Plasma cutting gun: a precise conductor who controls the power of lightsaber

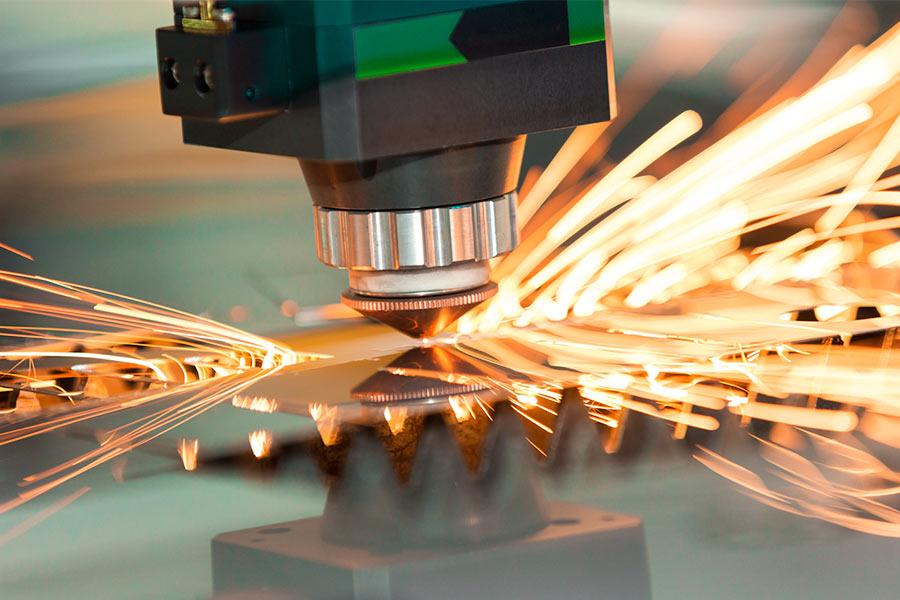

When the plasma cutting machine cuts through the metal, sparks fly and the cut is as smooth as a mirror. The speed and power it shows often remind people of the indestructible energy weapons in science fiction movies. However, what drives this visible hot “lightning” is not magic, but a precise, compact and perfectly coordinated system – the plasma cutting gun (or cutting torch). It is like a skilled conductor, bringing together high voltage electricity, compressed gas and cooling medium in a small space, accurately guiding the tens of thousands of degrees of plasma arc to complete the feat of cutting.

Quick reference chart of core component consumables functions and replacement guide

| Core components (consumables) | Function | Simple analogy | Key replacement indicators |

|---|---|---|---|

| Electrode | Generates and conducts plasma arc | Flint in lighter | The center pit is more than 1mm deep, or is obviously deformed, blackened and oxidized |

| Nozzle | Focuses and constrains the plasma jet | Garden hose nozzle | The nozzle is deformed, enlarged, not smooth (out of round), and the inner wall is severely ablated |

| Swirl ring | Makes the gas rotate and stabilizes the arc | Washing machine turbine | Cracks, blockages (air holes are blocked), and deformation |

| Protective cap | Fixes and protects internal consumables | Flashlight head cover | Thread damage, cracking, and inability to effectively tighten and fix internal components |

| Shield | Protects the nozzle and sets the cutting height | Soldier’s shield | Burning perforation, cracks, and severe deformation (affecting height sensing) |

| Gun body | Connects all components and cables | Gun body | Physical damage (cracks, bends), loose or damaged connectors (gas/electricity) |

Here’s What You’ll Learn:

- 30-second preview of the main concepts: How plasma jets transform from compressed air to metal cutting tools

- The combined fighting mechanism of the five major consumables – the design secrets from the electrode hafnium core to the swirl ring oblique hole

- The hidden safety secrets in the gun body structure: Why a simple interlock device can prevent disastrous failures

- The three major differences between machine guns and hand guns, and the fatal impact of poor choices on cutting quality

- The harsh reality of precision manufacturing: How a 0.1mm deviation of a poor-quality copy nozzle can increase cutting cost by 50%

- A real case study from an industrial workshop – How a steel structure factory saves 370,000 yuan a year from the use of advanced consumables

- Deep analysis of high-frequency issues: 6 things operators need to know, including electrode replacement indicators and swirl ring failure indicators

