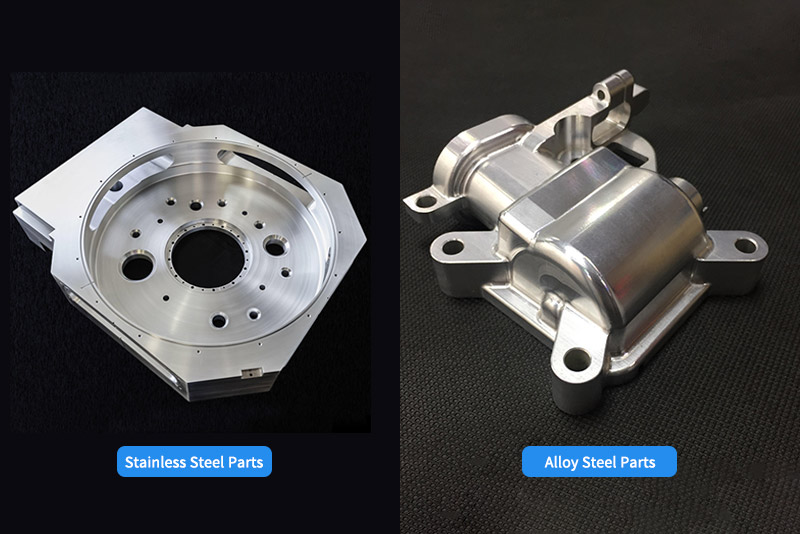

Metal is an alloy of iron and carbon and a fundamental a part of industries corresponding to development and the navy resulting from its energy, sturdiness, customizability, and fast fabrication. Of the a number of varieties of metal obtainable out there, the alloy metal vs stainless-steel comparability is without doubt one of the many comparisons frequent amongst producers who need to work with metal.

Choosing any of the 2 varieties of metal ought to solely happen after understanding their properties in relation to the challenge. In consequence, this text breaks down the whole lot you must know in regards to the comparability of stainless-steel vs alloy metal. It exhibits the traits, behaviors, and variations between alloy metal and stainless-steel so you’ll be able to select any of them in your challenge.

Composition and Classification Distinction Between Alloy Metal and Stainless Metal

To efficiently select the precise kind of metal after the alloy metal vs stainless-steel comparability, producers should completely perceive the whole lot about them. In consequence, this part will focus on the composition and classification to indicate the distinction between alloy metal and stainless-steel.

Alloy Metal

An alloy metal is a sort of metal that incorporates multiple alloying aspect, except for the carbon and iron in carbon steel. Such alloying parts assist enhance sure traits not current or low within the guardian metal supplies. Examples embody energy, put on resistance, toughness, and hardness.

Low Alloy Metal vs Excessive Alloy Metal

Alloy steels are categorised into excessive and low alloy steels based mostly on the share of alloying parts (not the carbon and iron) current.

- Low alloy metal incorporates alloying parts that kind nothing greater than 5% of the overall materials composition. Incorporating the alloying parts will increase the fabric’s mechanical properties and corrosion resistance in comparison with the bottom metal. Widespread alloying parts that may make up low alloy steels embody Nickel (Ni), Chromium (Cr), Vanadium (V), Copper (Cu), Tungsten (W), and Boron (B)

- Excessive alloy metal incorporates alloying metal that kinds greater than 5% of the overall materials composition. The upper share drastically will increase the supplies’ mechanical properties. Stainless-steel is an instance of excessive alloy metal because it incorporates a minimum of 12% Chromium relying on the stainless-steel grade.

Widespread Alloying Components and Their Results

Utilizing over 20 alloying parts can improve carbon metal’s mechanical properties. Every alloying aspect has the distinctive properties it bestows on carbon metal. Under are the 5 most typical alloying parts:

- Manganese withsmall quantities of phosphorus and sulfur makes the shaped metal alloy much less brittle and extra malleable.

- Chromium has an impact relying on the share. When used at a small share (0.5% – 2%), it could possibly enhance the fabric’s hardness. The next share (4% – 18%) can improve corrosion resistance.

- Vanadium in about 0.15% can enhance carbon metal’s energy, warmth resistance, and total grain construction. When used with Chromium, the shaped metal alloy has elevated hardness with out dropping formability.

- Nickel additionally has an impact relying on the share. At about 5%, the shaped metal alloy has elevated energy. The next share (over 12%) will improve the shaped alloy’s corrosion resistance.

