Traditional CNC cutting tools such as end mills, lathes and grinders can machine parts that do not require complex machining geometries. But what if you need to produce parts that are so complex that even advanced 5-axis machine cutting tools can’t do the job efficiently?

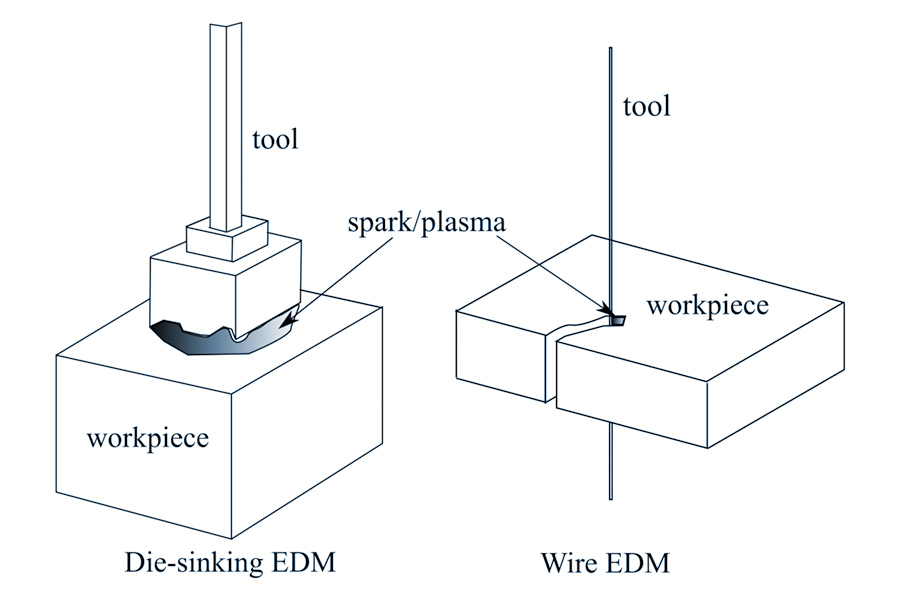

Electrical discharge machining (EDM) equipment solves this problem. There are two types of EDM technologies: electrical discharge forming and wire cutting. The type of EDM that is best suited to machine the parts you need depends on the specific application and requirements of your job. In this guide, we will learn together what a sinker EDM is, how it works, its areas of application, its pros and cons, and more, so that you can Find the right machining method when you need to produce very complex parts.

What is a sinker EDM?

