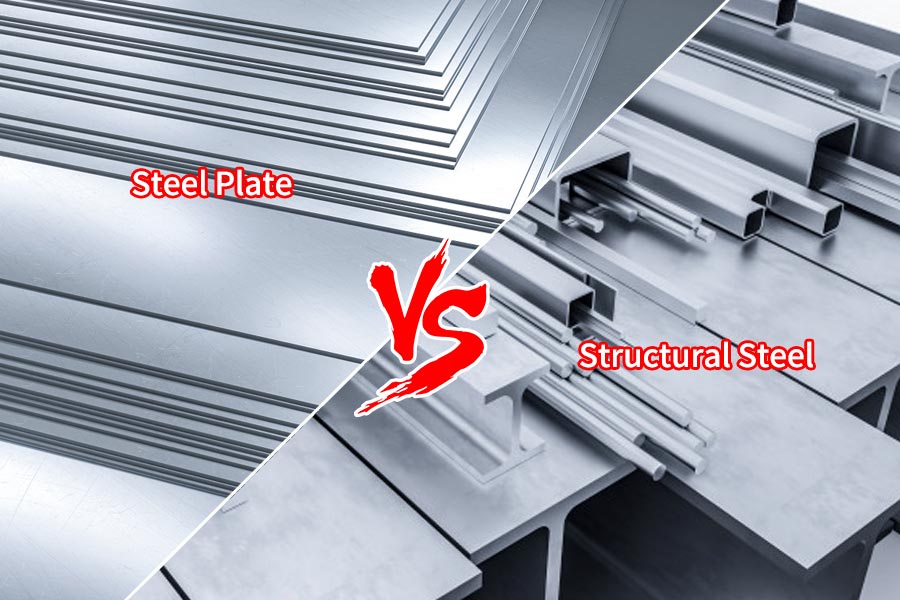

In the vast field of metalworking and material science, sheet plate and structural steel each play a pivotal role. They are not only the indispensable basic materials of modern manufacturing industry, but also attract much attention because of their unique performance and extensive application scenarios. However, despite the same metal materials, sheet plate and structural steel have significant differences in the definition, characteristics, use and processing methods. What are the specific differences between sheet plate and structural steel? Next, we will explore many aspects to reveal the mystery between these two metal materials.

What is a steel plate?

Steel plate is a widely used flat steel, made of molten steel after cooling. Steel plates usually have a regular rectangular shape and can be made directly rolled or cut from wide steel strips. The thickness, width and length of the steel plate can be customized according to the specific requirements to meet the requirements of different industries and applications.

What is structural steel?

Structural steel refers to the steel that meets the specific strength and formability grade, mainly for bearing and other purposes. In these purposes, the strength of steel is an important design standard.

What are the classification of steel plate?

1.By thickness

- Thin plate: steel plate less than 4 mm (0.2 mm).

- Medium thick steel plate: steel plate with thickness between 4 and 60 mm.

- Extra thick steel plate: thickness of 60~115 mm.