The Core Principle: How a Plasma Cutter Works

| Stage | Key actions and changes | Result/product | Core role |

|---|---|---|---|

| Start | Press the switch, high-frequency circuit is excited | Initial arc is generated between nozzle and electrode | Provide initial energy required for ionization |

| Ionization | High-pressure gas flows through high-temperature arc | Gas is heated to extremely high temperature (tens of thousands of ° C), atoms are decomposed and ionized | Conductive plasma is formed |

| Cutting | Plasma is confined and ejected from the nozzle at high speed | Produce high-temperature, high-speed plasma jet | Melt and blow away conductive metal to form a cut |

1. Initiation:

- When the operator removes his hand from the switch on the cutting gun, the high-frequency circuit inside the machine or the high-voltage pulse circuit is activated.

- This cycle generates a short, high-energy spark (high-frequency arc) between the nozzle (usually tungsten or hafnium and negatively charged) and the electrode (positively charged) in the cutting gun, but without any physical contact between them (non-contact arc ignition). This provides the first energy source for the secondary ionization of the gas.

2. Ionization

- At the same time or later, compressed air (or a protective gas such as nitrogen, argon, hydrogen, etc., depending on the work and material) is fed into the cutting gun’s chamber under pressure.

- The high-pressure gas travels through the tiny opening between the electrode tip and nozzle, directly through the initial arc formed in step 1.

- The high arc energy instantly heats the flowing gas to extremely high temperatures (usually 10,000°C to 30,000°C or higher).

- In these extremely high temperatures, atoms of the gas molecule (such as N₂, O₂) gain enormous energy, and electrons that are outside their nuclei get stripped off. The gas is converted from a stable molecular state to a mixture of positive ions (nuclei) and free electrons carrying a negative charge. This is plasma – the fourth state of matter. Now, the plasma has extremely high temperature and conductibility.

3. Cutting:

- The ionized plasma is closely confined and accelerated by the nozzle geometry.

- This highly collimated, highly hot and highly high-speed (nearly sonic or even supersonic) plasma jet is strongly ejected out of the nozzle orifice.

- When the jet impacts the conductive metal workpiece (workpiece is typically clamped on the positive side of the power supply to form a closed circuit), two significant effects occur:

- Thermal energy effect: The extremely high heat immediately vaporizes the metal.

- Kinetic energy effect: The huge kinetic energy of the high-speed air jet forcibly blows (flushes) out the molten metal liquid from the cut.

- This is done repeatedly as the cutting gun moves along a pre-programmed path, making a neat, narrow cut in the metal.

Plasma cutting machines use high-frequency arcs to ionize high-pressure gas to generate ultra-high-temperature, high-speed plasma jets and use their enormous thermal and kinetic energy to melt and move conductive metals away, cutting them efficiently.

