire drawing, etc. are oftentimes underestimated. Numerous processes, thickness of coating, color, level of weather resistance requirement have astronomical cost differences. Make sure the process specifications and acceptability are well established.

- Hidden costs: Management charges, shipping, mold fees (small production runs), quality inspection charges, etc. all must reasonably be budgeted for.

2. Value appraisal: Beyond nominal price value

- Transparency is the standard: A good quote should have an easy-to-read design and be as distinguishable as possible with respect to the various costs (at least the main processes and material), rather than providing a general “one price”. Lack of clarity is the herald of a trap.

- Supplier capabilities = potential value: High-value suppliers are typically able to provide design optimization suggestions (DFM). For example, by optimizing nesting or structural design, you can trim 15% of material. While its processing unit cost is 5% higher, its overall cost (material + process) is lower, the manufacturing cycle is shorter, and the performance of the product is improved. Low-cost suppliers are difficult to provide such value-added service.

- Quality and stability: A good quality control system, stable yield ratio, and on-time shipping capacity all mean lower risks and long-term costs. That defect rate or rework rate that comes with low cost may wind up costing you more than you paid for.

- Communication and service: Those suppliers who respond quickly, communicate effectively, and can resolve issues satisfactorily have lower coordination costs.

Reading sheet metal fabricating quotes isn’t just “number size.”. You must decipher the cost structure like a detective, and determine the total value and risk of the supplier like a strategist. Avoid the temptation of “one price” and embrace partners that provide open quotes, specialist advice (e.g., DFM), and reliable services. A genuinely cost-effective quote is one that can yield you the best overall cost and the lowest risk. Choosing a supplier is really choosing a trusty manufacturing partner.

Final Screening: Five Critical Questions To Pose To Contenders

When the moment comes to make a stainless steel processing partner choice, cost no longer enters the equation. Now, conduct a good old-fashioned “interview” with the factory like a serious buyer – these five basic questions will be your aid to chase the fog away:

“Can you show us a stainless steel product case such as our project?”

This one gets straight to the point and goes over their experience by hand. Ask them to display real pictures, design drawings and even customer reviews (in the name of secrecy). Real success stories are worth a thousand words, and can simply affirm whether their technical understanding and implementation capabilities meet your specifications.

“What is the normal delivery cycle? How does your plant handle emergency orders?”

It is as much a timeline question, as a stress test of production capacity elasticity and supply chain robustness. A transparent standard cycle is the base, and emergency capacity enlargement solutions (e.g., production line tweaking and acceleration scheduling) indicate their crisis management abilities and their actual concern for customers.

“From material to end product, how does the quality control process ensure each step?”

Thorough examination of the severity of their quality system. Approved suppliers will be required to provide detailed information on incoming material inspection (material certification), process monitoring (online measurement of critical dimensions), finished product full inspection/sampling inspection requirements and tools (such as precision measuring tools, three-dimensional), and outline the mechanism of closed-loop processing for non-conforming products. Severe processes are the only pillar of quality uniformity.

“If there is potential for optimization in the design, will your engineers participate in collaborative improvement?”

This is intended to measure their degree of cooperation and technical drive. Excellent partners will not simply go along passively with drawings, but will spur technical dialogue and share experiences in order to improve product performance, manufacturability or cost-effectiveness. Positive responses are indicative of a future win-win partnership.

“Other than central processing, what other value-added services do you provide?”

Examine the business’s extended value of services. Do they provide pre-assembly of components, special packaging (rust protection, customer branding), logistical support or just surface treatment, etc.? Integrated services can simplify your supply chain and reduce management complexity and hidden costs.

These five questions are like precision probes that go deep into the surface commitments and reach the core capabilities and collaborative genes of the factory. The quality of answers will obviously inform you who is your true partner worthy of trust – allowing you to have confidence as strong as steel while making the final choice.

