The emergence of Xiaomi YU7 has ignited the enthusiasm of the market with its unique design and positioning. As a highly anticipated SUV, it carries not only the expectations of consumers, but also the ultimate pursuit of precision, strength and reliability of core components. Under this high standard, CNC (computer numerical control) machining technology stands out and becomes a key manufacturing method to shape the bones of SU7 and ensure its performance and quality.

However, when the focus is on a specific YU7 CNC component, a seemingly simple but extremely complex question emerges: “How much does it cost?” The answer to this question is far from being summarized by a simple number. Because from a piece of raw metal billet to a precision part that fits tightly on YU7, the final quotation is the result of a series of quantifiable engineering decisions.

This article will take you through the appearance of price and go deep into the cost maze of CNC machining. From the trade-offs in material selection to the challenges of geometric complexity; from the stringent requirements for accuracy and tolerance setting to the precise arrangement of machining process routes; to the added value of surface treatment and the economic leverage of order size – we will reveal each key variable that affects the final price of Xiaomi YU7 CNC parts one by one, and interpret the cost code behind this precision for you.

A Quick Chart Of The Core Drivers Of CNC Machining Costs

In order to help you quickly grasp the core driving factors that affect CNC costs, we first summarize them in a table.

| Cost drivers | Low-cost scenario | High-cost scenario | Cost optimization strategy |

|---|---|---|---|

| Part materials | Aluminum alloy 6061 and other common alloys | Titanium alloy (Ti-6Al-4V), Inconel and other special alloys | Select the most cost-effective material based on strength and weight requirements |

| Geometric complexity | 2.5D features, easy to reach by tools | Deep cavities, thin walls, complex surfaces | Simplify the design, use standard fillet radius, avoid complex cavities |

| Tolerance accuracy | Standard tolerance (such as ±0.1mm) | Very high precision tolerance (such as ±0.01mm) | Only mark strict tolerances on key mating parts |

| Order quantity | 100+ pieces (effectively share the setup cost) | 1-5 pieces (the setup cost of each piece is very high) | Integrate requirements and produce in small batches |

| Surface finishing | No finishing or simple sandblasting | Anodizing, chrome plating, precision grinding, etc. | Select the simplest post-processing required for the function |

Why Did YU7 Choose CNC? Precision, Speed, And Real Materials

In the development and initial production of high-performance models such as YU7, there is no room for compromise in prototype verification and small-batch trial production. At this time, CNC machining technology stands out and becomes the undisputed first choice. Its core advantages lie in the perfect combination of precision, speed and real materials:

Unparalleled precision: the cornerstone of performance

With its computer-controlled precision motion system, CNC machining centers can cut metal with micron-level accuracy (±0.025mm or even higher). This is crucial for core areas such as YU7’s suspension geometry, steering system bearing holes, and key engine components. Tight assembly ensures the accuracy of the interaction between components, which directly lays a solid foundation for vehicle handling, stability and final performance. Any assembly error may be magnified at high speed or extreme conditions, resulting in performance degradation or even failure risks. CNC fundamentally eliminates this hidden danger.

Extremely fast delivery: Seize the R&D initiative

Compared to traditional casting or injection molding processes that rely on long mold opening cycles, the response speed of CNC machining is revolutionary. It usually takes only a few days from digital models to physical parts in hand. This means that YU7 engineers can obtain fully functional test prototypes within 48-72 hours and immediately put them into bench testing or real vehicle verification. Design defects can be quickly exposed and corrected, and the R&D iteration cycle is greatly compressed, allowing YU7 to complete optimization faster and accelerate its market or track.

Real material verification: the ultimate guarantee of data reliability

This is the irreplaceable core value of CNC. YU7’s components are directly processed from solid metal blocks such as high-performance aluminum alloys and special steels that are exactly the same as mass-produced parts. Using these prototypes for strength testing, fatigue testing, thermal management analysis or dynamic load simulation, the data obtained has the highest fidelity and predictive value. Key performance indicators such as material stress-strain behavior, failure mode, and heat dissipation characteristics are truly reflected, providing solid and reliable data support for subsequent mass production design, avoiding performance misjudgment and design rework risks caused by material differences.

