Thread whirling milling and thread milling are two generally used strategies for thread processing in manufacturing. Understanding the variations between them is essential for selecting probably the most appropriate processing technique, which might considerably enhance processing effectivity and accuracy, whereas lowering prices.

Selecting the proper thread processing technique not solely impacts processing effectivity and product high quality but in addition straight influences manufacturing prices. Threaded parts play roles in fastening and energy transmission in mechanical design. Due to this fact, the accuracy of thread processing is essential for the efficiency of the whole mechanical system.

Variations between Thread Whirling Milling and Thread Milling

| Side | Thread Whirling Milling | Thread Milling |

|---|---|---|

| Definition | A high-speed technique for milling threads, utilizing specialised, high-efficiency thread processing machines or gadgets. | Normally carried out on thread milling machines, utilizing both disk-shaped or comb-shaped milling cutters. |

| Effectivity | Excessive processing effectivity, which might improve effectivity by greater than ten instances in comparison with conventional strategies. | Effectivity could not match that of whirling milling. |

| Accuracy | Excessive processing accuracy, with the floor roughness reaching Ra0.8 microns. | The pitch accuracy can typically attain stage 8 to 9, and the floor roughness is R5 to 0.63 microns. |

| Process | The product is fashioned in a single cross with out the necessity for knife withdrawal and eccentric reducing. | Requires a machining middle with three-axis linkage (or above) with spiral interpolation operate. |

| Utility | Extra favored in large-scale manufacturing attributable to its excessive effectivity and one-pass formation. | Could also be extra economical by way of gear and gear prices, particularly for small-scale manufacturing or diversified thread specs. |

| Value | The price of gear and instruments could also be increased attributable to its excessive effectivity. | Could also be extra economical by way of gear and gear prices. |

Each thread whirling milling and thread milling have their benefits. The selection of the appropriate technique is determined by the particular processing wants, effectivity necessities, accuracy requirements, and value issues. The kind of thread, the traits of the processing materials, and the dimensions of manufacturing ought to be considered when making a choice. By selecting the suitable processing technique, the standard of thread processing might be ensured, whereas maximizing cost-effectiveness.

