3-Axis CNC Machining

Definition and Capabilities

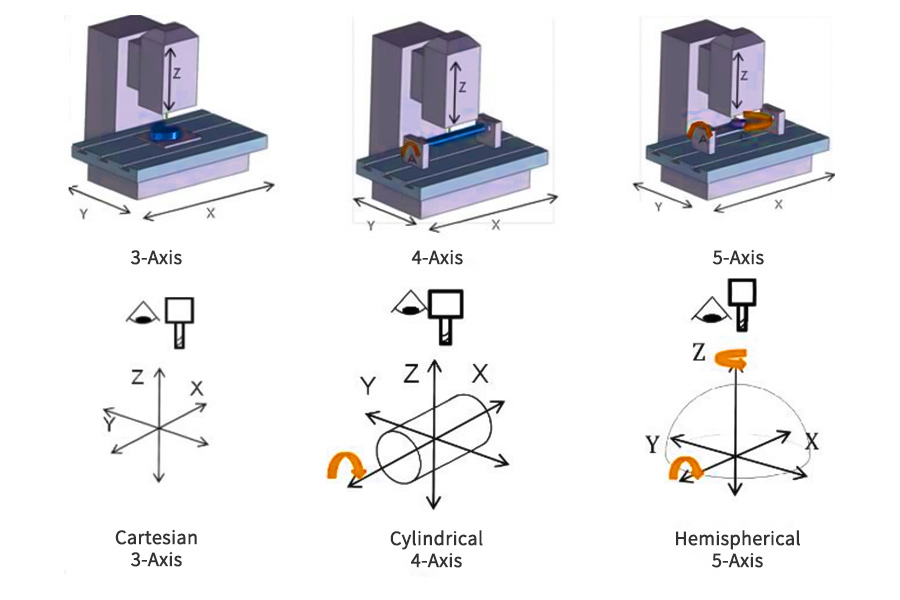

3-axis CNC machining includes the coordinated motion of the reducing device or workpiece alongside three axes: X, Y, and Z. This permits for the creation of parts with 2D and a pair of.5D geometries, comparable to panels, enclosures, and easy mechanical elements. The process is adept at dealing with a variety of supplies and geometries, making it versatile for numerous purposes.

Advantages and Disadvantages

Some great benefits of 3-axis CNC machining embody cost-effectiveness, ease of operation, easy programming, and low upkeep. It additionally ensures excessive precision in materials elimination and minimizes the necessity for guide intervention, which boosts productiveness. Nonetheless, it has limitations when it comes to the complexity of parts it could produce and is much less environment friendly in manufacturing advanced shapes. The setup might be time-consuming, and the machines might be costly to accumulate and function. Moreover, 3-axis machines might wrestle with non-conventional shapes or designs with deep, slender cavities.

4-Axis CNC Machining

Definition and Capabilities

4-axis CNC machining provides a rotational axis, the A-axis, permitting the workpiece to rotate across the X-axis. This allows the machining of parts which might be theoretically potential on a 3-axis machine however extra economically viable on a 4-axis machine, comparable to advanced profiles and cam lobes. There are two kinds of 4-axis machining: indexing and steady.

Advantages and Disadvantages

The first benefits of 4-axis CNC machining embody the power to carry out multi-side machining and cheaper manufacturing for bigger volumes whereas sustaining excessive precision. Nonetheless, 4-axis machines include increased prices, costly fixtures, and should have restricted pace in comparison with 5-axis machines.

5-Axis CNC Machining

Definition and Capabilities

5-axis CNC machining includes two further axes, usually the A-axis and B-axis, permitting for the machining of advanced geometries and the power to machine completely different sides of a workpiece with out repositioning. The sort of machining is good for creating advanced and exact parts, comparable to these discovered within the aerospace and medical industries.

Advantages and Disadvantages

5-axis CNC machines supply elevated effectivity, improved accuracy, decreased device modifications, and flexibility. They will produce extremely advanced 3D shapes and are able to machining with shorter instruments, which is good for deeper parts and tougher supplies. Nonetheless, they’re considerably dearer than 3-axis machines. Additionally they require extra intensive operator coaching and contain advanced programming, which might enhance operational prices.