With its three core advantages of extreme precision, extreme speed and real materials, CNC machining perfectly meets the stringent requirements of the prototype development and small batch trial production stages of models such as YU7 that pursue peak performance. It not only accelerates the R&D process, but also fundamentally guarantees the reliability of key component design and the validity of test data. It is an indispensable manufacturing tool for YU7 to move from drawings to reality and from concepts to excellence.

5 Key Factors Affecting CNC Machining Prices

The price of CNC machining is affected by many factors, and a deep understanding of these factors can help with accurate budgeting and optimized design. The following are five core influencing factors and their subdivisions:

1. Material cost

- Raw material purchase price: The base price of different metals (such as aluminum alloy, stainless steel, titanium alloy, copper) or engineering plastics varies significantly.

- Material machinability:

- Machining efficiency: The cutting speed of hard materials (such as stainless steel and titanium alloy) must be reduced, which significantly increases the processing time.

- Tool wear: Difficult-to-process materials wear tools severely, resulting in frequent tool changes and increased costs.

- Special requirements: Some materials may require specific tools, coolants or processing parameters, adding additional costs.

- Material scarcity and procurement difficulty: The procurement cost of unconventional or special specification materials is higher.

2. Machine hours

- Machine tool running time: The actual cutting time of the part on the machine tool is the core of the cost, which is directly multiplied by the machine tool hourly rate (including equipment depreciation, energy consumption, land occupation, and basic labor).

- Key factors affecting working time:

- Part size and volume: The larger the size, the longer it takes to remove material.

- Geometric complexity: Complex surfaces, deep cavities, thin walls, small features, etc. require slower feed speeds, more passes, and more complex programming strategies.

- Number of machining operations: Parts that require multiple operations such as milling, turning, drilling, and tapping take longer.

- Material hardness and characteristics: As mentioned earlier, hard materials are slow to process.

- Precision requirements: High-precision areas usually require slower finishing speeds.

3. Setup and programming

- CAM programming: Engineers write tool path programs based on 3D models, and programming of parts with high complexity takes longer.

- Production preparation:

- Tooling fixture design and production/selection: When special fixtures are required, the design and production costs need to be shared.

- Machine tool clamping and debugging: The operator installs the fixture, workpiece, and tool, and performs precise tool alignment, alignment, and trial cutting.

- Cost sharing characteristics: This part is a fixed cost, which has a huge impact on small batches or single-piece production. When the batch is large, the cost per piece is reduced.

4. Tolerance and surface finish requirements

- Processing difficulty increases sharply:

- Processing speed: In order to achieve high precision and finish, the feed and speed must be greatly reduced to avoid vibration and deformation.

- Processing process: It is usually necessary to add semi-finishing and multiple finishing processes.

- Equipment and tool requirements: Higher-precision machine tools, higher-quality precision tools and special processing technologies may be required.

- Inspection cost increases:

- Inspection frequency: More frequent process inspections and final inspections are required.

- Inspection equipment: Strict tolerances often rely on more precise (and expensive) inspection equipment, such as three-dimensional coordinate measuring machines (CMMs).

- Inspection time: Precision inspections themselves take longer.

5. Post-processing

- Surface finishing: Select according to functional or appearance requirements, and the cost varies:

- Anodizing: Commonly found in aluminum alloys, divided into ordinary anodes and hard anodes, color selection affects the price.

- Electroplating: such as chrome plating, nickel plating, zinc plating, etc.

- Spraying: painting, powder coating (powder coating).

- Sandblasting/polishing: improve appearance and feel.

- Heat treatment: such as quenching, tempering, carburizing, etc., used to change the mechanical properties of materials (such as hardness, strength).

- Others: such as passivation, cleaning, laser marking, silk screen printing, etc.

- Superimposed costs: Each additional post-processing process means additional material costs, equipment usage fees, labor costs and possible logistics costs (outsourced processing).