Processing Ideas

Thread Whirling Milling

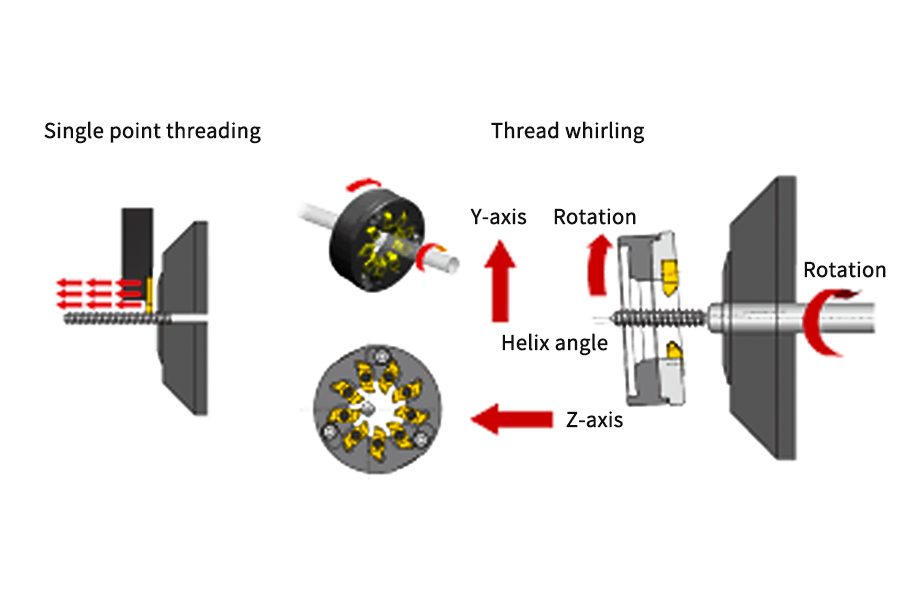

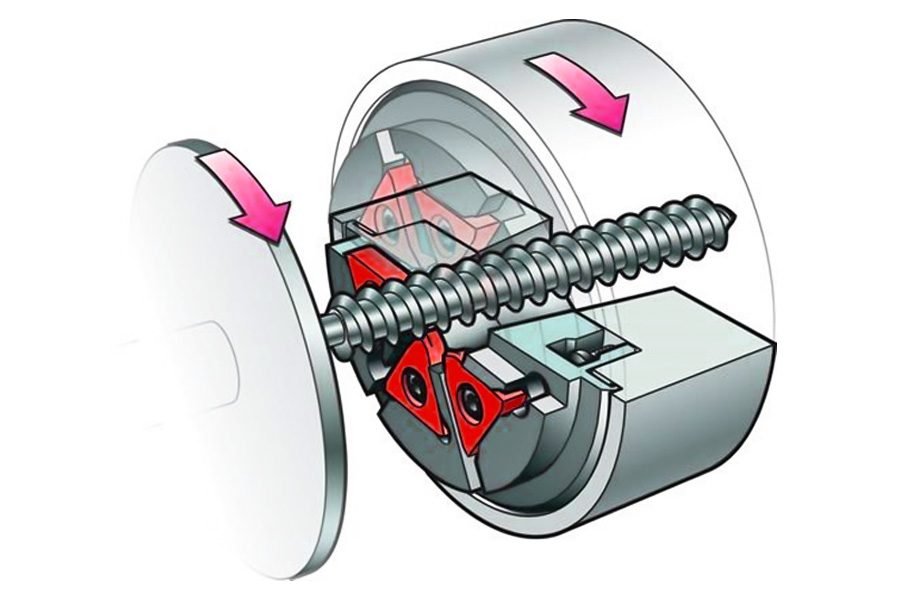

Thread whirling milling is a particular processing technique that makes use of a singular device. It processes threads by axially feeding whereas rotating at excessive velocity. The attribute of this technique is as soon as fashioned, no want for a number of reducing, therefore, it has excessive processing effectivity and accuracy.

Thread Milling

Thread milling, alternatively, makes use of a ball-end mill or an finish mill. It processes threads by programming to manage the shifting trajectory of the device. The attribute of this technique is its potential to process threads of assorted specs, providing excessive flexibility, however it could require extra processing time.

Processing Traits

| Processing Methodology | Processing Pace | Processing Accuracy | Processing Value | Relevant Scope |

|---|---|---|---|---|

| Thread Whirling Milling | Quick | Excessive | Excessive | Appropriate for processing lengthy threads, deep threads, and multi-start threads |

| Thread Milling | Gradual | Medium | Low | Appropriate for processing quick threads, shallow threads, and single-start threads |

Comparability of Advantages and Disadvantages

| Processing Methodology | Advantages | Disadvantages |

|---|---|---|

| Thread Whirling Milling | Quick processing velocity, excessive processing accuracy, quick chips, lengthy device life | Excessive processing price, excessive gear necessities, advanced programming |

| Thread Milling | Low processing price, low gear necessities, easy programming | Gradual processing velocity, medium processing accuracy, lengthy chips, quick device life |

Choice information: Comparability of spiral and thread milling

When choosing the thread machining technique, it’s essential to comprehensively think about the elements comparable to processing effectivity, accuracy, price and thread sort. This is a information primarily based on the most recent analysis that can assist you make the fitting alternative.Processing effectivity

Spiral milling: with extraordinarily excessive processing effectivity, the velocity can attain 400 meters per minute, which is a number of instances and even ten instances that of conventional turning processing. Thread milling: Though extra environment friendly, however in comparison with cyclone milling, its processing velocity is slower.Machining accuracy