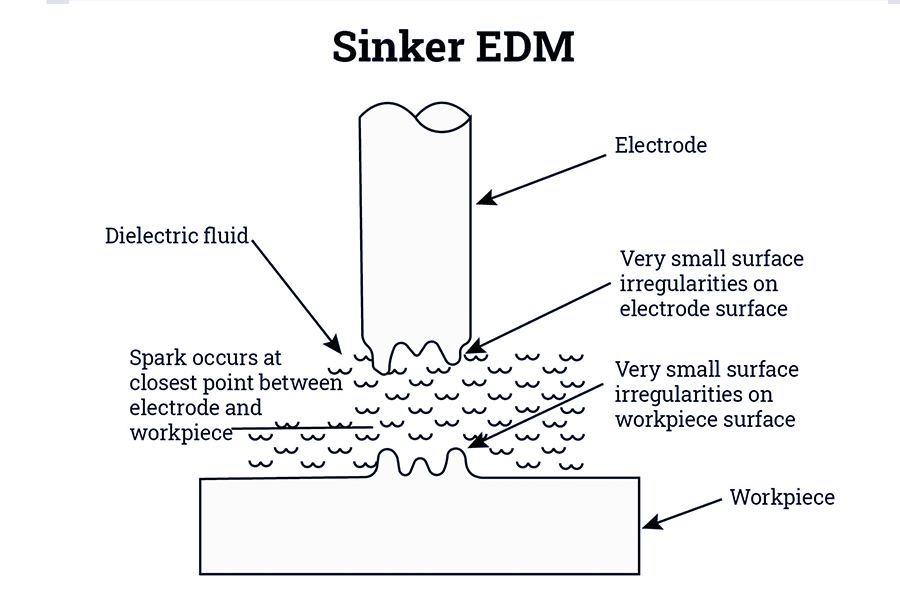

Sinker EDM, which is also called ram EDM, volume EDM and cavity EDM, is a type of EDM used to produce cavities in metal workpieces. This is done using an electrode tool that is the shape of the cavity being created. The shaping tool, or die, can be machined to create complex positive shapes that are then used to erode materials from the workpiece to create the cavity. These tools are generally made out of materials like graphite, tungsten and copper.

How Does Sinker EDM Work?