CNC machining quotation is the result of comprehensive calculation of five dimensions: material basis, processing efficiency (man-hours), initial investment (programming settings), quality threshold (tolerance) and value-added process (post-processing). Clarifying these factors and their sub-items can more effectively communicate and control costs during the design and inquiry stages.

Material selection: balancing weight, strength and cost

There is no such thing as a “one-size-fits-all” solution when choosing materials for a project. The key is to understand the characteristics of different materials and choose the “best fit” solution based on the specific function of the part, the working environment, the load requirements and the budget constraints. The following is a comparative analysis of commonly used metal materials:

Material Selection Quick Check Table

| Material Category | Representative Grade | Core Advantages | Major Disadvantages | Typical Application Scenarios |

|---|---|---|---|---|

| Aluminum Alloy | 6061 | High cost-effective, easy to process | Relatively low strength | Body structural parts, brackets, shells |

| 7075 | Extremely high strength (close to steel) | High cost, difficult to process | Key structural parts, high-performance components | |

| Stainless Steel | 304 | Good corrosion resistance | Higher cost than carbon steel | Exhaust system, general exposed fasteners |

| 316L | Excellent corrosion resistance (especially chloride resistance) | Highest cost | Harsh corrosive environment, marine applications | |

| Alloy Steel | 4140 | High strength and toughness | Heavy, requires heat treatment | Drive shaft, gears, high-load connectors |

Aluminum alloy (lightweight first choice):

6061: The king of cost-effectiveness. While providing good strength, it is relatively low in cost and easy to process (cutting, welding, forming). It is a common choice for lightweight design and is very suitable for structural parts that do not require extremely high absolute strength (such as body frames, brackets, shells, non-critical connectors).

7075: Strength benchmark. Its strength is comparable to many steels and is the strongest type of aluminum alloy. But the cost is significantly higher material cost and processing difficulty (poor cutting performance and poor weldability). It is suitable for key parts with extremely high requirements for weight reduction and strength (such as high-performance suspension parts and key load-bearing structural parts), and the cost-effectiveness needs to be carefully evaluated.

Stainless steel (corrosion-resistant guard):

304: General-purpose corrosion-resistant stainless steel. It has good corrosion resistance (especially in atmospheric and freshwater environments), and the cost is relatively controllable compared to the stainless steel family. It is widely used in parts that require a certain degree of corrosion resistance, such as automotive exhaust systems (especially the front and middle sections), exterior fasteners, and decorative parts.

316L: Upgraded corrosion resistance. By adding molybdenum, the pitting and crevice corrosion resistance is significantly improved, especially for chloride environments (such as salt water, snow melting agents). But the cost is the highest among the three. Suitable for key components in harsh corrosive environments (such as marine equipment, key exposed parts of vehicles in coastal areas, and chemical-related components).

Alloy steel (Strong Responsibility – 4140):

4140: Balance of high strength and toughness. After proper heat treatment (quenching + tempering), it can obtain very high strength and good toughness, and can withstand impact and heavy loads. The cost is relatively moderate (between aluminum alloy and high-grade stainless steel). The main disadvantage is high density (heavy). It is an ideal choice for transmission systems and high-load components of chassis (such as drive shafts, gears, connecting rods, high-strength bolts, shaft parts).

There is no absolute “optimal” material selection. The key is to find the “best match” balance point according to the specific application scenario (strength requirements, weight restrictions, corrosion environment, budget).

