What’s CNC metal cutting process?

CNC metal cutting is a producing process that makes use of computerized controls to function and manipulate machine and cutting instruments to form inventory materials, similar to metallic, into customized parts and designs. This process has developed from the numerical management (NC) machining process, which utilized punched tape playing cards. CNC machining provides varied capabilities and operations, however the elementary rules stay largely the identical all through all of them.

CNC Metal Cutting Process Rules

The CNC metal cutting process operates on a number of key rules:

-

Laptop Numerical Management (CNC): On the coronary heart of the process is the precept of laptop numerical management. The CNC system makes use of a software program program, written in G-code, to regulate the motion of the chopping software. This permits for exact, repeatable cuts and excessive ranges of automation.

-

Subtractive Manufacturing: CNC metal cutting is a kind of subtractive manufacturing. This implies it begins with a strong block of fabric (the workpiece) and removes materials to form the workpiece into the specified kind. That is in distinction to additive manufacturing processes like 3D printing, which construct up materials layer by layer.

-

Toolpath: The toolpath is the route that the cutting software follows to take away materials from the workpiece. The toolpath is decided by the CNC program and could be as easy or as advanced as essential to create the specified half.

-

Velocity and Feed Charges: The pace and feed charges are vital parameters within the CNC metal cutting process. The pace refers back to the rotational pace of the chopping software or the workpiece, whereas the feed fee is the pace at which the chopping software strikes by way of the workpiece. These charges have to be rigorously managed to realize the specified lower high quality and to forestall injury to the software or workpiece.

-

Coolant: Many CNC metal cutting processes use a coolant to scale back warmth and friction in the course of the chopping process. The coolant also can assist to take away chips from the cutting space.

-

Workholding: Workholding gadgets, similar to clamps and vises, are used to carry the workpiece securely in place in the course of the chopping process. That is essential for security and for reaching correct cuts.

CNC Metal Cutting Process

The CNC metal cutting process includes a number of steps:

-

Workholding: This refers back to the strategies and gadgets used to safe the workpiece firmly in the course of the chopping process. Frequent workholding strategies embody clamps, vises, fixtures, and chucks.

-

Programming and Set-Up: CNC machine chopping requires programming the machine to carry out particular operations.

-

Cutting: The process makes use of bodily contact to take away materials from a strong block of fabric (referred to as the clean or workpiece), utilizing a variety of chopping instruments. This excessive stage of commercial automation makes CNC machining appropriate for a one-off half and mid-volume manufacturing.

-

Limitations: Restricted software entry creates design restrictions. As CNC machining is a subtractive manufacturing process that removes materials from a strong clean, the software must entry all mandatory machining surfaces. Options similar to undercuts and inner geometries can’t be machined as a consequence of restricted software entry.

Varieties of CNC Metal Cutting Machines

There are a number of varieties of CNC metallic chopping machines, every with its distinctive capabilities:

-

CNC Lathes and Spinning Lathe Machines: These machines work greatest for sooner, extra correct creation of spherical parts. They contain a lathe set with a clean (a metallic sheet or tube) that rotates at excessive speeds whereas a metallic spinning curler shapes the workpiece right into a desired form.

-

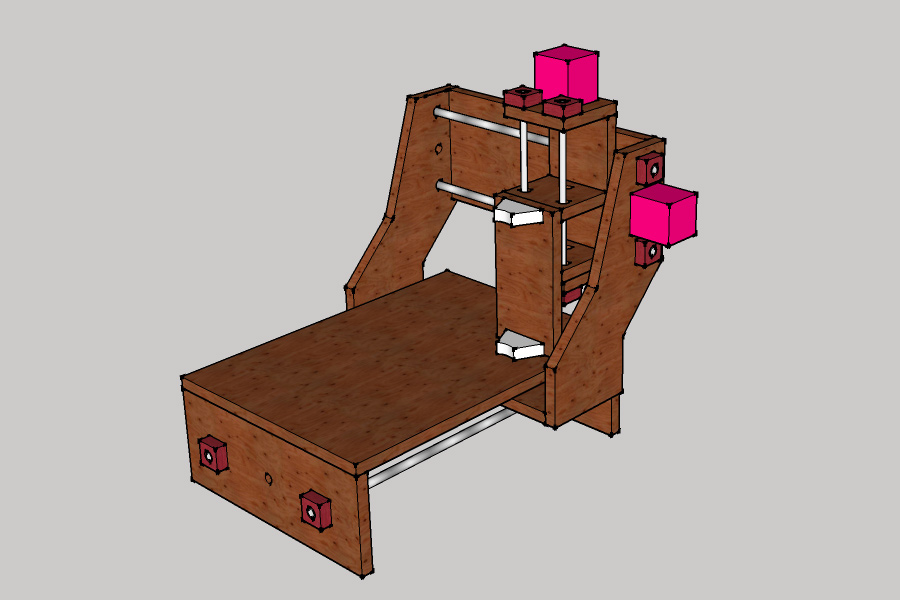

CNC Router Machines: CNC routers are used to chop mill tender metal plates, eradicating additional materials to offer the metallic a particular form. They carry out easy and quick drilling and special-shaped chopping. CNC routers also can lower mill tender metallic plates similar to aluminum, brass, copper, acrylic board, plastics, and delicate metal .