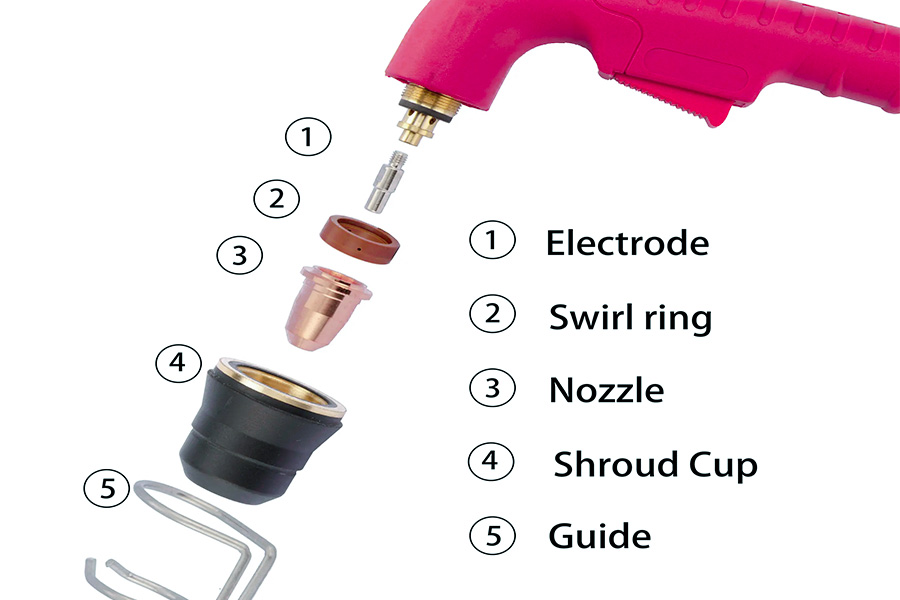

The Consumables: Heart of the Plasma Torch

These exacting pieces of equipment are the “soldiers on the battlefield” of the plasma cutting gun. Their coordinated movement and state directly add up to the quality, speed and general potency of the cutting. What follows is a brief overview of its major constituents:

| Part Name | Main Material | Core Function |

|---|---|---|

| Electrode | Copper substrate + Hafnium/Zirconium core | The starting point for the arc, like the “spark plug” of the system. |

| Nozzle | High thermal conductivity/wear-resistant material (such as copper) | The core precision small hole focuses the plasma to form a high-intensity cutting jet, which determines the cutting fineness and speed. |

| Swirl ring | Engineering plastic or ceramic | The gas is rotated through the inclined hole to form a vortex, stabilize the arc, constrain the jet and assist in cooling the nozzle. |

| Protective cap | Metal | Fix the electrode, nozzle and swirl ring in the correct position to ensure structural stability and sealing. |

| Shield | Metal | The outermost layer of protection, preventing slag splashing to damage the internal parts, and maintaining the distance between the nozzle and the workpiece during drag cutting. |

1. Electrode:

Core: Hafnium/zirconium emission core + copper body.

Function: Shape and convey plasma arc (tip ablation consumption).

Key: Control arc initiation, arc stability, and cutting initiate quality.

2. Nozzle

Core: Precision conical/cylindrical center hole.

Function: Compress, speed up, and focus arc and gas into high-energy plasma jet.

Key: Cutting capacity (fineness/thickness/speed) is determined by the aperture. Hole condition directly affects the quality of cutting.

3. Vortex ring:

Core: With a specific angle oblique hole (high temperature resistant material).

Function: Guide gas rotation (vortex).

Key: Vortex stabilizes the arc, protects the inner wall of the nozzle, and optimizes the jet energy density.

4. Protective cap:

Core: Metal structural parts (with threads/snaps).

Function: Precisely press and fix the electrode, swirl ring, and nozzle to ensure structural integrity and sealing.

Key: Ensure precise coordination of components. Looseness will seriously affect performance and safety.

5. Shield:

Core: Metal cover with a large center hole.

Physical protection: block slag and protect internal components.

Maintain distance: provide a stable nozzle-workpiece distance during drag cutting.

Key: Extend the life of internal components, simplify operation (drag), and improve safety and consistency.

The electrode generates arc, the swirl ring stabilizes the gas and the arc, the nozzle gathers energy to form a blade, the protective cap is fixed and coordinated, and the shield protects the distance – the five precisely cooperate to form the “heart” of plasma cutting, and its state determines the success or failure of cutting.