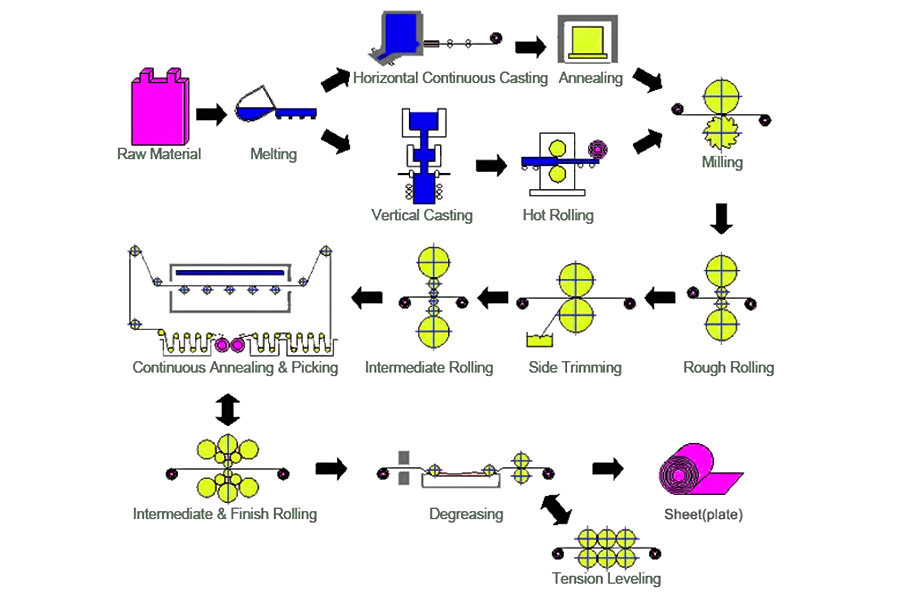

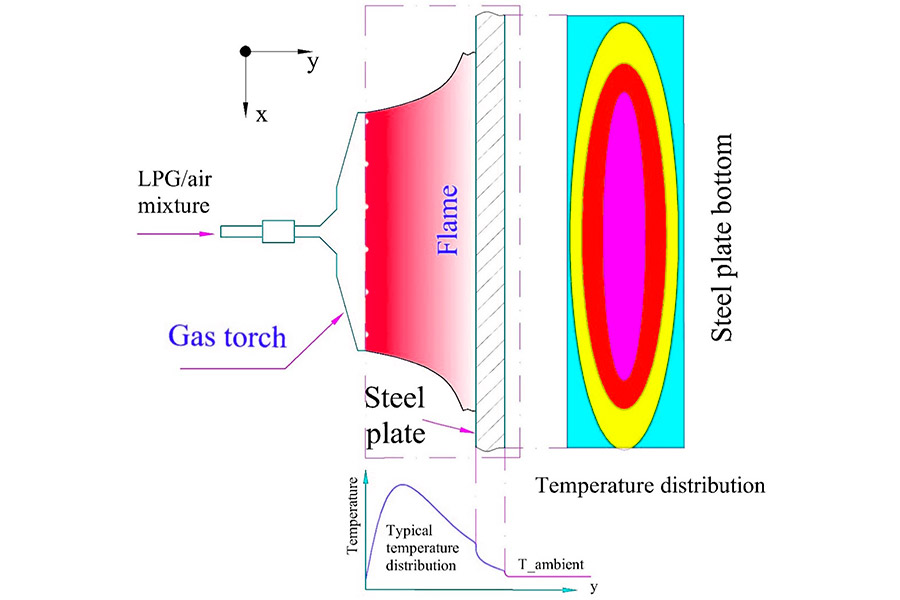

2.Classification by rolling way

- Hot rolled steel plate: the high temperature rolled steel plate surface is rough, but good strength and toughness.

- Cold rolled steel plate: the steel plate rolled by cold rolling mill at room temperature has a smooth surface and high size precision, but its strength and toughness are slightly lower than that of hot rolled steel plate.

3.By steel classification

- Ordinary steel, high quality steel, alloy steel, spring steel, stainless steel, tool steel, heat-resistant steel, bearing steel, silicon steel and industrial pure iron sheet, etc. These steel plates have different mechanical and chemical properties due to the different alloy elements and impurities contained.

What are the categories of structural steel?

Classification by chemical composition

- Carbon structural steel: This is a kind of steel that does not contain specially added alloy elements. It mainly contains carbon, silicon, manganese, sulfur, phosphorus and other elements, among which carbon is the main factor that determines its strength. According to the carbon content, carbon structural steel can be divided into low carbon steel (carbon content less than 0.25%), medium carbon steel (carbon content ranging from 0.25% to 0.6%) and high carbon steel (carbon content more than 0.6%).

- Alloy structural steel: on the basis of carbon structural steel, alloy structural steel has added one or more alloy elements, such as chromium, nickel, molybdenum, vanadium, titanium, niobium, boron, copper, rare earth and so on. The addition of these alloy elements can significantly improve the steel strength, toughness, wear resistance, corrosion resistance and other properties.

Classification by mechanical properties

- Low alloy high strength structural steel: this kind of steel is to add a small amount of alloy elements (usually not more than 3%) on the basis of carbon structural steel, through heat treatment to obtain good comprehensive mechanical properties. It is mainly used in building, Bridges, vehicles, ships, pressure vessels and other structural parts.

- High quality carbon structural steel: this steel has low sulfur, phosphorus content and non-metal inclusion content, and has good mechanical properties and processing properties. It is mainly used for the manufacture of various mechanical parts and engineering structural parts.

