Imagine walking into a busy CNC machining shop: the machines are running at high speeds, metal chips are flying, but there is no familiar, pungent smell of cutting fluid mist in the air. Looking around, the ground is no longer wet and greasy, but clean and dry. The machine tools themselves and the work area are also very clean, no longer covered with oil and coolant residue. This is not a future factory scene in a science fiction movie, but a reality that dry machining technology is gradually realizing.

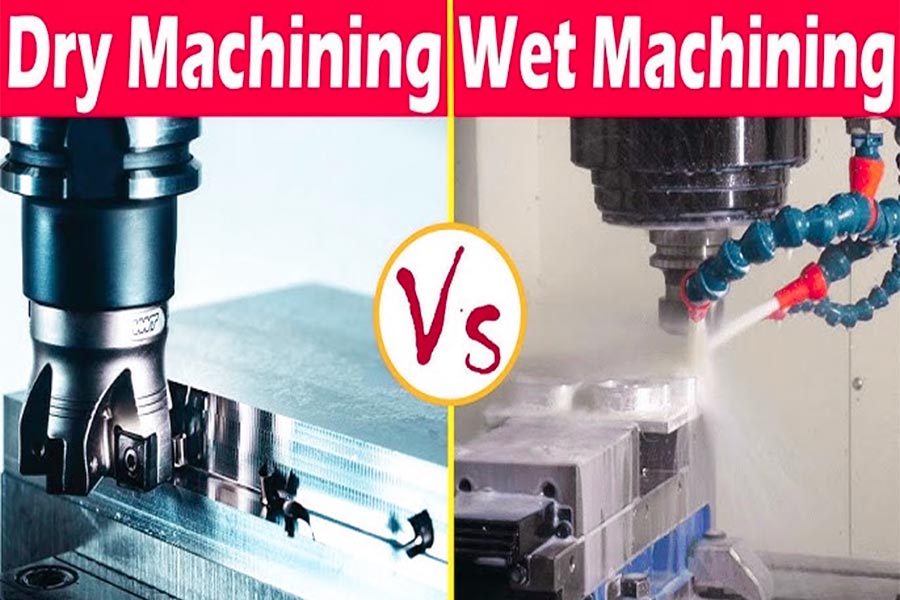

So, what is dry machining? As the name suggests, it refers to a manufacturing process that does not use any traditional liquid coolant (cutting fluid) during the metal cutting process. But don’t just think it’s as simple as “turning off the coolant switch”! Dry machining is far from a stopgap measure or a simple subtraction operation. It is essentially a set of highly sophisticated, interlocking system engineering. Its successful implementation depends on a deep understanding and coordinated optimization of machine tool design, tool technology (especially advanced coatings), machining parameter strategy and even the entire production process. It represents a modern manufacturing concept that is cleaner, more sustainable and also achieves high

performance.

Machining Type Quick Reference

| Machining Type | Core Definition | Key Advantages | Key Challenges |

|---|---|---|---|

| Dry Machining | Cutting without using liquid coolant at all. | Reduced cost (no need to purchase and handle coolant), environmentally friendly, clean workpiece, clear vision. | Heat management, fast tool wear, difficult chip evacuation, restrictions on materials and tools. |

| Wet Machining | Cutting with a large amount of liquid coolant (oil-based or water-based). | Good cooling effect, good lubricity, smooth chip evacuation, and long tool life. | High cost, environmental pollution, waste liquid treatment, and workpiece cleaning. |

| Minimum Quantity Lubrication (MQL) | A machining method that uses a very small amount (ml/hour) of lubricating oil mixed with compressed air and then sprayed into the cutting area. | It is between dry and wet, with better cooling and lubrication effect than dry, and better environmental protection than wet. | Special equipment is required, and the cost is higher than dry. |

Here’s What You’ll Learn:

- The core secret of dry machining: Where does the heat go? Uncover how dry machining cleverly uses chips to remove 80% of the heat, and how high-speed cutting, advanced tools and coatings, and compressed air work together.

- Dry vs. wet vs. MQL: How to choose the right solution for your project? A clear comparison framework that weighs cost, efficiency, environmental protection and material properties, and locks in the best processing method in 60 seconds.

- Conquer challenging materials: Which materials are the “chosen ones” for dry machining? Identify the advantages of cast iron, certain aluminum alloys, and hardened steel, and learn how to avoid the risks of dry machining of stainless steel, high-temperature alloys, and titanium alloys.