Three axis, 4 axis and 5 axis CNC machining capability comparability:

| Machining Sort | Machining Precision | Form Capabilities | Machining Effectivity |

|---|---|---|---|

| 3-Axis CNC Machining | Excessive | 2D and a pair of.5D geometries comparable to panels, enclosures, and easy mechanical elements | Medium |

| 4-Axis CNC Machining | Excessive | Can machine extra advanced shapes, comparable to advanced profiles and cam lobes | Excessive |

| 5-Axis CNC Machining | Very Excessive | Can machine probably the most advanced 3D shapes, comparable to elements within the aerospace and medical industries | Very Excessive |

CNC Machining Vary Comparability: 3-Axis, 4-Axis, and 5-Axis

3-Axis CNC Machining: 3-axis CNC machines can transfer in three instructions: X, Y, and Z. They’re appropriate for machining 2D and a pair of.5D geometries, comparable to panels, enclosures, and easy mechanical elements. Nonetheless, the machining vary of those machines is restricted in comparison with higher-axis machines, as they can not execute the simultaneous linkage of 4 axes.

4-Axis CNC Machining: Introducing an extra rotational axis, the A-axis, 4-axis CNC machines enable the workpiece to rotate across the X-axis. This added flexibility allows the machining of parts with extra advanced geometries. There are two kinds of 4-axis machines: one which solely carves or cuts on one facet within the materials (4th axis flat-plane router machine), and one other that may carry out 3D rotary carving or reducing (4th axis 3D CNC router machine).

5-Axis CNC Machining: 5-axis CNC machines make the most of two further axes, usually the A-axis and B-axis. This enlargement in functionality permits for the machining of advanced geometries and the power to machine completely different sides of a workpiece with out repositioning. With the power to carry out single-step machining, these machines cut back lead time and permit for entry to advanced half geometries. They’re generally used for very advanced elements which might be stable and would in any other case should be solid.

Three-axis CNC machining: appropriate for machining easy formed parts, comparable to plates, blocks, and so on.

4-axis CNC machining: appropriate for machining advanced form parts, comparable to cylinders, surfaces, and so on.

5-axis CNC machining: appropriate for machining high-precision, advanced form parts, comparable to aerospace parts, medical gear and so forth.

Three -, 4 – and five-axis CNC machining prices:

3-Axis CNC Machining Prices

- Hourly Charges: The fee for 3-axis CNC machining is roughly $35-$40 per hour .

- Regional Variations: In Europe, the associated fee is usually in the identical vary as a result of increased dwelling requirements , whereas in China, corporations like RapidDirect supply extra aggressive charges starting from $8 – $10 per hour.

- Components Influencing Price: The price of 3-axis CNC machining might be influenced by materials prices, which might range considerably primarily based on the kind of materials and its measurement , and by the complexity of the half being machined.

4-Axis CNC Machining Prices

- Hourly Charges: The fee for 4-axis CNC machining is usually included within the multi-axis class, which ranges from $75 to $120 per hour.

- Complexity and Effectivity: The elevated complexity and effectivity of 4-axis machines can result in increased prices in comparison with 3-axis machines.

5-Axis CNC Machining Prices

- Larger Prices: 5-axis CNC machining is dearer than 3-axis and 4-axis as a result of its superior capabilities.

- Hourly Charges: The hourly price for 5-axis CNC machining can attain as excessive as $75 to $150 , and in some instances, $200 per hour.

- Materials and Complexity: Using tougher supplies and the necessity for specialised instruments can enhance the associated fee as a result of slower reducing speeds and elevated device put on.

- Software program and Gear: The specialised CAM software program and the basic complexity of 5-axis machines with further motors and management methods contribute to the upper value.

Basic Concerns

- Materials Prices: Materials prices can vary from $3 per kilogram to over $200 per kilogram for CNC inventory billets.

- Design and Quantity: The design complexity and the amount of manufacturing are important elements that have an effect on CNC machining prices.

- Price-Saving Methods: To scale back prices, optimizing design, deciding on applicable supplies, and growing manufacturing quantity are efficient methods .

