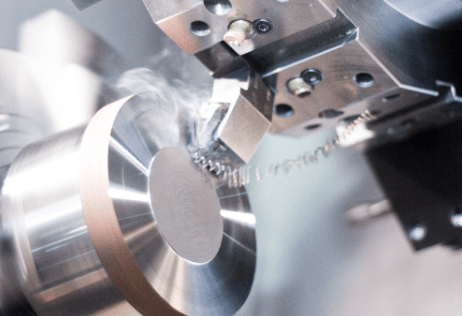

CNC machining is a manufacturing process that uses computer-controlled machines to remove material from a workpiece. This process offers a wide range of advantages over traditional machining methods, but it also has some disadvantages. In today’s manufacturing world, CNC machines are like high-tech magic. They’ve changed how we make things, using computers to do the hard work.

In this article, we will explore the advantages and disadvantages of CNC machining in detail.

Advantages of using CNC Machine

1.Precision

One of the primary advantages of CNC machining is precision. With the ability to control the movement of the cutting tool with high precision, CNC machines can produce parts with consistent quality and. This precision are essential for industries such as aerospace and medical device manufacturing, where even small errors can have significant consequences.

2.accuracy

How closely the produced part matches the plans reflects the project’s accuracy. With human machinists, mistakes can create minor differences in precision that could cause significant problems. Applications that require parts to meet strict design guidelines may fail with even small deviations from the correct design. Automating production with CNC machining reduces accuracy problems, but the operator still has some control over the process.

Machining projects’ accuracy depends heavily on the operator. Because the operator plays such a pivotal role, finding a machine shop that puts extra effort into projects is critical to getting the results you want.

To improve accuracy, the user controls the tool calibration and operating environment when operating a CNC machine. Operators must also recognize when machining tools get too dull to create required results and if the machine requires service to restore accuracy.

CNC machining’s added accuracy makes repeatability possible. If you have a large order of multiple replicas of a part, with CNC machining, you can have those parts produced with improved accuracy compared to handmade components.

3.Efficiency

CNC machining has significantly improved efficiency and productivity in manufacturing. With the ability to produce parts quickly and accurately, CNC machines reduce lead times and improve turnaround times. Additionally, CNC machines can handle complex geometries and intricate designs, reducing the need for manual intervention and improving overall efficiency.

4.Versatility

CNC machining is highly versatile, making it ideal for use in a variety of industries and applications. It can work with a wide range of materials, including metals, plastics, and composites, and can produce parts with complex geometries and intricate designs. This versatility allows manufacturers to produce parts for a variety of industries and applications, making it the perfect solution for those looking to expand their business.