- The cornerstone of successful dry machining: the “hard core” requirements of machine tools and tools. Master machine tool rigidity, high-speed capability, chip removal design, and the selection points of high-temperature resistant tool substrates, special geometry angles and key coating technologies.

- Insights from actual combat: A dry machining victory for a complex cast aluminum part. Follow our 5-axis machining case to see how to overcome the pain points of wet machining and achieve a 20% increase in efficiency and a win-win situation in terms of cost and environmental protection.

- Clarify key misunderstandings: Dry machining ≠ “Dry Run”! Answer common confusions (FAQ) about workpiece thermal damage, adaptability of existing equipment, noise and regional prevalence differences.

Now, let’s explore the world of dry machining and unlock the potential of efficient, clean and sustainable manufacturing.

How Dry Machining Works: Replacing the Coolant

| Aspect | Description |

|---|---|

| Where does heat go | In ideal dry machining, about 80% of the cutting heat is taken away with the chips instead of being conducted to the workpiece or tool, avoiding thermal damage. |

| High-speed cutting (HSM) | Through extremely high speed and feed, the chips are ensured to fly away quickly before heat is transferred, reducing heat accumulation in the workpiece and tool. |

| Advanced tool materials | Use cubic boron nitride (CBN), polycrystalline diamond (PCD) or specially coated cemented carbide to maintain hardness and wear resistance at high temperatures. |

| Special tool coatings | Coatings such as TiAlN (titanium aluminum nitride) form an aluminum oxide protective film at high temperatures, providing heat insulation and lubrication, reducing friction heat. |

| Compressed air assist | Used to blow away chips and take away some heat, while preventing chip accumulation and indirectly cooling the processing area. |

Heat Destination:

The majority of the cutting heat (approximately 80%) is evacuated through the chips in dry machining, rather than being conducted to the workpiece or tool. This is due to the high-speed cutting process, where the chips escape quickly before heat has an opportunity to be transferred, thus saving workpiece accuracy and tool life.

Key technologies:

- High-speed cutting (HSM): Using extremely high rotation speed and feed speed, chips are sure to be produced and expelled rapidly and significantly reduce the residence time of the heat on the workpiece as well as tool.

- Advanced tool materials: Tool materials, such as cubic boron nitride (CBN) and polycrystalline diamond (PCD), have high-temperature stability and would be able to withstand wear and deformation without coolants.

- Special coating of tools: TiAlN coating creates a hard aluminum oxide layer at elevated cutting temperatures, which not only offers insulation but also lubrication and minimizes the generation of friction heat.

- Compressed air support: Compressed air is utilized primarily for chip removal and removing a minimal quantity of heat, such that the chips are not allowed to generate extra heat by secondary friction while maintaining the working area free from chips.

Dry machining completely abolishes the use of traditional coolants by idealizing cutting dynamics and tool technology, managing heat and making chips the fundamental heat-transferring medium.

Dry vs. Wet Machining: Efficiency vs. Environment

| Comparison dimensions | Dry machining | Wet machining |

|---|---|---|

| Cost | No coolant-related costs | Coolant costs account for 15-20% of manufacturing costs |

| Environmental protection | Zero pollution (no waste liquid, no chemical hazards) | There are skin irritation, respiratory risks and water and soil pollution |

| Efficiency | High cutting speed (when conditions are suitable) | Stable heat dissipation prolongs tool life |

| Applicability | Depends on material properties and process optimization | Strong versatility, especially suitable for high-heat scenarios |

1. Cost comparison: Hidden costs determine competitiveness

In wet machining, the overall cost of coolant in a cycle is a substantial burden:

- Direct expenses: buying good-quality cutting fluid, constant replenishing and consumption;

- Maintenance expenses: energy consumption by the circulation system, maintenance of filtering devices, and pipeline cleaning;

- End treatment: toxicity of waste liquid requires professional treatment (e.g., chemical decomposition), and the cost can reach $200/ton.

Absolutely avoids the above links, which tends to reduce the total manufacturing cost by 15-20%, especially for mass production.

2. Environmental protection comparison: eliminating industrial toxins from the source

The environmental shortcomings of wet machining focus on cutting fluid:

- Health hazards: operator contact induces dermatitis, and oil mist causes respiratory diseases (such as metalworking fluid pneumonia);

- Ecological risks: heavy metal/mineral oil wastes liquid leak into the ground or water body, destroying the ecosystem;

- Compliance pressure: industrial wastewater release is strictly regulated by nations (e.g., EPA, REACH regulations).

