As increasing need for precision, complex, and lightweight components is developing in high-end manufacturing, five-axis CNC machining technology is emerging as a key driving force for the aerospace and medical device industries.

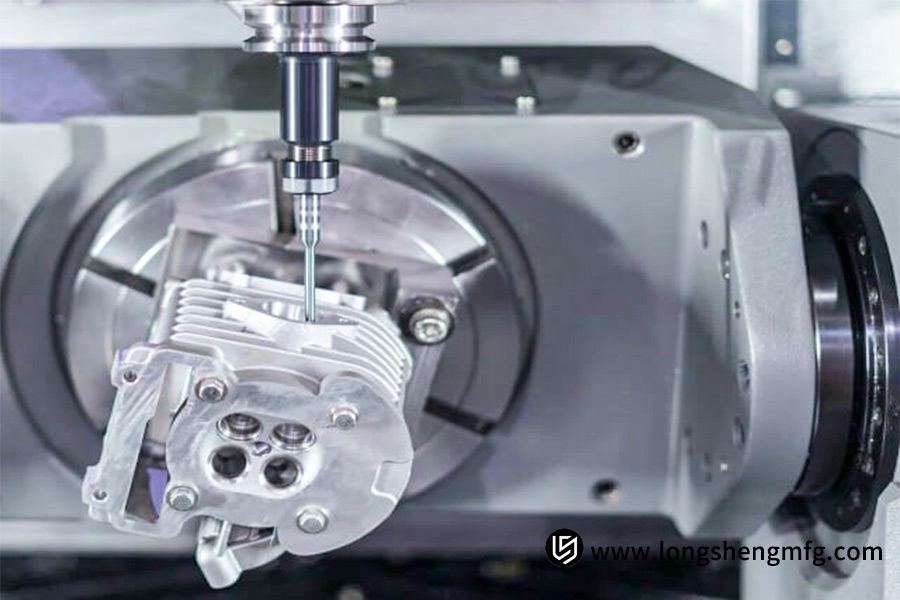

The technology employs multi-dimensional coordinated cutting to achieve simultaneous machining of high-precision curved surfaces, special-shaped structures, and deep cavities. This significantly increases efficiency and makes impossible shapes in conventional three-axis machine tools possible.

In aerospace, it enables the manufacture of thin, light, yet very powerful engine blades and fuselage sections; in medicine, it enables the precise tailoring of implants and surgical instruments to precisely match individual needs.

With its “one-step clamping, complete forming” advantage, five-axis machining bypasses the constraints of conventional methods and is a pioneering force taking high-end production to the realms of precision, efficiency, and customization. To get right to the point, here is a quick summary of the key findings.

Five-Axis vs. Three-Axis CNC Machining Core Quick Reference

| Evaluation Dimensions | Three-Axis Machining (3-Axis) | Five-Axis Machining (5-Axis) |

| Machining Accuracy | Requires multiple setups, resulting in large cumulative errors and lower precision. | Single setup allows for multi-faceted machining, eliminating repetitive positioning errors and achieving extremely high precision. |

| Machining Efficiency | Complex parts require multiple adjustments and setups, resulting in long setup times and low efficiency. | Single setup allows for the majority of machining, reducing downtime and increasing efficiency severalfold. |

| Complexity Capability | Can only machine top and simple sidewall features; cannot handle complex curved surfaces, deep cavities, or special-shaped structures. | Can efficiently process complex free-form surfaces, inclined holes, undercuts, and any other spatial geometry. |

| Surface Quality | When machining steep sidewalls, the ball cutter’s linear speed is low, resulting in poor surface quality. | The cutter consistently maintains optimal cutting posture and linear speed, resulting in superior surface finish. |

| Cost Structure | The machine tool has a low initial investment and is relatively simple to program and operate. | The machine tool, programming software, and specialized technicians are expensive. |

| Applicability | Suitable for high-volume production of simple parts such as plates and discs. | Designed specifically for small-batch, high-mix, and highly complex precision parts (such as impellers and bone implants). |

Despite higher initial investment, five-axis machining is now an essential core manufacturing process for complex, life-critical, and performance-critical parts in industries such as aerospace and medical devices.