- Tungsten will enhance the structural make-up of the shaped metal alloy. Moreover, it will increase the warmth resistance resulting in an elevated melting level.

Stainless Metal

Stainless-steel is a excessive alloy metal identified for its excessive corrosion resistance and aesthetic enchantment. Typically, it incorporates a minimum of 10.5% Chromium, accountable for the hardness and corrosion resistance, lower than 1.2% Carbon, and different alloying parts.

Chromium Content material and Its Significance

Relying on the wanted properties and the grade, stainless-steel may also incorporates different alloying parts corresponding to titanium, manganese, and nickel. The presence of Chromium results in the formation of chromium oxide when in touch with oxygen. This process, often called stainless steel passivation, helps to guard the steel and permits it to self-repair itself. Resulting from its properties, stainless-steel is necessary within the following methods.

- Its excessive warmth resistance makes it necessary in warmth exchangers, boilers, valves, and superheaters.

- It prevents bacterial progress, making it relevant in features requiring excessive hygiene.

- It has a excessive strength-to-weight benefit which makes it helpful within the automotive and plane business.

- It’s 100% recyclable.

Widespread varieties of stainless-steel

Many types of stainless steel supplies are categorised into 5 main teams. Under is a brief rationalization of the varieties of stainless-steel.

- Austenitic Stainless Metal Grades are nonmagnetic SS that incorporates 17-25% Chromium and 8-20% Nickel and different alloying parts. They’ve glorious ductility, corrosion resistance, and toughness, excessive formability and weldability. In addition they comprise molybdenum which vastly enhances corrosion resistance. Examples embody 304/304L, 316/316L, and 253.

- Ferritic Stainless Metal Grades comprise 10.5% Chromium accountable for its corrosion resistance. They’re used within the annealed situation as strengthening will not be doable or helpful with chilly working or warmth therapy. Moreover, their lack of toughness which reduces their structural software and limits their availability to sheet and coil. Examples embody 409 and 430 SS.

- Martensitic Stainless Metal Grades comprise 12 to 16% Chromium and 0.08% to 2% carbon. They’re warmth treatable, have diminished weldability, decrease ductility and will not be suitable with chilly working. Examples embody the 410, 420C, and 431 Grades of SS.

- Duplex Stainless Metal Grades comprise equal parts of austenite and ferrite. They comprise 18-29% Chromium, 3-8% Nickel, and different alloying parts corresponding to Molybdenum and Nitrogen. They’re sturdy, sturdy, corrosion-resistant, and proof against pitting and chloride stress. Nonetheless, they aren’t topic to warmth therapy and reply poorly to chilly working. Nonetheless, they’re magnetic, weldable, and straightforward to manufacture. Examples embody 2205 and S32750 grades of SS.

- Precipitation-hardening stainless-steel grades comprise 12-16% Chromium and 3-9% Nickel and small alloying parts corresponding to Al, Cu, and Ti, which might kind a precipitate. They’re warmth treatable, sturdy, and really ductile. Machining happens within the annealed situation, after which tempering happens.

Evaluating Mechanical Properties of Alloy Metal vs Stainless Metal

The mechanical properties are the most important type of alloy vs stainless-steel comparability. Though every kind of alloy or stainless-steel can differ, under are a common illustration of their comparability by way of their mechanical properties:

Tensile Power

Tensile energy denotes the power of a fabric to face up to tensile stress earlier than breaking, and it is determined by the alloy and the warmth therapy process. Alloy steels have greater tensile energy (758-1882) than stainless-steel (515-827). In consequence, alloy steels have extra structural functions.

Hardness

Hardness is a measure of a fabric to withstand put on and abrasion and is determined by the fabric composition and warmth therapy. Resulting from lower than 5% alloying parts, alloy steels have the next hardness starting from 200HB to 600HB (Brinell hardness) and put on resistance than stainless-steel. Stainless-steel ranks 8 on the Mohs hardness scale and 150HB to 300HB on the Brinell scale, which renders it much less onerous than most metals, though it’s tougher than supplies corresponding to copper and aluminum.

Ductility

Ductility measures the power of a fabric to elongate with out present process fracturing, relying on the warmth therapy. Alloy steels have the next ductility than stainless-steel. In consequence, they’re extra appropriate for functions that require forming shapes with out breaking. That is evident of their functions in precision-required engineering in making delicate elements.