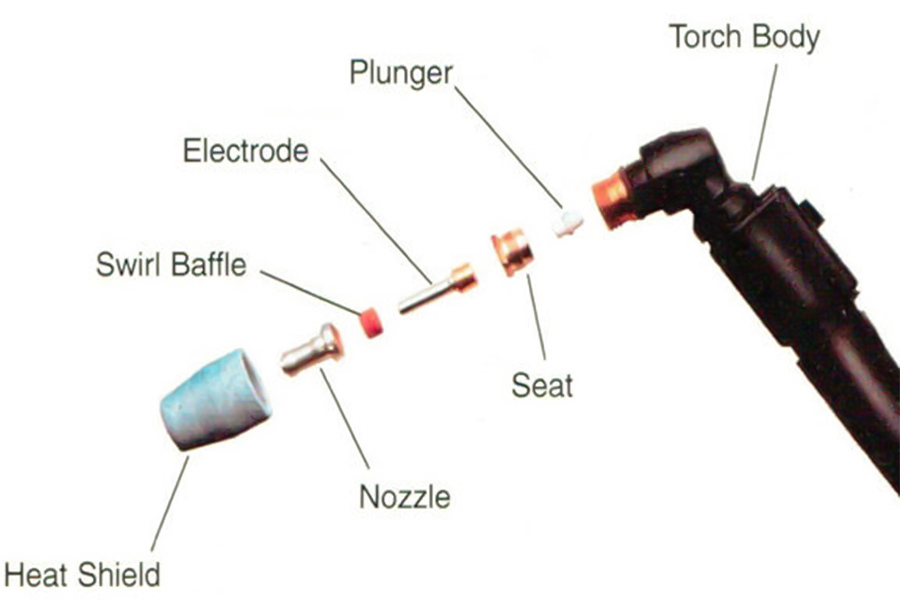

The Torch Body: More Than Just a Handle

| Component name | Functional positioning | Key features |

|---|---|---|

| Body | Core structural frame | The foundation for connecting all components, non-consumable, provides stable support |

| Handle & Trigger | Human-machine interaction interface | Provides grip comfort and operation control (such as start, stop) |

| Safety Interlocks | Safety guarantee mechanism | Forced detection of consumable status to prevent invalid or dangerous start |

| Leads & Connectors | Leads & Connectors | Energy and signal channels Transmit gas, electricity and control signals necessary for work |

1. Body:

As the “skeleton” and basic platform of the entire pistol structure, its core role is to integrate and fix all other key components (handles, switches, safety interlocks, internal pipes, circuits, cable interfaces, etc.).

It is usually not a consumable part itself, but it is the foundation for the stable and reliable operation of the entire tool. A sturdy and well-designed gun body ensures the precise alignment of each component, the stability of operation, and the ability to resist the stress of the working environment. It defines the basic shape and functional layout of the pistol.

2. Handle & Trigger:

This is the main contact point for the operator to directly interact with the equipment. The design of the handle directly affects the operating comfort, grip stability and operator fatigue, and is a key manifestation of ergonomics.

The switch (usually manifested as a trigger or button) is the direct channel for the operator to issue start, stop or other control instructions. Its sensitivity, travel and feedback are essential for precise control. This part of the design is designed to allow the operator to safely and effectively command the device to move.

3. Safety Interlocks:

This is a critical protection mechanism. Its core function is to detect whether key consumables (e.g., welding wire and conductive nozzle in welding gun, glue cartridge in glue gun, etc.) are correctly installed and in place.

If the consumables do not meet the installation conditions (such as not installed, not installed properly, mismatched models, etc.), the safety interlock system will prevent the equipment from starting (e.g., locking the switch function or cutting off the main power supply/gas line). This effectively prevents the equipment from running at no load, misoperation, potential equipment damage or safety accidents caused by missing or incorrect installation of consumables, and is a key line of defense to ensure the safety of personnel and equipment.

4. Leads & Connectors:

These components constitute the “lifeline” between the pistol and the host or external supply source. They are responsible for transmitting a variety of resources necessary for the operation of the equipment:

Gas: such as welding shielding gas, spray atomization gas, etc.

Electricity: Provides energy for heating elements, drive motors, control circuits, etc.

Start/control signal: Transmits the operator’s instructions through the switch, and the host’s feedback signal on the pistol status (sometimes).

Reliable, well-sealed interfaces and sturdy, wear-resistant cables are the basis for ensuring continuous and stable transmission of energy and signals, which directly affects the performance and reliability of the equipment.

The pistol body is far more than a grip. It is a central unit that integrates core functions such as structural support (gun body), human-machine control (handle and switch), safety assurance (safety interlock) and energy signal transmission (cable and interface). The various components work together to ensure the safe and efficient operation of the equipment.

Manual vs. Mechanized: Different Parts for Different Jobs?

| Features | Manual cutting gun | Machine cutting gun |

|---|---|---|

| Shape/handle | Ergonomic handle with trigger | Straight “pencil” or “cylindrical” shape, no trigger |

| Operation method | Manual handheld operation, trigger control start and stop | CNC system controls movement and start and stop |

| Shield cover design | Design is more suitable for drag cutting | Design focuses more on automatic arc voltage height control (THC) |

| Core adaptation | Adapt to operator handheld movements | Adapt to automatic control and high-precision height control |

| Design concept | Human-computer interaction first | System integration and precision first |

Manual cutting gun:

Its core design revolves around the operator’s comfort and control convenience. The ergonomic handle and intuitive trigger allow the operator to hold it stably for a long time and accurately control the start and stop of cutting. The shape and exhaust method of the shield are also optimized for handheld movement (especially drag cutting method) to ensure operational safety and clear vision. It relies on the operator’s experience and feel to maintain the cutting height.