Five-axis machining, through its “one-setup, full-scale forming” technology, surpasses traditional three-axis machining in precision, efficiency, and capability for complex geometric formation.

Why Trust This Guide? Practical Experience From LS Experts

This wisdom is directly from LS Precision‘s over two decades of experience with five-axis CNC machining. As a certified vendor to many of the world’s top companies in the aerospace and medical sectors, LS Precision boasts world-class five-axis machine tool fleets from Haitian and DMG Mori Seiki:

- In parallel, LS Precision has established strict quality control processes in accordance with the AS9100 aerospace quality standard and the ISO 13485 medical device quality management system standard.

- The absolute accuracy of 0.001mm of LS Precision and extensive process parameter library of difficult-to-machine aerospace-grade metals such as titanium alloys and high-temperature alloys are the underlying strength behind our authoritative advice.

LS Precision’s history is far more than academic:

- It is a product of successful roughing and finishing of precision turbine blades for jet engines to deliver reliability under hostile conditions;

- It is a product of machining complex biocompatible materials for orthopedic implants (such as artificial joints) that are tailored to the patient’s unique anatomy.

- All optimization of complex tool paths and vibration and chatter elimination is accomplished with a given purpose of tackling real-production problems for our clients.

It is this actual-world experience, gained by the successful production of tens of thousands of flight and life-critical components, which lies behind every solid conclusion and suggestion made within our cost guide.

What Is Five-Axis CNC Machining? How Does It Achieve The Formation Of Complex Curved Surfaces In One Pass?

Five-axis CNC machining is a sophisticated manufacturing method supplementing the three linear axes (X, Y, and Z) with two rotation axes (historically known as A, B, or C). Because of the excellent coordinate precision of the five axes, the CNC machine is able to locate the tool to perform on the workpiece at any location in three-dimensional space and thus mill, drill, and profile complex curved paths within a single setup.

1. Five-Axis CNC Machining Can Perform Single-Step Forming of Complex Surfaces:

The benefit of single-step forming of complex curved surfaces through five-axis CNC machining is:

- Multi-axis link control: The cutting tool can dynamically alter its position while continuing to move in a continuous manner, maintaining the most economical cutting angle under any condition.

- Single-shot clamping: The workpiece is clamped once to the worktable to mill nearly all the features except the bottom face in order to avoid compound error by re-clamping.

- Improved tool life: Short tools are employed with the tool tilt angle set for machining deep cavities or steep walls in order to avoid vibration and enhance cutting stability.

2. Aerospace applications:

In aeronautics, for example, aerodynamic shapes and free surfaces of turbine blades are highly complex. The discs and blades can be turned in one setup to high profile tolerance with surface finish in five-axis turning, and it is extremely critical to engine reliability and efficiency.

3. Medical device applications:

In bio-medical implants such as custom-made artificial joint replacement implants, five-axis machining can mill very complex biomimetic surface finishes to precision that are accurately in accordance with the human body from patient CT scans and cannot be done by three-axis machining.

4. Five-axis CNC machining technology advantages over three-axis machining:

Against three-axis machining, five-axis CNC machining possesses the following significant benefits:

- Higher overall accuracy (avoiding successive clamping errors);

- Improved surface quality (maintaining the tool in the optimum cutting position);

- Reduced cycle time (reduced auxiliary time and clamping time).

Due to its built-in multi-axis capability and one-clamping-operation finish machining, five-axis CNC machining is now the solution at the heart of the manufacturing conundrum posed by highly complex, high-precision aerospace and medical parts.

Why Is Five-Axis CNC Technology Essential For The Aerospace Industry?

Five-axis CNC machine tools took up the pioneer machinery role in aerospace manufacturing from the industry’s unlimited search for part performance, reliability, and light weight. Their inexorable presence are mostly due to the fact that they are able to offer answers to intricate geometries, harsh material issues, and unyielding reliability.

1. The harsh material issues and tight tolerances of aerospace components:

Aerospace parts’ close tolerances and high material content are unachievable with traditional machining processes. Take engine turbine blades, for example. Their aerodynamic shape has a direct impact on engine efficiency and reliability.