Impression Resistance

The upper hardness of alloy steels in comparison with stainless-steel will increase influence resistance, making them extra appropriate for functions that obtain common shock or influence. Stainless-steel has the next likelihood of rupturing when utilized in such instances resulting from its decrease hardness and toughness.

Fatigue Power

Fatigue energy measures the power of a fabric to withstand stress for a given variety of cycles. The fatigue stress is the best stress the fabric can resist. For instance, stainless 316L has a fatigue energy of 146.45Mpa. Typically, stainless-steel has decrease fatigue energy in comparison with alloy metal. Nonetheless, some grades, such because the duplex SS, have excessive fatigue energy resulting from their microstructure.

Corrosion Resistance Distinction Between Alloy Metal and Stainless Metal

One other main the 2 metal comparability is in its corrosion resistance properties, and it additionally is determined by the kind of SS and alloy metal. Under is a common illustration of their comparability.

Normal corrosion resistance

Stainless-steel was made to beat corrosion and rust resulting from Chromium, which kinds about 30-80 nanometers of oxide layer on publicity to oxygen. In consequence, they’ve the next corrosion resistance than another alloy metal, which doesn’t comprise Chromium in that prime share. Not like alloy metal, they don’t require a protecting end after manufacturing. Nonetheless, every grade of stainless-steel has its corrosion resistance.

Pitting and crevice corrosion

Pitting and crevice corrosion are localized corrosion that’s frequent to stainless-steel. Pitting happens because of the localized breakdown of the protecting coating of the stainless-steel materials because of the presence of chloride ions and different ions. When such happens, the fabric turns into comprised, resulting in corrosion.

Crevice corrosion happens at joints the place two steel parts, corresponding to fasteners, are in shut contact. The presence of crevices promotes the buildup of chloride salts, moisture, and different pollution, which promotes the breakdown of the stainless-steel. Typically, the presence of Chromium reduces the possibilities of pitting and crevice corrosion in comparison with alloy metal.

Galvanic Corrosion

Galvanic corrosion happens when a steel’s presence results in the opposite’s corrosion. For such a corrosion, there should be a metallic anode, cathode, and electrolyte. Alloy metal is extra subjectable to galvanic as it could possibly simply give out electrons in comparison with stainless-steel, the place Chromium prevents such electron giveaway. Resulting from galvanic corrosion on alloy metal, stainless-steel is usually not mixed with alloy or carbon metal. Moreover, because it has a noble electrochemical potential, it’s much less vulnerable to galvanic corrosion.

Stress Corrosion Cracking

Stress corrosion cracking happens in lots of metals, corresponding to alloy metal and stainless-steel, in an atmosphere. It happens when low alloy metal is positioned in water, or stainless-steel is positioned in impartial aqueous or acidic options. Stainless-steel is extra proof against stress corrosion cracking, particularly the ferritic grades corresponding to 430 and 444.

Components Affecting Corrosion Resistance

Many components can have an effect on the corrosion resistance of a steel, corresponding to stainless-steel. By understanding these components, it’s doable to regulate the speed of corrosion related to a fabric. The components embody:

- Presence of Coating and Remedy: The presence of coatings can defend the fabric, therefore decreasing its corrosion.

- Warmth Remedy: Subjecting the fabric to warmth therapy processes corresponding to annealing and quenching can alter its microstructure and scale back corrosion resistance.

- Materials Floor Situation: A broken materials floor are extra vulnerable to corrosion than clean surfaces.

- pH: This denotes the acidity and alkalinity of the medium by which the fabric is positioned. At a pH of 1-7, the corrosion resistance of alloy metal reduces. At the next pH, it turns into unaffected.

- Electrochemical Potential: Each steel has an electrochemical potential on immersion in an electrolyte; measuring the potential denotes the power of a steel to corrode quick.

- Forms of Ions: The presence of ions, corresponding to chlorides, can scale back the corrosion resistance of a steel. One other problematic ion is the sulfate ion, identified for its damaging results.

- Conductivity: For corrosion to happen, the medium by which the steel is should be conductive. In consequence, corrosion can’t happen in distilled water.

- Temperature: Stainless-steel and alloy metal have a discount in corrosion resistance at the next temperature. This is because of elevated diffusion charges of the electrolytes or oxygen.