3-axis vs. 5-axis: Paying The Price For Complexity

When choosing a CNC machining method, the complexity of the part directly determines your cost investment. As mainstream technologies, the core differences and cost impacts of 3-axis and 5-axis can be quickly referenced in the following table:

| Comparison Dimensions | 3-axis CNC machining | 5-axis CNC machining | Core cost impact |

|---|---|---|---|

| Machining freedom | X, Y, Z three linear axes | X, Y, Z three linear axes + A, B (or C) two rotary axes | 5-axis flexibility is significantly improved |

| Typical applicable parts | Planes, steps, straight holes, regular shapes | Complex curved surfaces, engravings, inclined features, deep cavities, spatial special-shaped structures | 5-axis solves geometric shapes that cannot be processed by 3-axis |

| Number of clamping | Parts need to be turned over and re-clamped multiple times to process different surfaces/features | Most (5 surfaces) processing can be completed with a single clamping | 5-axis greatly reduces clamping time/cost and reduces the risk of human error |

| Accuracy and error | Multiple clampings are prone to introduce cumulative errors | Single clamping ensures higher overall accuracy and position tolerance | 5-axis improves the yield rate of complex parts |

| Equipment/hour rate | Relatively low | Significantly higher | 3-axis has obvious cost advantages on simple parts |

3-axis machining: An economical choice for simple geometry

- How it works: The tool moves along three mutually perpendicular linear axes, X, Y, and Z, and can only machine one face of the workpiece (usually the top face) at a time.

- Advantages: Low equipment purchase and maintenance costs, relatively simple programming, low technical threshold for operation, and the hourly rate is usually the lowest among the three.

- Limitations and cost traps: When machining complex parts (such as those requiring multi-faceted features or deep cavities), the workpiece must be manually re-clamped multiple times. This not only significantly increases setup time and labor costs, but also introduces new positioning errors in each clamping, resulting in reduced positional accuracy between features and even increased scrap rates. For parts with only simple features such as planes, steps, and straight holes, 3 axes are the most efficient and economical choice.

5-axis machining: An efficient conqueror of complexity

- How it works: On the basis of 3 linear axes, two rotation axes are added (usually A axis rotates around X axis and B axis rotates around Y axis). This allows the tool to approach the workpiece from any angle, or the workpiece itself can be tilted to the optimal machining position.

- Core Value: One clamping for complex machining.

- Much less setup: For such complex surfaces as YU7 hub, precision cavity of turbine blade, or multi-angle holes/faces of suspension link, traditional 3-axis requires consecutive exact clamping to complete, while 5-axis could be completed in one time clamping, thereby greatly saving cost and setup time.

- Improve quality and accuracy: Single clamping eliminates repositioning error, has high-accuracy positional relationships between fine features, and holds superior surface quality (e.g., it is possible to use shorter tools on complex surfaces to reduce vibration).

- Unleash complex geometry: 5-axis becomes practically a must for angle milling, side walls of deep cavities, and smooth continuous complex surfaces (like impellers, mold cavities, bone implants).

- Cost considerations: 5-axis machines are expensive, hard to program (require professional CAM software and engineers), and costly to repair, with attendant much higher hourly cost than 3-axis. However on extremely complicated parts, reduced re-clamping time, labor, fixture cost, and greater yield rates tend to offset greater hourly cost, with attendant lower total cost of manufacture and faster delivery.

Complexity is a double-edged sword: 3-axis for simple geometry is cost- and worry-saving, whereas 5-axis for complicated shape looks pricey per piece but achieves cumulative cost advantages through optimization and precision. Get it right, don’t pay for unnecessary complexity, and don’t compromise quality and delivery time in order to underestimate the task.

Case Study: YU7 Aluminum Alloy 7075 Suspension Arm Bracket Cost Analysis

Part Specifications

- Dimensions: 200×100×50mm

- Material: 7075-T6 Aluminum Alloy

- Properties: Multiple precision holes (tolerance ±0.05mm), slender load-carrying structure, natural anodized finish