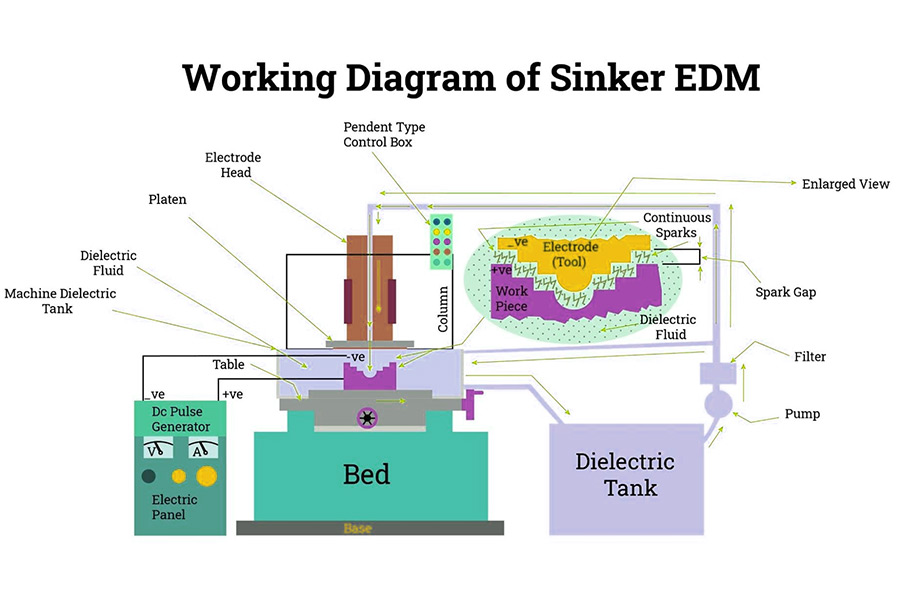

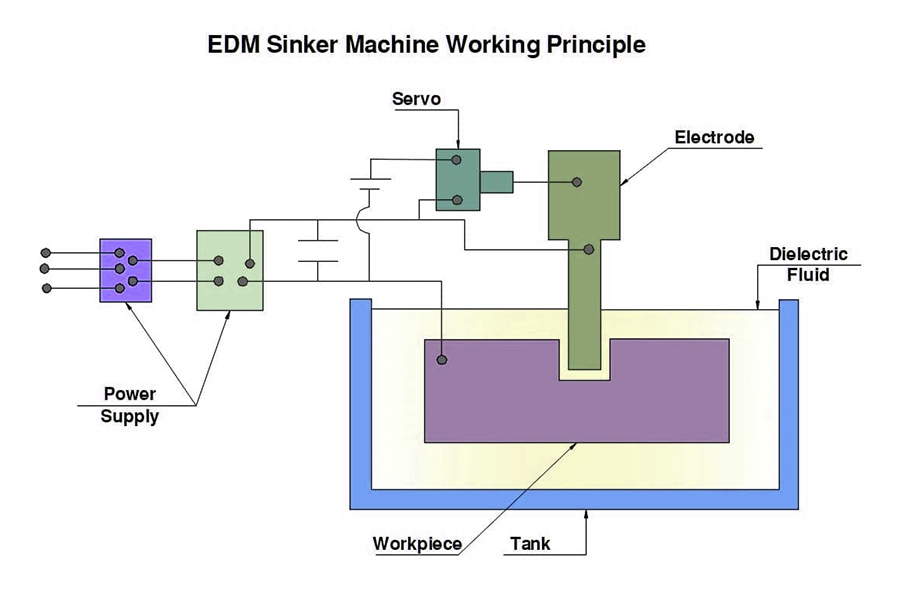

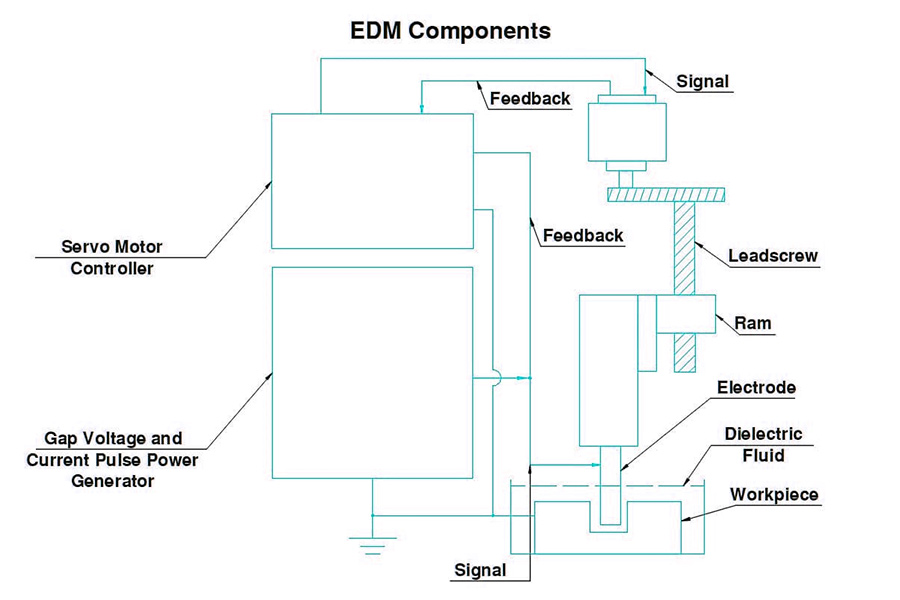

Here’s how a sinker EDM machine works, you submerge two conductive components in some insulated liquid (dielectric) that is used to control the spark, cool the workpiece and flush out the eroded particles. The Electrode is suspended from the Ram of the machine and the workpiece s mounted to the table. Each of these components are electrically connected to the machines Generator which is set on and off according to need. The controller will switch the current on and off automatically as needed in accordance with the parameters that were given for the project typically based on the electrode size and material removal rate as well as workpiece surface finish desired. Controlled erosion takes place when a series of powerful sparks are generated one after the other, gradually etching and burning away at the material until the desired shape is achieved.

The Sinker EDM Process

The sinker EDM process is used by manufacturers due to its ability to cut extremely tiny pieces with exceptional tolerances. It is often used to produce detailed products that are too delicate to be produced using any other process. Sinker EDM is used to produce prototypes for customers to examine and for engineers to adjust for other means of processing.

1.Design the Electrode

The first step in the Sinker EDM process is to design the electrode. The electrode is typically made of copper or graphite and is shaped to match the desired shape of the workpiece. The electrode is mounted on the machine’s electrode holder and connected to the power supply.

2.Prepare the Dielectric Fluid

A dielectric fluid is used in the EDM process to act as a coolant and an electrical insulator. During the EDM process, the dielectric fluid circulates around the electrode and workpiece to prevent arcing and to remove the eroded material. It helps control the temperature of the machining area to prevent thermal expansion.

The types of dielectric fluids are made from petroleum based liquids or synthetic oils with some water based fluids also being available. Dielectric fluids are formulated to have high electrical resistance and low viscosity with the ability to insulate the electrical discharge and flow freely around the workpiece. Some types of dielectric fluids contain additives to improve their cooling and lubricating properties.