Warmth Remedy and Fabrication Distinction

Warmth therapy is a technique to enhance the mechanical properties of the alloy and stainless-steel. Under are the distinctions within the alloy metal vs stainless-steel comparability.

Warmth Remedy Processes

- Annealing is a warmth therapy process that will increase the ductility of the 2 varieties of metal. It includes heating the metal, soaking it, and permitting it to chill slowly (by wrapping it in an insulating materials or leaving it alone). Alloy metal requires a decrease annealing temperature than stainless-steel resulting from its greater carbon content material.

- Normalizing is a warmth therapy process appropriate for eradicating inside stress after warmth therapy. It includes heating the steel to a excessive temperature and letting it endure air cooling. Normalizing is determined by the thickness of the steel half.

- Hardening is a warmth therapy process that goals to extend the energy of the fabric, lower ductility, and enhance brittleness. Alloy steels require quenching throughout the air-cooling process. Moreover, it’s simpler to harden alloy steels than carbon metal because of the greater carbon content material.

- Tempering is one other warmth therapy process involving heating the steel to a temperature under its higher essential level, holding the temperature for a very long time, and cooling the air. This results in a discount in brittleness and hardness and results in the reduction of inside stress.

Weldability

Each supplies are extremely weldable. Nonetheless, stainless-steel is extra weldable than alloy metal to the decrease carbon composition and the presence of Chromium which creates a steady oxide layer that may resist corrosion. Nonetheless, the weldability is determined by the grades, as martensitic and duplex SS are much less weldable.

Machinability

Machinability denotes the power to chop or machine a fabric. Stainless-steel has a decrease machineability than alloy metal making it much less suitable with processes corresponding to CNC machining. For instance, 304 stainless-steel has a 40% machinability ranking in comparison with alloy steels corresponding to 1018, with a 78% machinability. Nonetheless, some alloys, corresponding to HSLA metal, have decrease machinability.

Formability

Formability denotes the power of the fabric to endure deformation with out being broken. Stainless-steel formability is determined by the obtainable grade, with martensitic metal having the least formability.

Purposes Distinction

Each varieties of metal are relevant underneath completely different situations. Under are the frequent makes use of of ally metal and stainless-steel and the choice standards.

Widespread Uses of Alloy Steel

Total, alloy metal is frequent in varied industries requiring energy, sturdiness, and put on resistance. Alloy metal finds frequent software within the following areas.

- Development: Alloy metal, resulting from its energy and sturdiness, is relevant in making parts utilized in making bridges, buildings, and pipelines.

- Automotive business: Alloy metal is appropriate for marking automotive elements corresponding to gears, axles, and crankshafts.

- Aerospace business: Alloy metal is relevant in making high-stress automotive elements like touchdown gear and turbine blades.

- Software making: Alloy metal has excessive hardness and put on resistance, making it an ideal materials for producing drills, noticed blades, milling cutters and different instruments.

- Oil and fuel business: Alloy metal is appropriate for making parts that may stand up to excessive temperatures and strain, corresponding to pipelines and valves.

Widespread Uses of Stainless Steel

Stainless-steel is frequent in lots of industries resulting from its glorious corrosion resistance. Some frequent functions of those supplies embody.

- Kitchenware: Stainless-steel is extensively relevant in making kitchen utensils corresponding to cutlery, cookware and cutlery. Its extensive use is because of being straightforward to scrub, corrosion resistance, aversion to staining, and being hygienic.

- Structure and development use supplies in structural elements corresponding to constructing facades and handrails resulting from their energy, sturdiness, and corrosion resistance.

- Medical tools is most time made from stainless-steel resulting from its biocompatible, sterilization assist, and corrosion and marking resistance.

- The automotive business makes use of stainless-steel to make automotive elements corresponding to exhaust programs, physique panels, and trim as its corrosion resistance.

- The chemical and petrochemical business is utilized in lining reactors and storage tanks due to its corrosion resistance, which helps scale back publicity to chemical compounds and excessive temperatures.

Choice Criteria for Choosing the Right Type of Steel

Choosing the proper varieties of metal in your challenge includes understanding the completely different choice standards.

- Utility: The very first thing to contemplate when selecting the best kind of metal is the appliance which determines the required properties of the metal.

- Properties: The applying will decide the properties wanted. For instance, if the appliance is in a structural aircraft, a high-strength and difficult kind of metal is appropriate. In a marine atmosphere, corrosion resistance is extra necessary.