- Batch: 10 pieces

Cost estimate details (before optimization)

| Cost item | Calculation logic | Cost (yuan) |

|---|---|---|

| 1. Material cost | Blank size 220×120×55mm (15% margin) Volume: 0.001452m³ → Weight ≈4.06kg (density 2.8g/cm³) 7075 aluminum unit price: ¥110/kg → ¥446.6 Total material cost for 10 pieces: ¥4,466 | ¥4,466 |

| 2. Programming and setup | CAM programming (engineer ¥400/h × 3h) Machine tool setup (operator ¥200/h × 1.5h) Total: ¥1,200 + ¥300 = ¥1,500 | ¥1,500 |

| 3. Processing cost | 5-axis CNC rate: ¥800/h (including equipment depreciation/energy consumption) Working hours per piece: 2.5h → Total working time for 10 pieces: 25h | ¥20,000 |

| 4. Post-processing | Natural color anodizing: ¥60/piece Total cost for 10 pieces: ¥600 | ¥600 |

| 5. Quality inspection cost | CMM full inspection (key dimensions/form and position tolerances) Single piece inspection takes 0.5h → Inspector ¥300/h Total cost for 10 pieces: ¥1,500 | ¥1,500 |

| Total cost | Total: 4,466 + 1,500 + 20,000 + 600 + 1,500 | ¥28,066 |

| Cost per piece | 28,066 ÷ 10 | ¥2,806.6 |

DFM optimization solution: corner sharpness are substituted with R3 fillets

Optimization impact

- Original design: internal corner sharpness includes tool change + speed decrease processing, easy tool vibration, usage of time 2.5h/item

- After optimization: constant tool path can be ensured by R3 fillets, processing time decreases to 2.25h/item (saving 0.25h/item)

Cost comparison after optimization

| Cost item | Cost before optimization | Cost after optimization (calculation logic) | Savings |

|---|---|---|---|

| Processing cost | ¥20,000 | 2.25h/piece × 10 × ¥800 = ¥18,000 | ¥2,000 |

| Total cost | ¥28,066 | 28,066 – 2,000 = ¥26,066 | ¥2,000 |

| Unit cost | ¥2,806.6 | ¥2,606.6 | ¥200 |

| Cost reduction ratio | – | (2000÷28066)×100% ≈ 7.1% | 7.1% |

- Measurement of the value of DFM: Alone, substituting the sharp corner by R3 fillet can save ¥200/piece and lower the entire cost by 7.1%, demonstrating that small design change has a huge cost effect.

- Labor time sensitivity: The processing cost forms up to 71% (¥20,000/28,066), the major source of breakthrough cost saving.

- Batch amplification effect: For a batch of 100 pieces, optimization itself can together save ¥20,000 (the equivalent of making 7 parts for free).

Case inspiration: For high-precision industries such as aerospace/racing, DFM can be used in advance to avoid difficult-to-process features such as sharp corners and deep grooves to actually reduce processing costs by 15%~20%, improving structural fatigue life.

CNC money-saving design list: intelligent optimization, direct cost reduction

In CNC machining, up to 75% of the cost is locked in the design stage (Harvard Business School research). Cut costs at the source of design through the following key design optimizations:

- Aperture uniformity: Reduce the number of holes with different diameters. Every time you reduce a tool change, you save 2-5 minutes of machine time, significantly improving efficiency.

- “Big” liberation of inner corners: The inner corner radius (R) must be ≥ the radius of the tool used. Too small R forces the use of a small knife and multiple fine-tuning, which causes rapid tool wear and a surge in machining time.

- Reject “fragile” design: Slender bosses, ribs or too thin wall thickness (recommended ≥ 0.8mm) are very easy to vibrate and deform, difficult to process, high scrap rate, and increase costs.

- Text/Logo engraving is preferred: Raised text requires milling a large amount of surrounding material, which is time-consuming and material-consuming. Change to engraving (depth of about 0.5mm is sufficient), and efficiency is significantly improved.

- Make way for the tool: Make sure the tool can enter the cutting area vertically (avoid narrow and deep grooves and strange angles). Reserve enough exit space to prevent collision damage or forced step-by-step processing.

Every fine-tuning is a real cost saving. Incorporating these principles when designing drawings will reap smoother production, lower scrap rates and more competitive part costs. Smart investment in the design stage will result in significant cost reduction in the processing stage – making smart design your most powerful cost control tool.

Beyond Machining: “Hidden” Costs That Cannot Be Ignored

When you enter geometric parameters in an online quoter and get a seemingly affordable number, do you think that’s all? The truth is often hidden beyond “machining time” and “material cost“, and those unlisted “hidden” costs are waiting to emerge.