FAQ – Final Questions on Selecting a Stainless Steel Processing Plant

1. How to get an accurate quote quickly?

Provide 3D CAD information (e.g., STEP/IGES file) and 2D plans (PDF file with clear tolerance, material and surface treatment requirements). The more detailed the information (especially on special processes or close tolerances), the more accurate and efficient the quote will be. Quality factories generally reply to detailed quotes on full information within 48 hours, without repeated communication delays.

2. Whether I should search for different types of factories for small batch orders and large orders?

No deliberate distinction is required. Modern integrated factories (such as LS) have adaptive small batch quick prototyping teams (facilitating iteration samples) and automated manufacturing lines (for batch shipping). The most crucial aspect is to verify if the factory clearly declares its area of service and review its pragmatic cases in terms of scale orders (such as how to seamlessly transition from 10 prototypes to 10,000-piece mass production).

3. What if I know nothing about stainless steel materials?

This is the spirit of professional processing plants. Formulate clearly the situation of product application (e.g., outdoor corrosion resistance, food contact or high temperature condition), and reliable partners will recommend materials (e.g., 304 medical grade or 316L acid corrosion resistance) and even provide sample authentication. They might also give you cost-effective solutions (like substituting 304 with 430 to save money) simultaneously in order to avoid you falling into the pitfall of parameter choice.

Conclusion: Beyond “nearby”, define “best”

During the search for the “Top 10 Best Stainless Steel Sheet Metal Fabrication Companies Near Me,” there came a central reality: the concept of the actual “best” is not necessarily by the “nearness” of physical distance. This list is intended to provide you with useful reference, but above all, it is meant to highlight a concept – choosing a stainless steel sheet metal processing company is actually an intensive quest for “value” as contrasted with “distance.”.

The ease of distance is important, but the core values such as excellent processing quality, guaranteed delivery, exceptional technical skills, clear communication, and the ability to provide you with suggestions for design optimization (DFM) are the cornerstone of project success and long-term cooperation satisfaction. The assessment framework we offer (e.g., technical skills, equipment accuracy, quality control procedure, material knowledge, service turnaround time, etc.) is an effective tool for you to dispel the haze and correctly filter out genuinely capable and reliable industry partners.

End your search and begin enjoying the “best” value!

It’s time to put an end to the groping in the ocean of information blind! LS not only has the most advanced stainless steel sheet metal processing technology capabilities and strict quality inspection you require, but also has efficient and convenient online services. We’re convinced that we can be an active competitor on your shortlist and are awaiting the opportunity to serve you with our craftsmanship and expertise.

Act now and see the difference yourself: Post your design sketches and instantly get a detailed, clear and competitive price quote with free manufacturing feasibility study (DFM). Allow our specialists to reveal the potential for more efficient design, design for better quality and cost savings. Choose value, choose professionalism, let your next stainless steel sheet metal job start with LS, and feel the big difference made by the “best” partner! Upload drawings and start your way of great quality!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Fantastic goods from you, man. I’ve understand your stuff previous to and you’re just extremely wonderful.

I really like what you have acquired here, really like what you’re stating and the way in which you say it.

You make it entertaining and you stll care for to keep it

sensible. I can’t wait to read far more from you. This is really a tremendous site.

Hello! I just want to give a huge thumbs up for the great information you’ve got here on this post. I shall be coming again to your blog for more soon.

I am delighted that I detected this website, just the right info that I was looking for! .

hey there and thank you for your info – I’ve definitely picked up anything new from right here. I did however expertise several technical issues using this web site, as I experienced to reload the website a lot of times previous to I could get it to load correctly. I had been wondering if your web hosting is OK? Not that I am complaining, but sluggish loading instances times will very frequently affect your placement in google and could damage your high-quality score if ads and marketing with Adwords. Anyway I am adding this RSS to my email and could look out for a lot more of your respective intriguing content. Make sure you update this again soon..

There are some fascinating closing dates on this article but I don’t know if I see all of them heart to heart. There’s some validity but I will take maintain opinion till I look into it further. Good article , thanks and we want more! Added to FeedBurner as effectively