Machine cutting gun:

The design fully serves automated integration and high-precision cutting. The trigger is omitted, and the shape is simple (mostly straight), which is convenient for the CNC platform to firmly clamp and accurately position. The core of the design of its consumables (such as electrodes, nozzles) and key components (especially shields) is to perfectly coordinate with the automatic arc voltage height control system (THC). THC requires specific physical structures (such as specific shield shape, sensor position) to monitor and dynamically adjust the torch height in real time to achieve the highest cutting accuracy and stability, which is unmatched by manual operation.

Manual cutting guns are optimized for manual operation, emphasizing the comfort and control of human-machine interaction; machine cutting guns are born for automation integration, and the core lies in cooperating with the system (especially THC) to achieve precise height control and cutting accuracy.

Why Precision Manufacturing Matters for Plasma Parts

| Comparison dimensions | Precision manufacturing parts | Cheap imitations |

|---|---|---|

| Processing technology | CNC/EDM precision machining | Ordinary machine tool rough machining |

| Concentricity | ≤0.01mm deviation | Often visible eccentricity |

| Surface finish | Ra0.4μm mirror effect | Ra3.2μm and above have machining lines |

| Material purity | 99.97% high-purity copper/hafnium | Adulterated recycled materials |

| Life performance | 8-15 hours of continuous stable cutting | Arc blow occurs in 2-5 hours |

| Cutting quality | Cutting slope ≤3° | Slope ≥8° and severe slag |

The core value of precision manufacturing

The performance limit of plasma components depends on the weakest link. Take the nozzle as an example. Its 0.8-1.2mm center hole is processed by Swiss Thornas Swiss CNC machine and fully inspected by three-coordinate measuring instrument to ensure that the 50,000 rpm plasma jet does not deflect. The hafnium core of the electrode needs to be sintered under argon protection. Insufficient purity will directly produce “double arcing effect” (Double Arcing), causing the nozzle and electrode to break down at the same time.

Balance between cost and return

Although precision manufacturing increases the cost of nozzles by 3-5 times, the benefits it brings are growing exponentially:

- Cutting speed increased by 20% (thanks to stable arc)

- Replacement frequency of consumables reduced by 60%

- Cutting cost per meter decreased by 40%

The essence of plasma cutting is the art of energy control, and precision manufacturing is the technical guarantee to ensure that every joule of energy is accurately directed to the workpiece.

Case Study: A CNC Shop’s Quest for Perfect Consumables

Challenge:

In order to control costs, a large steel structure manufacturer we serve tried to use lower-priced third-party consumables on its multiple CNC plasma cutting machines. However, this led to significant cutting quality issues (such as increased dross), and the consumables wore out faster, requiring more frequent replacement. The end result was that the expected cost savings were not realized, and the overall operating costs increased.

LS’s Contribution:

Although LS does not directly produce the final plasma cutting consumables, we play the role of a key supply chain partner. We provide high-precision in-line CNC machining services to a leading high-end plasma consumables manufacturer, specializing in machining the most core and demanding metal parts of its consumables – copper electrode bases and nozzle blanks.

Results:

With LS’s strict process control and advanced CNC machining capabilities, we ensure that every batch of copper bases and nozzle blanks manufactured for our partners has extremely high dimensional accuracy, geometric consistency and excellent surface quality. These high-precision basic components are the fundamental guarantee for the excellent performance of its high-end consumables. Finally, the use of our precision machined parts consumables successfully helped the steel structure company solve the cutting quality problem, significantly reduced dross, and greatly extended the service life of consumables. This directly translated into longer uptime, fewer downtimes for replacement, and better cutting results, ultimately achieving its initial goal of reducing comprehensive operating costs.

Core Confirmation:

This case vividly proves that the excellent performance of terminal equipment and the cost-effectiveness of end users are often based on the precision and reliability of upstream core component manufacturing. LS is precisely by providing world-class precision CNC machining services and enabling our partners to produce top consumables, thereby creating real and measurable value for end users.