Classification by use

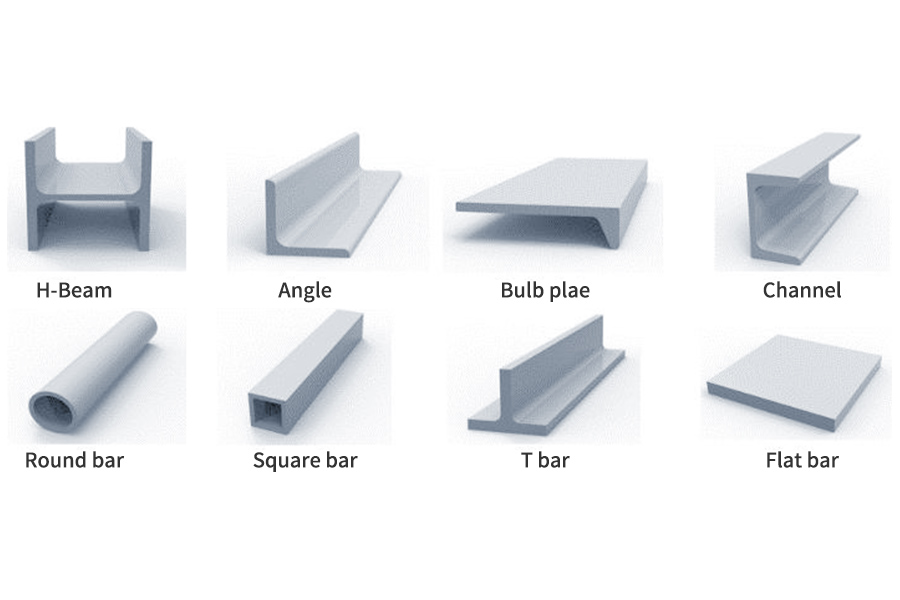

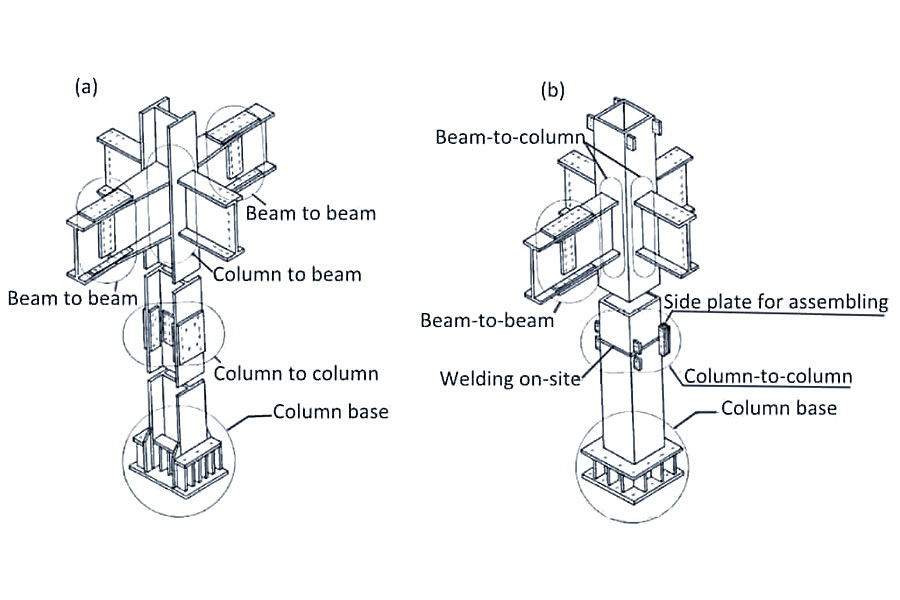

- Building structural steel: mainly used in construction and civil engineering, such as I-steel, channel steel, Angle steel, round steel, flat steel, etc.

- Structural steel for mechanical manufacturing: mainly used for the manufacture of various mechanical parts, such as shaft, gear, connecting rods, bolts, etc.

- Structural steel for ships and Bridges: this steel requires high strength, toughness and good welding performance, used in the manufacture of hull, bridge and other structural parts.

- Structural steel for petrochemical industry: mainly used in petrochemical equipment, such as pressure vessel, pipeline, etc., which requires good corrosion resistance and high temperature performance.