- Tooling costs: When you need to challenge special alloys or process tiny features (such as micro-holes with a diameter of 0.5mm), ordinary tools are not up to the task. At this time, special high-performance tools – whose prices are often several times or even ten times that of standard tools – become necessary. This investment is often quietly ignored by the quoter.

- Tooling/Fixtures: Special-shaped parts or precision positioning requirements? General fixtures are powerless. At this time, designing and manufacturing special tooling becomes the only option. This one-time investment (sometimes far exceeding the cost of the part itself) is completely invisible in the simple quotation system, but it is real and heavy.

- Minimum order fee: Even if your part structure is simple, many factories still have a minimum consumption threshold. Even if the actual processing only takes a few minutes, you may have to pay a few hours of basic fees. When trial-producing in small batches, this often causes the unit price to soar unexpectedly.

- Expedited fees: When the delivery time is compressed to 1/3 of the original plan or even shorter, expedited fees become inevitable – usually an additional 20%-50%. This “time premium” is rarely reflected in standard quotations, but becomes a decisive factor in urgent needs.

Therefore, in the face of the convenient numbers of online quoters, please be more sober: those unspoken tools, tooling, minimum order thresholds and expedited fees are the key variables that ultimately determine the total cost. Only by deeply communicating the details and evaluating these hidden links in advance can we truly avoid the “low price” trap – sometimes, they are enough to double the total cost.

From single pieces to small lots: economies of scale

In small batch production and prototyping, the total cost of a product consists of two main components:

Fixed costs (upfront costs): Fixed costs are usually expended only once or are really the same, regardless of how many pieces you produce, 1 or 100. For example:

- Programming/setup time: Time spent by a programmer coding a CNC program, configuring machine parameters, and adding custom tools/fixtures for a specific part.

- Mold/tool preparation: Creation, fabrication, or debugging necessary molds and fixtures.

- First-article inspection and debugging: Adjustments, tests, and verification required to make the first qualified part.

- Order processing/administration costs: Administrative costs of ordering processing, communication, and planning production.

Variable costs (piece cost): These vary directly with the quantity of parts produced. Illustration:

- Raw materials: Actual material consumed in producing each part.

- Machine running time: Actual machine tool hours (electricity, tool usage, etc.) taken in producing each part.

- Direct labor (operation): Time an operator spends running and observing the machine in order to produce parts (usually figured by piece or by shift).

- Post-processing (if necessary): Deburring, cleaning, surface finishing, etc., each product might require.