Dry machining removes pollution from the source with “zero liquid use”, which aligns with the green manufacturing trend and has a profound impact on lowering enterprise environmental compliance costs.

3. Efficiency comparison: technical flexibility is the priority

Potential and challenge of dry machining:

- Advantages: No interference from coolants, increased cutting speeds (e.g., milling of aluminum alloys at high speed) and decreased working hours in single-piece work can be achieved;

- Disadvantages: Frictional heat buildup accelerates tool wear. In the absence of parameter optimization (e.g., feed rate, coated tool), repeated tool changes will reduce overall efficiency.

- Wet machining stability

Coolant permanently lubricates and cools, extending tool life by 30%-50%, which is priceless when cutting hard-to-cut materials such as titanium alloys and high-temperature alloys.

Technical balance point: Dry machining requires supporting measures-

- Utilize high-temperature resistant carbide/ceramic coated tools

- Design air cooling/micro-lubrication (MQL) to assist in supporting heat removal

- Optimize cutting parameters and machine tool rigidity

Dry machining leads the revolution in manufacturing with cost advantage and ecogenes, but its possible efficiency has to be unleashed by freeing process optimization; wet machining is still the first choice for high-load machining by virtue of its stability and universality-the balance of fortunes between the two depends on the subtle interplay of technical flexibility and environmentally friendly goals.

MQL: The “Golden Mean” Between Dry and Wet?

| Aspect | Description |

|---|---|

| Definition | MQL, also known as minimal lubrication or quasi-dry machining, is a technology that uses extremely small amounts of lubricating oil in mechanical machining. |

| Principle | A very small amount of lubricating oil is atomized and mixed with compressed air, and then precisely sprayed into the cutting area to achieve efficient lubrication and cooling. |

| Advantages | It combines the cleanliness and environmental protection of dry machining with the lubrication and cooling advantages of wet machining, making it an ideal compromise. |

| Application | It has significant effects in high-friction processes such as tapping and drilling, improving machining efficiency and tool life. |

1. What is MQL?

MQL, or Minimum Quantity Lubrication, is also called quasi-dry machining or micro-lubrication. MQL is a sophisticated machining lubrication technology that uses a negligible quantity of lubricating oil (usually only a few milliliters per hour), avoiding the over-lubrication danger of traditional wet machining without encountering the ordeal of dry machining friction.

2. Principle:

The working mechanism of MQL is to atomize a minute quantity of lubricating oil into tiny oil droplets with the help of an atomizer, mix it with compressed air to form a mist mixture, and then spray it precisely into the cutting zone with a nozzle. It ensures that the lubricant comes in direct contact with the friction point and forms an instant cooling effect and friction reduction without creating much waste liquid.

3. Advantages:

The advantages of MQL are the benefits of dry machining (clean, environmentally friendly, and no treatment of waste liquid) and wet machining (effective lubrication and cooling). Specifically, it conserves more than 90% of lubricating oil; lessens environmental pollution; increases cleanliness of the working environment; extends tool life; and slashes energy costs. It is an economic and effective compromise.

4. Application:

MQL is widely used in strong friction mechanical processing operations, especially tapping, drilling, milling and turning. For example, in the metal processing industry, it can significantly reduce tool wear and heat deformation, improve processing accuracy and efficiency, and be utilized for precision manufacturing in the fields of automobiles, aerospace, etc.

In short, MQL as a novel lubrication technology best fulfills the “golden section” between dry and wet processing in the manufacturing industry with an easy means of sustainable production.

What are the Best Materials for Dry Machining

| Material type | Suitability for dry machining | Key features | Precautions |

|---|---|---|---|

| Cast iron | ★★★★★ | Graphite self-lubricating, easy chip breakage | One of the most ideal materials for dry machining |

| Certain aluminum alloys | ★★★★☆ | Fast heat dissipation during high-speed cutting | Material sticking to the tool must be avoided |

| Hardened steel | ★★★★☆ | Suitable for hard turning/milling | CBN/ceramic tools required |

| Stainless steel/high-temperature alloy | ★★☆☆☆ | Poor thermal conductivity, work hardening, severe heat accumulation | Great challenges for dry machining |

| Titanium alloy | ★☆☆☆☆ | High chemical activity, low ignition point, easy to stick to the tool | Extremely high risk for dry machining |

1. Ideal dry machining material

Cast Iron

- Self-lubricity: Graphite components form a lubricating film during cutting, significantly reducing friction.