Advantages and disadvantages: steel plate VS structural steel

| sheet plate | structural steel | |

| Advantages | high strength | Improper handling is easy to rust |

| Good plasticity and toughness | Good plasticity and toughness | |

| Good weldability and workability | Weldability and workability | |

| Corrosion resistance and wear resistance | Corrosion resistance and wear resistance | |

| Prices are relatively low | Economy and recyclability | |

| Recyclable reuse | Design and construction flexibility | |

| A wide range of applications | High safety | |

| Disadvantages | The weight is larger | Easy to be affected by the environment |

| Strong thermal conduction performance | High welding requirements | |

| Improper handling is easy to rust | The cost is relatively high |

Application range: steel plate vS structural steel

Steel plate

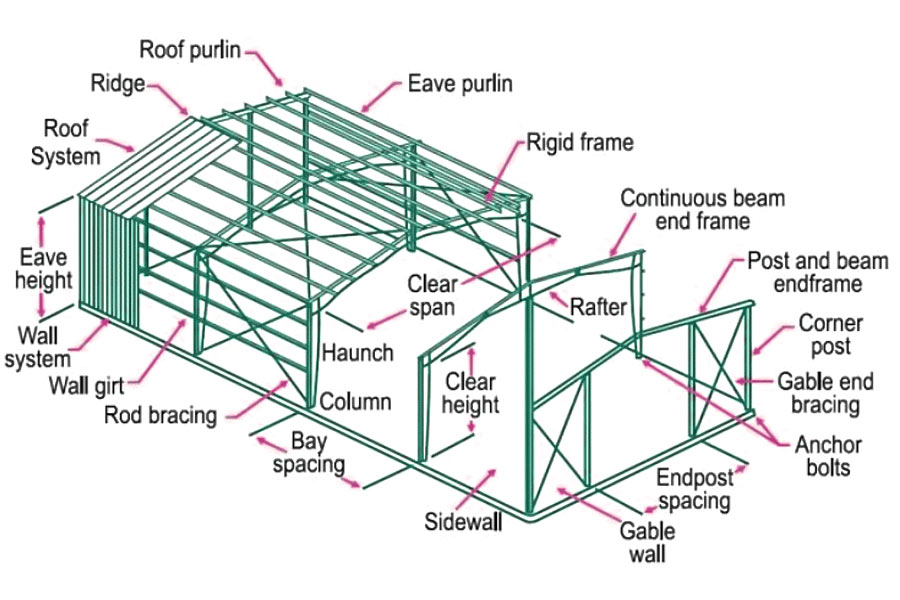

1.Construction field

In the building structure, the steel plate needs to meet enough strength and toughness, to be able to withstand various loads and meet the stability requirements of the building structure. Steel plate is usually used for the structural support of buildings and Bridges. Compared with traditional concrete structures, steel plate has higher strength, lighter weight, and good plasticity and workability, which can be more flexible in the design and construction of buildings. In addition, steel plate is also widely used in roof and wall covering materials, waterproof, fire, corrosion and other characteristics.

2.Machinery manufacturing

steel plate can be used in the manufacturing of nuclear power plants, wind power plants, thermal power stations and other mechanical equipment, but also widely used in the high-speed rail, urban rail and other rail transit equipment manufacturing field.

3.Automobile manufacturing

The application scope of steel plate in the field of automobile manufacturing includes body structure, hood, door, etc., among which the automobile plate needs to have high strength, corrosion resistance, wear resistance and weldable ability.

Structural steel

Construction field

The main use of structural steel in the construction field is as the building frame, wall support and other components. Its advantage is that it can withstand a large load and has a relatively light weight, making the building more stable and reliable.

Bridge field

Structural steel is also widely used in the field of bridge. As a public facility carrying vehicles and pedestrians, the bridge must have the ability to bear a large load, and should also have the characteristics of wind resistance, earthquake resistance and corrosion resistance. Structural steel has become an important material for bridge construction because of its high strength, good rigidity, light weight and strong corrosion resistance.

Road field

In road construction, structural steel is mainly used for the manufacture of road guardrail, highway suspension bridge and other related facilities. These facilities need to have a high carrying capacity and safety performance, and structural steel is widely used to achieve these functions.

Value comparison: steel plate vS structural steel

The value comparison of steel plate and structural steel involves many aspects, including material, performance, use and market price.

Material and performance

The material of structural steel is high strength and low alloy structural steel, whose composition is richer than ordinary steel plate, so it has high strength and good plasticity and weldability. This makes the structural steel perform well in bearing large loads and special performance requirements. While the ordinary steel plate is mainly carbon steel plate, its carbon content is relatively low, the strength is lower than the structural steel plate, and is not corrosion resistant, easy to rust.