- Value: The kind of metal is determined by its composition and manufacturing process. You must make sure you select an economical choice that falls in your price with out dropping high quality.

- Availability is one other issue you should contemplate earlier than selecting any metal. Availability may also have an effect on the associated fee and the manufacturing process.

- Manufacturing process: The selection of the manufacturing process, like CNC machining, sheet metal fabrication may also affect the choice process. Some varieties of metal are simpler to process than one another, relying on their hardness.

Value and Environmental Issues

Earlier than selecting between alloy or stainless-steel, you must also examine the associated fee and environmental results.

Worth Comparison Between Alloy Steel and Stainless Steel

Resulting from a lesser alloying aspect, alloy metal grades are less expensive than customary stainless grades. Typically, the worth is determined by components corresponding to grades, avialian, and manufacturing process, however stainless-steel can price between $800 to $2,500 per ton. However, alloy metal prices between $600 and 800 per ton. ·

· Lifecycle Costs

The lifecycle price of a fabric is the overall price of proudly owning the fabric. This consists of its preliminary value, upkeep and restore price, and disposal. Stainless-steel has the next preliminary price. Nonetheless, it self-repairs and is 100% recyclable. Subsequently, the general lifecycle price is decrease than alloy metal.

· Environmental Impression and Sustainability

In comparison with alloy metal, stainless-steel has excessive environmental benefits resulting from its properties. Its recyclability reduces the necessity for brand new uncooked supplies. Moreover, its sturdiness and corrosion resistance makes it sustainable. Stainless-steel additionally has low toxicity, decreasing its unhealthy environmental impacts. Total, stainless-steel has a low environmental influence and is extremely sustainable.

Choosing the proper materials and utilizing the precise manufacturing service are figuring out components in a challenge’s success. At LongSheng, we provide on-demand steel fabrication providers, together with CNC machining, die casting, and sheet steel fabrication. We additionally present several types of metal for choice and advocate the perfect materials for any steel challenge. Navigate to our on-line citation platform for a fast citation that denotes completely different supplies, finishes, portions, and many others., and a DfM evaluation.

Advantages of Alloy Metal Over Stainless Metal

Alloy metal has a number of benefits over stainless-steel and is a fabric value contemplating for a wide range of functions.

- It’s cost-effective.

- It’s extremely versatile resulting from its greater machinability.

- It has greater temperature resistance.

- It has the next strength-to-weight ratio.

Advantages of Stainless Metal Over Alloy Metal

Stainless-steel is additionally a extensively used materials that has a number of benefits over alloy metal.

- It has the next corrosion resistance.

- It has a greater aesthetic enchantment.

- It has low upkeep.

- It’s extra ductile.

- It’s recyclable.

What Are Similarities Between Alloy and Stainless Metal

Alloy metal and stainless-steel share many similarities collectively.

Each are Iron-Based Alloys

Each parts are alloys of irons, making them iron-based alloys. Nonetheless, they will comprise different parts in a unique proportion, which determines their properties.

Enhanced Properties

Each varieties of metal have enhanced properties based mostly on the added alloying parts. For instance, the presence of Chromium vastly enhances the corrosion resistance of each supplies.

Versatility

Alloy metal and stainless-steel are relevant in numerous situations based mostly on their properties. Each supplies have discovered use within the development, equipment, and automotive business and will be fabricated into varied shapes and kinds.

Fabrication and Welding

Each supplies have greater fabrication and welding properties in comparison with carbon metal. Nonetheless, alloy metal is healthier.

Warmth therapy

You may topic each supplies to a warmth therapy to change properties corresponding to hardness, ductility and brittleness. On the one hand, warmth therapy for alloy metal consists of quenching and tempering, annealing, and normalizing. However, stainless-steel undergoes annealing, stress relieving, and hardening.

Recyclability

Sure, each supplies are recyclable. Alloy metal may also be melted and reused to make new parts with out dropping them.

Choosing the Proper Metal for Your Utility

Utilizing the components under, you’ll be able to be capable to choose the precise metal in your software:

Practical Requirements

The purposeful requirement of the fabric will decide the varieties of metal appropriate for such a challenge. For instance, corrosion resistance turns into necessary if the half is utilized in a marine atmosphere. In consequence, such parts must be constructed from a chrome steel grade. One other instance is structural functions corresponding to development, the place sturdy alloy metal could be a more sensible choice.