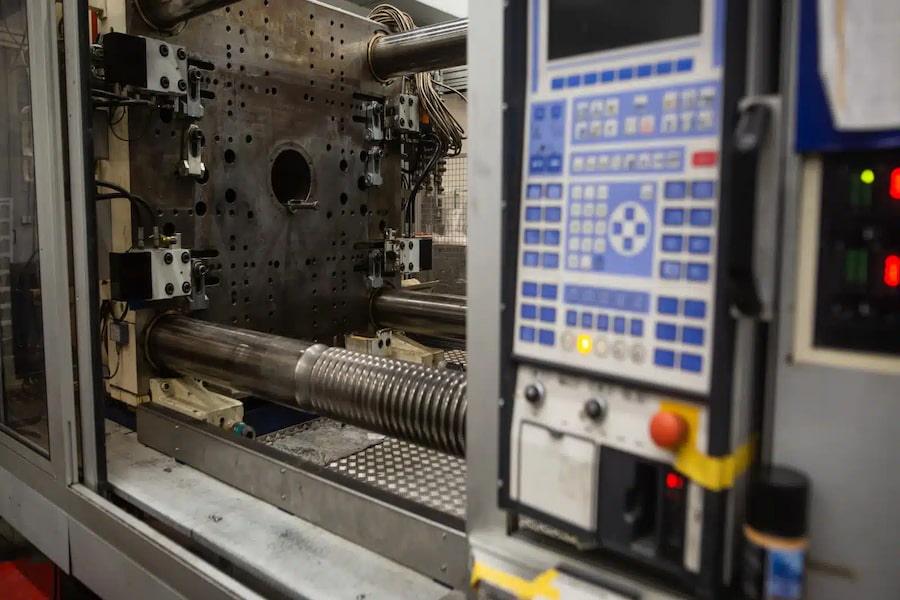

5.Automation

One of the most significant advantages of CNC machining is automation. These machines can be programmed to perform a wide range of tasks, reducing the need for human intervention and resulting in significant cost savings for manufacturers.

6.Advanced Production Options

The software used in CNC machines opens up a realm of possibilities. You can manufacture complex products which are tough or nearly impossible to create on traditional machines. Moreover, unlike traditional machinery where you might need to replace parts or even the entire machine to upgrade your production capabilities, in CNC machinery you just need to update the software.

7.Reliability

Because CNC machining processes run on software instead of human force, errors are virtually zero when the file is correct and designed with DFM (design for manufacturing) in mind. CNC’s reliable production will deliver what you expect every time.

8.Reduce Labor Costs

CNC machines don’t need a lot of people to watch over them. One person can take care of many machines at once, which saves a lot of money on workers.

9.Scalability

You don’t need to worry about having one, ten, or a thousand pieces produced with the same precision in specifications and quality. CNC machining is ideal for you whether you need one piece or hundreds, and even if you request an additional batch later, you will always get what you ordered.

10.Energy Efficient

We understand that you might also worry about the environmental impact of using CNC as your manufacturing technology. Good news for you: CNC machining is very energy efficient, which means it will use the least amount of energy possible thanks to its highly advanced CAM software that allows for pre-production processing. As a flexible production technology, it is possible to produce on demand and reduce inventory to reduce carbon emissions.

Disadvantages of using CNC Machine

1.High Initial Investment

One of the primary disadvantages of CNC machining is the high initial investment required to purchase and maintain the machines. CNC machines are expensive, and they require regular maintenance to ensure proper operation. Additionally, CNC machines require skilled operators to program and operate the machines, adding to the overall cost of the process.

2.Maintenance & Repair Costs

Even though they save on workers, CNC machines need a lot of care. Fixing them can be pricey, and you need people who know what they’re doing. Regular checkups are a must.

3.Limited Flexibility

While CNC machining is highly versatile, it does have some limitations in terms of flexibility. CNC machines are designed to perform specific tasks and operations, and they may not be suitable for all applications. Additionally, making changes to the machining process can be challenging and time-consuming, limiting the flexibility of the process.

4.Dependence on Computer Software

CNC machines are controlled by computer software, which can be a disadvantage in some cases. If the software is not up to date or is not working correctly, it can cause delays and production issues. Additionally, programming the machines requires skilled operators who are familiar with the software, adding to the overall cost of the process.

5.Material Waste

This one greatly depends on your design qualities. CNC is a subtractive manufacturing process that can generate unnecessary waste if you need to remove too much material to achieve your design. If your project has a very intricate design, maybe CNC is not the best fit in this scenario.

6.Training & Skill Requirements

To run a CNC machine, you need smart workers. They have to understand the computer program and be good at solving problems. This means they need extra training.

7.Operator Error

The operator has a significant level of control over a CNC machining project’s accuracy. While operator error can cause problems with the accuracy of the machined part or the program used to create it, you can do some things to avoid these issues.

First, find a machine shop with well-trained personnel who know how to get maximum accuracy from the machine.

Secondly, the shop should verify the accuracy of products produced to ensure they match expectations. The manufacturing company you choose should work with you throughout every stage of the project. If you bring a part request, the company should help you with creating a CAD drawing, choosing materials, getting approval for the design, creating a prototype and manufacturing the entire order. These steps help avoid possible errors.