- Outsourcing: Outsourcing to a trusted producer can present higher worth for cash and doubtlessly decrease prices.

Further Prices

- Publish-Processing: Prices for post-processing comparable to meeting and floor ending operations can add to the entire value.

- Revenue Margins: CNC corporations usually goal for a ten to twenty% revenue margin, however this could range .

- Tooling: Customized tooling required for particular manufacturing wants can enhance prices.

- Delivery: The selection of transport choices and the urgency of supply can have an effect on the general value .

Gear value: The price of three-axis CNC machine instruments is the bottom, and the price of five-axis CNC machine instruments is the best.

Processing value: The price of three-axis CNC machining is the bottom, and the price of five-axis CNC machining is the best.

Select LongSheng Machine Works for Your CNC Manufacturing Wants

Whenever you want one of the best in CNC manufacturing and equipment, flip to LongSheng Machine Works. We’re backed up by our over 10 years of expertise working within the machining trade and workers of professional workforce members with CNC certification. As an organization, we’re devoted to delivering distinctive worth to each consumer we serve. Resulting from this dedication, we will produce customized machining parts and elements and construct customized equipment particularly designed in your firm’s wants.

Overview our CNC precision machine companies right now to see what we will do for you. You probably have any questions or are able to companion with us, please contact us.

FAQs

How to decide on the appropriate CNC machining methodology?

Choosing the suitable CNC machining methodology requires consideration of a number of elements:

Form of the Workpiece: Completely different axes CNC machines are suited to machining completely different shapes. For example, 3-axis CNC machines are primarily appropriate for machining 2D and a pair of.5D geometries, comparable to panels and enclosures. Then again, 4-axis and 5-axis CNC machines can process extra advanced 3D shapes.

Machining Precision: Should you want excessive precision, you would possibly want to decide on a 4-axis or 5-axis CNC machine. These machines can concurrently lower in a number of instructions, bettering machining precision.

Machining Effectivity: If it is advisable quickly produce numerous parts, you would possibly want to decide on a 3-axis or 4-axis CNC machine. Their machining pace is usually quicker than 5-axis machines.

Price: Completely different axes CNC machines additionally range in value. Typically, 3-axis machines are the least costly, and 5-axis machines are the most costly. Due to this fact, it is advisable select the suitable CNC machining methodology primarily based in your funds.

Complexity of the Components: If the parts it is advisable machine are very advanced, you might want to decide on a 4-axis or 5-axis CNC machine. They will concurrently lower in a number of instructions, permitting them to create advanced shapes.

Which is healthier for 3-axis, 4-axis or 5-axis CNC machining?

There is no such thing as a absolute “higher” relating to 3-axis, 4-axis, and 5-axis CNC machining. The suitable selection is determined by your particular machining wants and funds.

3-Axis CNC Machining: 3-axis CNC machines are primarily suited to machining 2D and a pair of.5D geometries, comparable to panels and enclosures. These machines are comparatively cheap and easier to function.

4-Axis CNC Machining: 4-axis CNC machines add a rotational axis to the present three, enabling them to deal with extra advanced geometries. They’re notably helpful for machining parts that require reducing on a number of faces.

5-Axis CNC Machining: 5-axis CNC machines are probably the most advanced, in a position to concurrently lower in 5 instructions to create very intricate shapes. Nonetheless, 5-axis machines are additionally the most costly, requiring expert operators and complicated programming.

Useful resource

Multiaxis machining is a manufacturing process that includes tools that transfer in 4 or extra instructions and are used to fabricate parts out of metallic or different supplies by milling away extra materials, by water jet cutting or by laser cutting. From Wikipedia.

In abstract

The selection between 3-axis, 4-axis, and 5-axis CNC machining is determined by the complexity of the half, the precision required, and the funds out there. Whereas 3-axis machines are extra reasonably priced and simpler to make use of, they’re restricted within the complexity of parts they’ll produce. 4-axis machines supply a center floor with the power to machine extra advanced parts. 5-axis machines, then again, are probably the most superior and succesful, but additionally the most costly when it comes to preliminary funding, operation, and upkeep.