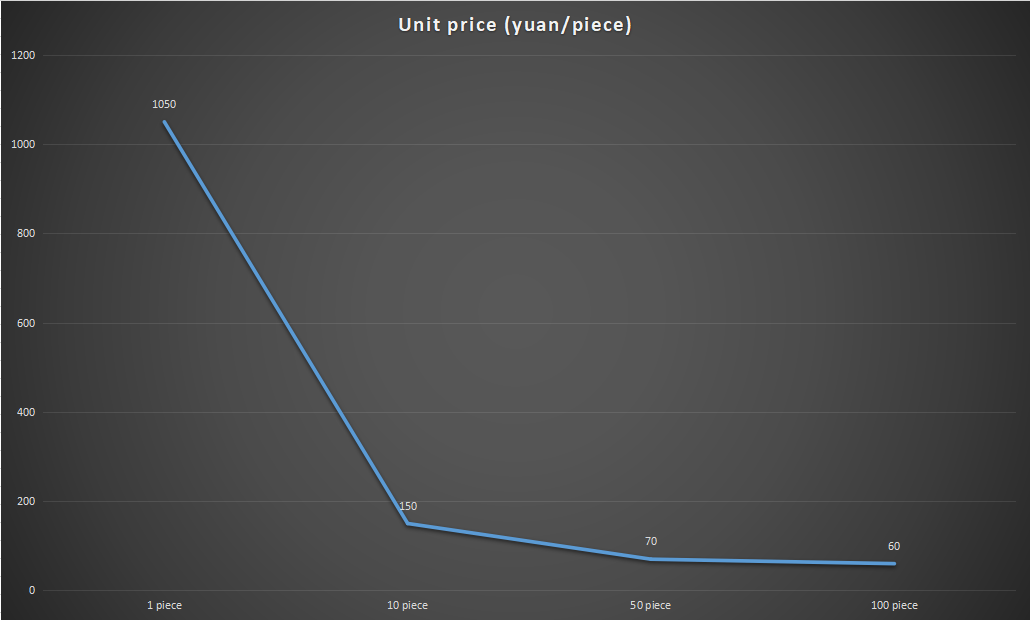

How is the unit price decreasing with quantity?

Unit price = (fixed cost / quantity produced) + unit variable cost

| Production quantity | Unit price (yuan/piece) | Calculation logic (fixed cost 1000 yuan + unit variable cost 50 yuan) |

|---|---|---|

| 1 piece | 1050 | (1000/1) + 50 = 1050 |

| 10 piece | 150 | (1000/10) + 50 = 150 |

| 50 piece | 70 | (1000/50) + 50 = 70 |

| 100 piece | 60 | (1000/100) + 50 = 60 |

Why is it decreasing? Primary reasons:

- Fixed costs are “watered down”: This is the most important reason. The high initial programming, setting up and preparation costs are spread over more and more units as the amount produced increases, leading to a substantial reduction in this part of the cost borne by each unit.

- Learning curve effect (secondary): It can also be observed in small lots. Workers become more skilled and the process is more efficient, which can reduce unit processing time or scrap rate to a minor extent, reduce unit variable costs or improve effective output further.

Strategic significance to customers:

Awareness of this curve is critical:

- Prototype stage: 1-2 have to be produced in order to validate the design, but the unit price is extremely high. The budget has to take this into account.

- Small batch approach: In case it is established that larger than 1-2 units are required (e.g., for test, demo, and mini trails), it is often a much better idea to make a somewhat larger reasonable batch (e.g., 10-50 units) all at once rather than making extremely small batches (1-5 units each time) repeatedly. This can have a great flattening effect on fixed costs and achieve improved unit prices.

- Balance point: You have to balance unit cost of purchase and income/occupation of inventory costs. It’s least expensive to produce 100 units and all that, but if the demand is only 20 units, the remaining 80 units will be inventory cost and risk. Economic batch optimum usually occurs where unit price reduction curve is beginning to fall off seriously (for example, at 50 units in our case).

FAQ: Questions answered

1. Does 5-axis machining always need to be more expensive than 3-axis machining?

Not necessarily. Although the equipment cost for 5-axis machining is relatively higher, it can economically save total working time and the cost of labor on complex parts by reducing multiple clamping and repositioning. For example, for curvaceous surface or deep hole machining, finishing multiple-faceted processes in a single clamping can increase efficiency by 20-30% and reduce overall manufacturing costs. Therefore, the choice is conditional upon the complexity of the part, and we recommend verifying the specific design and optimizing the solution.

2. What percentage of the total price is the actual cost of the material?

The material cost percentage varies by material type: common materials such as aluminum alloys are generally 10-20%, and exotic metals such as titanium alloys may be more than 50%, due to their premium purchase cost and difficult processing. The time of processing, equipment wear and tear, and surface finishing are other expenses that we shall calculate live from the order to remain transparent. For example, material ratio can be lower in mass orders but higher in precision parts or small-volume orders.

3. If I don’t specify the tolerance, what standard will be used in processing?

We will use the ISO 2768-m (medium grade) industry standard by default that specifies standard ranges of dimensional and geometric tolerances, such as linear dimension tolerance ±0.2mm, that is standard for most mechanical components. This provides equal processing and economy without the added expense of excess accuracy. In cases where the part has special requirements, we recommend annotation to achieve optimum results, but minimum quality can be guaranteed in the absence of annotation.