- Chip control: Brittle materials make chips easy to break and avoid wrapping around the tool.

- Heat dissipation: The heat generated by cutting is mostly taken away by the chips, reducing thermal deformation of the workpiece.

Certain Aluminum Alloys

- High-speed advantage: Under high-speed cutting (such as >500 m/min), the cutting heat is taken away by the fast-flying chips.

- Low cutting force: Soft materials reduce tool load, but coated tools are required to prevent material adhesion (such as DLC coating).

Hardened Steels (>45 HRC)

- Hard machining technology: Use CBN (cubic boron nitride) or ceramic tools for hard turning/milling to avoid interference from cutting fluid.

- Thermal management: Cutting heat is concentrated on the chips, and the temperature rise of the workpiece is controllable, which is suitable for precision machining.

2. Challenging dry machining materials

Stainless steel and high temperature alloys (such as Inconel)

- Poor thermal conductivity: Heat accumulates at the tool tip, accelerating tool wear (mainly crater wear).

- Work hardening: Hardening of the cutting area leads to chipping of the cutting edge, requiring frequent tool changes.

- Solution: Minimal lubrication (MQL) is usually required to assist heat dissipation.

Titanium alloys (such as Ti-6Al-4V)

- Chemical affinity: Diffusion wear occurs with tools (especially cobalt-containing cemented carbides) at high temperatures.

- Ignition point risk: Cutting temperatures exceeding 500°C may cause chip combustion (especially fine chips).

- Tendency to stick to the tool: It is easy to generate built-up edge and damage the surface quality.

- Mandatory requirement: Cutting fluid must be used to prevent fire when machining aviation parts.

The success of dry machining is highly dependent on material properties: cast iron is the first choice due to its self-lubricating property, some aluminum alloys and hardened steel perform well in high-speed/hard machining, while stainless steel, high-temperature alloys and titanium alloys require strict risk assessment or auxiliary processes due to heat dissipation and chemical property limitations.

What Special Requirements Does Dry Machining Have For Machine Tools And Cutting Tools?

| Element | Machine Tools | Cutting Tools |

|---|---|---|

| Core Features | Rigidity, Thermal Management, Chip | Evacuation Heat Resistance, Wear Resistance, Chip Evacuation |

| Rigidity | Extremely high rigidity (against greater cutting force/vibration) | Base material needs to be strong and impact resistant |

| Spindle | High-speed spindle (maintain cutting efficiency) | – |

| Servo system | Fast response (high precision, high dynamic performance) | – |

| Chip Evacuation Design | Key! Large inclination base, center air outlet (instead of coolant) | Key! Optimized chip groove, special edge design |

| Thermal Management | Good heat dissipation design (structure, air cooling) | Core! High temperature resistant substrate + key coating |

| Substrate | – | Ultrafine particle cemented carbide, metal ceramic, CBN, PCD (high heat resistance) |

| Geometry | – | Special edge design (control cutting force/heat) |

| Coating | – | Key to success! AlTiN, TiSiN and other nanocomposite coatings |

1. Machines:

- High rigidity: Resist the increased cutting force and vibration caused by dry cutting.

- High-speed spindle: Maintain efficiency and use cutting heat to soften the material (in some cases).

- Fast-response servo: Ensure high-speed and high-dynamic machining accuracy.

- Efficient chip removal: Core requirement! Design includes:

- Large inclination base (gravity chip removal).

- Powerful chip removal device (vacuum/spiral/air blowing).

- Center exhaust (key!): High-pressure gas replaces coolant, forced chip removal, auxiliary cooling, and spindle protection.

2. Tools:

High-temperature resistant substrate: Must withstand extremely high cutting temperatures. Commonly used:

- Ultra-fine carbide / metal ceramic (high strength and wear resistance).

- CBN / PCD (extremely heat-resistant materials).

Optimized geometry:

- Enhanced cutting edge: Anti-micro-collapse (such as passivation).

- Wide and smooth chip groove: Core requirement! Ensure smooth chip discharge and prevent clogging (such as parabolic trough type, the number of cutting edges may be reduced).

High-performance coating: the key to success!

- Requires extreme high temperature resistance, high hardness, wear resistance, low friction, and thermal barrier.