The dielectric fluid is a highly critical part of the sinker EDM process since it flushes away the bits of burnt metal and electrode from the work area into the filtration system.

3.Prepare the Workpiece

The workpiece, composed of a ferrous conductive metal, is selected as a metal that can be shaped to conform to the end product. It is placed on a worktable and secured using clamps or fixtures. The workpiece is lowered into a tank filled with the dielectric fluid with the surface to be machined exposed.

4.Position the Electrode

The electrode is positioned over the workpiece, using a servo control system, and lowered into the dielectric fluid until it touches the surface of the workpiece.

5.Initiate the Spark

The power supply sends a high-voltage electrical discharge between the electrode and the workpiece. This creates a spark that erodes the workpiece material and shapes it according to the electrode’s geometry. When the electrode gets close to the workpiece, an electrical sparks jumps between it and the workpiece. The spark generates temperatures as high as 8000°C up to 12000°C (14,432°F up to 21,632°F), which erodes the metal in the shape of the electrode.

6.Control the Spark

The spark is controlled by adjusting the pulse duration, current, and other parameters of the power supply. The workpiece is eroded in a controlled manner, removing minute particles of material. The dielectric fluid circulates around the machining area to remove the eroded material and prevent arcing.

7.Monitor the Process

The progress of the process is monitored by the controller that switches on and off as needed in accordance to the electrode size, material removal rate, and the desired surface finish. The operator can adjust the machining parameters as needed to ensure that the process is proceeding smoothly and accurately.

8.Finishing the Workpiece

Sinker EDM produces very smooth, even, mirror-like finishes, which may require extra processing depending on the parameters of the part being produced. Finishing enhances the appearance and durability of the part as well as meets the dictates of its design.

- Painting – The three methods for painting sinker EDM products are powder coating, liquid coating, or e-coating.

- Powder coating includes electrostatically charging the powder such that it leaves a scratch resistant, smooth, uniform finish.

- Liquid coating is applying paint to the surface of the part.

- E-coating involves dipping the workpiece into a bath of paint after which part and paint are electrified.

- Transfers – Transfers are designs or labels that are applied by a heated press that applies pressure to transfer the design or label.

- Assembly – The part produced by sinker EDM may be part of a larger assembly.

- Drilling – Drilling is completed using drill presses, peck drills, tapping, or milling machines to place holes in the part. The type, size, angle, and kinds of holes are determined by the parts design.

- Deburring – Deburring is a common finishing process for all forms of metal machining and is completed using abrasive flow, an electrochemical process, or a thermal process. Each process is designed to smooth edges and remove extra and unwanted material.

Advantages of EDM machines

- Accuracy: EDM machines are suitable for precision machining and can form extremely precise features.

- Tools: Unlike other machining processes, EDM does not require tools that are harder than the workpiece.

- Shapes: This process is suitable for creating complex shapes and fixtures, including irregularly shaped blind holes.

- Risk: This is a low risk process.

- Metal Type: As long as the metal is electrically conductive, EDM is suitable for processing it.

- Low-stress machining: Unlike aluminum machining, EDM does not induce stresses that could deform the cutting tool or workpiece.

- Complex structures: Since it does not necessarily cut through the workpiece unless necessary, it is suitable for manufacturing thin walls, blind cavities, cross-sections, etc.

disadvantages of EDM machines

- Material limitations: EDM is only suitable for machining conductive materials. Therefore, the process is not suitable for plastics and composite materials.

- High energy consumption: This process consumes a lot of energy compared to CNC machine tools. It requires a lot of electricity to generate enough energy for the process.

- Time: The process is more expensive and time-consuming than traditional machining.