Five-axis CNC machine tools utilize multi-axis linkage control, whereby the tool follows the curve in the best angle of precision milling. It can be machined in single-blade form in one step, canceling out many clamping errors entirely and very uniform surface accuracy for each blade.

Likewise, during machining of big wing structures and fuselage frames, five-axis technology holds the potential for integral machining of complex internal cavities and stiffening ribs with significant weight savings and retaining structural integrity. It greatly affects aircraft performance and fuel efficiency.

2. Machining of aerospace materials (titanium alloys and high-temperature alloys):

Aerospace materials such as high-temperature alloy and titanium alloy possess high strength and thermal resistance but are extremely difficult to machine with severe tool wear and deformation in parts.

Five-axis CNC machine tools, due to the flexible description of the relative position between the tool and the workpiece, realize more rational cutting load distribution, chip breaking, and heat dissipation, which substantially extended the tool life, ensured machining deformation and dimensions stability of the parts and surface integrity.

Five-axis CNC machinery not only ensures accurate manufacturing of sophisticated components, but it is also the most appropriate technological base for ensuring high reliability, maintainability, and economic efficiency of aircraft hardware.

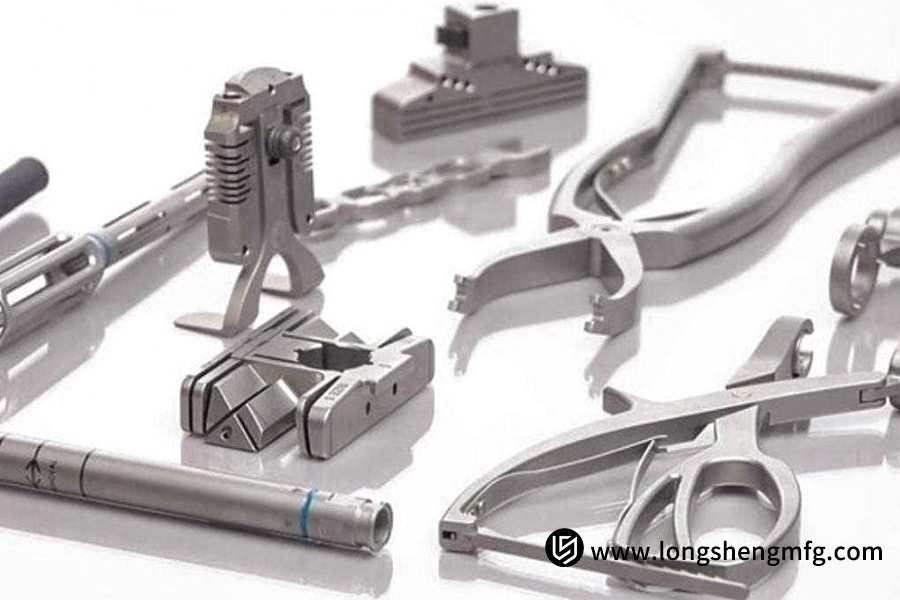

How Can Medical Device Manufacturing Benefit From The Precision Of Five-Axis Machining?

Medical device manufacturing involves extremely accurate levels of biocompatibility, personalization to the patient, and high level of accuracy, an aspect in which five-axis CNC machining technology unfolds its invaluable potential. Its application in the medical industry has revolutionized the manufacturing of implants, surgical tools, and diagnostic devices.

1. Applications in the production of medical implants:

In manufacturing medical implants such as artificial hip and knee arthroplasty and dental implantation, five-axis technology allows for milling complex biomimetic surfaces with flawless conformity to the human bone anatomy straight from the patient’s radiology data.

This not only enables true “personalized customization” but also leads to virtual bone-implant fit, reduces patient discomfort, and accelerates recovery. Additionally, its high dynamic machining capability achieves extremely high surface finish, reducing the region of bacterial adhesion and friction by several orders, and meeting the first fundamental requirement of biocompatibility.

2. Precision and advanced medical device applications:

For extremely small segments of high-precision surgical instruments and advanced diagnostic equipment, five-axis machining enables single-stroke molding of even very minute internal flow channels and slender gear layouts with precision.

The clear, blemish-free process of manufacturing completely eliminates the possibility of blind points for cleaning and guarantees a stable autoclave environment for an extended period, providing a robust hardware foundation for efficient surgery and accurate diagnosis.