Frequently Asked Questions About Plasma Components

1. When should I replace the electrode and nozzle?

Best practice is to replace the electrode and nozzle at the same time to ensure the stability and performance of the cutting system. When the pit depth in the center of the electrode exceeds 1 mm, it indicates that the electrode has been excessively worn, which will affect the arc stability and lead to poor cutting quality. Similarly, if the nozzle orifice is significantly deformed, enlarged or damaged, it must be replaced immediately, otherwise it may cause airflow turbulence, uneven cuts, and even accelerate the damage of other components. Ignoring these signs will increase maintenance costs and safety risks, so it is critical to regularly check and replace consumables in a timely manner according to these standards to maintain efficient cutting and extend the life of the equipment.

2. Is the role of the swirl ring really that important?

Absolutely important, because the swirl ring is responsible for generating and controlling a stable vortex of gas, which is the core mechanism of plasma cutting. A cracked, blocked or damaged swirl ring will disrupt the uniformity of the gas flow, resulting in a tilted cutting surface, increased dross, deteriorated cut quality, and may quickly burn out the nozzle. This not only affects cutting accuracy, but also shortens the life of consumables and increases downtime. Therefore, regularly checking the swirl ring to ensure that it is intact is a key step to maintain cutting efficiency and avoid unexpected failures, and it must not be ignored.

3. What personal protective equipment (PPE) is required for plasma cutting?

At least the following protective equipment is required: a welding mask that meets the shading number requirements to protect the eyes from strong arc light and ultraviolet damage, a fire-resistant operating suit to prevent sparks or slag from igniting clothing, leather gloves to resist high temperatures and metal splashes, and protective shoes to avoid foot burns or heavy objects. Protecting the eyes, skin and respiratory tract is crucial because the cutting process produces high-intensity radiation, heat, smoke and particulate matter, which may cause burns, vision damage or inhalation hazards. The correct use of PPE can significantly reduce the risk of accidents and ensure safe operation.

4. Can I mix consumables from different brands?

It is strongly not recommended to mix consumables from different brands because each brand has differences in design tolerances, material properties and airflow dynamics of components such as electrodes and nozzles. Mixing may lead to unstable airflow, arc blow or uneven pressure, which may cause a decline in cutting performance, such as rough cuts, increased dross, excessive consumables consumption, and even damage to the internal components of the cutting gun. Insisting on using the same brand of consumables can ensure compatibility and optimal airflow control, avoid unnecessary repairs and cost waste, and maintain cutting quality and equipment reliability.

Conclusion

Every component of a plasma cutting gun is crucial. As a core consumable, its manufacturing accuracy directly determines the finish, verticality and economic benefits of the finished product. In-depth understanding of the function of the components and selection of high-quality products are essential elements for operators to improve their professional capabilities.

The precision standards required to manufacture high-performance plasma nozzles are exactly what we do with every project. Whether you need precision-machined metal or plastic parts – from prototypes to mass production – please say no to mediocre quality. Upload your CAD file to our secure online platform now and get a transparent CNC machining quote and free manufacturability analysis report in seconds. Let us escort your project with professional manufacturing!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Unquestionably consider that that you stated. Your favourite reason appeared to be at the web the simplest thing to remember of. I say to you, I certainly get annoyed while other people think about issues that they plainly don’t know about. You controlled to hit the nail upon the top and outlined out the whole thing with no need side effect , other people can take a signal. Will likely be back to get more. Thank you

Woah! I’m really loving the template/theme of this blog. It’s simple, yet effective. A lot of times it’s challenging to get that “perfect balance” between superb usability and appearance. I must say you have done a very good job with this. Additionally, the blog loads very fast for me on Internet explorer. Outstanding Blog!

Absolutely written content, thanks for entropy. “You can do very little with faith, but you can do nothing without it.” by Samuel Butler.

I was recommended this web site by my cousin. I’m not sure whether this post is written by him as no one else know such detailed about my problem. You’re wonderful! Thanks!

Great goods from you, man. I have understand your stuff previous to and you are just too great. I really like what you have acquired here, certainly like what you are stating and the way in which you say it. You make it enjoyable and you still take care of to keep it wise. I cant wait to read much more from you. This is really a great website.