-

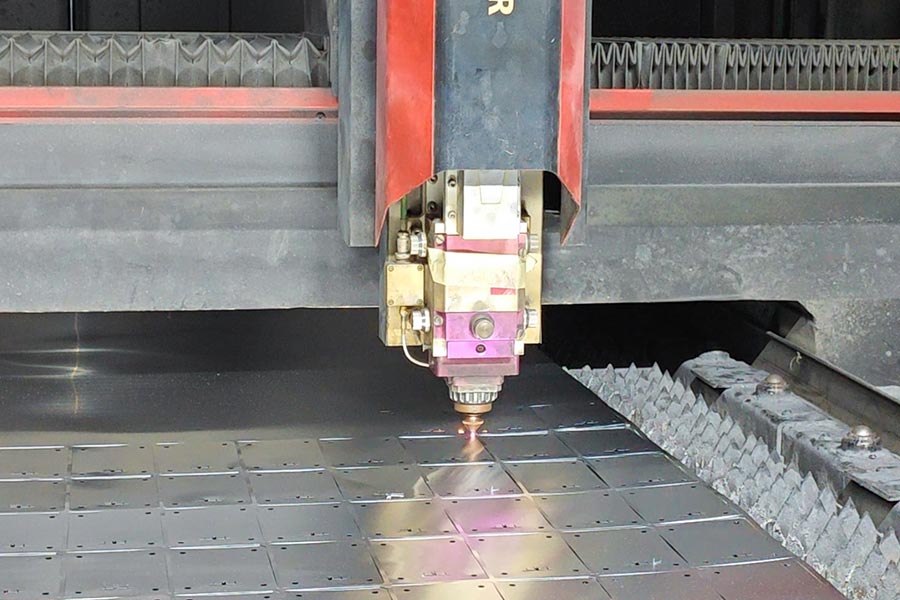

CNC Plasma Cutting Machines: These machines lower as much as 3″ delicate metal, 4″ stainless-steel, and three” aluminum and are able to producing each straight and bevel cuts. They’re constructed to chop metallic plates in addition to metallic pipes .

-

CNC Oxy-Gasoline Cutting Machines: These machines are additionally able to chopping metallic plates in addition to pipes .

-

CNC Waterjet Cutting Machines: These machines work with a extremely pressurized jet of water, or a combination of water and an abrasive, to chop supplies starting from wooden to metal. They produce no smoke and are used as a cooler different for supplies which can be unable to bear the heat-intensive processes of different CNC gear.

Software Areas of CNC Metal Cutting

CNC metallic chopping processes are extensively utilized in varied industries as a consequence of their precision and effectivity. Listed here are among the key utility areas:

| Software Fields | Description |

|---|---|

| Mechanical Manufacturing | CNC metallic chopping is extensively used within the manufacturing business to create customized parts and parts, similar to automotive parts, aerospace parts, and mechanical parts. |

| Aerospace | Within the aerospace business, CNC metallic chopping is used to fabricate parts for plane and spacecraft. Its excessive precision and consistency make it extremely useful on this business. |

| Car Manufacturing | The auto business makes use of CNC metallic chopping to supply automotive parts, together with engine parts, suspension programs, and physique parts. |

| Electronics | The electronics business makes use of CNC metallic chopping to supply parts for digital gadgets, together with laptop {hardware} and shopper electronics. |

| Mildew Manufacturing | CNC metallic chopping can be extensively utilized in mold manufacturing, used to make varied molds, together with injection molds, die casting molds, and stamping molds. |

| Medical Gear | Within the medical discipline, CNC metallic chopping is used to fabricate surgical devices and medical gear. The excessive precision of CNC chopping permits for the manufacturing of intricate and delicate parts required on this business. |

Conclusion

CNC metal cutting is a exact and environment friendly manufacturing process that makes use of computerized controls to form inventory materials into customized parts and designs. The process operates on a number of key rules, together with laptop numerical management, subtractive manufacturing, toolpath, pace and feed charges, coolant, and workholding.

There are a number of varieties of CNC metallic chopping machines, every with its distinctive capabilities, together with CNC lathes, CNC router machines, CNC plasma cutting machines, CNC oxy-fuel cutting machines, and CNC waterjet cutting machines.

