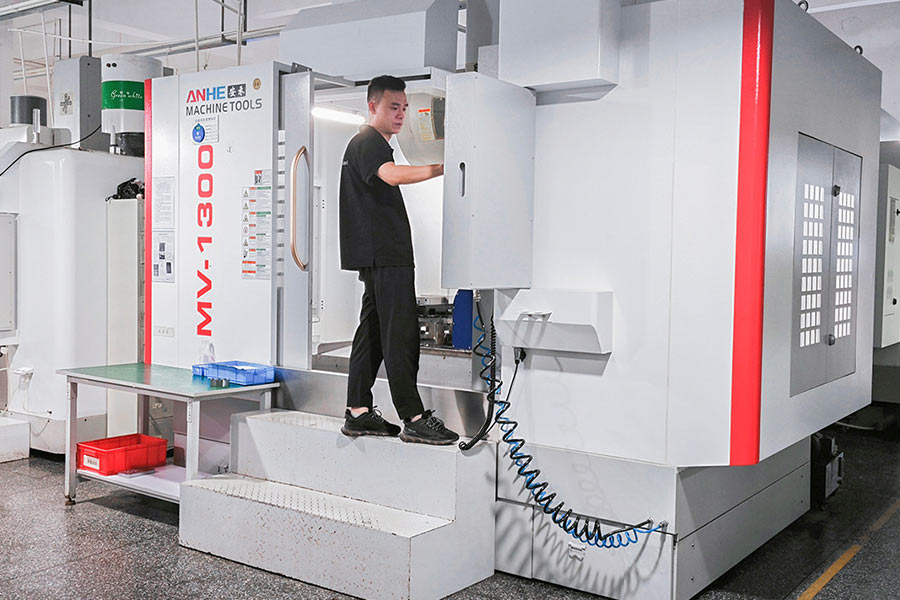

The standing and benefits of China as a serious participant in CNC machining providers are indeniable. As the biggest manufacturing nation globally, China has intensive expertise in CNC machining, superior gear, and an unlimited variety of technical abilities. These benefits enable China to offer high-quality, environment friendly, and fairly priced CNC machining providers.

The true value of CNC machining

How a lot does CNC machining actually value? A easy CNC half can value from as little as $100 per piece, whereas bigger metallic parts would possibly escalate into a number of thousand {dollars} or greater. There are numerous components that provides to the price of CNC machining, from materials, labour to the gear, and plenty of different little components like changeover, cleansing, upkeep and so forth.

Components affecting the value of personalized CNC machining providers in China

Materials and Measurement of the Workpiece: Totally different supplies, corresponding to aluminum, metal, copper, and plastic, every with various levels of hardness, energy, and abrasion resistance, can have an effect on the problem and value of machining. Moreover, the scale of the half being machined can influence the value; the bigger the scale, the extra materials and machining time required, therefore a better value.