Five-axis CNC machining, accommodates with ease the unique demands of medical device manufacturing for complex curved surfaces, custom fit, and ultra-high surface finish.

What Are The Quality Advantages Of Five-Axis Machined Parts?

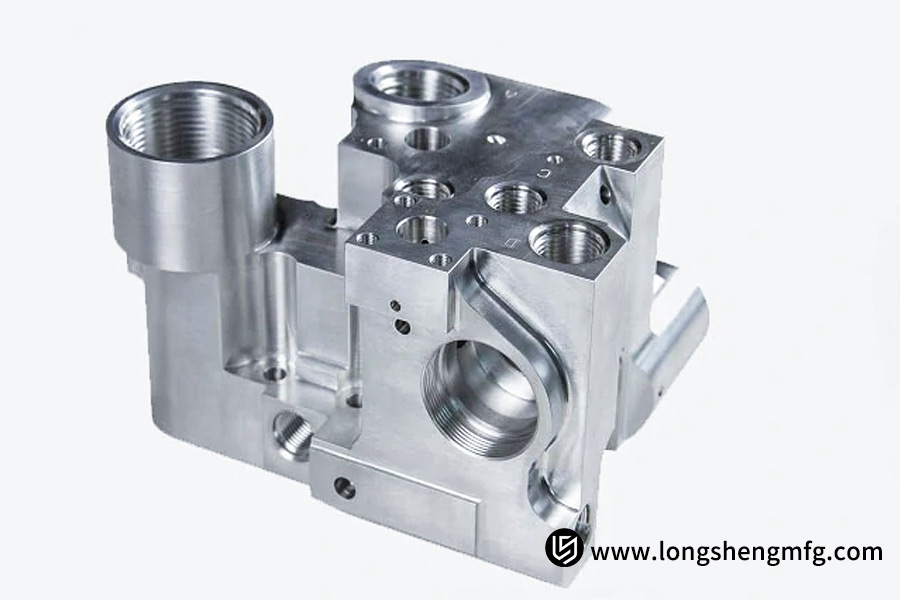

The five-axis CNC machined components have far-reaching quality advantages, which find expression primarily in the three basic qualities of dimensional accuracy, form and position tolerance, and surface integrity. The parts are of significantly higher quality than conventional machining techniques.

1. Dimensional accuracy:

In dimensional accuracy, since five-axis CNC machined components complete most features in a single setup, progressive error by successive repositioning and reset is completely eliminated.

Stable control of critical dimensions to the micron order (typically to IT7 or better) is thus attained. For example, aeroplane engine blade profile accuracy can be maintained at ±0.01mm, thereby achieving highly consistent aerodynamic performance.

2. Geometric tolerances:

Geometrically, five-axis technology’s multi-axis linkage capability makes it simple to meet complex contour, positional, parallel, and perpendicularity tolerances. The tool is never compelled to cut at other than the optimum angle, irrespective of deflection and deformation due to tool extension or erroneous tool location, with very high geometric fidelity.

3. Surface integrity:

The maximum advantage is to surface integrity. Five-axis machining resists tool axis location fluctuation in a way such that the ball end mill tip (the region of zero linear velocity) is moved away from the workpiece surface and maintains the greatest linear velocity along the tool side edge.

This achieves extremely low surface roughness (Ra < 0.4μm), prevents chatter marks and vibration lines completely, and forms a homogeneous residual compressive stress layer, greatly increasing part fatigue strength and corrosion resistance, the secrets to long aerospace part life and biocompatibility of medical implants.

Five-axis CNC machined components have set new industry benchmarks in geometric consistency, surface finish, and accuracy.

How Does Online Five-Axis Machining Services Change The Traditional Manufacturing Model?

Online five-axis CNC machining services are revolutionizing traditional manufacturing practices with their new digital and networked model. With cloud collaboration, intelligent algorithms, and global manufacturing networks, they enable easy transition from conceptual design to product shipment, highly increasing the accessibility and manufacturing efficacy of high-technology, complex parts.