Applications of sinker EDM

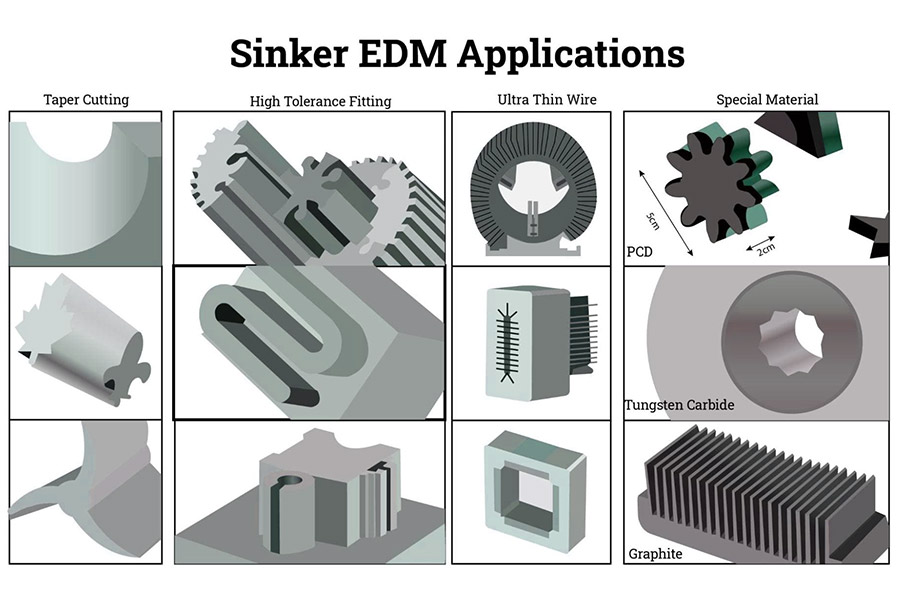

Sinker EDM is used to create complex cavities and is therefore particularly useful for fabricating molds, dies, and other forms of tooling — especially from hard materials like tool steel. It is also better than other machining processes for creating sharp inside corners and deep ribs.

Common sinker EDM applications include:

- Rapid Tooling

- Mold making

- Injection molding molds

- Dies

- Fine details

- Sharp inside corners

- Deep and thin ribs

- Blind cavities

- Blind keyways

- Internal splines

- Threads

The Differences between sinker EDM and wire EDM

| Sinker EDM | Wire EDM |

| Shaped tool sunk into workpiece from above | Thin wire cuts into workpiece from side |

| Movement principally along Z axis | Movement principally along X and Y axes |

| Tool usually made of graphite | Wire usually made of brass |

| Dielectric liquid usually hydrocarbon oil | Dielectric liquid usually deionized water |

| Ideal for tooling, molds, dies | Ideal for tooling, punches, dies |

Material selection by EDM sinker machining

Material selection is an important consideration in sinker EDM, since the type of material being machined has an impact on the success and outcome of the process. There are several factors that need to be considered when selecting a material for sinker EDM machining. The key factor in the process is the conductivity of the workpiece that is being shaped.

Conductivity

Only metals with conductivity can be used in the sinker EDM process. Other materials, such as ceramics, can have conductive metals included in their processing such that they can be shaped by sinker EDM. The process of sinker EDM includes the easy flow of electricity to create the electrical discharge. A conductive workpiece completes the electrical circuit created by the sinker EDM machine and allows current to pass through it. Untreated ceramics and plastics are unable to conduct electricity and cannot be processed by sinker EDM.

Melting Point

The melting point of the material being machined is an important consideration that impacts the amount of energy required to melt the material and the rate of the erosion process. Higher melting points require more energy and longer cycle times. The sinker EDM process is not affected by the hardness of a metal but its thermal properties determine its machinability.