Application

Due to its high strength and excellent mechanical properties, structural steel is widely used in heavy industrial fields such as building structure, machinery manufacturing and power station engineering. In these areas, structural steel can withstand large loads to ensure the safety and stability of the structure. The steel plate is used in automobile, home appliances, light industry and other fields because of its extensive performance and use. Their high strength, corrosion resistance and plasticity make steel an ideal material for many products.

Market prices

Due to the higher requirements of structural steel material and production standards, its price is usually higher than that of ordinary steel plate. On the market, the price of structural steel plate is often two to three times that of ordinary steel plate. However, the specific price will also be affected by the market supply and demand relationship, raw material costs and production process and other factors.

In general, the steel plate and the structural steel each have their own advantages and disadvantages in terms of value. Structural steel occupies an important position in the heavy industry field with its high strength and excellent mechanical properties, but its price is relatively high. The steel plate is widely used in many fields for its wide performance and use and relatively low price. Therefore, when choosing steel plate or structural steel, it is necessary to weigh and choose according to the specific application scenarios and requirements.

What is the difference between steel plate and structural steel?

The difference between steel plate and structural steel is mainly reflected in the following aspects:

Material and ingredients

Steel plate: usually carbon steel plate, its carbon content is relatively low, and the composition is relatively single. Ordinary steel plate is not resistant to corrosion and easy to rust.

Structural steel: the material is high strength and low alloy structural steel, its composition is more abundant than ordinary steel plate, including carbon, silicon, manganese, sulfur, phosphorus and other alloy elements. These alloy elements give the structural steel a higher strength and good mechanical properties.

Features and Performance

Steel plate: with high strength and load-bearing capacity, but also has good plasticity and toughness. Steel plate has a long service life, which is not easy to bend and break, but it is relatively weak in corrosion resistance.

Structural steel: in addition to having high strength and toughness, structural steel also has good weldability and processability. This makes the structural steel perform well in bearing large loads and special performance requirements.

Use and application

Steel plate: widely used in construction, Bridges, vehicles, ships, containers and other fields. Its high strength and load-bearing capacity make steel plates an important material in these fields.

Structural steel: mainly used in building structure, machinery manufacturing, power station engineering and other heavy industrial fields. In these areas, structural steel can withstand large loads to ensure the safety and stability of the structure.

On accuracy and processing process

Steel plate:The production accuracy of steel plate is usually customized according to specific needs, and many different processing technologies such as cutting, stamping, bending and welding can be used to complete the molding and connection.

Structural steel:The accuracy requirement of structural steel is quite high, but in the manufacturing process, more attention is given to the stability and safety of the overall structure. For some special parts, in order to improve their performance or extend the service life, it is necessary to ensure its better comprehensive performance, so it is necessary to machining structural steel. The manufacturing process of structural steel usually covers multiple steps, including welding, forging, hot rolling and cold rolling.

The advantages of personalized sheet metal production

The production process of customized sheet metal is to customize metal products according to specific standards. Through the analysis and comparison of various forming processes under the existing technical conditions, a new stamping process suitable for large complex shape workpiece processing —— “primary drop material” punching composite die process is proposed. This method is a highly accurate and efficient metal parts manufacturing technology that can satisfy the customer.

1.The design is highly flexible

Through personalized sheet metal processing, we can obtain higher design flexibility. By analyzing each link of the production process, determine the time and cost of each process step, and then the data are input into the computer, so that the precise design scheme can be obtained in the design stage. With the ability of customproducts to specific needs, customers have the ability to create products that meet their unique requirements. This approach helps to use resources more efficiently, reduce waste and enhance productivity.

2.A description of the accuracy and accuracy

Personalized sheet metal production requires utilizing cutting-edge tools and technology to produce highly precise and precise finished products. In these processes, the processing errors must be accurately controlled and they do not exceed the standard size. In this way, we are able to make products with higher quality, stricter tolerances, and higher consistency. Among these precision parts, dimensional precision is one of the most important parameters, which in turn depends on the precision of the measurement results. This precision and accuracy are particularly critical for many industries, such as aerospace, automotive, and healthcare.

3.Economic and efficient

For many enterprises, creating personalized sheet metal manufacturing has become a more cost-effective strategy. Customers can reduce resource waste, greatly reduce material overhead, and improve production processes by developing goods that meet specific needs. This approach is expected to improve work performance, reduce downtime, and reduce overall costs.

4.Implement quality supervision

Personalized sheet metal production can bring us more excellent quality management. No matter from the design stage to the production of the finished product, all the process links can be carefully monitored and appropriately adjusted, to ensure that the top quality requirements are met. The method is able to achieve reliable, long-term, and coherent functional performance.