CNC metal cutting is broadly utilized in varied industries, together with manufacturing, development, electronics, medical gadgets, papermaking mills and corrugators, shopper analysis, and IoT networks. Regardless of some limitations, its excessive stage of automation and precision makes it a most popular selection for a lot of manufacturing wants.

FAQs

What’s CNC cutting materials?

CNC machines can lower by way of almost any materials you may consider. Probably the most generally employed supplies embody varied varieties of metallic, similar to stainless-steel and titanium, in addition to quite a lot of plastics like ABS, Acrylics, Delrin, HDPE, and Nylon. Different supplies that can be utilized embody foam, similar to carving foam and inflexible foam, which are usually extra light-weight but sturdy.

How correct is CNC metal cutting?

The precision of CNC metallic chopping is remarkably excessive. This manufacturing process makes use of preprogrammed laptop software program to dictate the motion of manufacturing unit instruments and equipment. CNC machining can accomplish three-dimensional chopping duties in a set of prompts. The CNC process surpasses the constraints of guide management, the place dwell operators are wanted to immediate and information machine instruments with levers, buttons, and wheels. To an observer, a CNC system may resemble an everyday set of laptop parts, however the software program program and console utilized in CNC machining distinguish it from all different types of computation. CNC metallic chopping can be utilized to process quite a lot of supplies, together with metallic, plastic, wooden, glass, foam, and composites, and finds purposes in quite a lot of industries, similar to large-scale CNC machining, telecommunications parts and prototyping, and CNC machining aerospace parts, which require tighter tolerances than different industries.What’s the price of CNC metal cutting?

The price of CNC metal cutting can range considerably primarily based on a number of elements. These embody the kind of CNC machine used, the complexity of the mission, the fabric being lower, and the required precision or tolerances.

Several types of CNC machines, similar to laser cutters, waterjet cutters, and CNC routers, have completely different prices related to them. As an example, machines that use a high-powered laser to chop by way of supplies can vary from 4kW to 12kW, impacting the general price.

The complexity of the mission additionally performs a big position in the associated fee. Extra advanced initiatives that require excessive precision and tight tolerances will typically price extra. It is because top-quality machines that may lower with precision to tighter tolerances as a part of the manufacturing process are dearer to function.

The fabric being lower is one other issue that influences the associated fee. As an example, sure supplies, similar to titanium, are more difficult to machine and require particular cutters, which may improve the associated fee.

Lastly, the operator’s wage also can impression the associated fee. Multi-axis machines are dearer to run and may price between $75 and $120 per hour. Nevertheless, the price of CNC machined parts is usually calculated as the whole price of uncooked supplies, plus the price of any particular fixturing, plus the labor hours taken to machine every half.

Typically, the value of CNC machines can vary from just a few thousand {dollars} as much as lots of of hundreds of {dollars} for advanced machines. Nevertheless, it is essential to notice that these prices can range extensively primarily based on the elements talked about above.

study CNC metal cutting know-how?

Understanding CNC Metal Cutting

CNC (Laptop Numerical Management) know-how varieties the inspiration of CNC machine metallic chopping. It includes using computerized programs to regulate the actions and operations of the chopping software. The CNC machine interprets directions from a pc program and interprets them into exact actions, making certain accuracy and repeatability.

Studying Sources

There are a number of methods to study CNC metallic chopping know-how:

Complete Guides and Books: There are quite a few guides and books accessible that present useful insights and sensible data to navigate the world of CNC machine metallic chopping. These assets typically cowl the fundamentals of CNC know-how, the varieties of CNC machines, and the completely different supplies that may be lower utilizing CNC machines.

On-line Programs and Tutorials: There are various on-line platforms that supply programs and tutorials on CNC metallic chopping. These programs typically cowl subjects like the basics of CNC machining, methods to function CNC machines, and methods to design parts for CNC machining. They could additionally embody sensible workout routines that will help you acquire hands-on expertise.

Palms-On Coaching: CNC metallic chopping machines require coaching to make use of. It is not a plug-and-play setup and can want certification to function. Operators can be required to coach in computer-aided design. They may even be required to discover ways to function CNC machines.

Neighborhood Workshops and Maker Areas: These are locations the place people can entry instruments and gear, together with CNC machines, to work on their very own initiatives. They typically supply courses and workshops on varied subjects, together with CNC metallic chopping.

Sensible Suggestions

When utilizing a CNC to chop metallic, it is very important use chopping fluid and study completely different toolpaths, similar to ramp or helix lower to reduce software put on. Understanding the machinability of various metals can be essential, as not all CNC machines can lower all varieties of metallic.

Experimentation

Lastly, do not be afraid to experiment and study by doing. Begin with easy initiatives and regularly tackle extra advanced ones as your abilities enhance. Keep in mind, the important thing to mastering any new ability is observe and persistence.