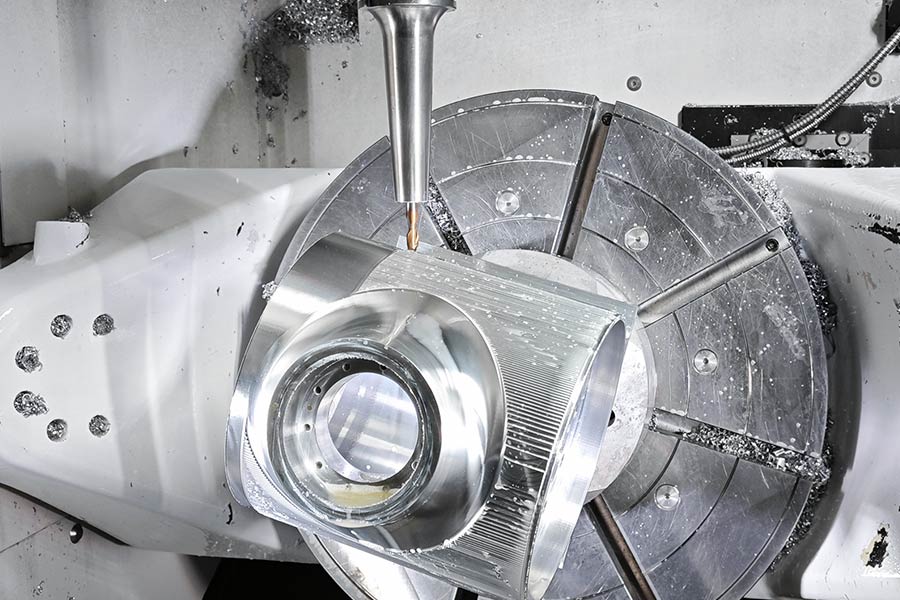

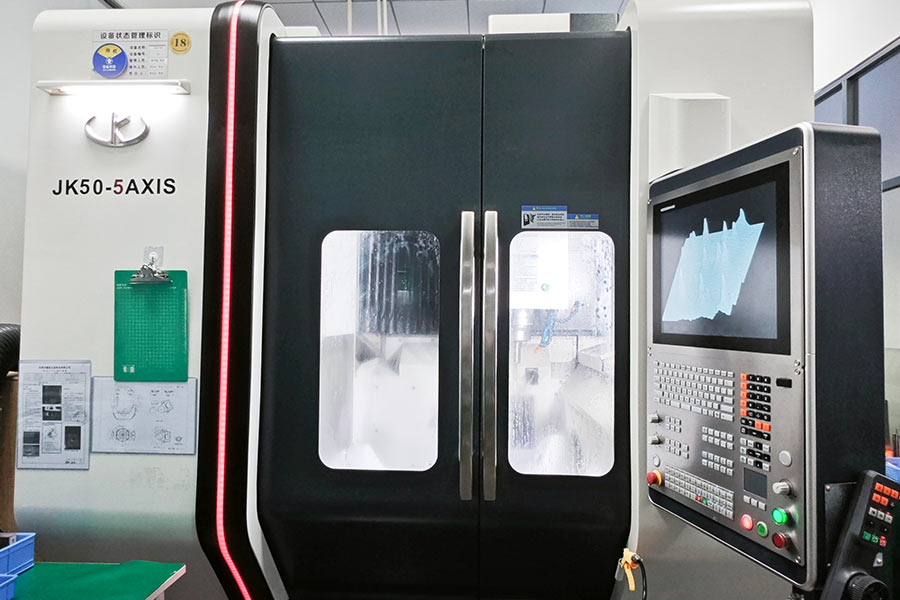

Machining Precision and Complexity: When greater precision and extra advanced machining is required, it calls for extra subtle gear and expertise. For example, a 5-axis CNC machining middle can produce parts of advanced shapes and high-precision necessities, however the prices for gear operation and upkeep would even be greater, resulting in a rise in value.

Machining Amount and Supply Time: The quantity of machining is a big issue affecting the value. Batch machining can distribute mounted prices corresponding to gear, labor, and administration, thus lowering the unit product value. Then again, if early supply is required, producers might have to work extra time or prioritize the order, which could incur further prices.

Location and Qualification of the Machining Firm: The labor value and market competitors degree of the machining firm’s location can have an effect on the value. For example, first-tier cities might have greater labor prices than second or third-tier cities, however they might even have greater market competitors, forcing producers to cut back costs to draw clients. Furthermore, bigger firms typically have greater {qualifications} and a extra complete administration system, offering higher providers, therefore doubtlessly greater costs.

China customized CNC machining service value overview

Common Value Degree in China’s CNC Machining Service Business: In China, the value of CNC machining providers can fluctuate as a result of a variety of things corresponding to the dimensions of the machining firm, the sophistication of the gear, the fabric being machined, and the complexity of the product. In lots of circumstances, pricing is often calculated on an hourly foundation. Relying on totally different wants and situations, the hourly value ranges roughly from 10 to 30 US {dollars}.