The melting temperature of a workpiece determines how the sinker EDM machine performs and is measured by the metal removal rate (MRR), which is affected by a metal’s melting point and thermal conductivity. Of the various metals used for sinker EDM machining, tungsten carbide has an extremely high melting point.

| Metal | F° Melting Point | C° Melting Point |

| Aluminum (6061-T6) | 1080° – 1200° | 582° – 649° |

| Inconel (718) | 2300° – 2437° | 1260° – 1336° |

| Stainless Steel (410) | 2700° – 2790° | 1482° – 1532° |

| Tool Steel (06) | 2732° | 1500° |

| Titanium (Ti-6AL-4V) | 3000° | 1649° |

| Tungsten Carbide (K-68) | 6054° | 3360° |

Machinability

The machinability of the material is also an important consideration as it impacts the efficiency and effectiveness of the sinker EDM process. Materials that are difficult to machine, such as hardened steels, require more time and energy to remove material and may wear down the electrode more quickly.

Surface Finish Requirements

The surface finish of a part is reflected in its appearance and affects how it slides over another part. In sealing applications, surface finish is essential. The sinker EDM process creates micron (µ) sized holes across the workpiece, which is different from cutting tools that leave a directional lay.

One of the main reasons for using sinker EDM is the types of finishes that it produces that require very little after production processing. Sinker EDM is unaffected by the hardness of a material, which makes the selection of type of metal easier.

Metals Formed by Sinker EDM Machining

Steel Alloys

All forms of steel are machined by the sinker EDM process. They are used for their toughness, strength, durability, and resilience. Alloy steels have elements added to improve their properties including chromium, cobalt, columbium, molybdenum, manganese, nickel, titanium, tungsten, silicon, and vanadium. The various alloys change the properties of steel and add desirable characteristics.

Copper

Copper is the perfect choice for the sinker EDM process since it has such high conductivity. The use of copper restricts the process due to copper heating quickly and passing the heat through the metal, which requires that the process be slowed and carefully controlled. Sinker EDM works with copper components that have thin walls without warping or distorting the walls.

Tungsten Carbide

Tungsten carbide is a difficult metal to machine since it has high hardness and melting point and is brittle, which makes sinker EDM the perfect method for machining it. The heat that is generated is conducted differentially due to the structure of tungsten carbide.

Electrodes for tungsten carbide are made of copper using negative electrode polarity, which produces very low surface roughness. When machining tungsten carbide, using sinker EDM, the removal rate is very slow due to the nature of the metal. Small intricate and complex geometries can be produced using the process.

Titanium

Titanium has exceptional strength to weight ratio, corrosion resistance, and the ability to withstand high temperatures. Due to its biocompatible properties, it is widely used for medical implants. The high hardness of titanium makes it difficult to machine using conventional machining methods. As with tungsten carbide, it is machined using copper electrodes with pulse on and off time.

Nickel Alloys

Inconel, Hastelloy, and Monel are nickel alloys with resistance to heat, corrosion, and oxidation. They are used for high temperature applications like gas turbines, aerospace, and chemical processing equipment.

Aluminum

Aluminum is an extremely abundant metal that is used in a wide assortment of applications and products. Its natural resistance to oxidation, corrosion, and rust makes it a highly durable metal. Aluminum is seldom used in its pure form and is normally alloyed with other metals to improve its properties. It is well suited for work with sinker EDM due to its ability to be shaped into intricate and complex shapes.

Variations of Sinker EDM Machines

Automated Sinker EDM

Automatic EDM machines use cutting-edge robotics and automation to simplify the manufacturing process and improve work efficiency. This kind of machine has the advantages of high rigidity, high precision, high efficiency and high reliability. This batch of equipment is suitable for large-scale manufacturing of parts and basically requires no human intervention.

Micro Sinker EDM

Micro EDM machines are specifically designed to manufacture tiny, high-precision parts. This machine tool is a mechatronic equipment with extremely high-speed processing capabilities. This batch of machines uses cutting-edge technologies such as ultra-fine wire technology and high-precision servo systems to achieve very high precision and surface smoothness. Micro-EDM is driven by a micromotor. Micro-cutting technology can achieve micron (µ) dimensions, which are one-millionth of a meter or smaller.