- Mainstream: AlTiN (high hardness and oxidation resistance) and its improved types.

- Preferred high performance: TiSiN, AlCrSiN and other nano-composite coatings (ultra-high hardness/stable/wear-resistant).

The success of dry machining depends on the strong rigidity, high speed, fast response and efficient chip removal (especially center exhaust) of the machine tool, as well as the coordinated support of the heat-resistant substrate, optimized geometry (heavy chip removal) and key high-performance coatings (such as nano-composite coatings) of the tool.

What is a “Dry Run”? Is It the Same?

| Features | Dry Run | Dry Machining |

|---|---|---|

| Essence | Program verification and safety check steps | Actual metal cutting processing method |

| Purpose | Verify the correctness of the CNC program path and check potential collision and interference risks | Complete the cutting of the workpiece without using cutting fluid |

| Execution method | The machine tool spindle is not clamped with a workpiece (usually no tool is installed or a dummy tool is installed), and the program is run in the “idle” state | The machine tool spindle is clamped with a workpiece and a tool to perform real metal removal operations |

| Is it related to actual cutting | No – No chips are generated and no material is removed | Yes – Chips are generated and material is removed |

| Main concerns | Program logic, coordinate points, motion trajectory, tool change points, fixture/machine tool interference | Tool life, processing quality, workpiece temperature, chip removal, surface finish |

| Application scenarios | The first time a new program is put on the machine, after the program is modified, after the fixture is replaced, preventive safety measures | Specific materials (such as cast iron), specific processes, environmental protection requirements, cost reduction |

| Core risks | Program errors or path interference lead to damage to the machine tool, tool, fixture | Overheating leads to rapid tool wear, thermal deformation of the workpiece, poor surface quality, and chip adhesion |

1.Dry Run

Essence: Program safety verification step (not actual machining).

Operation: Do not install workpiece/tool (or install fake tool), let CNC program run empty.

Purpose: Check program path, logic errors, collision risks (such as fixture/machine tool interference).

Key point: No cutting, purely preventive safety inspection to avoid equipment damage.

2.Dry Machining

Essence: Actual cutting process (no cutting fluid).

Operation: Clamp real workpiece and tool to remove material.

Purpose: Environmental protection (no cutting fluid pollution), reduce costs, simplify cleaning.

Key point: There is real cutting, but it faces challenges such as heat dissipation difficulties, fast tool wear, and thermal deformation of workpieces.

Dry Run is a “safety rehearsal” of the program (no cutting), and dry machining is “cutting without coolant” (real machining). The essence and purpose of the two are completely different.

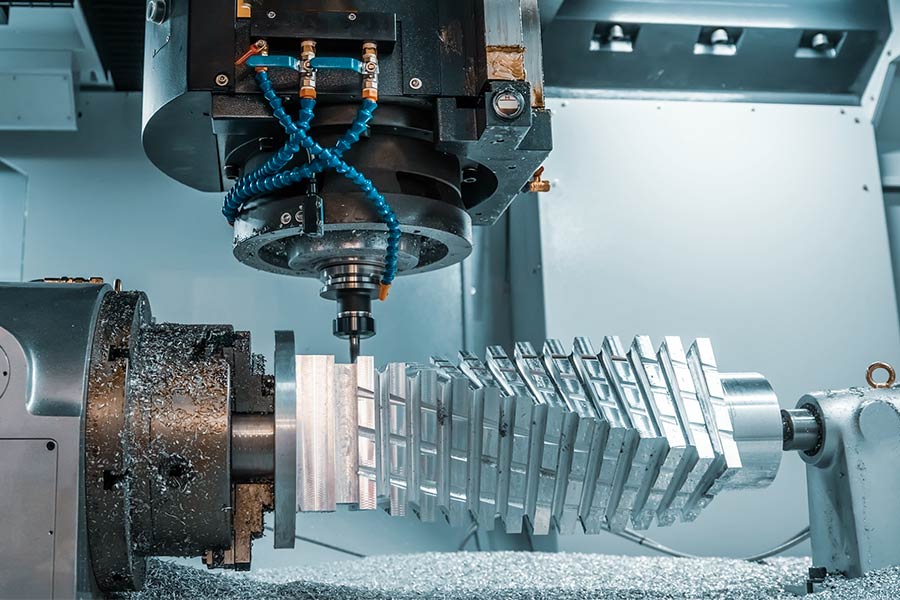

Case Overview: High-efficiency dry 5-axis machining solution for gearbox housing

1. Project background:

We recently successfully machined a cast aluminum gearbox housing with a complex structure for a customer. The part contains multiple face systems and deep inner holes that need to be precisely machined, and is required to be completed on a 5-axis linkage CNC machine.