Funds Constraints

Funds constraints can decide the precise varieties of metal in your challenge. When it comes to price, alloy metal is less expensive than stainless-steel. Nonetheless, you shouldn’t sacrifice high quality a lot for price

Aesthetic Preferences

When it comes to aesthetic enchantment, stainless-steel is a well-liked alternative. In consequence, it’s common in structure and inside design. The fabric has a extremely reflective floor, making it glossy and trendy. Moreover, it is available in a number of funhouses and shapes that give producers a variety of merchandise.

Upkeep and Lifespan

Stainless-steel is the higher choice by way of upkeep and lifespan. It requires little to no upkeep and has a protracted lifespan resulting from its self-repairing nature. Moreover, it’s recyclable.

Conclusion

Alloy metal and stainless-steel are two varieties of metal with distinct properties. On the one hand, alloy metal has many mechanical properties, together with excessive energy, toughness, and put on resistance, making it appropriate for high-performance and durability-required functions. However, stainless-steel has glorious corrosion resistance and aesthetic enchantment, making it best for harsh and corrosive environments. Each are necessary supplies in trendy manufacturing. Are you searching for high quality metal supplies or a steel fabrication process? At LongSheng, we provide the perfect at a aggressive value.

FAQs

Which is healthier for outside functions, alloy metal or stainless-steel?

When contemplating outside functions, the selection between alloy metal and stainless-steel is influenced by their respective properties and upkeep necessities. Stainless-steel, containing chromium for corrosion resistance, is appropriate for outside use resulting from its skill to withstand rust when uncovered to water or air. Nonetheless, it calls for common upkeep to protect its look and protecting chromium oxide layer. However, alloy metal, whereas not inherently corrosion-resistant like stainless-steel, affords distinctive energy and sturdiness, making it a strong alternative for outside environments. The choice between these supplies must be based mostly on the precise environmental situations and the extent of upkeep that may be constantly supplied.

Can alloy metal resist corrosion?

Sure, alloy metal can resist corrosion, however the extent of its resistance is determined by the precise alloy composition and the environmental situations it’s uncovered to. Whereas stainless-steel is famend for its corrosion resistance resulting from its chromium content material, which kinds a protecting oxide layer, sure alloying parts in alloy metal may also contribute to its corrosion resistance in varied environments. The resistance of alloy metal to corrosion can range based mostly on components such because the presence of particular alloying parts and the kind of corrosion it’s uncovered to. Subsequently, when contemplating using alloy metal in functions the place corrosion resistance is essential, it’s important to rigorously consider the precise alloy composition and its suitability for the supposed environmental situations.

How does the price of alloy metal examine with stainless-steel?

The price of alloy metal in comparison with stainless-steel can range based mostly on a number of components, together with the precise grades, availability, and manufacturing processes. Typically, resulting from a lesser quantity of alloying parts, alloy metal grades are sometimes less expensive than customary stainless-steel grades. Nonetheless, it is necessary to notice that the worth of each alloy metal and stainless-steel is determined by components corresponding to grades, availability, and the manufacturing process. Stainless steels are typically dearer than carbon metal, with prices sometimes 4 to 5 occasions greater than carbon metal in materials prices. The extra alloying parts a metal incorporates, the dearer it tends to be. Moreover, the fluctuating costs of nickel, an necessary alloying agent in stainless-steel, can influence the general price of stainless-steel. Subsequently, when contemplating the price of alloy metal versus stainless-steel, it is important to have in mind the precise grades, availability, and manufacturing processes to make an knowledgeable choice based mostly on the necessities of the appliance.

What are the frequent grades of stainless-steel?

The frequent grades of stainless-steel embody these inside the austenitic household, which is the preferred and extensively used around the globe. This household usually consists of chromium and nickel, with some grades additionally incorporating manganese and molybdenum. Widespread grades inside the austenitic household embody 304 stainless-steel and 316 stainless-steel, that are probably the most prevalent grades. Moreover, different frequent grades are 409 stainless-steel and 430 stainless-steel. These stainless-steel grades are categorised as austenitic, characterised by their 18-30% chromium and 6-20% nickel as main alloying additions. Different households of stainless-steel embody martensitic, ferritic, and austeno-ferritic, every providing distinct properties and functions.

Your posts are far more than just words on a screen; they are a rallying call for positivity and unity.