High-Speed Sinker EDM

High-speed EDM machines use cutting-edge technologies such as high-frequency generators, cutting-edge servo systems, and high-speed spindles to improve the speed and accuracy of their processing. It is a new type of high-efficiency machine tool. The main purpose of this batch of machines is to handle high-speed processing tasks while ensuring processing accuracy and surface smoothness.

Four-Axis Sinker EDM

Based on standard three-axis motion control, the four-axis EDM machine adds a fourth axis, which makes its machining process more complex and precise. Because this machine tool has high control accuracy and stability, it can meet the precision machining requirements of different industries, especially the refinement needs of complex curved surface parts. During the machining process, the function of the fourth axis is to adjust the angle and positioning of the electrode, which is very critical for manufacturing complex shapes and properties.

Five-Axis Sinker EDM

The five-axis EDM machine adds a fifth-axis component to the traditional three-axis motion management system, making the entire processing process more complex and precise. The fifth axis has the ability to precisely manipulate the angle and position of the workpiece during the machining process, which will greatly facilitate the manufacturing of parts with complex shapes or unique features.

Computer Numerical Control (CNC) Sinker EDM Process

When certain easily breakable parts require extremely small dimensional features, EDM machines work together with CNC to manufacture them. Under the guidance of the CNC program, the wires are continuously delivered to the machine’s dielectric fluid and are guided by upper and lower diamond guides, which guide the wires and ensure that they can operate smoothly according to the instructions of the CNC system controller. The multi-axis movement characteristics of a CNC EDM machine give it the ability to program complex and precise cutting tasks to achieve fine shapes.

Choose Longsheng for all your EDM processing needs

If you need to produce very complex parts, choose Longsheng as your trusted sinker EDM partner.

We provide a full range of machining solutions for a variety of industries. Our 15 years of experience in custom machine building, machining and manufacturing operations means we can help you get the machining services and parts you need to ensure product quality, timeliness and performance.

conclusion

As a highly precise processing tool, the Sinker EDM machine plays a vital role in the manufacturing industry. Its further development will inevitably push the manufacturing industry towards higher precision and efficiency, and provide better services for various industries. Precision, more reliable parts and process support.

FAQs

What are the processing costs for Sinker EDM?

The processing cost of Sinker EDM involves many aspects, including equipment cost, processing efficiency and material consumption, labor cost and other costs. In order to reduce processing costs, we can choose appropriate machine tools and electrode materials, improve processing efficiency and material utilization, optimize discharge parameters and processing strategies, reduce processing time and waste generation, strengthen operator training and management, and improve operating skills and safety awareness. , Pay attention to environmental protection and safety issues, and reduce the occurrence of environmental pollution and safety accidents. It can reduce the processing cost of Sinker EDM while ensuring processing quality and efficiency.

What is the machining accuracy of Sinker EDM?

Sinker EDM has high machining accuracy, especially when processing complex parts and hardened conductive materials. However, the specific level of machining accuracy depends on a variety of factors, including machine tool accuracy, electrode design, discharge parameters, and workpiece material. In order to obtain ideal machining accuracy, it is necessary to select appropriate machining parameters and electrode design according to specific machining needs and conditions, and perform necessary machine tool maintenance and adjustments.

How efficient is Sinker EDM?

The processing efficiency of Sinker EDM is relatively low, especially for parts with complex shapes, and the processing time may be long.The processing efficiency of Sinker EDM is affected by many factors, but by selecting appropriate machine tools, optimizing discharge parameters, designing reasonable electrodes, and adopting new technologies, processing efficiency can be improved and production needs can be met. In practical applications, comprehensive consideration and optimization adjustments need to be made according to specific circumstances.

What is the surface quality of Sinker EDM?

The surface quality processed by Sinker EDM is affected by various factors such as discharge parameters, electrode material and shape, and workpiece material. By optimizing discharge parameters, selecting appropriate electrode materials and shapes, and controlling thermal effects during processing, the surface quality of Sinker EDM can be effectively improved. In practical applications, appropriate processing parameters and strategies need to be selected based on specific processing requirements and workpiece characteristics.