Reference Costs for Totally different Varieties of CNC Machining Companies: Several types of CNC machining require several types of gear and expertise, so their costs fluctuate. For instance:

-

3-Axis CNC Milling: This can be a frequent kind of CNC machining, primarily used for machining easy parts and merchandise. As a result of the expertise and gear are comparatively frequent, the value is comparatively decrease, roughly 10-20 {dollars} per hour.

-

5-Axis CNC Milling: This can be a extra advanced machining technique that may process advanced three-dimensional shapes. As a result of it requires extra superior gear and expertise, the value is greater, roughly 20-30 {dollars} per hour.

-

CNC Turning: This machining technique is principally used for machining shafts and cylindrical parts, with an hourly value of roughly 15-25 {dollars}.

-

CNC Grinding: This can be a high-precision machining technique, primarily used to enhance the floor high quality and dimensional accuracy of parts, with an hourly value of roughly 20-30 {dollars}.

Components Affecting Value Fluctuations: The worth of CNC machining providers may also be affected by many exterior components, corresponding to:

-

Uncooked Materials Costs: If the value of uncooked supplies goes up, the machining value will even enhance, which can result in an increase in machining costs.

-

Change Fee Fluctuations: If the service supplier must import gear or uncooked supplies, fluctuations within the trade charge might have an effect on their prices, thereby affecting the machining value.

-

Market Provide and Demand: If the market demand for CNC machining will increase and the availability can’t meet the demand, costs might go up. Conversely, if there may be an oversupply, costs might go down.

Conclusion

The principle content material of the textual content revolves across the components influencing the value of personalized CNC machining providers in China. These components embody:

- Processing Materials and Measurement: The issue and value of processing fluctuate drastically amongst totally different supplies. Bigger sizes require extra processing time and value.

- Processing Precision and Complexity: Increased precision and complexity require extra subtle gear and expertise, resulting in a value enhance.

- Processing Amount and Supply Time: Batch processing can dilute prices, whereas shorter supply instances normally require further charges.

- Location and {Qualifications} of the Processing Firm: The price of labor and market competitors in numerous areas have an effect on the value. Bigger firms normally have greater {qualifications} and costs.

Common Value Degree

The typical value degree within the Chinese language CNC machining service business is about $10-30 per hour, relying on the above components. Listed below are the reference costs for several types of CNC machining providers:

- Three-axis CNC milling: $10-20 per hour

- 5-axis CNC milling: $20-30 per hour

- CNC turning: $15-25 per hour

- CNC grinding: $20-30 per hour

Components corresponding to uncooked materials costs, trade charge fluctuations, and market provide and demand relationships may cause value fluctuations.

Sensible Recommendation for Selecting a CNC Machining Service Firm

When selecting a CNC machining service firm, customers ought to contemplate these components to discover a cost-effective and dependable service supplier. They need to consider the processing capabilities, {qualifications}, and popularity of the corporate, and examine the costs of various firms whereas contemplating the standard of service. It is also necessary to think about the supply time and after-sales service. By doing so, customers can discover a CNC machining service firm that gives high-quality providers at an affordable value.

LongSheng Estimate the price of your CNC half

How a lot will your CNC half value to make? Add your 3D CAD on our on the spot quote, select LongSheng, materials, and floor end to get a free quote. To start out machining, to put your order with us on-line. Alternatively, for personalised help, submit your inquiry and challenge particulars HERE, and an knowledgeable from our crew will promptly get again to you.

FAQs

How to make sure the standard of CNC machining providers?

To make sure the standard of CNC machining providers, numerous strategies and requirements of high quality inspection may be employed. These strategies are essential for verifying that the machined parts meet the required specs and high quality requirements. Listed below are some sensible strategies for customers to assist them discover high-value and dependable CNC machining service suppliers:

-

Machine Instrument Accuracy Take a look at: This includes checking the centering and motion accuracy of the machine software, together with numerous parameters such because the orientation of the spindle, bracket, axis, and so forth. The principle shaft’s perpendicularity to the worktable, angle, bend, and linear axis are additionally examined.