Thirdly, look for a company that acknowledges and learns from its mistakes. While CNC machining has a lower chance for human error than manual part creation, mistakes can happen. The company should correct the error and change procedures based on what the experience taught its workers. When you find a company willing to correct and learn from mistakes, you can develop a relationship with a shop that will continue improving and providing you with better service.

| Advantages | Disadvantages |

|---|---|

| Precision | High initial investment |

| Efficiency | Limited flexibility |

| Versatility | Dependence on computer software |

| Automation | Material waste |

| Reduce labour costs | Maintenance & repair costs |

| Scalability | training and skill requirements |

| Energy efficient | Operator error |

| Accuracy | |

| Advanced Production Options | |

| Reliability |

do you really need to use cNC machine?

Do you need CNC machining for your project? The answer depends on what you need and how quickly you need it. Alternatives to CNC machining may take much longer to execute or have higher chances of errors.

Many projects that require the following tasks are suitable for CNC machining:

- Milling

- Drilling

- Turning

CNC machining works well in creating parts that require these operations, need high levels of precision and accuracy and have moderate sizes.

Pros and Cons of CNC Machining

CNC machining offers some drawbacks, such as cost, size limitations and the potential for human error. However, with the many ways you can make decisions before and during the process of getting your project completed, you may mitigate the effects of some of these negative points on your order.

For many in the defense, aerospace, medical, marine, automotive and electrical industries, CNC machining provides unmatched precision, repeatability and accuracy. Companies in these industries and many others request made-to-order parts through a machine shop because they can quickly get the high-quality components they need.

By programming the computer and setting the device to run, employees at machine shops can work on orders 24 hours a day, reducing creation time. With a consistent program, the machine produces replicas with identical accuracy and precision, regardless of the order’s size.

Finding balance when placing orders with a third-party company is always vital. If you need the advantages of this manufacturing style and can work with the few drawbacks it has, choose CNC machining for your next made-to-order part project.

Just as you carefully choose the type of manufacturing for your parts, put the same care into finding a company to fulfill your order. Worker training and customer service should not be afterthoughts. Find a company that will partner with you throughout the process. If they make a mistake, they should correct the error and ensure you feel confident in the integrity of the parts in your order.

advantages of longsheng cNC machining

Our precision CNC machine not only cover the CNC machine of individual workpiece, but also cover the entire production cycle, including design, model making, prototyping and mass production. And it can ensure that the CNC parts size is within an acceptable range and effectively fits with other CNC parts.

| Abilities | CNC Milling | CNC Turning |

|---|---|---|

| Maximum Part Size | 1300mm × 800 mm × 300mm 51.2in. × 31.5in. × 11.8in. | 300mm × 500mm 11.8in. × 19.7in. |

| Minimum Part Size | 1mm × 1mm 0.04in. × 0.04in. | 1mm × 1mm 0.04in. × 0.04in. |

| Minimum Feature Size | +/- 0.3mm +/- 0.011in. | +/- 0.3mm +/- 0.011in. |

| Standard Tolerances | +/- 0.005mm +/- 0.0002in. | +/- 0.005mm +/- 0.0002in. |

| Linear Dimension | +/- 0.005mm +/- 0.0002in. | +/- 0.005mm +/- 0.0002in. |

| Hole Diameters (Not Reamed) | +/- 0.005mm +/- 0.0002in. | +/- 0.005mm +/- 0.0002in. |

| Shaft Diameters | +/- 0.005mm +/- 0.0002in. | +/- 0.005mm +/- 0.0002in. |

Conclusion

CNC machining offers a wide range of advantages over traditional machining methods, including precision and accuracy, increased efficiency and productivity, versatility, reduced costs and waste, and automation. However, it also has some disadvantages, such as a high initial investment, limited flexibility, and dependence on computer software. By understanding the advantages and disadvantages of CNC machining, manufacturers can determine if it is the right solution for their specific needs and requirements.

If you’re interested in learning more about CNC machining or implementing CNC machining in your manufacturing process, be sure to consult with experts in the field to determine the best solutions for your specific needs and requirements.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items

fAQs

What is role of CNC technology in modern manufacturing?