In traditional manufacturing, customers are presented with lengthy offline quotations for prices, complex technical exchanges, and open-ended production timelines. But now online five-axis CNC machining service platforms (such as LS Precision’s digital manufacturing platform) have completely reworked this process:

- Customers simply upload an online 3D model, and the system automatically performs a design-for-manufacturing (DFM) review based on wise algorithms and delivers a real-time quotation.

- After an order has been accepted, the best production capacity is automatically assigned by the platform, and customers can track the production process in clear view in real-time, from steps like raw material procurement to processing status, and quality inspection reports, in the way one tracks a package.

Not only does this model reduce quote time from days to minutes, but it also eliminates information asymmetry through full-process digital control to ensure reliability and traceability for complex five-axis part machining.

The essence of online five-axis CNC machining services is the precise, efficient and transparent connection of manufacturing resources. It lowers the threshold for using high-end manufacturing technology.

How Does Customized Five-Axis Machining Meet The Needs Of Specialized Industries?

Customized five-axis CNC machining is a leading solution to meet the industry-specific requirements of the aerospace and medical device industries. Both sectors have material property, process, and traceable quality specifications far exceeding general requirements. Customized five-axis CNC machining precisely addresses these requirements by utilizing detailed, personalized services.

1. Applications of customized five-axis machining in the aerospace industry:

In the aviation sector, LS Precision not only provides machining of advanced materials such as titanium alloys and high-temperature alloys, but also performs the stringent conditions of AS9100D aviation quality system certification.

- For mission-critical engine parts, LS Precision implement end-to-end tool life management and machining parameter optimization to ensure cutting process stability.

- LS Precision also have a full-process traceability system that records material batch numbers, tooling used, and quality checks taken on each part to meet aviation part traceability requirements.

2.Applications of customized five-axis machining in medical device manufacturing:

LS Precision Manufacturing provides a cleanroom processing facility that complies with the demands of ISO13485 standards to ensure that implants are shielded from contamination during processing.

- For personalized implants, LS Precision designed a seamless conversion process from medical imaging information to five-axis machining routes with anatomical alignment.

- Special capability surface treatments (including micro-arc oxidation and sandblasting passivation) optimize biocompatibility and human safety compliance of implants.

Custom-made five-axis CNC machining, by comprehensively embedding industry standards, specialized processes, and quality control mechanisms, provides manufacturing solutions that precisely meet the unique needs of the aerospace and medical sectors.

LS Case Study: How To Process High-Precision Turbine Blades For Aerospace Customers?

Turbine blades are known as the “heart” of aircraft engines, and their manufacturing quality directly determines the overall performance and safety of the engine. As new-generation aircraft equipment strives for higher thrust-to-weight ratios and enhanced high-temperature resistance, turbine blades face the manufacturing challenges of tougher materials, more complex surfaces, and near-extreme precision requirements.

This case study, using a high-pressure turbine blade mass production project for an aerospace client as an example, systematically illustrates how LS Precision achieves efficient and stable machining of high-performance nickel-based alloy blades through comprehensive precision process design and technological breakthroughs.

1. Customer challenge:

Aerospace business needed mass-producing a new range of airplane engine turbine blades, presenting three primary challenges:

- The blades consisted of high-strength nickel-based high-temperature alloy, which showed extreme work hardening and low thermal conductivity;

- The aerodynamic shape was a sophisticated free-form surface that needed an accuracy of ±0.02mm;

- The root and tenon needed micron-level fit precision, which had direct implications for the engine’s high-speed operation safety.

2. LS Precision’s solution:

LS Precision put together a specialized technical team to create a completely customized solution:

- In the initial step, a five-axis precision machining process was adopted, using special tooling to enable space positioning of blades such that there is a single clamping fixture for the whole machining of blade body, shroud, and tenon.

- A multi-layer gradient cutting technique was developed to address the needs of the high-temperature alloy. That is, a high depth of cut and low speed strategy was used in rough machining to remove great amounts of stock, while a small width of cut and high speed strategy was utilized in fine machining for preserving surface integrity.

- An in-machine measurement system was used, with 3D scanning and inspection performed after machining on every third part, allowing real-time compensation for tool wear caused dimension deviations.

3. Final results:

By methodical process innovation, LS Precision Manufacturing made it possible for the customer to accomplish mass production successfully:

- The blade profile accuracy was kept under constant control to ±0.015mm, with surface roughness Ra of <0.4μm.