2. Customer pain points (traditional wet machining):

The part has a complex inner cavity structure and many deep holes, which makes it difficult to completely remove the cutting fluid. A special cleaning process is required, which increases the cost.

Residual cutting fluid has the risk of affecting the subsequent assembly quality and sealing reliability.

Wet machining brings with it workshop environment maintenance challenges and high waste fluid treatment costs.

3. Dry machining solution provided by LS:

- Professional evaluation: Our engineers first confirmed that the cast aluminum material provided by the customer is very suitable for dry machining.

- Optimized process: For different machining features (plane milling, deep hole machining, etc.), we planned high-speed milling strategies and accurately selected high-performance carbide tools (equipped with special anti-friction coatings) to ensure efficient cutting and heat control without coolant.

- Advanced equipment guarantee: The solution relies on our high-speed 5-axis machining center equipped with a powerful spindle and an efficient compressed air chip blowing system. This system can effectively remove chips and control the temperature of the machining area.

Significant results:

- Successfully achieved high-quality dry machining, completely eliminating the use of cutting fluid and its related costs.

- Completely eliminated the risk of cutting fluid residue, eliminating the subsequent complex cleaning process and its costs.

- Thanks to the optimized high-speed dry cutting process and machine tool performance, the overall machining cycle was shortened by 20%.

4. LS core value embodiment:

We not only provide cutting-edge 5-axis CNC machining services, but also strive to maximize the comprehensive value of cost savings (saving fluid, saving cleaning), efficiency improvement (shortening cycle) and environmentally friendly production (no waste fluid treatment) for customers through the application of advanced manufacturing processes such as dry machining. This gearbox housing project is an example of the perfect combination of our process engineering capabilities and efficient production platform.

FAQs

1. Will dry machining damage my parts?

If the process parameters and tool selection are correct, it will not cause damage. Because the heat is mainly carried away by the chips, thermal damage to the workpiece is avoided. However, if the operation is not done properly, such as wrong parameter settings or tool wear, it may cause part burns or dimensional deviations, so it is necessary to strictly follow the specifications and monitor the process.

2. Can my own CNC machine tool perform dry machining?

In theory, it is possible, but the effect depends on the rigidity of the machine tool, the spindle speed range and the chip removal capacity. It is recommended to start testing with easy-to-machine materials such as cast iron, use tools designed for dry machining, and ensure that the equipment can withstand high heat and cutting forces to avoid performance degradation or failure.

3. Is dry machining noisier than wet machining?

Generally, yes, dry machining is noisier. Because there is no damping effect of cutting fluid, the cutting sound is sharper and louder. This may increase the noise level in the working environment, which needs to be alleviated by protective measures such as soundproofing or noise reduction equipment, but it does not affect the machining quality itself.

4. Why is dry machining more popular in Europe than in North America?

This is related to differences in environmental regulations. Europe has implemented stricter environmental regulations, such as reducing waste liquid discharge requirements, forcing manufacturers to give priority to green technologies such as dry machining or minimal lubrication (MQL). Although North America is promoting it, the regulations are relatively loose, so Europe has been popularized earlier.

Conclusion

Dry machining is more than just a “coolant-free” machining method. It represents the future direction of efficient, clean and sustainable manufacturing. Although it has its challenges, the economic and environmental benefits it brings are huge.

Successfully implementing dry machining requires deep process knowledge, the right equipment and top tool technology. It’s not a simple switch, but a complete system.

Want to free your project from the constraints of coolant and achieve a win-win situation in cost and efficiency? This requires the wisdom of experts. Upload your CAD file to LS’s online platform now, and LS engineers will evaluate the best solution for you using dry machining, MQL or traditional wet machining, and provide you with a transparent 5-axis CNC machining quotation. Let us use greener technology to create greater value for you!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Keep functioning ,remarkable job!

Hello there, I found your web site by way of Google while searching for a related matter, your web site got here up, it appears to be like great. I have bookmarked it in my google bookmarks.

Hello, Neat post. There is an issue along with your site in web explorer, might check this?K IE still is the market chief and a large part of other people will pass over your excellent writing due to this problem.