4. Does your real-time quotation system take all of those factors into account?

Yes, our intelligent algorithm takes geometry, material type, tolerance level, processing technology and factory capacity in real time into account, and along with the past data, calculates correct quotes. For example, it takes 5-axis requirements or material ratios into account, and provides optimized prices depending on the existing capacity and cost. The whole process takes place within seconds, which makes it efficient and reliable.

How does LS help you?

LS brings engineering expertise and uncompromising transparency to every single aspect of CNC machining:

- Instant and clear quotes: Our AI-driven platform analyzes your CAD model comprehensively, incorporates material properties (machinability, hardness), geometric complexity, accuracy tolerances (e.g., IT7), multi-axis machining approach and post-processing needs, and instantaneously offers a quote with clear cost breakdown. You can clearly see where every cost is coming from, e.g., materials, machining hours, tools, clamping, etc., without hidden costs.

- Professional DFM checking (free of charge): Prior to ordering, our intelligent system integrates with a vast machining database and is reviewed by experienced engineers to proactively identify problems in the design that can increase costs or risks (such as thin walls, sharp corners, and difficult-to-machine features), and provide optimization suggestions based on actual combat experience to improve manufacturability and cost-effectiveness upfront.

- Professional engineering support: You have the backing of an experienced team of aerospace, medical and other engineering professionals. We work closely together to provide professional guidance for decision-making on materials (Machinability vs. performance), tolerance optimization (avoidance of unnecessarily strict exactness), process planning (economical tool path, efficient clamping set up) and post-processing selection, and translate technical strength and weaknesses of different solutions and cost/delivery time impact.

- Single-stop precision manufacturing: Integrating advanced equipment (3-axis to 5-axis milling/turning compound) and end-to-end capabilities, with serious quality control (ISO 9001/AS9100), we provide seamless services from precision machining to expert post-processing (surface treatment, deburring, and testing). The process is open to view, and quality reports (e.g., FAI) are provided at critical nodes in order to ensure that the process is controllable and the results are accurate.

LS’ professionalism lies in its engineering background; our openness aims to establish trust. Let us provide your precision manufacturing needs through open and transparent cooperation.

Conclusion

Producing the CNC components of Xiaomi YU7 is not a one-number expense, but an equation that can be optimized through talent and smart design. Having knowledge of the major drivers behind it is the starting point toward mastering your project budget and timeline.

Ready to get the best value accessories for your YU7? Tell us your own needs now – whether it is replacing the original bumper, modifying the wheels, or looking for a quality aftermarket filter! You can:

- Leave a note on the LS official website to let the name of the required accessories and the year of the YU7 be known.

- Upload part details (optional): Attach part numbers or good-quality photos to maximize match accuracy.

In a matter of minutes, you will receive:

Detailed, clear and transparent quotations: Clearly mention the price of accessories and the service fee.

Free adaptability consultation: Our professionals in YU7 will study the options to create a flawless fit for your car.

Single-stop service option for professional procurement and fitting.

Don’t be concerned by imprecise pricing information! Act now and bring peace of mind and vitality to your YU7 by professionalism and transparency. Click the link below or call us to activate accurate service!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

There is noticeably a bundle to know about this. I assume you made certain nice points in features also.

I have been checking out a few of your posts and it’s pretty good stuff. I will surely bookmark your blog.

Thank you so much for your support and following! It means a lot to me. I will continue to share valuable content, and I hope to surprise you with more great content in the future.

As soon as I detected this internet site I went on reddit to share some of the love with them.

Keep functioning ,terrific job!

Thanks for the sensible critique. Me & my neighbor were just preparing to do a little research on this. We got a grab a book from our local library but I think I learned more clear from this post. I am very glad to see such magnificent info being shared freely out there.

I just couldn’t depart your web site prior to suggesting that I really enjoyed the usual info an individual provide for your visitors? Is going to be back regularly in order to investigate cross-check new posts

Wonderful blog! I found it while browsing on Yahoo News. Do you have any suggestions on how to get listed in Yahoo News? I’ve been trying for a while but I never seem to get there! Thank you