Spiral milling: As a result of one-tool forming and eccentric reducing don’t must withdraw the device, the processing accuracy may be very excessive, and the floor roughness can attain Ra0.8 microns, which is 2 ranges increased than the normal processing technique. Thread milling: can even acquire good machining accuracy management, appropriate for top precision necessities of the workpiece.Processing price

Spiral milling: Though the gear price is increased, however as a result of there is no such thing as a want to alter the lathe construction, simple set up, saving the price of funding in particular machine gear. Thread milling: requires the usage of a 3-axis CNC machine device, the associated fee is decrease than the faucet, however a single thread milling cutter is dearer than the faucet.Thread sort

Rotary thread milling: appropriate for processing lengthy thread, deep thread, multi-thread, the device adopts a convertible blade, might be utilized to a wide range of pitch thread reducing. Thread milling: Broad utility vary, can process a wide range of working situations of thread, appropriate for brief thread, shallow thread, single thread.Different issues

Spiral milling: has a excessive diploma of automation, can obtain totally computerized processing. Thread milling: good device versatility, excessive processing security, even when there’s a damaged knife won’t damage the parts. Nevertheless, the programming is comparatively troublesome, which limits its large utility.Conclusion

Spiral milling has apparent benefits in processing effectivity and accuracy, and is appropriate for machining advanced thread sorts, however at a better price. The thread milling price is low, the applying vary is large, however the effectivity and accuracy are barely inferior. Your alternative ought to be primarily based on the particular processing wants and value funds.Why select LongSheng in your thread whirling venture?

Selecting LongSheng for thread whirling might be advantageous for a number of causes:

-

Superior Expertise: LongSheng is thought for its superior expertise in thread whirling. This ensures excessive precision and effectivity in thread machining, making it a dependable alternative for advanced threading duties.

-

High quality Assurance: LongSheng has a powerful repute for high quality assurance. Their thread whirling instruments and machines bear rigorous testing and high quality checks to make sure they meet excessive requirements, offering customers with confidence of their efficiency and sturdiness.

-

Buyer Help: LongSheng affords wonderful buyer assist. They supply complete after-sales service and technical assist, serving to prospects to unravel any issues they could encounter throughout the usage of their thread whirling instruments and machines.

-

Innovation: LongSheng is dedicated to steady innovation. They commonly replace their thread whirling expertise to maintain up with the most recent business traits and buyer wants, making certain they continue to be a number one alternative available in the market.

-

Value-Efficient Options: LongSheng offers cost-effective options for thread whirling. Their instruments and machines are competitively priced, providing excessive worth for the associated fee, particularly contemplating their superior expertise and prime quality.

FAQs

What are the several types of thread milling?

There are primarily two kinds of thread milling: single-point thread milling and multi-point thread milling. Single-point thread milling makes use of a single reducing device for machining, whereas multi-point thread milling makes use of a number of reducing instruments concurrently, which might enhance the machining effectivity.

What parts are appropriate for thread whirling milling?

Thread whirling milling is appropriate for machining advanced thread sorts comparable to lengthy threads, deep threads, and multi-start threads. As well as, for parts that require excessive precision and excessive effectivity, thread whirling milling can also be an acceptable alternative.

What are the necessities for reducing instruments in thread whirling milling?

Thread whirling milling has excessive necessities for reducing instruments. Firstly, the reducing instruments must have adequate hardness and put on resistance to make sure machining accuracy and gear life. Secondly, the form and dimension of the instruments should be suitable with the kind of thread being machined. Lastly, the reducing instruments must have good thermal stability to forestall overheating and deformation throughout high-speed machining.

study thread whirling milling programming?

To study thread whirling milling programming, one should first grasp the fundamental information of CNC programming, then delve deeper via studying related textbooks and reference books, or attending specialised coaching programs. As well as, sensible expertise can also be crucial, and one can enhance their programming abilities via precise operation and apply.