- The tenon-tooth fit provided H4 tolerances, which fully met the 20,000 rpm high-speed application needs of the engine.

- The rate of product yield increased from the industry standard level of 85% to 98.5%, which helped the customer reduce the overall processing cost per component by 30%.

Through this case, LS Precision applied its knowledge to the extreme and received hands-on experience. The high-quality results validated LS Precision’s expertise at producing difficult-to-make components.

Five-Axis Machining Price Structure And Optimization Strategies

The five-axis CNC machining cost is made up of different factors, primarily equipment depreciation, tool wear, professional programming and operator costs, material cost, and quality inspection. The awareness of such cost drivers contributes to effective optimization methods to achieve cost control without sacrificing precision quality.

1. Cost in-depth analysis:

High-performance five-axis machine tools require significant capital expenditures:

- Equipment depreciation is a cost factor.

- Consumables for hard-to-machine materials (titanium alloys, for example) are significant.

- More importantly, intricate parts require experienced programmers and process engineers, and labor costs are more than 25%.

- For accuracy reasons, online inspection and accurate measurement contribute to costs as well.

2. Specific optimization strategies:

Regarding the price structure of five-axis machining, LS Precision provides you with specific optimization strategies as follows:

- Design Optimization: Design with manufacturers earlier (DFM) in order to minimize difficult features to machine such as deep holes and sharp corners and thereby save on machining time.

- Process Innovation: Use high-performance cutting tools and optimize cutting conditions to achieve highest material removal rates and lowest unit time.

- Batch Strategy: Rationally plan production batches and reduce machine tool commissioning and setup time through continuous production, thereby distributing unit costs.

- Standardization: Use standardized fixtures and tools wherever feasible in order to reduce non-recurrent expenses on special tooling.

With strategies such as design and manufacturing collaboration, process optimization, and production planning, significant savings can be achieved without sacrificing quality, making this sophisticated technology create more value.

Five-axis CNC machining price is the addition of the value of technology, expertise, and precision manufacturing.

FAQs

1.Can five-axis machining achieve the surface finish required for medical implants?

Yes. Five-axis machining has the potential to achieve the surface finish requirement of medical implants. Adopting optimized machining processes and parameter conditions, LS Precision’s five-axis machining is capable of generating surface finish of medical grade at Ra < 0.2μm. If you need finishing services for medical implants, you can contact the professionals at LS Precision.

2. How do you process the difficult-to-machine materials commonly used in the aerospace industry?

LS Precision has extensive experience and expertise in machining such difficult-to-machine materials. We utilize advanced tooling technology and process solutions to efficiently process aerospace materials including titanium alloys and nickel-based high-temperature alloys. If you need to process difficult-to-machine materials commonly used in the aerospace field, you can contact the professionals at LS Precision.

3. What are the minimum order quantities and lead times?

LS Precision can hold high volumes of orders across all sizes, from prototype to production, with typical lead times being 2-4 weeks and rush service available if the project needs urgent priority. Furthermore, LS Precision has a minimum order quantity of one piece. LS Precision Professional Service is your one-stop service. No matter how much your order is, we can provide you with service.

4. How do you ensure traceability and consistent quality during the machining process?

An excellent traceability system ensures traceability and consistent quality during machining. LS Precision maintains an excellent traceability system of quality with complete records of machining and inspection reports for each part to ensure traceability. You don’t have to worry about quality, we have a professional team and quality assurance system.

Conclusion

Five-axis CNC machining, by surpassing the capabilities of conventional machining, demonstrates tremendous value in forming complex surfaces, ultra-high precision control, and working with hard-to-cut materials. It is particularly suited for the high standards of high-end equipment for light weighting, high performance, and high reliability.

LS Precision invite you to experience our the world-class five-axis machining solutions, leveraging our rich industry experience and cutting-edge technology platform. Let us add value to your project with our precision manufacturing potential.

If you require machining of intricate parts, please contact LS Precision technical experts today. You will be provided with a free technical solution consultation and detailed project assessment.

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Pingback: In-House vs. Online CNC Service: A Cost-Benefit Analysis for Engineers