-

Half or Product Take a look at: Producers make the most of floor profilometers to measure floor roughness and hardness testers to find out a fabric’s resistance to deformation, guaranteeing the machined parts meet the required requirements. Closing inspection is performed to substantiate that the completed parts meet all design and high quality requirements earlier than dispatch .

-

Process Monitoring and Management: This includes checking process steps at every stage to keep away from errors and guarantee high quality at each degree of the product lifecycle. Parameters corresponding to fast prototyping, tight tolerances, and spindle checks are important features of high quality inspection in CNC machining.

Instance: When participating with a CNC machining service supplier, you’ll be able to request an in depth high quality inspection report for the machined parts. This report ought to embody data on the inspection strategies used, measurements of floor roughness, hardness, and different related parameters, in addition to the outcomes of the inspection. By reviewing this report, you’ll be able to make sure that the parts meet the required specs and high quality requirements, offering confidence within the reliability of the CNC machining providers.

Easy methods to talk with CNC machining service firm wants?

To successfully talk with a CNC machining service firm relating to your necessities, you’ll be able to make use of the next communication methods and concerns:

-

Clearly Articulate Product Necessities: Present detailed descriptions of the specs, dimensions, materials necessities, and machining precision of the parts wanted. Guarantee mutual understanding of the product’s necessities.

-

Present Detailed Drawings and Directions: Furnish correct CAD drawings and related directions, together with particular machining necessities, floor remedy specs, and so forth., to facilitate the service firm’s exact understanding of the necessities.

-

Open Communication: Preserve open communication with the machining service firm, promptly addressing their questions and considerations to make sure easy communication all through the whole machining process.

-

Understanding Machining Processes: Acquire an understanding of primary machining processes and their limitations to think about sensible machining situations throughout communication.

Instance: When speaking with a CNC machining service firm, you’ll be able to present detailed half drawings containing all product specs and necessities, and focus on any particular machining wants with them. Through the communication, you’ll be able to inquire about their perspective on particular machining processes and make mandatory changes primarily based on their strategies to make sure the ultimate product meets the anticipated necessities.

Easy methods to keep away from frequent disputes within the process of CNC machining providers?

To keep away from frequent disputes within the process of CNC machining providers, preventive measures and resolution strategies may be applied. These measures are important for sustaining a easy and productive relationship with the CNC machining service supplier. Listed below are some sensible strategies:

-

Clear Communication and Documentation: Be sure that all necessities, specs, and expectations are clearly communicated and documented in a proper settlement or contract. This contains particulars corresponding to half specs, tolerances, high quality requirements, supply schedules, and pricing agreements.

-

Common Communication: Preserve open and common communication with the CNC machining service supplier all through the challenge. This contains offering updates on any adjustments in necessities, addressing any considerations promptly, and in search of clarification on any ambiguous factors.

-

Set up High quality Requirements: Clearly outline the standard requirements and inspection standards for the machined parts. This could embody specifying acceptable tolerances, floor end necessities, materials certifications, and any particular testing or inspection protocols.

-

Signing Contracts: Formalize the settlement with a signed contract that outlines the phrases and situations of the challenge, together with cost phrases, mental property rights, legal responsibility clauses, and dispute decision mechanisms.

Instance: For instance, when participating a CNC machining service supplier, it’s important to have an in depth contract that clearly outlines the challenge scope, high quality requirements, supply schedules, and pricing agreements. Within the occasion of a dispute relating to the standard of the machined parts, the contract can function a reference level to resolve the difficulty amicably. Common communication and updates all through the challenge also can assist in addressing any potential points early on, guaranteeing a easy and mutually useful collaboration.

Rescourse

The relevant data and market research data in this paper are referred to grandviewresearch.