5.The turnover speed is fast

Through the personalized sheet metal production process, we can quickly achieve, and further shorten the production cycle. Relying on the strength of targeted production of products, the enterprise can quickly meet the evolving market demand and retain its own market advantage. This is particularly critical for industries when the deadline is critical.

In short, personalized sheet metal making has many advantages, both in terms of design flexibility and in a quick turnaround time. Customers can choose personalized manufacturing methods to produce products that meet their specific needs, thus improving product quality control and reducing production costs. If you are exploring a way to manufacture metal parts that is both stable and efficient, then choosing a customized sheet metal production is undoubtedly your first choice.

How to choose the right material?

Choosing the right steel depends on your specific needs, and considerations include:

Strength and toughness

As the core component of static or dynamic load, its strength and toughness are important considerations. In the selection of steel, it is necessary to choose the material strength and toughness matching steel according to the actual load conditions of the building components.

Shape and size

Different building components require different shapes and sizes of steel, such as beams, columns, plates, etc. Therefore, when selecting steel, it is necessary to ensure that the shape and size of the selected steel can meet the design requirements.

Chemical composition

The chemical composition of steel directly affects its performance and service life. When choosing steel, we need to pay attention to its chemical composition, especially the carbon content, sulfur content, phosphorus content and other indicators. High-quality steel usually has a low impurity content and strict composition control.

Production standard

Different steel production standards correspond to different performance and quality requirements. When selecting steel, it is necessary to confirm that it meets the relevant national or industrial standards and regulations to ensure the quality and reliability of the steel.

Cost performance

In the construction industry, high-quality steel is usually more expensive. Therefore, in the selection of steel, it is necessary to comprehensively consider its performance, price and service life and other factors, in order to choose the most cost-effective steel.

Purpose and demand

The use and demand of steel are also the factors to be considered when choosing steel. Different steel is suitable for different occasions and needs, such as construction steel, machinery manufacturing steel, power station engineering steel, etc. Therefore, in the selection of steel, it is necessary to choose the appropriate steel types and specifications according to the specific use of occasions and requirements.

Why choose Longsheng as your next metal manufacturing project?

At Longsheng, we are not only proficient in a variety of sheet metal processing skills, but also we have a professional technical team that can provide leading sheet metal manufacturing services to make high quality parts for you at a very competitive price. As a company certified by ISO 9001:2015, we focus on the construction of a quality management system to provide reliable service for our customers.

Our team of experts has experience in performing DfM (Manufacturability Design) analysis to improve your design. We are not only a manufacturer, but also a partner dedicated to providing full support and professional advice to ensure that the design can reduce manufacturing costs while still meeting high quality standards.

If you have a design model to manufacture, please upload it to us immediately and we will offer you a quote immediately. Choosing Longsheng is to choose high quality, high technical level and high cost performance of sheet metal processing partners. Let us work together to create excellent parts for your project and achieve greater success.

Conclusion

When choosing structural steel and steel plate, we need to consider the material, performance, use, specification, size, price and cost. If the project requires high strength, good corrosion resistance of steel, and the application scenario is in the heavy industry field, then structural steel may be a better choice. If the project requirements for steel are not high, and the application scenario is in the light industry field, then the steel plate may be a more appropriate choice. Steel plate is a good choice for high load and high impact force; structural steel has high precision, high stability and good seismic performance.

FAQs

Which is better, steel plate or structural steel?

Steel plate and structural steel are not directly comparable concepts because they each refer to different material properties and application scenarios. To judge which is better actually depends on the specific use requirements, design requirements and cost considerations.

What factors will affect the price of steel plate and structural steel?

The price of steel plate and structural steel is affected by a variety of factors, including raw material prices, supply and demand relations, production costs, international market prices, transportation costs, quality and technical requirements, and national policies. Therefore, in the purchase of steel plate and structural steel, it is necessary to consider these factors, choose cost-effective products, in line with their own needs.

How to improve the service life of steel plate and structural steel?

Select steel with high strength, high toughness and good corrosion resistance. In the design stage, the stress situation, working environment and use requirements should be fully considered, and the structural form and section size should be reasonably designed to avoid stress concentration and excessive deformation. In the manufacturing process, the chemical composition, mechanical properties and dimensional precision of steel should be strictly controlled to ensure the product quality. Regular inspection of steel plate and structural steel, timely find and deal with cracks, corrosion and other problems.